________________________________________________________________________________

1106 Perkins Motor - Connecting Rod and Piston Ring (Inspect and adjust)

Inspect the Piston and the Piston Rings - Check the piston for wear and

other damage. Check that the piston rings are free to move in the

grooves and that the rings are not broken.

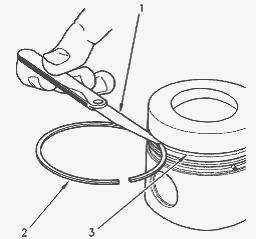

(1) Feeler gauge (2) Piston ring (3) Piston grooves

Inspect the Clearance of the Piston Ring - Remove the piston rings and

clean the grooves and the piston rings. Fit new piston rings (2) in the

piston grooves (3). Check the clearance for the piston ring by placing a

suitable feeler gauge (1) between piston groove (3) and the top of

piston ring (2).

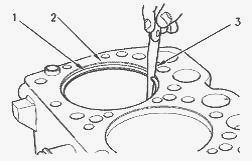

(1) Piston ring (2) Cylinder ring ridge (3) Feeler gauge

Inspect the Piston Ring End Gap - Clean all carbon from the top of the

1106 Perkins cylinder bores. Place each piston ring (1) in the cylinder

bore just below the cylinder ring ridge (2). Use a suitable feeler gauge

(3) to measure piston ring end gap. The coil spring must be removed from

the oil control ring before the gap of the oil control ring is measured.

Connecting Rod Inspect

These procedures determine the following characteristics of the

connecting rod - The length of the connecting rod. The distortion of the

connecting rod. The parallel alignment of the bores of the connecting

rod. If the crankshaft or the 1106 Perkins cylinder block are replaced,

the piston height for all cylinders must be measured. The grade of

length of the connecting rods may need to be changed in order to obtain

the correct piston height.

If the grade of length must be changed, one of the following actions

must be taken: New connecting rod assemblies that are the correct grade

of length must be installed. New piston pin bearings must be bored after

installation in the original connecting rods. When the piston pin is

installed, always install new retaining rings on each end of the piston

pin. If the piston pin cannot be removed by hand, heat the piston to a

temperature of 45±5C (113±9F) in order to aid the removal of the piston

pin. Heating the piston to this temperature may also aid the

installation of the piston pin.

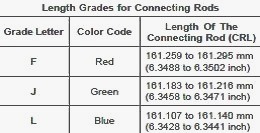

Length of The Connecting Rod

The connecting rod length (CRL) is the length of the connecting rod.

Refer to Table for each grade of length of connecting rod. In order to

ensure that the piston height above the 1106D Perkins cylinder block is

correct, three grades of connecting rods “F” to “L” are used during

manufacture at the factory.

Replacement connecting rods are available in

three grades. These grades of connecting rod are “F” to “L”. The grade

of length is identified by a letter or a color which is marked on the

side of the connecting rod. The longest grade is marked with the letter

“F”. The shortest grade is marked with the letter “L”.

The difference in length between each grade of connecting rods is the

following value: 0.076 mm (0.0030 inch) The grade of length of a

connecting rod is

determined in the factory by machining an eccentric hole in a

semi-finished piston pin bushing.

Therefore, the grade of length is

determined by the position of the

center of the hole in the piston pin bearing. If the connecting rod must

be replaced, a new connecting rod assembly must be purchased and

installed. A new

piston pin bearing is installed in the new connecting rod at the

factory. The bore of the piston pin bearing is reamed to the correct

eccentricity.

Piston Pin Bearings

If the piston pin bearing requires replacement but the original

connecting rod is not replaced, the following procedures must be

performed: Determine the grade of

length of the connecting rod. Use one of the following characteristics:

The mark, The color, Measuring the length.

Ensure that the connecting rod is aligned parallel and that the

connecting rod is not distorted. Remove the piston pin bearing from the

connecting rod. Install a

new bearing in the connecting rod. The new bearing is partially

finished. The new bearing must be bored off-center to the correct

diameter. This off-center

position is determined by the grade of length of the connecting rod.

Surface finish of the bored hole in the piston pin bearing Ra 0.8

micrometers.

Machine the ends of the piston pin bearing to the correct length. Remove

any sharp edges. If the grade of length of the connecting rod is

changed, the letter that

is stamped on the connecting rod must be removed. Each a letter that is

for the new grade of length on the side of the connecting rod. Do not

stamp a new letter

on the connecting rod. The force of stamping may damage the connecting

rod.

Measure The Length Of The Connecting Rod - If the mark or the color of

the grade of length cannot be observed on the connecting rod, perform

the following

procedure:

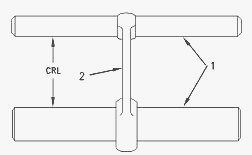

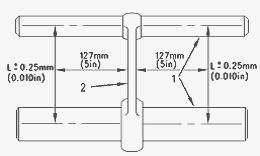

(1) Measuring pins (2) Connecting rod (CRL) Connecting Rod Length

Use the following tools in order to measure the length of the connecting

rod: Appropriate gauges for measuring distance, Measuring pins (1).

Ensure that the

measuring pins (1) are parallel. “CRL” is measured when the bearing for

the crankshaft journal is removed and the original piston pin bearing is

installed.

Distortion of The Connecting Rod - Use the following tools in order to

measure the distances for the connecting rod (2) which are specified in

illustration:

Appropriate gauges for measuring distance, Measuring pins (1).

(1) Measuring pins (2) Connecting rod (L) The length between the centers

of the piston pin bearing and the crankshaft journal bearing is shown in

illustration.

Measure the connecting rod for distortion and parallel alignment between

the bores. The bores for the crankshaft bearing and the bearing for the

piston pin must

be square and parallel with each other within the required limits. If

the piston pin bearing is removed, the limit “L” is the following value:

± 0.25 mm (± 0.010 inch).

The limits are measured at a distance of 127 mm (5.0 inch) from each

side of the connecting rod. If the piston pin bearing is not removed,

the limit “L” is the

following value: ± 0.06 mm (± 0.0024 inch) L is equal to 219.08 ±

0.03mm(8.625 ± 0.001 inch). Inspect the piston pin bearing and the

piston pin for wear.

Measure the clearance of the piston pin in the piston pin bearing.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader