________________________________________________________________________________

1104C Perkins engine - Remove and refit the injection pump (MF 5400, 6400 tractors)

Removing the injection pump

Delphi DP210 pump

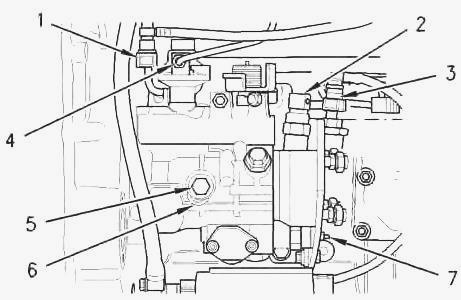

Take off the adjacent components. Check the position of the first

cylinder piston in compression at Top Dead Centre. Loosen the lock screw

(5). Turn the spacer (6) to allow the lock screw (5) to lock the pump

pin. Turn the pump pin anti-clockwise until slight resistance is felt

(Fig. 13). Tighten the lock screw to a torque of 17 Nm. The lock screw

(5) must be tightened to prevent the pump pin from turning. The pump pin

must not turn when the pump is removed.

Disconnect the fuel return line (1) (Fig. 13). Disconnect the fuel

supply line (3). Disconnect the connector (2) of the injection timing

solenoid (7). Remove the nut and retaining washer from the injection

pump gear. Extract the pump gear (9) using a suitable puller. Do not try

to extract the gear (8) by inserting a lever between the gear and the

housing. Take out the nut and screw. If necessary, take out the screw

(15) and the bracket (11) from the 1104 Perkins engine block. Take out

the screws (13) to remove the injection pump. Remove the injection pump.

Take off and discard the "O" ring (10).

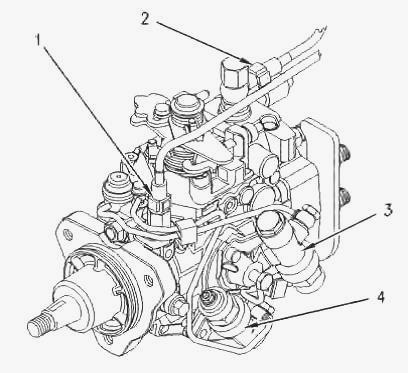

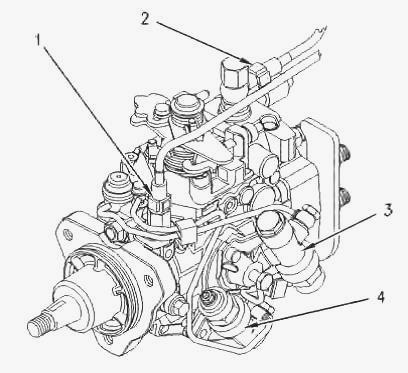

Bosch VE10 pump

Take off the adjacent components. Check the position of the first

cylinder piston in compression at Top Dead Centre. Mark and disconnect

the fuel pipes (1) and (2) from the injection pump (Fig. 16). Plug the

unions to keep dust out of the channels. Disconnect the injection timing

system connector (3). Disconnect the 1104C Perkins diesel engine stop

solenoid connector (4) (Fig. 16). Loosen the lock screw. Shift the

spacer to allow the lock screw to lock the pump pin. Turn the pump pin

anti-clockwise until slight resistance is felt. Tighten the screw to a

torque of 31 Nm. The lock screw (6) must be tightened to prevent the

pump pin from turning. The pump pin must not turn when the pump is

removed.

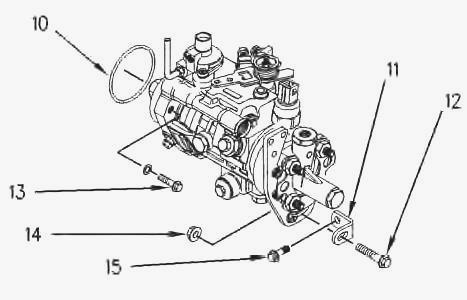

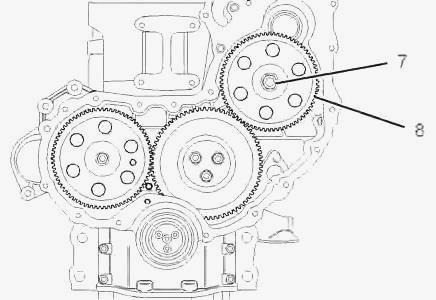

Remove the nut (7) and retaining washer from the injection pump gear

(8). Extract the pump gear (9) using a suitable puller. Do not try to

extract the gear (8) by inserting a lever between the gear and the

housing. Take out the nut (13) and screw (11) (Fig. 18). If necessary,

remove the bracket (10) and its screws from the 1104 engine block. Take

out the screws (12) to remove the injection pump. Remove the injection

pump. Take off and discard the "O" ring (9).

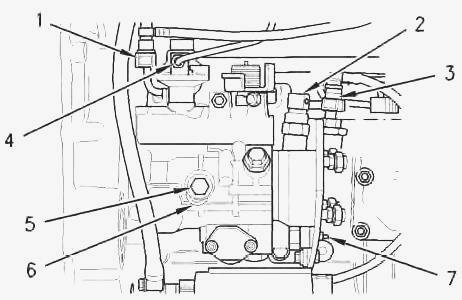

Refitting the injection pump (4-cylinder Perkins engine)

Delphi DP210 pump

The injection pump must be locked in rotation by the lock screw (5)

during reassembly. Do not loosen this screw before being instructed to

do so. If the lock screw has been loosened or if the pump shaft has

turned, contact a Perkins agent. Check the position of the first

cylinder piston in compression at Top Dead Centre. Do not lubricate the

"O" ring (10) (Fig. 19): it should be dry fitted. Fit a new "O" ring

(10) on the injection pump. Position the injection pump on the housing.

Refit the screws (13). Tighten the screws to 25 Nm. Refit the screw (15)

and bracket (11) if removed.

Check that the bracket properly supports the pump alone. Tighten the

screw (15) to 44 Nm. Refit the screw (12) and the nut (14). Ensure the

contact faces between the pump shaft and injection pump gear are clean.

Lubricate the threads of the pump shaft. The nut (8) should turn freely

until it reaches the gear. Position the injection pump gear on the pump

shaft. Refit the washer and nut (8). Turn the pump gear anti-clockwise

until there is no backlash. Tighten the nut to a torque of 24 Nm.

Reconnect all electrical connectors to the pump. Remove all dustproof

plugs and ensure the channels and unions are clean.

Refit the previously removed fuel channels (1) (3) and (4) (Fig. 20).

Loosen the lock screw (5). Move the spacer (6) so that it no longer

blocks the pump pin by tightening the screw (5). Tighten the screw to a

torque of 12 Nm. The spacer (6) must be correctly positioned and the

screw (5) correctly tightened to prevent contact between the injection

pump shaft and the screw (5). Tighten the nut (8) to a torque of 88 Nm.

Reassemble the adjacent components (injection channels, front cover

plate, fan, belts, crankshaft pulley).

Bosch VE10 pump

Check the position of the first cylinder piston in compression at Top

Dead Centre. Lightly lubricate a new "O" ring (9) with silicone oil. Fit

the new seal (9) to the pump. Position the injection pump on the

housing. Refit the screws (12). Tighten the screws to 25 Nm. Refit the

screw and bracket (10) if removed. Check that the bracket properly

supports the pump alone. Tighten the screw to a torque of 44 Nm. Refit

the screw (11) and the nut (13). Ensure the contact faces between the

pump shaft and injection pump gear are clean. Lubricate the threads of

the pump shaft. The nut (7) should turn freely until it reaches the gear

(8) (Fig. 23).

Position the injection pump gear on the pump shaft. Refit the washer and

nut (7). Turn the pump gear anti-clockwise until there is no backlash.

Tighten the nut to a torque of 24 Nm. Reconnect all electrical

connectors to the pump (Fig. 24). Remove all dustproof plugs and ensure

the channels and unions are clean. Refit the previously removed fuel

channels (1) (2) (Fig. 24).

Loosen the lock screw (6). Move the spacer (5) so that it no longer

blocks the pump pin by tightening the screw (6). Tighten the screw to a

torque of 12 Nm. The spacer (5) must be correctly positioned and the

screw (6) correctly tightened to prevent contact between the injection

pump shaft and the screw (6). Tighten the nut (7) to a torque of 88 Nm

(Fig. 23). Reassemble the adjacent components (injection channels, front

cover plate, fan, belts, crankshaft pulley).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader