________________________________________________________________________________

Perkins 1106 motor - Flywheel and Damper (Inspect and adjust)

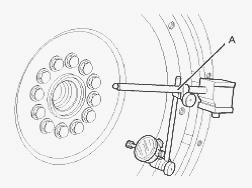

Alignment of the Flywheel Face - Set the pointer of the dial indicator

to 0 mm (0 inch). Turn the flywheel. Read the dial indicator for every

45 degrees. During the check, keep the crankshaft pressed toward the

front of the 1106 Perkins engine in order to remove any end clearance.

Calculate the difference between the lowest measurement and the highest

measurement of the four locations. This difference must not be greater

than 0.03 mm (0.001 inch) for every 25 mm (1.0 inch) of the radius of

the flywheel. The radius of the flywheel is measured from the axis of

the crankshaft to the contact point of the dial indicator.

Flywheel Runout - Set the pointer of the dial indicator to 0 mm (0

inch). Turn the flywheel. Read the dial indicator for every 45 degrees.

Calculate the difference between the lowest measurement and the highest

measurement of the four locations. This difference must not be greater

than 0.30 mm (0.012 inch).

Concentricity and Alignment of the Flywheel Housing - This check must be

made with the flywheel and the starter removed and the bolts for the

flywheel housing tightened lightly. Set the pointer of the dial

indicator to 0 mm (0 inch). Check the concentricity at intervals of 45

degrees around the flywheel housing.

Calculate the difference between the lowest measurement and the highest

measurement. This difference must not be greater than the limit that is

given in Table. Any necessary adjustment must be made on the flywheel

housing. Then, recheck the concentricity.

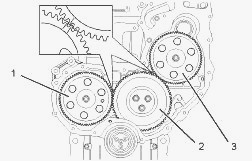

Inspect the Gear Group - Inspect the gears for wear or for damage. If

the gears are worn or damaged, use new parts for replacement.

(1) Camshaft gear (2) Idler gear (3) Fuel injection pump gear

(4) Crankshaft gear

Measure the backlash between the camshaft gear (1) and the idler gear

(2). Measure the backlash between the idler gear (2) and the crankshaft

gear (4). Measure the backlash between the fuel injection pump gear (3)

and the idler gear (2). Measure the end play on idler gear (2).

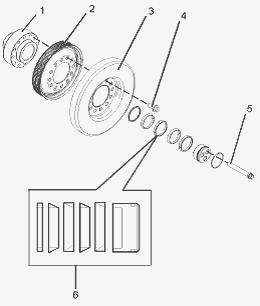

Vibration Damper adjust - The vibration damper is installed on the front

of the crankshaft. There are two types of hub assembly that can be

installed to this engine. The vibration damper is installed in order to

help remove torsional vibration in the 1106D Perkins motor.

(1) Crankshaft adapter (2) Pulley (3) Vibration damper (4)

Damper setscrews (5) Setscrews for the adapter (6) Hub assembly

Vibration damper with out hub assembly - Replace the vibration damper if

any of the following conditions exist: There is any impact damage to the

outer casing. There is leakage of the viscous fluid from the cover

plate. There is movement of the pulley or the outer ring on the hub.

There is a large amount of gear train wear that is not caused by lack of

oil. Analysis of the engine oil has revealed that the front main bearing

is badly worn. The 1106 Perkins engine has had a failure because of a

broken crankshaft.

Check the areas around the holes for the bolts in the vibration damper

for cracks or for wear and for damage. Use the following steps in order

to check the alignment and the runout of the vibration damper: Remove

any debris from the front face of the vibration damper. Remove any

debris from the circumference of the vibration damper. Mount the dial

indicator on the front cover. Use the dial indicator to measure the

outer face of the vibration damper. Set the dial indicator to read 0.00

mm (0.00 inch).

Rotate the crankshaft at intervals of 45 degrees and read the dial

indicator. The difference between the lower measurements and the higher

measurements that are read on the dial indicator at all four points must

not be more than 0.18 mm (0.007 inch).

If the reading on the dial indicator is more than 0.18 mm (0.007 inch),

inspect the pulley and the vibration damper for damage. If the pulley or

the vibration damper are damaged, use new parts for replacement. Move

the dial indicator so that the dial indicator will measure the

circumference of the vibration damper. Set the dial indicator to read

0.00 mm (0.00 inch).

Slowly rotate the crankshaft in order to measure the runout of the

circumference of the vibration damper. Use the highest reading and the

lowest reading on the dial indicator. The maximum and the minimum

readings on the dial indicator should not vary more than 0.12 mm (0.005

inch).

If the reading on the dial indicator is more than 0.12 mm (0.005 inch),

inspect the pulley and the vibration damper for damage. If the pulley or

the vibration damper are damaged, use new parts for replacement.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader