________________________________________________________________________________

John Deere 3120, 3320, 3520, 3720 - Service Engine

John Deere 3120, 3320, 3520, 3720 Engine Oil

Choose oil viscosity based on the expected air temperature

range during the period between oil changes. John Deere PLUS-50 oil is

recommended. TORQ-GARD SUPREME and oils meeting ACEA Specification E4/E5

may also be used. Other oils may be used if they meet one or more of the

following: API Service Classification CI-4, API Service Classification

CH-4, or ACEA Specification E3. Multi-viscosity diesel engine oils are

preferred. Do not use break-in oils. Checking Engine Speeds - Check

engine speeds when engine is warmed up and not under load. Observe tachometer.

Checking Engine Oil Level

Failure to check the oil level regularly

could lead to serious engine problems if oil level is low: Check oil

level before operating. Check oil level when the JD 3120, 3320, 3520,

3720 engine is cold and not running. Keep level between the Full and the

Add marks. Shut off engine before adding oil. Check engine oil when

engine is cold. If engine is warm, allow to cool for at least five

minutes before checking oil. Park the machine safely. Dirt and

contamination can enter engine when checking oil level. Clean area

around dipstick before loosening or removing. Remove dipstick. Wipe

with a clean cloth. Install dipstick. Remove dipstick. Check oil level

on dipstick. Oil level should be between levels on dipstick.

If oil level is low: Remove oil fill cap. Add proper engine oil

until oil level is within operating range on dipstick. Do not overfill.

Install oil fill cap. If oil is above level on the dipstick,

drain to proper level. Install dipstick.

John Deere 3120, 3320, 3520, 3720 Tractors - Changing Engine Oil and Filter

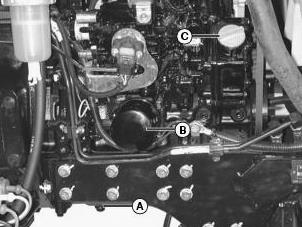

Run John Deere 3120, 3320, 3520 engine

to warm the oil. Park machine safely. Place drain pan under oil drain

located on left side of engine. Remove drain plug. Remove two drain

plugs on model JD 3720. Wipe dirt from around oil filter. Turn filter

counter-clockwise to remove. Put a light coat of clean engine oil on the

gasket of new filter. Install replacement oil filter by turning filter

clockwise until gasket contacts filter base. Tighten additional one-half

turn. Install drain plug. Do not overtighten. Install two drain plugs on

model JD 3720. Remove oil fill cap. Add recommended engine oil. Install

oil fill cap. Start and run engine at idle to check for leaks. Stop

engine. Fix any leaks before operating. Check engine oil level and add

oil if necessary.

Cleaning Rubber Dust Unloading Valve

Do not operate engine without air

cleaner element and rubber dust unloading valve installed. Park the

vehicle safely. Allow engine to cool. Access the engine compartment.

Squeeze dust unloading valve to clean. Remove and replace if

damaged. Servicing Air Filter Element - Dirt and debris can enter the

engine when removing the filter element. Service filter elements only

when red signal is in view in the instrument panel. Shut off engine and

turn off all lights before service.

John Deere 3120, 3320, 3520, 3720 Tractor - Servicing Primary Element

Park John Deere 3120, 3320, 3520, 3720 tractor. Allow engine to

cool. Check to be sure key switch and all lights are off. If the key

switch or any lights are left on, the air restriction indicator light

may continue to flash even after the filter has been replaced. Raise

hood. Release latches and remove air cleaner canister cover.

Remove and discard primary element. Clean out any dirt in canister,

taking care not to damage the secondary filter element. Replace with a

new primary filter element. Install air cleaner canister cover with

rubber dust unloading valve pointing downward. Check instruction

molded into canister cover for proper installation. Hook latches onto cover. Lower hood.

Servicing Secondary Element

Secondary element does not need routine

replacement. Visually inspect it without removing from canister. Do not

attempt to clean secondary element. If secondary element is replaced,

install new primary and secondary element immediately to prevent dust

from entering air intake system. Remove air cleaner canister cover.

Remove and discard primary air filter element. Remove and discard

secondary air filter element. Replace with a new secondary air

filter element. Install new primary air filter element. Replace air

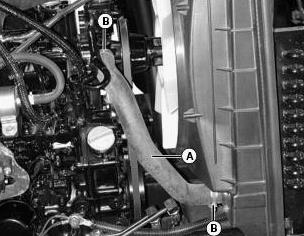

cleaner canister cover. Lower hood. Checking Air Filter Hose - Park

machine safely. Raise hood. Upper air intake flange must be properly

installed into shroud adapter on radiator support frame. Locate

lower air intake hose below muffler, and tighten hose clamps.

Lower hood.

Checking Air Restriction Indicator Light

JD 3120, 3320, 3520, 3720 Tractor Engine exhaust fumes contain carbon monoxide. Do not run an engine in an enclosed area without adequate ventilation. Be cautious and wear protective clothing when servicing or working near a hot engine and components. Keep hands, clothing, jewelry and long hair away from moving parts. Park the machine safely. Start the engine. Raise hood. Block the air intake hose with cardboard or other solid material. Do not block with a cloth or any other material which would allow air to flow. Increase throttle to full engine rpm. The air restriction indicator light on the instrument panel should illuminate. Turn off all light switches and stop the engine. The air restriction indicator light should go out. Remove block to air intake hose and lower the hood.

John Deere 3120, 3320, 3520, 3720 Cooling System

Checking Coolant Level

Using incorrect coolant mixture can damage the

radiator: Do not operate engine with plain water. Do not exceed a 50%

mixture of coolant and water. Aluminum engine blocks and radiators

require approved ethylene-glycol based antifreeze. If you suspect a

leak, check the coolant level by removing the radiator cap and looking

inside. Park the vehicle safely. Allow engine to cool. Raise hood. Check

recovery tank coolant level: If engine is warm, coolant level should

be between the FULL HOT line and the FULL COLD line. If engine

is cold, coolant level should be at the FULL COLD line on the

recovery tank. Remove recovery tank cap if necessary to add coolant.

Add pre-diluted coolant or specified ratio of antifreeze and water.

Install recovery tank cap. Lower hood.

John Deere 3120, 3320, 3520, 3720 Tractor Cooling System Service

Park machine safely. Allow engine to cool.

Raise hood. Slowly open radiator cap to the first stop to release

all pressure. Close radiator cap tightly. Position drain pan under

radiator petcock on left side of machine. Open petcock and drain

coolant. Disconnect coolant hose at connection to oil filter

base, and allow all coolant to drain into pan. After coolant drains from

the recovery tank, remove radiator cap. Close radiator petcock and

connect coolant hose. Flush cooling system. Flushing Cooling System -

Fill cooling system with clean water and John Deere Cooling System

Cleaner, or Cooling System Quick Flush or an equivalent. Follow

directions on container. Install and tighten radiator cap. Start and run

engine until it reaches operating temperature. Stop engine. Open

radiator petcock and disconnect coolant hose. Drain cooling system

immediately before rust and dirt settle. Close radiator petcock and

connect coolant hose.

John Deere 3120, 3320, 3520, 3720 Cooling System Filling

Using incorrect coolant mixture can damage the radiator: Do not operate engine with plain water. Do not exceed a 50% mixture of coolant and water. Aluminum engine blocks and radiators require approved ethylene-glycol based antifreeze. John Deere COOL-GARD coolant is recommended when adding new coolant to the cooling system. Follow the directions on the container for correct mixture ratio. Allow radiator to cool. Fill cooling system with recommended coolant. Install and tighten radiator cap. Run engine until it reaches operating temperature. Stop JD 3120, 3320, 3520, 3720 engine. Allow engine to cool. Some coolant may be drawn into the radiator from the recovery tank during cool down. Raise hood. Check recovery tank coolant level: After engine cools, coolant level should be at the FULL COLD line on the recovery tank. Remove cap rom recovery tank to add coolant if necessary. Lower hood.

Checking Radiator Hoses - Allow engine to cool. Raise hood. Check lower

radiator hose for damage or cracking. Replace if necessary. Tighten

hose clamps as needed. Check upper radiator hose for damage or

cracking. Replace if necessary. Tighten hose clamps as needed. Lower

hood.

Cleaning Radiator Screen and Fins

Raise hood. Lift and remove radiator screen off of clips on top of radiator. Clean screen with compressed air, brush or cloth, or screen may be carefully washed to remove dirt and debris. Reduced air intake can cause overheating. Keep radiator cooling fins clean. Do not use pressure washers to clean radiator cooling fins. The force produced by pressure washers will damage the radiator and cooling fins. Reduce compressed air pressure to 210 kPa (30 psi) when cleaning radiator and cooling fins. Spray compressed air straight into radiator. Do not spray radiator on an angle or cooling fins will be bent. Remove all dirt and debris from radiator fins, and fan shroud using compressed air or water. Install radiator screen. Lower hood.

John Deere 3120, 3320, 3520, 3720 - Servicing Belt

Adjusting Compressor Belt Tension

Raise hood. Apply moderate thumb

pressure to belt halfway between the pulleys. Belt should deflect

inward approximately 9 mm (3/8 in). Adjust belt tension if deflection is

more or less than specified. Loosen nut on tensioner sheave.

Slide tensioner downward for more tension on belt or upward for less

tension on belt. Tighten nut on tensioner sheave and check belt tension.

Adjust as necessary. Lower hood. Replacing Belt - Raise hood. Disconnect

black negative (-) cable from battery. Loosen nut on tensioner

sheave. Slide tensioner upward to remove tension on belt, and remove

belt from compressor sheave, engine sheave, and tensioner sheave.

Install new belt over engine sheave and then onto remaining sheaves.

Apply pressure to tensioner sheave until tension is correct and

tighten nut. Check belt tension, and adjust as necessary. Connect

black negative (-) cable to battery. Lower hood.

Servicing the Alternator Belt

Allow John Deere 3120, 3320, 3520, 3720

engine to cool. Raise hood. Apply moderate thumb pressure to belt

halfway between the pulleys. Belt should deflect inward approximately 9

mm (3/8 in.). Adjust belt tension if deflection is more or less than

specified. Loosen top adjusting bolt: For tractors without a cab, loosen

top adjusting bolt. For tractors with a cab, loosen top adjusting

bolt and nut. Loosen mounting bolt. Apply outward pressure to

alternator housing until tension is correct. Tighten bolts.

Check belt tension. Lower hood.

Servicing Water Separator Sediment Bowl

Allow engine to cool. Red ring

in bottom of sediment bowl will float on water. If ring is floating,

sediment bowl should be cleaned. Check for water and deposits in

sediment bowl. Clean sediment bowl and replace fuel filter if

necessary. Cleaning Water Separator Sediment Bowl - Close fuel shut-off

valve. Position drain pan under sediment bowl to catch fuel

spillage. Turn locking collar counterclockwise to remove bowl.

Remove and retain the plastic ring and spring from sediment bowl. Clean

bowl, plastic ring, and spring. Install plastic ring and spring in

original position in sediment bowl. Place sediment bowl and locking

collar in position. Tighten locking collar to filter head to secure.

Open fuel shut-off valve. Fuel system is self bleeding. Crank engine to

bleed fuel system.

Cleaning Fuel Filter Sediment Bowl and Replacing Filter

Allow John Deere 3120, 3320, 3520 engine to cool. Raise hood. Close fuel shut-off valve. Position drain pan under fuel filter sediment bowl to catch fuel spillage. Turn locking collar counterclockwise to remove bowl. Remove and discard the fuel filter. Remove and retain the plastic ring and spring from sediment bowl. Clean bowl, plastic ring, and spring. Install plastic ring and spring in original position in sediment bowl. Install new filter to filter head. Place sediment bowl and locking collar in position. Tighten locking collar to filter head to secure. Open fuel shut-off valve. Lower hood. Crank engine to bleed fuel system. Replacing Fuel Filter - Allow engine to cool. Close fuel shut-off valve. Position drain pan under fuel filter to catch fuel spillage. Turn filter counterclockwise to remove and discard. Apply fuel to surface of new filter gasket. Install new filter to filter head. Tighten to one complete turn after filter contacts head. Open fuel shut-off valve.

- JD 3120, 3320, 3520, 3720 Engine

- JD 3120, 3320, 3520, 3720 Transmission

- JD 3120, 3320, 3520, 3720 PTO

- JD 3120, 3320, 3520, 3720 Brakes and Wheels

- JD 3120, 3320, 3520, 3720 Hydraulic and Hitch

- JD 3120, 3320, 3520, 3720 Operating

- JD 3120, 3320, 3520, 3720 Troubleshooting

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

JD SPECS

JD SPECS JD LOADERS

JD LOADERS JD MAINTENANCE

JD MAINTENANCE JD INSTRUCTIONS

JD INSTRUCTIONS JD PROBLEMS

JD PROBLEMS JD 2025R

JD 2025R JD 3039R

JD 3039R JD 4044R

JD 4044R JD 4105

JD 4105 JD 4720

JD 4720 420 Loader

420 Loader 419 Loader

419 Loader 510 Loader

510 Loader 512 Loader

512 Loader 520 Loader

520 Loader 520M Loader

520M Loader 540M NSL

540M NSL 540 Loader

540 Loader 440R Loader

440R Loader H180 Loader

H180 Loader JD 5045E

JD 5045E JD 5085E

JD 5085E JD 5100M

JD 5100M JD 6105R

JD 6105R JD 6120M

JD 6120M JD 6155M

JD 6155M JD 6195R

JD 6195R JD 6210R

JD 6210R JD 7210R

JD 7210R JD 7250R

JD 7250R JD 7310R

JD 7310R JD 8245R

JD 8245R JD 8295R

JD 8295R JD 8370R

JD 8370R JD 9370R

JD 9370R 120R Loader

120R Loader D120 Loader

D120 Loader H120 Loader

H120 Loader 45 Loader

45 Loader 200CX Loader

200CX Loader D160 Loader

D160 Loader D170 Loader

D170 Loader H160 Loader

H160 Loader H165 Loader

H165 Loader H240 Loader

H240 Loader 210 Loader

210 Loader 220R Loader

220R Loader 300E Loader

300E Loader 300X Loader

300X Loader 300CX Loader

300CX Loader JD 9420R

JD 9420R JD 9510R

JD 9510R JD GX335

JD GX335 JD GX85

JD GX85 JD LA105

JD LA105 JD 5065M

JD 5065M JD 5055D

JD 5055D JD 5115R

JD 5115R JD 5105M

JD 5105M JD 6110R

JD 6110R JD 6130D

JD 6130D JD 6225

JD 6225 JD 7530

JD 7530 JD 4044M

JD 4044M JD 7185J

JD 7185J 300 Loader

300 Loader 300R Loader

300R Loader 320R Loader

320R Loader 400E Loader

400E Loader 410 Loader

410 Loader 430 Loader

430 Loader 460 Loader

460 Loader 521 Loader

521 Loader 531 Loader

531 Loader 541 Loader

541 Loader 551 Loader

551 Loader 631 Loader

631 Loader 651 Loader

651 Loader 661 Loader

661 Loader 603R Loader

603R Loader JD D130

JD D130 JD D160

JD D160 JD 325

JD 325 JD 335

JD 335 JD 345

JD 345 JD 2520

JD 2520 JD 3005

JD 3005 JD 3720

JD 3720 JD 1025R

JD 1025R JD 3033R

JD 3033R JD 5090EL

JD 5090EL JD 5100MH

JD 5100MH JD 5075GV

JD 5075GV JD 6090RC

JD 6090RC JD 6110B

JD 6110B 623R Loader

623R Loader 643R Loader

643R Loader 731 Loader

731 Loader 746 Loader

746 Loader 751 Loader

751 Loader 533 Loader

533 Loader 583 Loader

583 Loader 633 Loader

633 Loader 653 Loader

653 Loader 683 Loader

683 Loader H260 Loader

H260 Loader 663R Loader

663R Loader 663 Loader

663 Loader 683R Loader

683R Loader 753 Loader

753 Loader JD 6125J

JD 6125J JD 6150RH

JD 6150RH JD 6210J

JD 6210J JD 7195J

JD 7195J JD 8310

JD 8310 JD 6325

JD 6325 JD 5525

JD 5525 JD 5083EN

JD 5083EN JD 5100GN

JD 5100GN JD 5125R

JD 5125R 210C Backhoe

210C Backhoe 300D Backhoe

300D Backhoe 310G Backhoe

310G Backhoe 410G Backhoe

410G Backhoe 710G Backhoe

710G Backhoe 80 Loader

80 Loader 100 Loader

100 Loader 146 Loader

146 Loader 148 Loader

148 Loader 158 Loader

158 Loader 168 Loader

168 Loader 175 Loader

175 Loader 522 Loader

522 Loader 542 Loader

542 Loader 540R Loader

540R Loader 562 Loader

562 Loader 563 Loader

563 Loader 673 Loader

673 Loader 741 Loader

741 Loader L108 Automatic

L108 Automatic L120 Automatic

L120 Automatic LA110 Automatic

LA110 Automatic LA120 Automatic

LA120 Automatic LA150 Automatic

LA150 Automatic LT155

LT155 LT160 Automatic

LT160 Automatic LT180 Automatic

LT180 Automatic LTR180

LTR180 X165

X165 E100

E100 E120

E120 E150

E150 LTR166

LTR166 LA135

LA135 LA165

LA165 LX277

LX277 LX288

LX288 LX255

LX255 S240

S240 GT235

GT235 G110 Automatic

G110 Automatic JD 3203

JD 3203 JD 5520

JD 5520 JD 316

JD 316 JD 420

JD 420 JD 425

JD 425 JD 445

JD 445 JD_5050D

JD_5050D X300

X300 X304

X304 X310

X310 X110 Automatic

X110 Automatic H310 Loader

H310 Loader H340 Loader

H340 Loader H360 Loader

H360 Loader H380 Loader

H380 Loader H480 Loader

H480 Loader 240 Loader

240 Loader 245 Loader

245 Loader 260 Loader

260 Loader 265 Loader

265 Loader 600R Loader

600R Loader 620R Loader

620R Loader 640R Loader

640R Loader 660R Loader

660R Loader 680R Loader

680R Loader JD_5039D

JD_5039D X146R

X146R X360

X360 X155R

X155R X140 Automatic

X140 Automatic X350

X350 X380

X380 X500

X500 X590

X590 X700

X700 3036E

3036E 2038R

2038R 3038R

3038R 4049M

4049M JD 4100

JD 4100 X738

X738 X740

X740 X748

X748 X749

X749 X950R

X950R JD 4510

JD 4510 5045D

5045D 5050E

5050E 5060E

5060E 5078E

5078E