________________________________________________________________________________

John Deere 6068 diesel - Cylinder head inspect and reassembly operations

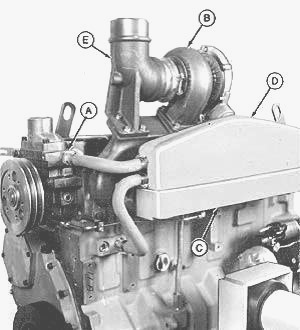

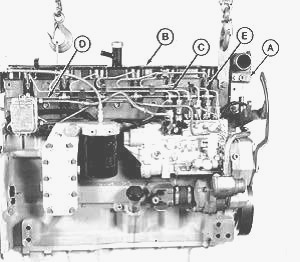

Remove cylinder head

Remove rocker arm cover, if not previously done. Drain all engine oil

and coolant. Disconnect turbocharger oil inlet line at turbocharger or

oil conditioning housing. Remove water manifold (A) and all coolant

piping. Remove turbocharger (B) and exhaust elbow (E). Remove air intake

manifold (C). Remove exhaust manifold.

A—Water Manifold, B—Turbocharger, C—Intake Manifold, D—Aftercooler

Assembly, E—Exhaust Elbow

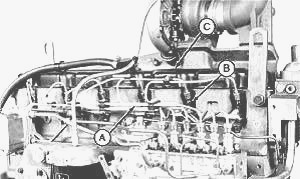

Remove fuel injection lines (A) and nozzles (B). Remove rocker arm cover

(C) and ventilator outlet hose assembly.

Remove six cap screws (A) and remove all four clamps (B). Lift rocker

arm assembly up and remove. Remove wear caps from valve stems. Remove

all 12 push rods and identify for reassembly.

Clean and inspect push rods as explained later in this group. Remove all

26 cylinder head cap screws. If cylinder head gasket failed, check and

record each cylinder head cap screw torque before removing. Make a

reference mark (in-line) on socket and cylinder head surface. Loosen cap

screw at least 1/2 turn. Retighten cap screw (using torque wrench) until

reference marks align, and record torque.

Remove cylinder head gasket. Inspect possible oil, coolant, or

combustion chamber leaks. Also, check for evidence of incorrect or

defective head gasket being used. Do not rotate crankshaft with cylinder

head removed unless all cylinder liners are secured with cap screws and

large flat washers as described later in this group.

Disassemble and inspect rocker arm shaft assembly

Make preliminary inspection during disassembly. Look for: Worn or scored

rocker arms, shaft, and shaft support. Weak or broken springs. Lube oil

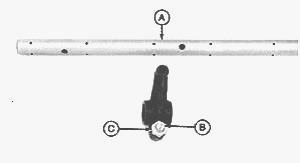

restriction. Remove plugs and washers from ends of rocker arm shaft.

Slide springs, rocker arms, and rocker arm supports off rocker arm shaft

identifying their parts for reassembly in the same sequence they were in

before disassembly. Inspect rocker arm shaft (A) for severe scratching,

scoring, or excessive wear at points of rocker arm contact. Measure

rocker arm and shaft. Compare with specifications given below.

Wear could indicate weak valve springs, bent push rods, or loose rocker

arm shaft clamps.

ROCKER ARM ASSEMBLY SPECIFICATIONS

Rocker Arm I.D - 19.07—19.10 mm (0.7507—0.7520 in.)

Rocker Arm Shaft O.D - 19.01—19.05 mm (0.7484—0.7500 in.)

Check rocker arm adjusting nut (C) and screw (B) for damage. Visually

inspect rocker arm for hairline cracks. Replace if necessary. Be sure

all oil holes in rocker arm shaft are clean and open. Clean all rocker

arm parts with clean solvent. Dry with compressed air. Check for cups or

concave wear on ends of rocker arms where they contact wear caps.

Examine spacer springs on shaft between rocker arms. Be sure they are

strong enough to exert a positive pressure on rocker arms. If the rocker

arm has been damaged by a valve failure, replace it and the push rods

when replacing valves. Roll rocker arm shaft and push rods on a flat

surface to check for bends or distortion. Replace parts as necessary.

Assemble and inspect rocker arm shaft assembly - Assemble parts on

rocker arm shaft opposite removal procedure. Make sure rocker arm shaft

end plugs are firmly seated against end of shaft, and washers are

installed on shaft.

Inspect and clean cylinder head

Inspect all John Deere 6068 diesel cylinder head passages for

restrictions. Heads with restricted or clogged passages can be cleaned

by soaking them in a tank of hot caustic solution. Scrape all old gasket

material from head. Use a powered wire brush to clean sealing surfaces.

If cylinder head is not put in a chemical hot tank for cleaning, clean

with solvent and a brush. Dry with compressed air and be sure to blow

out all passages.

Check cylinder head combustion face flatness - Check cylinder head

flatness using D05012ST Precision Straightedge and feeler gauge. Check

lengthwise, crosswise, and diagonally in several places. If any

measurement exceeds this specification, the cylinder head must be either

resurfaced or replaced.

CYLINDER HEAD TOP DECK FLATNESS SPECIFICATION

Maximum Out-of-Flat (Over Entire Length or Width) - 0.102 mm (0.0040

in.)

Straightness per any 305 mm (12 in.) Length - 0.025 mm (0.001 in.)

Measure cylinder head Thickness - Measure head thickness from valve

cover gasket rail-to-combustion face. If cylinder head thickness is less

than wear limit. Do not attempt to resurface. Install a new cylinder

head. If necessary to resurface cylinder head, a maximum of 0.762 mm

(0.030 in.) can be ground from new part dimension. Remove only what is

necessary to restore flatness. After resurfacing, check flatness as

described earlier and check surface finish on combustion face of head.

Check valve recess after grinding. Valve seat or valve face may be

ground to bring this characteristic within specification.

CYLINDER HEAD SPECIFICATIONS

Thickness - 155.45—155.71 mm (6.120—6.130 in.)

Wear Limit - 154.69 mm (6.09 in.)

Combustion Face Surface Finish (AA) - 0.015—0.0028 mm (60—110 micro-in.)

Maximum Wave Depth - 0.008 mm (0.0003 in.)

Install cylinder head

Thoroughly inspect new cylinder head gasket for possible manufacturing

imperfections. Return any gasket that does not pass inspection. Be sure

cylinder head and block gasket surfaces are clean, dry, and free of any

oil. Put a new head gasket on JD 6068 diesel cylinder block. Do not use

sealant on gasket; install dry. If cylinder head is lowered onto

cylinder block and you discover that the head is not positioned

correctly on locating dowels, remove cylinder head and install a new

gasket. Do not try to reposition cylinder head on the same gasket again

since the fire ring will possibly be damaged. Lower cylinder head everly

to correct position on block using appropriate lifting equipment. Make

sure that head is positioned correctly over dowels.

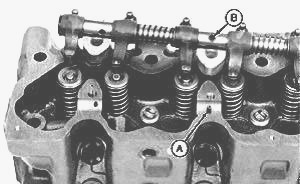

Install rocker arm assembly - Install push rods (A) in holes from which

removed. Install wear caps (B) on valves, making certain caps rotate

freely. Make sure spring pin (A) engages with hole (B) in shaft. Install

shaft clamps (B) and all six cap screws (A). Tighten cap screws to 75 Nm

(55 lb-ft).

Complete final assembly of injection pump side - Adjust valve clearance

as directed earlier in this group. Apply Adhesive or equivalent to new

gasket, and seal gasket to rocker arm cover (B). Be sure to follow the

manufacturer’s directions on the package for correct application

procedures and curing times. Install cover and tighten cap screws to 8

Nm (6 lb-ft) (72 lb-in.). Install fuel injection nozzles (E), leak-off

lines (D) and fuel injection lines (C). Connect ventilator outlet hose

to adapter on rocker arm cover and tighten clamp securely. Install water

manifold.

A—Water Manifold, B—Rocker Arm Cover, C—Fuel Injection Lines, D—Leak-off

Lines, E—Fuel Injection Nozzles

Complete final assembly on exhaust manifold side - Install front exhaust

manifold using new gaskets. Do not tighten cap screws until sealing ring

and rear exhaust manifold is installed. Install rear exhaust manifold

using new gaskets and sealing ring. Tighten cap screws in sequence shown

in bottom illustration to 47 Nm (35 lb-ft). Install turbocharger oil

return pipe, using a new O-ring.

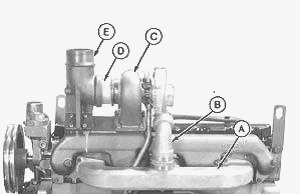

On some John Deere Engines, using new gaskets install intake manifold

(A). Tighten cap screws to 47 Nm (35 lb ft). On some Engines, install

intake coupling (B). Do not tighten clamps. On some Engines, install

turbocharger (C), adapter (D), and exhaust elbow (E). Position intake

adapter with turbocharger and intake manifold and tighten clamps

securely.

A—Intake Manifold, B—Intake Coupling, C—Turbocharger, D—Turbocharger

Adapter, E—Exhaust Elbow

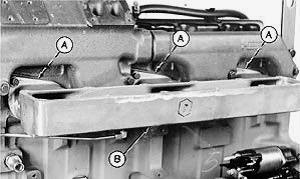

On JD diesel, use new gaskets (A) and install intake manifold (B).

Tighten cap screws to 47 Nm (35 lb-ft).

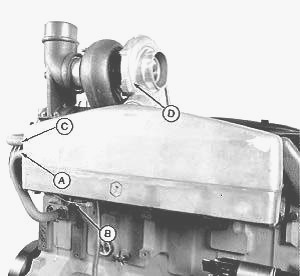

On JD Engines, using new gaskets and O-rings, install aftercooler and

cover - Install water inlet (A) and water outlet (C) hoses. Tighten hose

clamps securely. Install aneroid line (B), if equipped, and tighten

securely. Install turbocharger (D) with couplings. Tighten cap screws to

47 Nm (35 lb-ft). If engine oil was drained from crankcase, install new

oil filter and fill with clean oil of correct grade and viscosity. Fill

cooling system with clean coolant. Perform engine break-in.

A—Water Inlet Hose, B—Aneroid Line, C—Water Outlet Tube and Hose,

D—Turbocharger

Perform engine break-in - Run John Deere 6068 diesel engine at slow idle

no load for 2 minutes. Check for liquid leaks. Increase RPM to fast

idle, then load down to 50 rpm above rated speed for 20 minutes.

Dynamometer is the preferred load control, but engine can be loaded by

matching drag loads to gear selection. Recheck valve clearance and

adjust as necessary. Install rocker arm cover gasket and cover. Tighten

rocker arm cover cap screws to 8 Nm (6 lb-ft) (72 lb-in.). Retorque of

cylinder head cap screws after engine break-in is not required.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

JD SPECS

JD SPECS JD LOADERS

JD LOADERS JD MAINTENANCE

JD MAINTENANCE JD INSTRUCTIONS

JD INSTRUCTIONS JD PROBLEMS

JD PROBLEMS JD 2025R

JD 2025R JD 3039R

JD 3039R JD 4044R

JD 4044R JD 4105

JD 4105 JD 4720

JD 4720 420 Loader

420 Loader 419 Loader

419 Loader 510 Loader

510 Loader 512 Loader

512 Loader 520 Loader

520 Loader 520M Loader

520M Loader 540M NSL

540M NSL 540 Loader

540 Loader 440R Loader

440R Loader H180 Loader

H180 Loader JD 5045E

JD 5045E JD 5085E

JD 5085E JD 5100M

JD 5100M JD 6105R

JD 6105R JD 6120M

JD 6120M JD 6155M

JD 6155M JD 6195R

JD 6195R JD 6210R

JD 6210R JD 7210R

JD 7210R JD 7250R

JD 7250R JD 7310R

JD 7310R JD 8245R

JD 8245R JD 8295R

JD 8295R JD 8370R

JD 8370R JD 9370R

JD 9370R 120R Loader

120R Loader D120 Loader

D120 Loader H120 Loader

H120 Loader 45 Loader

45 Loader 200CX Loader

200CX Loader D160 Loader

D160 Loader D170 Loader

D170 Loader H160 Loader

H160 Loader H165 Loader

H165 Loader H240 Loader

H240 Loader 210 Loader

210 Loader 220R Loader

220R Loader 300E Loader

300E Loader 300X Loader

300X Loader 300CX Loader

300CX Loader JD 9420R

JD 9420R JD 9510R

JD 9510R JD GX335

JD GX335 JD GX85

JD GX85 JD LA105

JD LA105 JD 5065M

JD 5065M JD 5055D

JD 5055D JD 5115R

JD 5115R JD 5105M

JD 5105M JD 6110R

JD 6110R JD 6130D

JD 6130D JD 6225

JD 6225 JD 7530

JD 7530 JD 4044M

JD 4044M JD 7185J

JD 7185J 300 Loader

300 Loader 300R Loader

300R Loader 320R Loader

320R Loader 400E Loader

400E Loader 410 Loader

410 Loader 430 Loader

430 Loader 460 Loader

460 Loader 521 Loader

521 Loader 531 Loader

531 Loader 541 Loader

541 Loader 551 Loader

551 Loader 631 Loader

631 Loader 651 Loader

651 Loader 661 Loader

661 Loader 603R Loader

603R Loader JD D130

JD D130 JD D160

JD D160 JD 325

JD 325 JD 335

JD 335 JD 345

JD 345 JD 2520

JD 2520 JD 3005

JD 3005 JD 3720

JD 3720 JD 1025R

JD 1025R JD 3033R

JD 3033R JD 5090EL

JD 5090EL JD 5100MH

JD 5100MH JD 5075GV

JD 5075GV JD 6090RC

JD 6090RC JD 6110B

JD 6110B 623R Loader

623R Loader 643R Loader

643R Loader 731 Loader

731 Loader 746 Loader

746 Loader 751 Loader

751 Loader 533 Loader

533 Loader 583 Loader

583 Loader 633 Loader

633 Loader 653 Loader

653 Loader 683 Loader

683 Loader H260 Loader

H260 Loader 663R Loader

663R Loader 663 Loader

663 Loader 683R Loader

683R Loader 753 Loader

753 Loader JD 6125J

JD 6125J JD 6150RH

JD 6150RH JD 6210J

JD 6210J JD 7195J

JD 7195J JD 8310

JD 8310 JD 6325

JD 6325 JD 5525

JD 5525 JD 5083EN

JD 5083EN JD 5100GN

JD 5100GN JD 5125R

JD 5125R 210C Backhoe

210C Backhoe 300D Backhoe

300D Backhoe 310G Backhoe

310G Backhoe 410G Backhoe

410G Backhoe 710G Backhoe

710G Backhoe 80 Loader

80 Loader 100 Loader

100 Loader 146 Loader

146 Loader 148 Loader

148 Loader 158 Loader

158 Loader 168 Loader

168 Loader 175 Loader

175 Loader 522 Loader

522 Loader 542 Loader

542 Loader 540R Loader

540R Loader 562 Loader

562 Loader 563 Loader

563 Loader 673 Loader

673 Loader 741 Loader

741 Loader L108 Automatic

L108 Automatic L120 Automatic

L120 Automatic LA110 Automatic

LA110 Automatic LA120 Automatic

LA120 Automatic LA150 Automatic

LA150 Automatic LT155

LT155 LT160 Automatic

LT160 Automatic LT180 Automatic

LT180 Automatic LTR180

LTR180 X165

X165 E100

E100 E120

E120 E150

E150 LTR166

LTR166 LA135

LA135 LA165

LA165 LX277

LX277 LX288

LX288 LX255

LX255 S240

S240 GT235

GT235 G110 Automatic

G110 Automatic JD 3203

JD 3203 JD 5520

JD 5520 JD 316

JD 316 JD 420

JD 420 JD 425

JD 425 JD 445

JD 445 JD_5050D

JD_5050D X300

X300 X304

X304 X310

X310 X110 Automatic

X110 Automatic H310 Loader

H310 Loader H340 Loader

H340 Loader H360 Loader

H360 Loader H380 Loader

H380 Loader H480 Loader

H480 Loader 240 Loader

240 Loader 245 Loader

245 Loader 260 Loader

260 Loader 265 Loader

265 Loader 600R Loader

600R Loader 620R Loader

620R Loader 640R Loader

640R Loader 660R Loader

660R Loader 680R Loader

680R Loader JD_5039D

JD_5039D X146R

X146R X360

X360 X155R

X155R X140 Automatic

X140 Automatic X350

X350 X380

X380 X500

X500 X590

X590 X700

X700 3036E

3036E 2038R

2038R 3038R

3038R 4049M

4049M JD 4100

JD 4100 X738

X738 X740

X740 X748

X748 X749

X749 X950R

X950R JD 4510

JD 4510 5045D

5045D 5050E

5050E 5060E

5060E 5078E

5078E