________________________________________________________________________________

Perkins 1006 Engine - Flywheel and damper (MF 8100/8200)

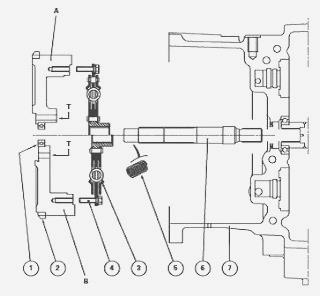

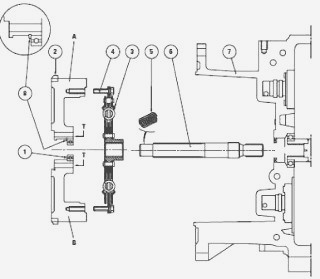

The damper (3) installed on the flywheel is secured by splines onto main

shaft (6). It provides a flexible connection between the Perkins

6-cylinder engine and gearbox and damps any vibrations caused by the

transmission. It is installed on MF 8110, 8120, 8130, 8210, 8220

tractors fitted with the Powershift AG150 (Fig1) Powershift Gearbox

AG250 (Fig2) and Heavy gearboxes (fig3).

AG 150 - AG250 versions (Fig.1-2) - Bearing (1) fit in the flywheel is

sealed on both faces. The seal is to give better reliability. The

bearing supports main shaft (6) and does not itself rotate. Its position

in the flywheel remains variable depending on the type of gearbox and

the motor type. It may be bearing on a shoulder of the flywheel, or on a

circlip. Spring (5) maintains the main shaft in position. The damper,

the main shaft and the bearing form an assembly rotating at the speed of

the flywheel.

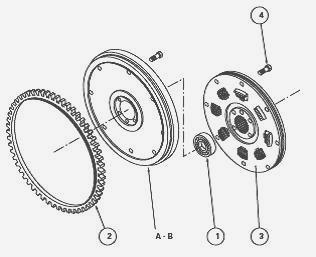

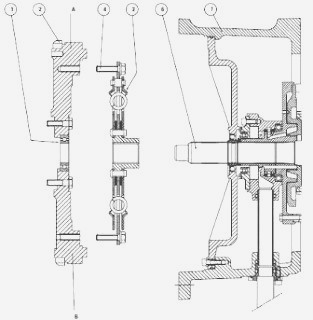

Heavy Duty version (Fig.3) - The principle of installation and operation

remain similar. Note, however, that: the spring is excluded, since the

main shaft installation differs from that shown for the previous

version; the bearing has one position only, and is in contact with the

shoulder of the flywheel. The part number of damper (3) differs

according to the version.

Split the MF 8100/8200 tractor between the engine and the gearbox.

Remove screws (4). Remove damper (3). Check the parts and replace any

that are faulty.

If the operation consists in changing the damper, also replace the

bearing.

Lightly coat the splines of the damper hub with GN grease + Molycote.

Refit and centre the damper, the offset on the hub pointing towards the

gearbox (Figs. 1 - 2). Lightly coat the threads of screws (4) with

Loctite 270 and torque to following values/ Powershift gearbox

(AG150-AG250): M10 screws: 68 - 92 Nm. Heavy gearbox: M12 screws: 102 -

138 Nm. Reassemble the tractor between the Perkins 1006 engine and

gearbox.

Powershift gearbox AG150

Parts list - (1) Bearing (2) Starter ring gear (3) Damper (4) Screw (5)

Spring (6) Main shaft (7) Gearbox A - 86 mm B - 107,95 mm

Powershift gearbox AG250

Parts list - (1) Bearing (2) Starter ring gear (3) Damper (4) Screw (5)

Spring (6) Main shaft (7) Gearbox (8) Circlip A - 86 mm B - 94 mm

Heavy gearbox

Parts list - (1) Bearing (2) Starter ring gear (3) Damper (4) Screw (5)

Spring (6) Main shaft (7) Gearbox A - 86 mm B - 107,95 mm

Split the MF 8110, 8120, 8130, 8210, 8220 tractor between the engine and

the gearbox. Lock the flywheel using a suitable fixture. Remove the

damper. Remove the flywheel. Drive out bearing (1) (Figs. 1-2).

- On certain types of installation (Figs. 1 - 2) , extraction of the

bearing is possible without removing the flywheel, using a slide hammer.

- If installing a type A flywheel and a Powershift gearbox AG250,

replace circlips (8) and the bearing (Fig. 1)

Refitting

Check the parts, replacing any that are defective. Screw two guide studs

opposite one another into the holes used for attaching the flywheel on

the crankshaft. Refit the flywheel.

Depending on the type of fixture, fit bearing (1) before or after

refitting the flywheel, using a suitable mandrel (dia. 62 mm,

corresponding to the hole in the external cage of the bearing).

Remove the guide studs. Torque the screws to 140 Nm. For the screw

torquing values on Valmet flywheels, refer to the engine repair manual.

Refit the damper. Reassemble the tractor between the 1006 Perkins motor

and gearbox.

Replacing the starter ring gear

Split the tractor between the engine and gearbox. Remove the damper.

Remove the flywheel. Using a suitable-strength drill bit, drill a hole

(D=5) to the same depth as the width of ring gear (2) to avoid touching

the flywheel. Use a suitable cold chisel to split the ring gear (Fig.

3). When breaking the ring gear, provide some protection to stop

splinters of material.

Heat a new ring gear to 245C in a furnace only. Install ring gear (2) on

the flywheel, with the teeth opening pointing towards the starter, and

fit rapidly into abutment. Allow to cool slowly. Refit the flywheel and

the damper. Reassemble the tractor between the engine and gearbox.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader