________________________________________________________________________________

Kubota B1550, B6100, B6200 - Engine Service

B1550, B6200 tractors are equipped with a Kubota D850 3-Cylinder Diesel

Engine. B6100 tractor is powered by D650 model.

Kubota B1550, B6100, B6200 Engine - Checking

and Adjusting

Compression Pressure

After warming up the engine, stop it and remove the air cleaner, the

muffler and all nozzle holders. Install a compression tester for diesel

engines to nozzle holder hole. After making sure that the speed control

lever is set at the stop position (Non-injection), run the engine at 200

to 300 rpm with the starter. Read the maximum pressure. Measure the

pressure more than twice. If the measurement is below the allowable

limit, check the cylinder, piston ring, top clearance, valve and

cylinder head. Variances in cylinder compression values should be under

10%.

Top Clearance

Remove the nozzle holder. Lower the piston in the cylinder. Insert a

high quality fuse from the nozzle holder hole on the piston except where

it faces the valve or the combustion chamber insert. Rotate the flywheel

until the piston is raised and lowered again. Take out the fuse

carefully. Repeat three times with a new fuse in the other directions.

Measure the thickness of the crushed fuse with vernier calipers. If the

measurement is not within the factory specifications, check the oil

clearance of the crank pin and clearance between the piston pin and

bushing. Head gasket thickness (after retightened) - 1.05 to 1.15 mm

(0.0413 to 0.0453 in). Protection - 0.25 to 0.55 mm (0.010 to 0.022 in).

Draining Cooling Water and Engine Oil

Never remove radiator cap until cooling water temperature is below its

boiling point. Then loosen cap slightly to the stop to relieve any

excess pressure before removing cap completely. Prepare a bucket. Open

the drain cock to drain cooling water. Prepare an oil pan. Remove the

drain plug to drain engine oil in the pan.

Air Cleaner and Muffler

Remove the air cleaner. Remove muffler retaining nuts to remove the

muffler. Install the muffler gasket so that its steel side face the

muffler.

Checking Engine Oil Level

Level the engine. To check the oil level, draw out the dipstick, wipe it

clean, reinsert it, and draw it out again. Check to see that the oil

level lies between the two notches. If the level is too low, add new oil

to the specified level. When checking the oil level, make sure a Kubota

B1550, B6100, B6200 tractor is on a flat surface. It is impossible to

check accurately if the tractor is not level. Check the oil level before

starting or more than 3 minutes after the engine has stopped. At other

times, the check will not be accurate as oil stagnates in certain engine

parts. When using an oil of different maker or viscosity from the

previous one, drain old oil. Never mix two different types of oil.

Kubota B1550, B6100, B6200 - Engine Oil

Changing

After warming up, stop the Kubota D850/D650 engine. To change the used

oil, remove the drain plug at the bottom of the engine and drain off the

oil completely. Reinstall the drain plug. Fill the new oil up to the

upper notch on the dipstick. Change the type of engine oil according to

the ambient temperature. Above 25C - SAE 30 or 10W-30, 0C to 25C - SAE

20 or 10W-30, Below 0C - SAE 10W or 10W-30.

Changing Engine Oil Filter Cartridge

Remove the oil filter cartridge with a filter wrench. Apply engine oil

to the rubber gasket on the new cartridge. Screw the new cartridge in by

hand. Over-tightening may cause deformation of rubber gasket. After

cartridge has been replaced, engine oil normally decreases a little.

Check the oil level and add new oil to the specified level.

Fuel Filter Cleaning

Water and grit present in the fuel will be extracted by the fuel filter.

When the filter is blocked/full, turn off the fuel tap, remove and clean

the filter. Air must always be removed when refitting the filter as

follows: Turn the fuel filter to the ON position. Open the taps as

follows - At the top of the injection pump. At the top of the fitter.

Half fill the tank. Turn the filter tap off. Fill the tank up to the

top. Run the engine for one minute then stop it. Turn off the pump tap.

Only open the pump tap and filter tap when draining.

Air Filter Cleaning

The air filter protects the engine from damaging dust and sand. It must

therefore be cleaned regularly to avoid engine seizure. Clean out the

dust from the filter cowling. Clean out the dust from the filter. When

installing the filter cowling, check that the "top" sign is well at the

top. The filter housing will otherwise leak air and particles will

damage the filter.

Kubota B1550, B6100, B6200 Engine -

Disassembly and Assembly

Cylinder Head Cover and Injection Pipe

Remove the cylinder head cover cap nuts. Remove the cylinder head cover.

Check to see that the cylinder head cover gasket is not defective.

Loosen the pipe damps. Remove the injection pipes.

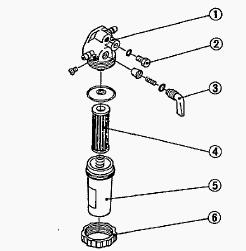

Nozzle Holder Assembly

Remove the fuel overflow pipes. Loosen the lock nuts, and remove the

nozzle holder assemblies with a nozzle holder socket wrench. Remove the

copper gaskets on the seats.

Alternator and Fan Belt

Remove the alternator. Remove the fan belt. Check to see that there are

no cracks on the belt surface. After reassembling the fan belt, be sure

to adjust the fan belt tension.

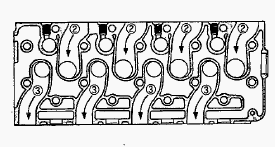

Cylinder Head

Loosen the pipe band, and remove the water return pipe. Remove the

cylinder head screws and nuts in the order, and remove the cylinder

head. Remove the cylinder head gasket and O-ring. Replace the head

gasket with a new one. Install the cylinder head, using care not to

damage the O-ring. Tighten the cylinder head screws and nuts gradually

in the order after applying engine oil. Retighten the cylinder head

screws and nuts after running the engine for 30 minutes.

Rocker Arm and Tappets

Remove the rocker arm bracket mounting nuts. Remove the rocker arm as a

unit. After reassembling the rocker arm, be sure to adjust the valve

clearance. Remove the tappets from the crankcase. Before installing the

tappets, apply engine oil thinly around them. Mark the cylinder number

to the tappets to prevent interchanging.

Valves

Remove the valve caps. Remove the valve spring collet, pushing the valve

spring retainer by valve spring replacer. Remove the valve spring

retainer, valve spring and valve stem seal. Remove the valve. Wash the

valve stem and valve guide hole, and apply engine oil sufficiently.

After installing the valve spring collets, lightly tap the stem to

assure proper fit with a plastic hammer.

Kubota B1550, B6100, B6200 - Gear Case

Fuel Feed Pump and Injection Pump Cover

Loosen the pipe clamp and remove the fuel pipe from the injection pump

side. Remove the fuel feed pump mounting nuts. Remove the fuel feed

pump. Apply a liquid gasket to the both sides of fuel feed pump gasket.

Remove the injection pump cover. Apply a liquid gasket to the both sides

of injection pump cover gasket.

Injection Pump, Fuel Feed Pump and Speed

Control Plate

The tip of wire is bent like the hook to hang governor springs. Remove

the socket head screws, and remove the engine stop solenoid. Remove the

screws and separate the speed control plate, taking care not to damage

the governor spring. Disconnect the governor spring and remove the speed

control plate using the specific tool. Remove the fuel feed pump.

Disconnect the start spring from the bracket using the specific tool.

Remove the socket head screws and nuts, and remove the injection pump.

Fan Drive Pulley

Secure the flywheel to keep it from turning. Remove the fan drive pulley

screw. Draw out the fan drive pulley with a puller. Install the pulley

to crankshaft, aligning the mark on them. Apply engine oil to the fan

drive pulley retaining screw. And tighten it.

Gear Case and Idle Gear

Remove the gear case. Apply a liquid gasket to both sides of the gear

case gasket. Grease thinly to the oil seal, and install it, ensuring the

Up does not come off. Remove the crankshaft collar. Remove the O-ring.

Remove the crankshaft oil slinger. Remove the external snap ring. Remove

the idle collar and idle gear. Remove the idle gear collar. When

installing the idle gear, be sure to align the alignment marks on gears.

Camshaft and Fuel Camshaft

Align the round hole on the cam gear with the camshaft stopper mounting

screw position. Remove the camshaft stopper mounting screws. Remove the

cam gear and camshaft. Apply engine oil thinly to the camshaft before

installation. Remove the fork lever holder mounting screws. Remove the

fork lever assembly. Remove the fuel camshaft stopper. Remove the fuel

camshaft and injection pump gear.

Kubota B1550, B6100, B6200 - Piston and

Connecting Rod

Oil Pan

Remove the oil pan mounting screws. Remove the oil pan by lightly

tapping the rim of the oil pan with a wooden hammer. Apply a liquid

gasket to both sides of the oil pan gasket. To avoid uneven tightening,

tighten mounting screws in diagonal order from the center.

Oil Strainer

Remove the oil strainer mounting screw. Remove the oil strainer. After

cleaning the oil strainer, install it. Install the oil strainer, using

care not to damage the O-ring.

Piston

Turn the flywheel, and bring the No.1 piston to the top dead center.

Pull out the piston upward by lightly tapping it from the bottom of the

crankcase with the grip of a hammer. Before inserting the piston into

the cylinder, apply enough engine oil to the cylinder. When inserting

the piston into the cylinder, face the mark on the connecting rod to the

injection pump. Do not change the combination of cylinder and piston.

Make sure of the position of each piston by marking. For example, mark

"1" on the No.1 piston. When inserting the piston into the cylinder,

place the gap of the compression ring on the opposite side of the

combustion chamber and stagger the gaps of the compression ring and oil

ring making a right angle from the gap of the compression ring.

Carefully insert the pistons using a piston ring compressor. Otherwise,

their chrome-plated section may be scratched, causing trouble inside the

liner.

Piston Ring and Connecting Rod

Remove the piston rings using a piston ring tool. Put the parting mark

for example, on the piston head. Remove the piston pin, and separate the

connecting rod from the piston. When installing the ring, assemble the

rings so that the manufacturer's mark near the gap faces the top of the

piston. When installing the oil ring onto the piston, place the expander

joint on the opposite side of the oil ring gap. Apply engine oil to the

piston pin. When installing the piston pin, immerse the piston in 80C

oil for 10 to 15 minutes and insert the piston pin to the piston. When

installing the connecting rod to the piston, align the mark on the

connecting rod to the parting mark. Mark the same number on the

connecting rod and the piston so as not to change the combination.

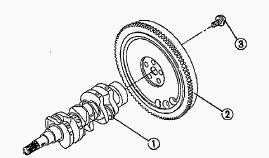

Kubota B1550, B6100, B6200 - Flywheel and

Crankshaft

Oil Pump and Crank Gear

Remove the starter. Straighten the washer, and remove the nut. Pull out

the oil pump drive gear with a puller. Remove the oil pump mounting

bolts. Remove the oil pump. Remove the crank gear with a special-use

puller set. Remove the feather key on the crankshaft. Check to see that

the feather key is on the crankshaft. Heat the crank gear to approx. 80C

(176F), and fit on the crankshaft.

Flywheel

Lock the flywheel not to turn using the flywheel stopper. Remove the

flywheel screws, except for two which must be loosened and left as they

are. Set a flywheel puller , and remove the flywheel. Apply engine oil

to the flywheel screws.

Bearing case cover and crankshaft

Before disassembling, check the side clearance of crankshaft. Also check

it during reassembly. Remove the bearing case cover mounting screws.

Screw two removed screws into the screw hole of bearing case cover to

remove it. Stretch the washer and remove the bearing case screw. Pull

out the crankshaft. Install the crankshaft sub assembly, aligning the

screw hole of main bearing case with the screw hole of cylinder block.

Apply engine oil to the seat and thread of bearing case screw. After

tightening it, bend the washer firmly. Install the bearing case cover to

position the casting mark on it upward. Tighten the bearing case cover

mounting screws with even force on the diagonal line.

Main Bearing Case Assembly

Be sure to install the thrust bearing with its oil groove facing

outward. Remove the two bearing case screws, and remove the main bearing

case assembly, being careful with the thrust bearing and crankshaft

bearing 2. Remove the main bearing case assemblies as above. Clean the

oil passage in the main bearing case. Apply dean engine oil on the

crankshaft bearing 2 and thrust bearings. Install the main bearing case

assemblies in the original positions. They are not interchangeable.

Kubota B1550, B6100, B6200 Engine

Troubleshooting

When Kubota D850 engine is difficult to start

Fuel is thick and doesn't flow - Check the fuel oil tank and fuel oil

filter. Remove water, dirt and other impurities. As all fuel oil will be

filtered by the filter, if there should be water or other foreign

matters on the filter, replace the filter.

Air or water mixed in fuel system - If air is in the fuel filter or

injection lines, the fuel pump will not work properly. To attain proper

fuel injection pressure, check carefully for loosened fuel lines, cap

nut, etc. Loosen air vent screws atop fuel filter and fuel injection

pump to eliminate all the air in the fuel oil system.

Thick carbon deposits on orifice of injection nozzle - This is caused

when water or dirt is mixed in the fuel. Clean the nozzle injection

piece, being careful not to damage the orifice. Check to see if nozzle

is working properly or not. If not, install a new nozzle.

Valve clearance is incorrect - Adjust valve clearance.

Leaking valves - Grind valve.

Fuel injection timing is incorrect - Adjust injection timing.

Engine oil becomes thick in cold weather and engine cranks slow - Change

grade of oil according to the weather (temperature).

Low compression - Bad valve or excessive wear of rings, pistons and

liners cause insufficient compression. Replace with new parts.

Battery is discharged and the engine will not crank - Charge battery.

Use decompression device. In winter, always remove battery from tractor,

charge fully and keep indoors. Install in tractor at time of use.

When Kubota D850 engine lacks power

Air cleaner is dirty or Fuel filter is dirty - Clean the element every

100-200 hours of operation.

Carbon around orifice of nozzle piece - Clean orifice and needle valve,

being very carefully not to damage the nozzle orifice. Check nozzle. If

defective, replace with new parts.

Compression is insufficient. Leaking valves - Bad valve and excessive

wear of rings, pistons and liners cause insufficient compression.

Replace with new parts. Grind valves.

Fuel is insufficient - Check fuel system.

Overheating of moving parts - Check lube oil system. Check to see if

lube oil filter is working properly. Filter screens or elements

deposited impurities would cause poor lubrication. Clean screens. Check

to see if bearing clearance are within factory specs. Check engine

timing.

Valves out of adjustment - Adjust to proper valve clearance.

Fuel injection pressure is incorrect - Adjust to proper pressure.

When Kubota D850 engine suddenly stops

Leak of fuel - Check the fuel tank and refill if necessary. Also check

the fuel system for air or leaks.

Bad nozzle - If necessary, replace with a new nozzle.

Moving parts are overheated due to shortage of lube oil or improper

lubrication - Check amount of engine oil with dipstick. Check

lubricating oil system. Check to see if element inside the lubricating

oil filter has become old and clogged. If necessary, replace with new

element. Check to see if the engine bearing clearances is within factory

specs.

When Kubota D850 engine must be stopped

immediately

Speed suddenly decreases or increases - Check the adjustments and timing

of injection and the fuel system.

Unusual sound is heard suddenly - Check all moving parts carefully.

Color of exhaust suddenly turns dark - Check the fuel injection system,

especially the fuel injection nozzle.

Bearing parts are overheated - Check the lubricating system.

Oil light lights up during operation - Check lubricating system. Check

to see if the engine bearing clearances are within factory specs. Check

the function of the regulating valve inside the oil filter. Check

pressure switch. Check filter base gasket.

Starter does not function

Defective Alternator rectifier - Repair Alternator and replace defective

rectifier. Dirty or corroded terminal contacts - Wash terminal with hot

water and tighten well. Bad brushes, armature or field - Replace.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES INSTRUCTIONS

INSTRUCTIONS PROBLEMS

PROBLEMS B2320

B2320 B2630

B2630 B2920

B2920 B3300SU

B3300SU BX2360

BX2360 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 BX2660

BX2660 L2501

L2501 L3240

L3240 L3540

L3540 L3940

L3940 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 L4400

L4400 L4600

L4600 L5040

L5040 L5740

L5740 MX4700

MX4700 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 B2710

B2710 BX23S

BX23S B3350

B3350 BX1880

BX1880 L4701

L4701 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 M100GX

M100GX M135GX

M135GX M6040

M6040 M8540

M8540 M95X

M95X LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 M5-091

M5-091 BX2680

BX2680 MX5200

MX5200 BX2380

BX2380 L3901

L3901 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605