________________________________________________________________________________

1106 Perkins diesel engine - Cylinder Block and Cylinder Head (Inspect and adjust)

Clean all of the coolant passages and the oil passages. Check the

cylinder block for cracks and damage. The top deck of the cylinder block

must not be machined. This will affect the depth of the cylinder liner

flange and the piston height above the cylinder block. Check the front

camshaft bearing for wear.

If a new bearing is needed, use a suitable adapter to press the bearing

out of the bore. Ensure that the oil hole in the new bearing faces the

front of the block. The oil hole in the bearing must be aligned with the

oil hole in the cylinder block. The bearing must be aligned with the

face of the recess.

Cylinder Head Inspect

Remove the cylinder head from the 1106 Perkins engine. Remove the water

temperature regulator housing. Inspect the cylinder head for signs of

gas or coolant leakage. Remove the valve springs and valves.

Clean the bottom face of the cylinder head thoroughly. Clean the coolant

passages and the lubricating oil passages. Make sure that the contact

surfaces of the cylinder head and the cylinder block are clean, smooth

and flat.

Inspect the bottom face of the cylinder head for pitting, corrosion, and

cracks. Inspect the area around the valve seat inserts and the holes for

the fuel injection nozzles carefully. Test the cylinder head for leaks

at a pressure of 200 kPa (29 psi).

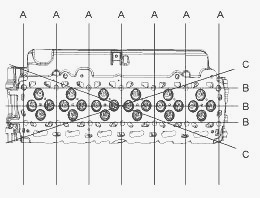

Flatness of the cylinder head - (A) Side to side, (B) End to

end, (C) Diagonal

Measure the cylinder head for flatness. Use a straight edge and a feeler

gauge to check the cylinder head for flatness. Measure the cylinder head

from one side to the opposite side (A). Measure the cylinder head from

one end to the opposite end (B). Measure the cylinder head from one

corner to the opposite corner (C).

Resurfacing the Cylinder Head

The bottom face of 1106D Perkins cylinder head can be resurfaced if any

of the following conditions exist: The bottom face of the cylinder head

is not flat within the specifications. The bottom face of the cylinder

head is damaged by pitting, corrosion, or wear.

The thickness of the cylinder head must not be less than 94.80 mm

(3.7323 inch) after the cylinder head has been machined. If the bottom

face of the cylinder head is resurfaced, the recesses in the cylinder

head for the valve seat inserts must be machined. The valve seat inserts

must be ground on the side which is inserted into the cylinder head.

Grinding this surface will ensure that no protrusion exists above the

bottom face of the cylinder head.

Piston Height Inspect

If any of the following components are replaced or remachined, the

piston height above the 1106 Perkins cylinder block must be measured:

Crankshaft, Cylinder head, Connecting rod, Bearing for the piston pin.

The correct piston height must be maintained in order to ensure that the

engine conforms to the standards for emissions. The top of the piston

should not be machined. If the original piston is installed, be sure

that the original piston is assembled to the correct connecting rod and

installed in the original cylinder.

Three grades of length of connecting rods determine the piston height

above the cylinder block. The grade of length of a connecting rod is

identified by a letter or a color. The letter or the color is marked on

the side of the connecting rod.

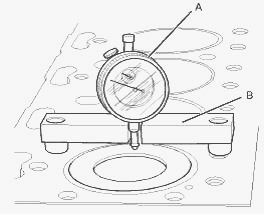

Use Tooling in order to measure the piston height above the cylinder

block. Use the cylinder block face to zero Tooling. Rotate the

crankshaft until the piston is at the approximate top center. Position

Toolings in order to measure the piston height above the cylinder block.

Slowly rotate the crankshaft in order to determine when the piston is at

the highest position. Record this dimension.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader