________________________________________________________________________________

Kubota B1700, B2400 - Transmission and PTO

Kubota B1700, B2400 - Transmission Components

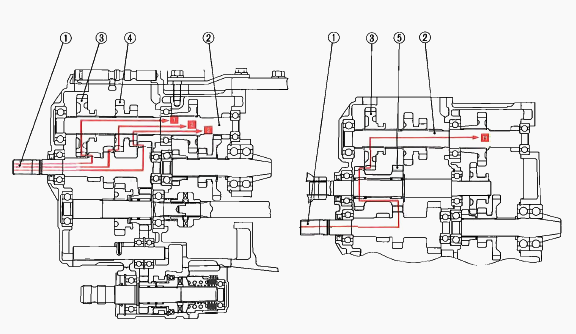

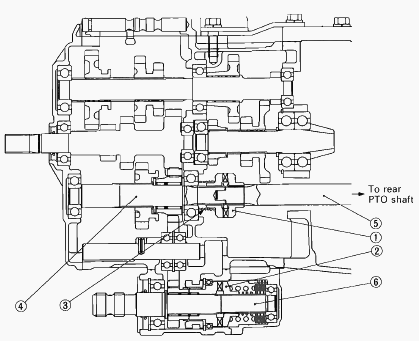

Main Gear Shift Section

1 - 2nd Gear Shaft with 13T, 13T and 18T Gear, 2 - 4th Shaft with 11T

Gear, 3 - 30T Shifter Gear, 4 - 17T-13T Shafter Gear, 5 - 16T-20T Gear

Besides neutral, four kinds of power flow (from clutch shaft to 4th

shaft) are available by operating the main gear shift lever to shift

positions on the 30T shifter gear (3) and 17T-13T shifter gear (4) on

the 4th shaft (2).

1st Position: 2nd Gear Shaft with 13T Gear (1) - 30T Shifter Gear (3) -

4th Shaft (2). 2nd Position: 2nd Gear Shaft with 13T Gear (1) - 17T-13T-

Shifter Gear (4) - 4th Shaft (2). 3rd Position: 2nd Gear Shaft with 18T

Gear (1) - 17T-13T Shifter Gear (4) - 4th Shaft (2). Reverse Position:

2nd Gear Shaft with 13T Gear (1) - 16T-20T Gear (5) - 30T Shifter Gear

(3) - 4th Shaft (2).

Hi-Lo Gear Shift Section

Two kinds of power flow (from 4th shaft to spiral bevel pinion shaft)

are available by operating the high-low gear shift lever to shift the

gear on the spiral bevel pinion shaft. Low Position - 4th Gear Shaft -

Shifter Gear - Spiral Bevel Pinion Shaft. High Position - 4th Shaft -

Gear - Shifter Gear - Bevel Pinion Shaft.

Front Wheel Drive Section

2-wheel drive or 4-wheel drive is selected by changing the position of

20T shift gear with the front wheel drive lever. When the front wheel

drive lever is set to "Disengaged," the 20T shift gear is neutral and

power is not transmitted to the front wheel drive shaft. When the front

wheel drive lever is set to "Engaged," the 20T shift gear slides to the

right to engage with 13T gear on the spiral bevel pinion shaft.

Therefore, the front drive shaft is actuated to drive the front wheels.

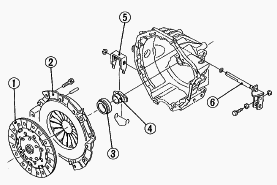

Kubota B1700, B2400 Tractor - Clutch

This tractor is used dry single plate type clutch. The clutch is located

between the engine and transmission and is operated by stepping on the

clutch pedal. When the clutch pedal is depressed, the clutch is

disengaged and when it is released, the clutch is engaged and power from

the engine is transmitted to the transmission.

1 - Clutch Disc, 2 - Pressure Plate Assembly, 3 - Release Bearing, 4 -

Release Rod, 5 - Release Fork, 6 - Clutch Rod

Engine torque is transmitted to the pressure plate assembly via the

flywheel (1) which is connected to the engine crankshaft. Therefore, the

clutch cover constantly runs with engine. The clutch disc (10) is

located between the flywheel (1) and the pressure plate (3) of pressure

plate assembly. Torque is transmitted to the clutch disc (10) by the

pressure created by diaphragm spring (4) installed in pressure plate

assembly. Then, the torque is transmitted to the transmission via the

clutch shaft (9). When the pedal (13) is depressed, the clutch release

hub (7) and the clutch release bearing (6) move towards the flywheel and

push the fingers of the diaphragm spring (4). In other words, this

movement pulls the pressure plate (3) up and disengages the clutch.

Clutch Engaged

When the clutch pedal is not depressed, the clutch release bearing (6)

and the fingers of diaphragm spring (4) are not connected to each other.

Accordingly, the pressure plate (2) is tightly pressed against the

flywheel (1) by the diaphragm spring (4). As a result, rotation of the

flywheel (1) is transmitted to the transmission through the clutch shaft

(8) due to the frictional force among the flywheel (1), clutch disc (10)

and pressure plate (2).

Clutch Disengaged

When the clutch pedal is depressed, the clutch rod is pulled to move the

clutch lever (11). Then, the release fork (9) pushes the release hub (7)

and release bearing (6) toward the flywheel. Simultaneously, the release

bearing (6) pushes the diaphragm spring (4). As the pressure plate (2)

is pulled by the diaphragm spring (4), the frictional force among the

flywheel (1), clutch disc (10) and pressure plate (2) disappears.

Therefore, rotation of the flywheel (1) is not transmitted to the clutch

disc (10), and then the rotation of the clutch shaft (8) stops.

Kubota B1700, B2400 Clutch - Checking And Adjusting

Clutch Pedal Free Travel

When checking, park the tractor on flat ground, apply the parking brake,

stop the engine and remove the key. Slightly depress the clutch pedal

and measure free travel at top of pedal stroke. If the measurement is

not within the factory specifications, loosen the lock nut and adjust

the clutch rod length. After adjusting it, be sure to keep the distance

for stopper bolt. After adjusting them, try to start engine. If no

start, check the safety switch setting position. Clutch pedal free

travel - 20 to 30 mm (0.79 to 1.18 in).

Clutch Pedal Stopper Bolt

Measure the clearance between stopper bolt and clutch housing. If the

measurement is not within the factory specifications, adjust it with the

clutch pedal stopper bolt. After adjustment, secure the stopper bolt

with the lock nut. Clearance between stopper bolt and clutch housing -

8.5 mm (0.33 in).

Safety Switch Setting Position

Measure the distance of safety switch when clutch pedal fully depressed.

If the distance is not within the factory specifications, adjust the

mounting position of safety switch. Safety switch distance - 17 to 21 mm

(0.67 to 0.83 in).

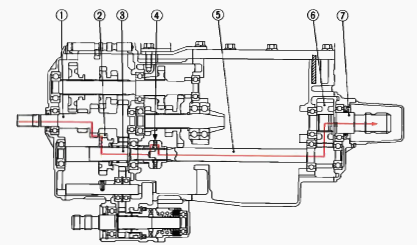

Kubota B1700, B2400 Tractor - Power Take-Off

Rear-PTO Shift Section

Besides neutral, one kind of power flow are available by operating the

PTO shift lever to shift positions of 17T shifter gear (2) for rear-PTO.

1 - 2nd Gear Shaft with 13T, 13T and 18T Gear, 2 - 17T Shifter Gear, 3 -

3rd Shaft, 4 - One-way Clutch, 5 - 5th Gear Shaft with 11T Gear, 6 - 24T

Gear, 7 - Rear-PTO Shaft

Rear-PTO Shift Lever ON position

2nd Gear Shaft with 13T Gear (1) - 17T Shifter Gear (2) - 3rd Shaft (3)

- One-way Clutch (4) - 5th Gear Shaft with 11T Gear (5) - 24T Gear (6) -

Rear PTO Shaft (7)

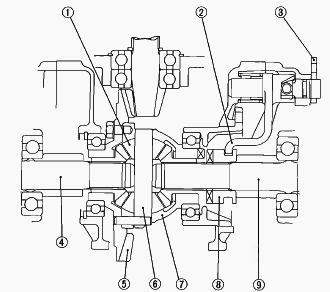

Mid-PTO Section

Besides neutral, one kind of power flow are available by operating the

PTO shift lever to shift positions of shifter (5) or 11T shifter gear

(7) for mid-PTO.

1 - 2nd Gear Shaft with 13T, 13T and 18T Gear, 2 - 13T Gear, 3 - 19T

Gear, 4 - 11T Gear, 5 - Shifter, 6 - One-way Clutch, 7 - Mid-PTO Shaft

Mid-PTO Shift Lever ON Position

2nd Gear Shaft with 18T Gear (1) - 13T Gear (2) - Clutch (6) - Mid-PTO

Shaft (7) 19T Gear (3) - 11T Gear (4) - Shifter (5) - One-way Clutch

One-way Clutch Cam Section

1 - Clutch Cam for Rear PTO, 2 - Clutch Cam for Mid-PTO, 3 - Clutch Cam

Spring, 4 - 3rd Shaft, 5 - 5th Gear Shaft, 6 - Mid-PTO Shaft

The one-way clutch cam is also called an overrunning clutch. It is

composed of a pair of clutch cams (7), (8) and a cam spring (3). One of

the clutch cam is splined to the shaft (6), and the other is splined to

the shaft (5). These two clutch cams (1), (2) are engaged with each

other by the force of the cam spring. As long as the shaft (4) is

rotating faster than the shaft (5), (6) these two clutch cams (7), (8)

will remain engaged, and the shaft (5), (6) is driven. But, if the PTO

shaft drives a rotary mower as an implement, for example, and the source

of power is stopped by pressing the clutch pedal, or if the engine speed

is lowered, the clutch cam (7) will overrun as shown in the figure. This

overrunning is caused by the inertia of the mower blades. Then,

engagement will not take place until the shaft (4) is running faster

than the shaft (5), (6). In this way, the one-way clutch cam protects

the transmission and engine power train against damage, by allowing the

PTO shaft and the shaft (5), (6) to overrun if PTO shaft over speeds.

Kubota B1700, B2400 - Differential Gear

Differential Function

During Straight Running - Rotation of the spiral bevel pinion is

transmitted to the spiral bevel gear and differential case. When road

resistance to the right and left wheels are equal, differential pinions

and differential side gears are all rotate as a unit. Both rear axles

received equal input, and both wheels turn at the same speed, allowing

the tractor to go straight ahead. At this time, differential pinions do

not rotate around the differential pinion shaft.

During Turning - When the tractor turns, the road resistance to the

inside tire increases (as if braking is applied to that side only). In

other words, if one of tires slows down, revolution difference is

generated in the differential side gears. When rotation of one

differential side gear becomes lower than the other, differential

pinions begin rotating around differential increased in speed by the

speed increment of differential pinion rotating around differential

pinion shaft. This means that rotation of one rear axle is slowed down

and that of the other rear axle is increased. Thus, the tractor turn

smoothly without power loss. The combined number of revolutions of the

right and left differential side gears is always twice that of the

spiral bevel gear. When spiral bevel gear revolution is 100 rpm, and if

one of the differential side gears stops moving, the revolution of the

other differential side gear becomes 200 rpm and if one rotates at 50

rpm, the other rotates at 150 rpm.

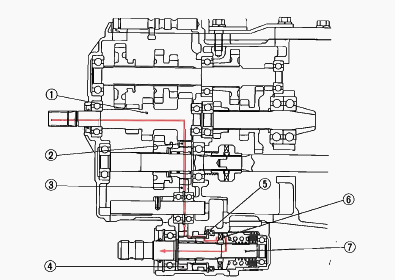

Kubota B1700, B2400 Differential Lock

1 - Differential Pinions, 2 - Shift Fork, 3 - Differential Lock Lever, 4

- Differential Gear Shaft, 5 - Spiral Bevel Gear, 6 - Differential

Pinion Shaft, 7 - Differential Case, 8 - Differential Lock Clutch, 9-

Differential Gear Shaft

When resistance to the right and left tires are greatly different due to

ground conditions or type of work, the tire with less resistance slips

and prevents the tractor from moving ahead. To compensate for this

drawback, the differential lock restricts the differential action and

causes both rear axles to rotate as a unit. When the differential lock

pedal is stepped on, it causes the differential lock lever (3) to

rotate, which will move the shift fork (2) and the differential lock

clutch (8) toward the spiral bevel gear (5). The differential lock

clutch (8) engaged with the teeth of the differential case (7) to cause

the differential case (7) and the differential lock clutch (8) to rotate

as a unit. Therefore, differential pinions (1) are unable to rotate

around differential pinion shaft (6) and identical revolutions are

transmitted to the right and left differential gear shafts (4), (9).

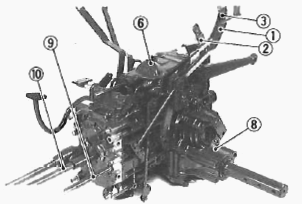

Kubota B1700, B2400 - Transmission Case

Separating Hydraulic Cylinder and Rear Axle Case

1 - Rear-PTO Shift Lever, 2 - Aux. Speed Change Lever, 3 - Mid-PTO Shift

Lever, 4 - Connecting Plate, 5 - Top Link Bracket, 6 - Hydraulic

Cylinder Assembly, 7 - Drawbar Frame, 8 - Rear Axle Case, 9 - Connecting

Pipe, 10 - Propeller Shaft, 11 - Universal Joint

Remove the connecting pipe (9) and propeller shaft (10). Tap out the

spring pins and remove the universal joint with front wheel propeller

shaft. Remove the external snap ring and remove the auxiliary speed

change lever (2) with rod, rear-PTO shift lever (1) and mid-PTO shift

lever (3). Remove the hook and connecting plate (4). Remove the top link

bracket. Remove the hydraulic cylinder mounting screws and dismount the

hydraulic cylinder assembly (6). Disconnect the differential lock rod.

Remove the drawbar frame mounting screws and remove the drawbar frame.

Remove the rear axle mounting screws and remove the rear axle case (8)

from the differential case. Apply liquid gasket to joint face of the

differential case and the rear axle case, differential case and the

hydraulic cylinder.

Separating Main Shift Cover, Mid-PTO Case and Transmission Case

Remove the main shift cover mounting screws and separate the main shift

cover with differential lock pedal. Remove the mid-PTO case mounting

screws and separate the mid-PTO case from transmission case. Remove the

rear-PTO cover mounting screws and separate the rear-PTO cover (couldn't

draw out completely). Remove the transmission case mounting screws and

nuts and separate the transmission case from differential case. Apply

liquid gasket to joint face of the main shift cover, transmission case,

differential case and mid-PTO case.

Front Cover

Remove the front cover mounting screws and remove the front cover. Apply

liquid gasket to joint face of the front cover and transmission case.

4th Gear Shaft

Remove the bearing, 30T shifter gear and 13T-17T shifter gear. Draw out

the 4th gear shaft with 19T gear rearward.

Spiral Bevel Pinion Shaft and 20T Shifter Gear

Remove the external snap ring and one-way clutch cam. Remove the spiral

bevel pinion shaft with 13T-32T shifter gear, 13T gear, and shift fork

with shift rod. Remove the external snap ring and remove the 20T shifter

gear. When installing the spiral bevel pinion shaft, be sure to install

the shim.

2nd Gear Shaft and Front Wheel Drive Shaft

Remove the 2nd gear shaft with bearing. Draw out the front wheel drive

shaft with 16T-20T gear. When installing the needle bearing into the

16T-20T gear, apply transmission oil to the needle bearings.

Middle Shaft and 3rd Shaft

Tap out the middle shaft and remove the 19T gear with bearing. Draw out

the 3rd shaft with 17T gear, 13T gear and shift fork with shift rod.

When assembling the 19T gear, face the chamfer side to the rear. When

installing the needle bearings into the 13T gear, apply transmission oil

to the needle bearings.

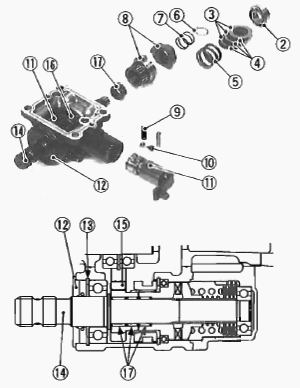

Mid-PTO Shaft and One-way Clutch

1 - Mid-PTO Case Rear Cover, 2 - Bearing, 3 - Friction Plate, 4 - Brake

Disc, 5 - Spring, 6 - External Snap Ring, 7 - Spring, 8 - One-way Clutch

Cam, 9 - Spring, 10 - Ball, 11 - Shift Arm, 12 - Oil Seal, 13 - Internal

Snap Ring, 14 - Mid-PTO Shaft, 15 - 11T Gear, 16 - Shifter, 17 - Needle

Bearing

Remove the mid-PTO case rear cover mounting screws and separate the rear

cover (1). Remove the bearing (2) and remove the friction plates (3),

brake discs (4) and spring (5). Remove the external snap ring (6) and

remove the spring (7) and one-way clutch cam (8). Remove the spring (9)

and ball (10). Draw out the dowel pin and remove the shift arm (11) with

shifter. Remove the oil seal (12) and internal snap ring (13). Remove

the mid-PTO shaft (14) with bearing, 11T gear (15) and shifter (16).

Apply grease to lip and outer of oil seal. When installing the needle

bearings (17) into the 11T gear and one-way clutch cam, apply

transmission oil to the needle bearings.

Main Gear Shift Fork

Remove the cotter pin and remove the spring and ball. Draw out the shift

rod and remove the 1st-reverse gear shift fork. Remove the 2nd-3rd gear

shift fork, in the same way as the 1st-reverse shift fork removing

procedure. Take out the interlocker and slide the shift arm stopper and

then remove the shim arm. Remove the shift shaft. When remove the

differential lock pedal shaft draw out the dowel pin first.

Kubota B1700, B2400 Tractor - Transmission Case Servicing

Bearing Checking

While holding the inner race, push and pull the outer race in all

directions to check for wear and roughness. Apply transmission oil to

the bearing and hold the inner race. For needle bearing, lay the needle

rollers to check for any damage and wear. Replace it if defects are

found.

Clearance Between Shift Fork and Shift Gear Groove

Insert the fork into the shift gear groove and measure the clearance

with a feeler gauge. If the clearance exceeds the allowable limit,

replace it. Clearance between shift fork and shift gear groove

(Allowable limit) - 0.5 mm (0.020 in).

Clearance between Gear and Shaft

Measure the gear I.D. with a cylinder gauge, and then shaft O.D. with an

outside micrometer. Measure the O.D. of two needles in the needle

bearing with an outside micrometer. Clearance is the difference between

the gear I.D. and the sum of shaft O.D. and two needles O.D. If the

clearance exceeds the allowable limit, replace it. Clearance between FWD

shaft and 16T-20T gear - 0.027 to 0.067 mm (0.0011 to 0.0025 in). FWD

shaft O.D. - 21.967 to 21.980 mm (0.8648 to 0.8654 in). 16T-20T gear

I.D. - 28.007 to 28.021 mm (1.1024 to 1.1032 in). Needle O.D. - 2.996 to

3.000 mm (0.1179 to 0.1181 in). Clearance between 13T gear and 3rd shaft

- 0.007 to 0.046 mm (0.0003 to 0.0018 in). 3rd shaft O.D. - 21.987 to

22.000 mm (0.8656 to 0.8661 in). 13T gear I.D. - 28.00 to 28.021 mm

(1.1026 to 1.1032 in). Needle O.D. - 2.994 to 3.000 mm (0.1179 to 0.1181

in). Clearance between 11T gear, one-way clutch cam and mid-PTO shaft -

0.020 to 0.026 mm (0.0008 to 0.0010 in). Mid-PTO shaft O.D. - 19.989 to

20.000 mm (0.7869 to 0.7874 in). 11T gear and one-way clutch I.D. -

24.007 to 24.020 mm (0.9452 to 0.9457 in). Needle O.D. - 1.997 to 2.000

mm (0.0786 to 0.0787 in).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605