________________________________________________________________________________

Kubota B1600, B1750, B7200, B8200 - Engine Maintenance

B1600, B1750, B7200, B8200 tractors are equipped with a Kubota D950 3

Cylinder Diesel Engine.

Kubota B1600, B1750, B7200, B8200 Engine -

Maintenance Check List

Initial 50 hours

Change engine oil and engine oil filter cartridge. Check fan drive belt

tension.

Every 100 hours

Change engine oil. Clean fuel filter. Clean air cleaner element. Check

battery electrolyte level. Check fuel line.

Every 200 hours

Replace engine oil filter cartridge. Check radiator hose and hose clamp.

Check fan drive belt tension.

Every 400 hours

Replace fuel filter.

Every 600 hours

Replace air cleaner element.

Every 2 months

Recharge battery if necessary.

Every year

Change anti-freeze and coolant. Clean radiator.

Every 2 years

Replace battery. Replace radiator hose. Replace fuel line.

Every 800 hours

Check valve clearance.

Daily

Check radiator screen. Check oil cooler exterior. Check coolant level.

Check oil and fuel level. Check tire pressure.

Kubota B1600, B1750, B7200, B8200 Engine

Maintenance

Changing Engine Oil

Before changing oil, be sure to stop the engine. Start and warm up the

engine for approx. 5 minutes. Place an oil pan underneath the engine. To

drain the used oil, remove the drain plug at bottom of the engine and

drain the oil completely. Screw in the drain plug. Fill new oil up to

upper notch on the dipstick. When using an oil of different manufacturer

or viscosity from the previous one, remove all of the old oil. Never mix

two different type of oil. Use the proper SAE Engine Oil according to

ambient temperatures. Engine Oil Capacity - 3.1 L.

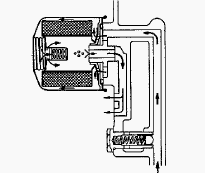

Kubota B1600, B1750, B7200, B8200 - Replacing

Engine Oil Filter Cartridge

Be sure to stop the engine before changing oil filter cartridge. Remove

the oil filter cartridge with the filter wrench. Apply a slight coat of

oil onto the cartridge gasket. To install the new cartridge, screw it in

by hand. Over tightening may cause deformation of rubber gasket. After

the new cartridge has been replaced, the engine oil normally decrease a

little. Thus see that the engine oil does not leak through the seal and

be sure to read the oil level on the dipstick. Then, replenish the

engine oil up to the specified level. To prevent serious damage to the

engine, replacement element must be highly efficient.

Checking Fan Drive Belt Tension

When making adjustments, park the vehicle on flat ground, apply the

parking brake and stop a Kubota D950 engine. If the fan drive belt

becomes loose, the engine may overheat. Check the fan drive belt

tension. Moderate belt tension is as follows. The belt should deflect

approx. 10 mm (0.4 in.) when the center of the belt is depressed with a

finger force of 98 N (10 kgf, 22 lbs). If no moderate belt tension,

loosen the adjusting bolt and tension bolt to stretch the belt and

adjust belt tension. After adjustment, securely tighten the their bolts.

Checking Fan Drive Belt Tension and Alternator

Drive Belt Tension

If the alternator drive belt becomes loose, the battery may not be

charged. Check the drive belt tensions. Moderate belt tension is as

follows. The belt should deflect approx. 10 mm (0.4 in.) when the center

of the belt is depressed with a finger force of 98 N (10 kgf, 22 lbs).

If no moderate belt tension, loosen the bolt and nut and adjust belt

tension. After adjustment, securely tighten the bolt and nut.

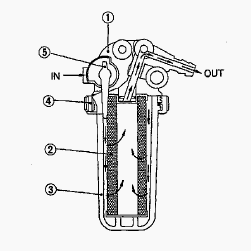

Cleaning Fuel Filter

When operation period reaches approx. 100 hours, clean the fuel filter.

Unscrew the wing bolt and knob bolt which fasten the engine cover RH,

and remove the cover. Close the fuel filter bowl cock. Unscrew and

remove the screw ring, and rinse the inside with kerosene. Take out the

element and dip it in the kerosene to rinse. After cleaning reassembling

the fuel filter, keeping out dust and dirt. Bleed the injection pump. If

dust and dirt enter the fuel, the fuel pump and injection nozzle are

subject to wear. To prevent this, be sure to clean the fuel filter bowl

periodically.

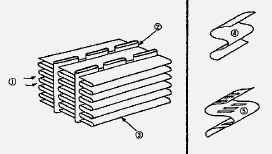

Checking and Cleaning Air Cleaner Element

The air cleaner uses a dry element, never apply oil. Grasp the evacuator

valve of the air cleaner to let the dust to fall once a week, but

everyday if working conditions are especially dusty. Do not touch the

filter element except in cases where cleaning is required. When cleaning

the element, refer to the instructions attached. If the element is

stained with carbon or oil, replace the filter. Change the element once

a year or every 6 times of cleaning (Rinsed with water).

Cleaning Air Cleaner Element

To clean the element, use clean dry compressed air on the inside of the

element. Air pressure at the nozzle must not exceed 205 kPa (2.1

kgf/cm2, 30 psi). Maintain reasonable distance between the nozzle and

the filter. To wash the element, use Filter Cleaner or equivalent, which

is especially effective on oily and soot-laden filters. Allow element to

soak 15 minutes. Then agitate element to dislodge loosened dust-rinse in

clear water-allow element to dry.

Checking Battery

Mishandling the battery shortens the service life and adds to

maintenance costs. Be sure to handle it correctly so that it will

develop its full potential performance. If the battery is weak, the

Kubota D950 engine is difficult to start and the light become dim. It is

important to check the battery daily and recharge before such trouble

occurs. The water in the electrolyte evaporates during recharging.

Liquid shortage damages the battery and excessive liquid spills over and

damages the body. If low, be sure to fill up the battery with distilled

water only. To charge the battery, connect the battery positive terminal

to the charger positive terminal and the negative to the negative, then

recharge in the standard fashion. A boost charge is only for

emergencies. It charges partially the battery at a high rate and in a

short time. When using a boost charged battery, it is necessary to

recharge the battery as early as possible after the operation has been

finished. Failure to do this extremely affects the service life.

Kubota B1600, B1750, B7200, B8200 - Checking

Fuel Line

Stop the engine when attempting the check and change prescribed below.

Remember to check the fuel line periodically. The fuel line is subject

to wear and aging, fuel may leak out onto the running engine, causing a

fire. Although checking the fuel pipe connections is recommended every

100 service hours, it should be done every 6 months, if operation does

not exceed 100 hours in 6 months. If the clamp is loose, apply a slight

coat of lubricant onto the threads and securely retighten it. The fuel

line is made of rubber and ages regardless of period of service. Replace

the fuel pipe together with the clamp every two years and securely

tighten. However if the fuel pipe and clamp are found damaged or

deteriorated earlier than two years, then change or remedy. After the

fuel line and clamp have been changed, bleed the fuel system. When the

fuel line is disconnected for change, close both ends of the fuel line

with a piece of clean cloth or paper to prevent dust and dirt from

entering. Entrance of dust and dirt causes malfunction of the fuel

injection pump. In addition, particular care must be taken not to admit

dust and dirt into the fuel pump.

Checking Radiator Hose and Hose Clamp

Checking radiator hose clamp tightness is specified about every 150

service hours, but every 6 months is all right so long as service

duration does not exceed 150 hours in 6 months. If the clamp is loose,

apply a slight coat of oil and securely retighten. The radiator hose is

made from rubber and tends to age. It must be changed every two years.

Also change the clamp and securely tighten.

Cleaning Radiator

Before changing antifreeze and coolant, clean the water cooling system

(radiator etc.). The water cooling system should be cleaned on the

following occasions: Every year service hours. When adding an antifreeze

solution. When changing from water containing antifreeze to pure water.

When cleaning the water cooling system, the Scale Inhibitor No. 20 is

recommended to effectively wash away the scale built-up.

Checking and Refueling

Stop the engine before adding fuel. Use only diesel fuel. Check the fuel

level. Take care that the fuel level does not fall under the prescribed

lower limit. Use No.2-D diesel fuel. Use No.1-D diesel fuel if the

temperature is below -10C (-15F). Fuel tank capacity 18 L. Always use a

strainer in refueling to prevent fuel injection pump from contamination.

Once the fuel tank becomes empty, air is admitted to the fuel system, in

such case, it will be necessary to bleed the fuel system before an

engine will start.

Kubota B1600, B1750, B7200, B8200 Engine

Troubleshooting

Kubota D950 Engine Does Not Start

Air in the fuel system - Vent, air.

Water in the fuel system - Replace fuel and Repair or Replace fuel

system.

Fuel pipe clogged - Clean.

Fuel filter clogged - Clean or Replace.

Excessive high viscosity of fuel or engine oil at low temperature - Use

the specified fuel or engine oil.

Fuel with low cetane number - Use the specified fuel.

Fuel leak due to loose injection pipe retaining nut - Tighten nut.

Incorrect injection timing - Adjust.

Fuel camshaft worn - Replace.

Injection nozzle clogged - Clean.

Injection pump malfunctioning - Repair or Replace.

Fuel lift pump malfunctioning - Repair or Replace.

Seizure of crankshaft, camshaft, piston, cylinder liner or bearing -

Repair or Replace.

Compression leak from cylinder - Check compression pressure.

Improper valve seat alignment, valve spring broken, valve seized -

Repair or Replace.

Improper valve timing - Correct or Replace timing gear.

Piston ring and liner worn - Replace.

Excessive valve clearance - Adjust.

Starter Does Not Run

Battery discharged - Charge.

Starter malfunctioning - Repair or Replace.

Starter switch malfunctioning - Repair or Replace.

Wiring disconnected - Connect.

Safety switch malfunctioning - Replace.

Kubota D950 Engine Revolution Is Not Smooth

Fuel filter clogged or dirt - Clean or Replace.

Air cleaner clogged - Clean or Replace.

Fuel leak due to loose injection pipe retaining nut - Tighten nut.

Injection pump malfunctioning - Repair or Replace.

Incorrect nozzle opening pressure - Adjust.

Injection nozzle stuck or clogged - Repair or Replace.

Fuel over flow pipe clogged - Clean.

Governor malfunctioning - Repair.

Either White or Blue Exhaust Gas Is Observed

Excessive engine oil - Reduce to the specified level.

Piston ring and liner worn or stuck - Repair or Replace.

Incorrect injection timing - Adjust.

Deficient compression - Check compression pressure.

Either Black or Dark Gray Exhaust Gas Is

Observed

Overload - Lessen the load.

Low grade fuel used - Use the specified fuel.

Fuel filter clogged - Clean or Replace.

Air cleaner clogged - Clean or Replace.

Deficient Output

Incorrect injection timing - Adjust.

Engine's moving parts seem to be seizing - Repair or Replace.

Uneven fuel injection - Repair or Replace injection pump.

Deficient nozzle injection - Repair or Replace nozzle.

Compression leak - Check compression pressure.

Excessive Lubricant Oil Consumption

Piston ring's gap facing the same direction - Shift ring gap direction.

Oil ring worn or stuck - Replace.

Piston ring groove worn - Replace piston.

Valve stem and guide worn - Replace.

Crankshaft bearing, and crank pin bearing worn - Replace.

Fuel Mixed into Lubricant Oil

Injection pump's plunger worn - Replace pump element or pump.

Fuel lift pump broken - Replace.

Water Mixed into Lubricant Oil

Head gasket defective - Replace.

Cylinder block or cylinder head flawed - Replace or Repair.

Low Oil Pressure

Engine oil insufficient - Replenish.

Oil strainer clogged - Clean.

Oil filter cartridge clogged - Replace.

Relief valve stuck with dirt - Clean.

Relief valve spring weaken or broken - Replace.

Excessive oil clearance of crankshaft bearing - Replace.

Excessive oil clearance of crank pin bearing - Replace.

Excessive oil clearance of rocker arm - Replace.

Oil passage clogged - Clean.

Different type of oil - Use the specified type of oil.

Oil pump defective - Repair or Replace.

High Oil Pressure

Different type of oil - Use the specified type of oil.

Relief valve defective - Replace.

Kubota D950 Engine Overheated

Engine oil insufficient - Replenish.

Fan belt broken or tensioned improperly - Replace or Adjust.

Cooling water insufficient - Replenish.

Radiator net and radiator fin clogged with dust - Clean.

Inside of radiator corroded - Clean or Replace.

Cooling water flow route corroded - Clean or Replace.

Radiator cap defective - Replace.

Radiator hose damaged - Replace.

Thermostat defective - Replace.

Water pump defective - Replace.

Mechanical seal defective - Replace.

Overload running - Loosen the load.

Head gasket defective - Replace.

Incorrect injection timing - Adjust.

Unsuitable fuel used - Use the specified fuel.

Battery Quickly Discharge

Battery fluid insufficient - Replenish distilled water and Charge.

Fan belt slips - Adjust belt tension or Replace.

Wiring disconnected - Connect.

Regulator defective - Replace.

AC dynamo defective - Replace.

Battery defective - Replace.

Kubota B1600, B1750, B7200, B8200 Engine -

Servicing Specifications

Lubrication System

Item - Factory Specifications / Allowable Limit

Engine Oil Pressure At Idle Speed - 68 kPa (10 psi) / No

Engine Oil Pressure At Rated Speed - 167 to 294 kPa (43 psi) / 167 kPa

(24 psi)

Inner Rotor to Outer Rotor Clearance - 0.11 to 0.15 mm (0.0043 to 0.0059

in) / 0.20 mm (0.0079 in)

Outer Rotor to Pump Body Clearance - 0.07 to 0.15 mm (0.0028 to 0.0059

in) / 0.25 mm (0.0098 in)

Inner Rotor to Cover End Clearance - 0.08 to 0.13 mm (0.0031 to 0.0051

in) / No

Kubota B1600, B1750, B7200, B8200 - Cooling

System

Item - Factory Specifications

Thermostat's Valve Temperature Opening start - 80.5 to 83.5C (176.9 to

182.3F)

Thermostat's Valve Temperature when completely opened - 95C (203F)

Radiator Water tightness at specified pressure - 137 kPa (20 psi)

Radiator Cap Opening Pressure - 10 seconds or more 88-59 kPa (13-9 psi)

Fan Belt Tension Deflection - 10 mm / 98N (0.4 in/22 lbs)

Fuel System

Item - Factory Specifications

Injection Order - 1-2-3

Injection Timing - 0.349 to 0.384 rad. (20 to 22 degrees) before T.D.C.

Pump Element (Fuel Tightness) - 60 seconds or more - 39.23-34.32 MPa

(5689-4978 psi)

Delivery Valve (Fuel Tightness) - 10 seconds or more - 21.57-20.59 MPa

(3129-2987 psi)

Injection Nozzle (Fuel Injection Pressure) - 13.73 to 14.71 MPa (1991 to

2133 psi)

Nozzle Valve Seat (Fuel Tightness) - When the pressure is 12.75 MPa

(1849 psi), the valve seat must be fuel tightness

Kubota B1600, B1750, B7200, B8200 - Cylinder

and Cylinder Head

Item - Factory Specifications / Allowable Limit

Cylinder Liner I.D. - 75.000 to 75.019 mm (2.9528 to 2.9535 in) / wear +

0.15 mm (0.0059 in)

Cylinder Liner I.D. - 75.500 to 75.519 mm (2.9725 to 2.9732 in) / wear +

0.15 mm (0.0059 in)

Cylinder Head Surface - No / 0.05 mm (0.0019 in)

Top Clearance - 0.6 to 0.8 mm (0.0237 to 0.0315 in) / No

Cylinder Head Gasket Shim - 0.2 mm (0.0079 in) / No

Cylinder Head Gasket - 1.15 to 1.30 mm (0.0453 to 0.0512 in) / No

Compression Pressure - 3.09 MPa (448 psi) / 2.32 MPa (337 psi)

Valves

Item - Factory Specifications

Valve Clearance (Cold) - 0.145 to 0.185 mm (0.0057 to 0.0073 in)

Valve Seat (Width) - 2.12 mm (0.0835 in)

Valve Seat (Angle) - 0.785 rad. (45 degrees)

Valve Face (Angle) - 0.794 rad. (45.5 degrees)

Valve Recessing - 0.9 to 1.1 mm (0.036 to 0.043 in)

Valve Stem to Valve Guide Clearance - 0.035 to 0.065 mm (0.0014 to

0.0025 in)

Valve Stem O.D. - 6.960 to 6.975 mm (0.2741 to 0.2746 in)

Valve Guide I.D. - 7.010 to7.025 mm (0.2760 to 0.2765 in)

Valve Timing and Valve Spring

Item - Factory Specifications / Allowable Limit

Inlet Valve Open - 0.35 rad. (20 degrees) before T.D.C. / No

Inlet Valve Close - 0.79 rad. (45 degrees) after B.D.C. / No

Exhaust Valve Open - 0.87 rad. (50 degrees) before B.D.C. / No

Exhaust Valve Close - 0.26 rad. (15 degrees) after T.D.C. / No

Free Length - 35.1 to 35.6 mm (1.382 to 1.401 in) / 34.8 mm (1.370 in)

Setting Load / Setting Length - 73.5N/31.0 mm (16.5 lbs/1.22 in) / 62.8

N/31.0 mm (14.1 lbs/1.22 in)

Tilt - No / 1.3 mm (0.051 in)

Rocker Arm and Camshaft

Item - Factory Specifications / Allowable Limit

Rocker Arm Shaft to Rocker Arm Clearance - 0.016 to 0.068 mm (0.0007 to

0.0026 in) / 0.12 mm (0.0047 in)

Rocker Arm Shaft O.D. - 10.973 to 10.984 mm (0.4321 to 0.4324 in) / No

Rocker Arm I.D. - 11.000 to 11.041 mm (0.4331 to 0.4347 in) / No

Camshaft Side Clearance - 0.07 to 0.22 mm (0.0028 to 0.0087 in) / 0.3 mm

(0.0118 in)

Camshaft Alignment - No / 0.08 mm (0.0031 in)

Cam Height (IN., EX.) - 26.88 mm (1.0583 in) / 26.83 mm (1.0563 in)

Camshaft Oil Clearance - 0.050 to 0.091 mm (0.0020 to 0.0035 in) / 0.15

mm (0.0059 in)

Camshaft Journal O.D. - 32.934 to 32.950 mm (1.2967 to 1.2972 in) / No

Camshaft Bearing I.D. - 33.000 to 33.025 mm (1.2993 to 1.3002 in) / No

Kubota B1600, B1750, B7200, B8200 - Timing

Gear

Item - Factory Specifications / Allowable Limit

Timing Gear Backlash - 0.042 to 0.115 mm (0.0017 to 0.0045 in) / 0.20 mm

(0.0079 in)

Idle Gear Side Clearance - 0.20 to0.51 mm (0.0079 to 0.0201 in) / 0.80

mm (0.0315 in)

Idle Gear Shaft to Idle Gear Bushing Clearance - 0.020 to 0.054 mm

(0.0008 to 0.0021 in) / 0.10 mm (0.0039 in)

Idle Gear Shaft O.D. - 29.967 to 29.980 mm (1.1798 to 1.1803 in) / No

Idle Gear Bushing I.D. - 30.000 to 30.021 mm (1.1811 to 1.1819 in) / No

Piston And Piston Ring

Item - Factory Specifications / Allowable Limit

Piston Pin-bore I.D. - 20.000 to 20.013 mm (0.7874 to 0.7879 in) / 20.03

mm (0.7886 in)

Compression Ring 2 to Ring Groove Clearance - 0.085 to 0.112 mm (0.0034

to 0.0044 in) / 0.20 mm (0.0079 in)

Piston Ring Groove Width - 1.555 to 1.570 mm (0.0613 to 0.0618 in) / No

Compression Ring 2 Width - 1.458 to 1.470 mm (0.0574 to 0.0578 in) / No

Oil Ring to Ring Groove Clearance - 0.020 to 0.055 mm (0.0008 to 0.0021

in) / 0.20 mm 0.0079 in)

Piston Ring Groove Width - 4.010 to 4.030 mm (0.1579 to 0.1586 in) / No

Oil Ring Width - 3.975 to 3.990 mm (0.1565 to 0.1571 in) / No

Piston and Piston Ring Oversize - + 0.5 mm (0.008 in)

Compression Ring 1 (Ring Gap) - 0.25 to 0.40 mm (0.0098 to 0.0157 in) /

1.25 mm (0.0492 in)

Oil Ring (Ring Gap) - 0.25 to 0.40 mm (0.0098 to 0.0157 in) / 1.25 mm

(0.0492 in)

Compression Ring 1 (Ring Gap) - 0.20 to 0.35 mm (0.0079 to 0.0138 in) /

1.25 mm (0.0492 in)

Compression Ring 2 (Ring Gap) - 0.30 to 0.45 mm (0.0118 to 0.0177 in.) /

1.25 mm (0.0492 in)

Oil Ring (Ring Gap) - 0.25 to 0.40 mm (0.0098 to 0.0157 in.) / 1.25 mm

(0.0492 in)

Piston and Piston Ring Oversize - + 0.5 mm (0.008 in)

Connecting Rod

Item - Factory Specifications / Allowable Limit

Connecting Rod Alignment - No / 0.05 mm (0.0020 in)

Piston Pin to Small End Bushing Clearance - 0.014 to 0.038 mm (0.0006 to

0.0015 in) / 0.15 mm (0.0059 in)

Piston Pin O.D. - 20.002 to 20.011 mm (0.7875 to 0.7878 in) / No

Small End Bushing I.D. - 20.025 to 20.040 mm (0.7884 to 0.7889 in) / No

Piston Pin to Small End Bushing Clearance (Service Parts Dimension) -

0.015 to 0.075 mm (0.0006 to 0.0029 in) / 0.15 mm (0.0059 in)

Piston Pin O.D. - 20.002 to 20.011 mm (0.7875 to 0.7878 in) / No

Small End Bushing I.D. - 20.026 to 20.077 mm (0.7885 to 0.7904 in) / No

Crankshaft

Item - Factory Specifications / Allowable Limit

Crankshaft Alignment - 0.02 mm (0.0008 in) / 0.08 mm (0.0031 in)

Crankshaft to Crankshaft Bearing 1 Oil Clearance - 0.034 to 0.106 mm

(0.0014 to 0.0041 in) / 0.20 mm (0.0079 in)

Crankshaft O.D. - 43.934 to 43.950 mm (1.7297 to 1.7303 in) / No

Crankshaft Bearing 1 I.D. - 43.984 to 44.040 mm (1.7317 to 1.7338 in) /

No

Crankshaft to Crankshaft Bearing 2 Oil Clearance - 0.034 to 0.092 mm

(0.0014 to 0.0036 in) / 0.20 mm (0.0079 in)

Crankshaft O.D. - 43.934 to 43.950 mm (1.7297 to 1.7303 in) / No

Crankshaft Bearing 2 I.D. - 43.984 to 44.026 mm (1.7317 to 1.7333 in) /

No

Crank Pin to Crank Pin Bearing Oil Clearance - 0.029 to 0.087 mm (0.0012

to 0.0034 in) / 0.20 mm (0.0079 in)

Crank Pin O.D. - 36.959 to 36.975 mm (1.4551 to 1.4557 in) / No

Crank Pin Bearing I.D. - 37.004 to 37.046 mm (1.4569 to 1.4585 in) / No

Crankshaft Side Clearance - 0.15 to 0.31 mm (0.0059 to 0.0122 in) / 0.50

mm (0.0197 in)

Crankshaft Sleeve Wear - 0.10 mm (0.0039 in) / No

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES INSTRUCTIONS

INSTRUCTIONS PROBLEMS

PROBLEMS B2320

B2320 B2630

B2630 B2920

B2920 B3300SU

B3300SU BX2360

BX2360 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 BX2660

BX2660 L2501

L2501 L3240

L3240 L3540

L3540 L3940

L3940 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 L4400

L4400 L4600

L4600 L5040

L5040 L5740

L5740 MX4700

MX4700 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 B2710

B2710 BX23S

BX23S B3350

B3350 BX1880

BX1880 L4701

L4701 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 M100GX

M100GX M135GX

M135GX M6040

M6040 M8540

M8540 M95X

M95X LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 M5-091

M5-091 BX2680

BX2680 MX5200

MX5200 BX2380

BX2380 L3901

L3901 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605