________________________________________________________________________________

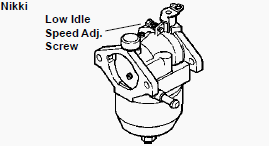

Kohler CV16S Engine - Nikki Carburetor

Kohler CV16S - Nikki Carburetor Adjustment

Kohler CV16S engines are equipped with fixed main jet Nikki carburetors.

Nikki carburetors only have a low idle speed screw. Carburetors will

have fixed idle fuel or a limiter cap on the idle fuel adjusting needle.

Carburetor adjustments should be made only after the engine has warmed

up. The carburetor is designed to deliver the correct fuel to air

mixture to the engine under all operating conditions. The main fuel jet

is calibrated at the factory and is not adjustable.

The idle fuel adjusting needle is also set at the factory and normally

does not need adjustment. Engines operating at altitudes above

approximately 1830 m (6000 ft.) may require a special high altitude main

jet. If, however, the engine is hard-starting or does not operate

properly, it may be necessary to adjust or service the carburetor.

Low Idle Speed Setting

1) Start the engine and run at half throttle for 5 to 10 minutes to warm

up. The engine must be warm before doing step 2.

2) Low Idle Speed Setting: Place the throttle control into the idle or

slow position. Set the low idle speed to 1200 RPM (±75 RPM) by turning

the low idle speed adjusting screw in or out. Check the speed using a

tachometer. The actual low idle speed depends on the application refer

to equipment manufacturer's recommendations. The recommended low idle

speed for basic engines is 1200 RPM. To ensure best results when setting

the low idle fuel needle, the low idle speed must not exceed 1200 RPM

(±75 RPM).

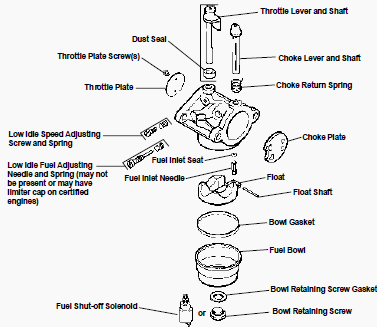

Kohler CV16S - Nikki Carburetor Disassembly

- Remove the bowl retaining screw, retaining screw gasket, and fuel

bowl.

- Remove the bowl gasket, float shaft, float, and fuel inlet needle.

- Remove the low idle speed screw and spring.

- If there is a low fuel adjusting needle without a limiter cap, remove

the needle and spring.

- Do not attempt to remove the needle if it has a limiter cap.

- Further disassembly to remove the welch plugs, main fuel jet, fuel

inlet seat, throttle plate and shaft, and choke plate and shaft is

recommended only if these parts are to be cleaned or replaced.

Main Fuel Jet Removal

The main jet on Nikki carburetors is threaded into the tip of the fuel

shut-off solenoid. It can be removed for inspection or cleaning.

Fuel Inlet Seat Removal

The fuel inlet seat is pressed into the carburetor body, do not attempt

to remove it. If necessary, clean it in place with aerosol carburetor

cleaner.

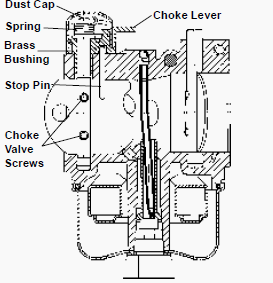

Choke Shaft Removal (Self-Relieving)

The self-relieving choke used on some carburetors. Use the following

procedure to replace the self-relieving choke components using Choke

Repair Kit. Remove the black dust cover. This cover snaps on and off.

Remove and discard the two screws fastening the choke plate to the choke

shaft. Remove and discard the choke plate and choke shaft from the

carburetor.

Remove the upper brass bushing using one of the following

procedures: Use a slide hammer type bearing puller. Use a screw

extractor (for 5/32 dia. hole). Secure extractor in a vise. Turn

carburetor on to the extractor. While pulling on the carburetor, lightly

tap the carburetor casting with a hammer or use a size 12-28 tap if a

screw extractor is not available.

Kohler CV16S - Nikki Carburetor Cleaning

- Carburetor body and bore; especially the areas where the throttle

plate, choke plate and shafts are seated.

- Idle fuel and idle ports in carburetor bore, main jet, bowl vent, and

fuel inlet needle and seat.

- Float and float hinge. Fuel bowl.

- Throttle plate, choke plate, throttle shaft, and choke shaft.

- Do not submerge the carburetor in cleaner or solvent when fiber,

rubber, or foam seals or gaskets are installed.

- The cleaner may damage these components.

Kohler CV16S - Nikki Carburetor Reassembly

Choke Shaft Installation (Self-Relieving)

Before installing kit parts, thoroughly clean the carburetor body with

compressed air. Install the new bushing through the new lever and align

the slot in the bottom of the lever over the lever stop pin. To ensure

the proper alignment of the upper bushing and the lower shaft hole use a

3/16 diameter drill blank to align the bushing as it is pressed into the

casting.

Install choke shaft and spring assembly with the lower spring tang installed in the second notch from the right. Loosely attach the choke plate to the choke shaft using the two screws provided in the choke repair kit. Apply Loctite to the threads of the choke plate retaining screws.

Secure these screws only after the choke plate is

properly aligned in the choke bore. To align choke plate, insert a 0.010

in. shim between the top right edge of the choke plate and bore. Then

while pushing down on the top of the choke shaft, tighten screws

securely.

Check choke shaft and choke plate for freedom of movement by performing

the following: Using the choke lever, close the choke plate. The choke

lever and choke plate should move in unison. While holding the choke

lever in the closed position, push on the long side of the choke plate.

The choke plate should open and spring closed freely.

While holding the

choke lever in the wide open position, the choke plate should be against

the wide open choke plate stop pin. Install new dust cover by pushing it

down until it snaps into place. After the carburetor is reinstalled on

the engine, recheck choke system for freedom of movement by moving the

wire link in the direction to close the choke and releasing it. The link

should move freely in both directions.

High Altitude Operation

When operating the engine at altitudes of 1830 m (6000 ft.) and above,

the main fuel mixture tends to get overrich. An overrich mixture can

cause conditions such as black, sooty exhaust smoke, misfiring, loss of

speed and power, poor fuel economy, and poor or slow governor response.

To compensate for the effects of high altitude, a special high altitude main fuel jet can be installed. High altitude jets are sold in kits which include the jet and necessary gaskets. Refer to the Parts Manual for the engine being serviced for the correct kit number.

________________________________________________________________________________

________________________________________________________________________________________

| KOHLER ENGINES SPECS AND SERVICE DATA |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KAWASAKI ENGINES SPECS AND SERVICE DATA |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| BRIGGS AND STRATTON ENGINES SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| HONDA ENGINES SPECS AND SERVICE DATA |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

CH12.5

CH12.5 CH14S

CH14S CH15S

CH15S CH16

CH16 CH18S

CH18S CH23S

CH23S CH25S

CH25S CH640S

CH640S CH730S

CH730S CH750S

CH750S CV15S

CV15S CV16S

CV16S CV18S

CV18S CV20S

CV20S CV22S

CV22S CV23S

CV23S CV25S

CV25S CV490S

CV490S CV491S

CV491S CV730S

CV730S CV740S

CV740S K161

K161 K181

K181 K241

K241 K301

K301 K321

K321 K341

K341 K361

K361 M18

M18 M20

M20 SV470S

SV470S SV530S

SV530S SV540S

SV540S SV590S

SV590S SV600S

SV600S SV710

SV710 SV715

SV715 SV725S

SV725S SV730S

SV730S SV735

SV735 FA210

FA210 FA210D

FA210D FB460V

FB460V FC150V

FC150V FC290V

FC290V FC420V

FC420V FC540V

FC540V FD501V

FD501V FD590V

FD590V FD620D

FD620D FD731V

FD731V FD750D

FD750D FH430V

FH430V FH500V

FH500V FH531V

FH531V FH580V

FH580V FH601V

FH601V FH680V

FH680V FS541V

FS541V FS600V

FS600V FS651V

FS651V FX651V

FX651V FX691V

FX691V FX730V

FX730V FH541V

FH541V FH641V

FH641V FH661V

FH661V FH721V

FH721V FS730V

FS730V 252707

252707 253707

253707 282707

282707 286707

286707 303777

303777 28N707

28N707 28M707

28M707 28Q777

28Q777 28R707

28R707 28S777

28S777 311707

311707 31A607

31A607 31C707

31C707 31N707

31N707 31Q777

31Q777 31R977

31R977 31R777

31R777 31P777

31P777 31P977

31P977 350777

350777 402707

402707 422707

422707 42A707

42A707 331777

331777 331877

331877 G50

G50 G100

G100 GC135

GC135 GC160

GC160 GC190

GC190 GS190

GS190 GX100

GX100 GX120

GX120 GX160

GX160 GX200

GX200 GXV120

GXV120 GXV160

GXV160 GXV270

GXV270 GXV340

GXV340 GXV390

GXV390 GXV610

GXV610 GCV520

GCV520 GCV530

GCV530 GXV620

GXV620 GXV630

GXV630 GCV145

GCV145 GCV160

GCV160 GCV170

GCV170 GCV190

GCV190 GCV200

GCV200 GSV190

GSV190 GX110

GX110 GX140

GX140 GV100

GV100 GXV140

GXV140