________________________________________________________________________________

1106 Perkins - Turbocharger (Inspect and adjust)

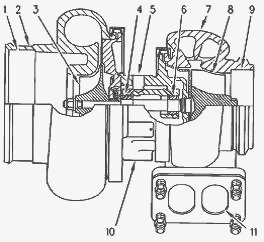

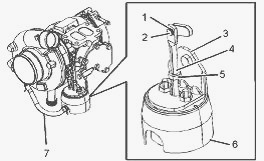

Turbocharger - (1) Air intake (2) Compressor housing (3)

Compressor wheel (4) Bearing (5) Oil inlet port (6) Bearing (7) Turbine

housing (8) Turbine wheel (9) Exhaust outlet (10) Oil outlet port (11)

Exhaust inlet

The turbocharger is mounted on the outlet of the exhaust manifold in one

of two positions on the right side of the engine, toward the top of the

engine or to the side of the diesel engine. The exhaust gas from the

exhaust manifold enters the exhaust inlet (11) and passes through the

turbine housing (7) of the turbocharger. Energy from the exhaust gas

causes the turbine wheel (8) to rotate. The turbine wheel is connected

by a shaft to the compressor wheel (3). As the turbine wheel rotates,

the compressor wheel is rotated. This causes the intake air to be

pressurized through the compressor housing (2) of the turbocharger.

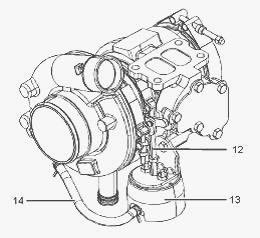

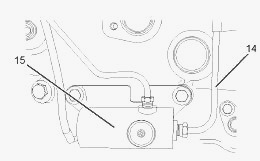

Turbocharger with the waste gate - (12) Actuating lever (13)

Wastegate actuator (14) Line (boost pressure)

(14) Line (boost pressure) (15) Waste gate solenoid

When the load on the 1106 Perkins engine increases, more fuel is

injected into the cylinders. The combustion of this additional fuel

produces more exhaust gases. The additional exhaust gases cause the

turbine and the compressor wheels of the turbocharger to turn faster. As

the compressor wheel turns faster, air is compressed to a higher

pressure and more air is forced into the cylinders. The increased flow

of air into the cylinders allows the fuel to be burnt with greater

efficiency. This produces more power.

A wastegate is installed on the turbine housing of the turbocharger. The

waste gate is a valve that allows exhaust gas to bypass the turbine

wheel of the turbocharger. The operation of the waste gate is dependent

on the pressurized air (boost pressure) from the turbocharger

compressor. The boost pressure acts on a diaphragm that is spring loaded

in the wastegate actuator which varies the amount of exhaust gas that

flows into the turbine.

If a waste gate solenoid (15) is installed, then the wastegate is

controlled by the engine Electronic Control Module (ECM). The ECM uses

inputs from a number of engine sensors to determine the optimum boost

pressure. This will achieve the best exhaust emissions and fuel

consumption at any given motor operating condition. The ECM controls the

solenoid valve, which regulates the boost pressure to the waste gate

actuator.

When high boost pressure is needed for the motor performance, a signal

is sent from the ECM to the waste gate solenoid. This causes low

pressure in the air inlet pipe (14) to act on the diaphragm within the

wastegate actuator (13). The actuating rod (12) acts upon the actuating

lever to close the valve in the waste gate. When the valve in the

wastegate is closed, more exhaust gas is able to pass over the turbine

wheel. This results in an increase in the speed of the turbocharger.

When low boost pressure is needed for the 1106 Perkins engine

performance, a signal is sent from the ECM to the wastegate solenoid.

This causes high pressure in the air inlet pipe (14) to act on the

diaphragm within the waste gate actuator (13). The actuating rod (12)

acts upon the actuating lever to open the valve inthe wastegate. When

the valve in the wastegate is opened, more exhaust gas from the engine

is able to bypass the turbine wheel, resulting in an decrease in the

speed of the turbocharger.

The shaft that connects the turbine to the compressor wheel rotates in

bearings (4 and 6). The bearings require oil under pressure for

lubrication and cooling. The oil that flows to the lubricating oil inlet

port (5) passes through the center of the turbocharger which retains the

bearings. The oil exits the turbocharger from the lubricating oil outlet

port (10) and returns to the oil pan.

Inspect and adjust

The condition of the turbocharger will have definite effects on engine

performance. Use the following inspections and procedures to determine

the condition of the turbocharger. Inspection of the compressor and the

compressor housing. Inspection of the turbine wheel and the turbine

housing. Inspection of the wastegate.

Inspection of the Compressor and the Compressor Housing - Inspect the

compressor wheel for damage from a foreign object. If there is damage,

determine the source of the foreign object. Replace the turbocharger.

Turn the rotating assembly by hand. While you turn the assembly, push

the assembly sideways. The assembly should turn freely. The compressor

wheel should not rub the compressor housing.

The turbocharger must be replaced if the compressor wheel rubs the

compressor wheel housing. Inspect the compressor and the compressor

wheel housing for oil leakage. An oil leak from the compressor may

deposit oil in the aftercooler. If oil is found in the aftercooler, then

drain and clean the aftercooler.

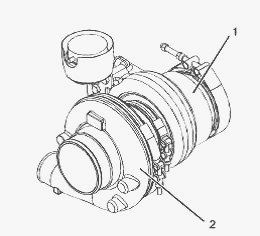

(1) Turbine housing (2) Compressor housing

Check the oil level in the crankcase. If the oil level is too high,

adjust the oil level. Inspect the engine crankcase breather. Clean the

1106 Perkins engine crankcase breather or replace the engine crankcase

breather if the engine crankcase breather is plugged. Remove the pipe

for the oil drain. Inspect the drain opening. Inspect the oil drain

line. Inspect the area between the bearings of the rotating assembly

shaft. Look for oil sludge. Inspect the oil drain hole for oil sludge.

Inspect the oil drain line for oil sludge in the drain line. If

necessary, clean the oil drain line.

Inspection of the Turbine Wheel and the Turbine Housing - Remove the air

piping from the turbine housing. Inspect the turbine for damage by a

foreign object. If there is damage, determine the source of the foreign

object. Replace turbocharger (2). Inspect the turbine wheel for the

carbon and other foreign material. Inspect turbine housing (1) for

carbon and foreign material. Replace the turbocharger, if necessary.

Turn the rotating assembly by hand. While you turn the assembly, push

the assembly sideways. The assembly should turn freely. The turbine

wheel should not rub turbine wheel housing (1). Replace turbocharger (2)

if turbine wheel rubs turbine housing (1). Inspect the turbine and

turbine housing (1) for oil leakage. Inspect the turbine and turbine

housing (1) for oil coking. Some oil coking may be cleaned. Heavy oil

coking may require replacement of the turbocharger.

Remove the pipe for the oil drain. Inspect the drain opening. Inspect

the area between the bearings of the rotating assembly shaft. Look for

oil sludge. Inspect the oil drain hole for oil sludge. Inspect the oil

drain line for oil sludge. If necessary, clean the drain line. If

crankcase pressure is high, or if the oil drain is restricted, pressure

in the center housing may be greater than the pressure of turbine

housing (1). Oil flow may be forced in the wrong direction and the oil

may not drain. Check the crankcase pressure and correct any problems. If

the oil drain line is damaged, replace the oil drain line. Check the

routing of the oil drain line. Eliminate any sharp restrictive bends.

Make sure that the oil drain line is not too close to the engine exhaust

manifold.

Inspection of the Wastegate - The wastegate controls the amount of

exhaust gas that is allowed to bypass the turbine side of the

turbocharger. This valve then controls the rpm of the turbocharger. When

the engine operates in conditions of low boost (lug), a spring presses

against a diaphragm in the canister. The actuating rod will move and the

wastegate actuator will close. The turbocharger can then operate at

maximum performance.

When the boost pressure increases against the diaphragm in the canister,

the wastegate will open. The rpm of the turbocharger becomes limited.

The rpm limitation occurs because a portion of the exhaust gases bypass

the turbine wheel of the turbocharger. The following levels of boost

pressure indicate a problem with the wastegate: Too high at full load

conditions / Too low at all lug conditions.

The boost pressure controls the maximum rpm of the turbocharger, because

the boost pressure controls the position of the wastegate. The following

factors also affect the maximum rpm of the turbocharger: The 1106

Perkins engine rating, The horsepower demand on the engine, The high

idle rpm, Inlet air restriction, Exhaust system restriction.

Check the Wastegate for Proper - Disconnect the pipe for the boost

sensor (7) at the wastegate actuator (6). Connect an air supply to the

wastegate actuator that can be adjusted accurately. Install Tooling to

the turbocharger so that the end of the actuator rod (4) is in contact

with Tooling (A). This will measure axial movement of the actuator rod

(4).

Slowly apply air pressure to the wastegate so that the actuator rod (4)

moves 1.0 mm (0.039 inch). Ensure that the dial indicator returns to

zero when the air pressure is released. Repeat the test several times.

This will ensure that an accurate reading is obtained. If the operation

of the wastegate is not correct, the actuator rod (4) can be adjusted.

Remove Tooling from the turbocharger.

When the air pressure is applied, loosen the nut (5) on the actuator.

Remove the circlip (1). Remove the pin (2) from the actuator rod (4).

When the air pressure is too low, adjust the end of the actuator rod (4)

in order to reduce the length of the actuator rod (4). If the air

pressure is too high, adjust the end of the actuator rod (4) in order to

increase the length of the actuator rod (4). Install the pin (2) to the

actuator rod (4). Install the circlip (1) to the actuator rod (4).

Tighten the nut (5) to a torque of 5 Nm (44 lb in). If the air pressure

is correct, remove the air supply. Remove Tooling. Install the pipe for

the boost sensor (7).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader