________________________________________________________________________________

Kubota B2050, B2350, B2650 - Transmission

Kubota B2050, B2350, B2650 - Manual

Transmission

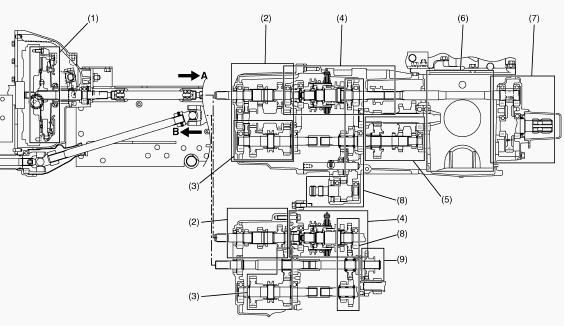

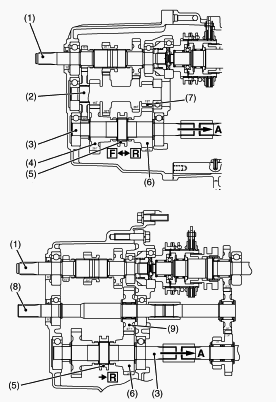

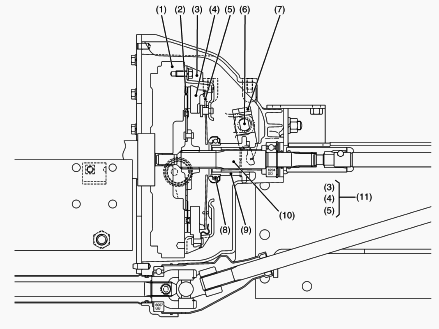

Manual Transmission (without Bi-Speed Turn Model): 1 - Main Clutch

Section, 2 - Main Gear Shift Section, 3 - Shuttle Shift Section, 4 -

Mechanical PTO Clutch Section, 5 - Range Gear Shift Section, 6 -

Differential Gear Section, 7 - Rear PTO Gear Section, 8 - Mid-PTO Gear

Section, 9 - Front Wheel Drive Gear Section, A - From Front Case, B - To

Front Axle

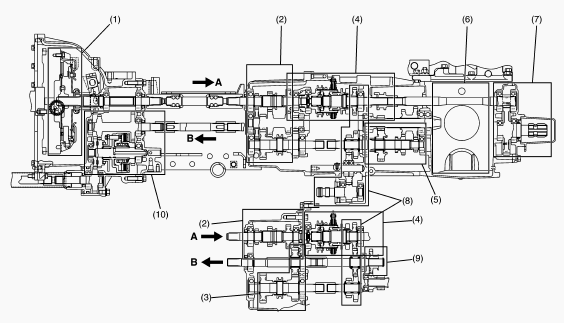

Manual Transmission (with Bi-Speed Turn Model): 1 - Main Clutch Section,

2 - Main Gear Shift Section, 3 - Shuttle Shift Section, 4 - Mechanical

PTO Clutch Section, 5 - Range Gear Shift Section, 6 - Differential Gear

Section, 7 - Rear PTO Gear Section, 8 - Mid-PTO Gear Section, 9 - Front

Wheel Drive Gear Section, 10 - Bi-Speed Turn Gear Section, A - From

Front Case, B - To Bi-Speed Turn Gear Section

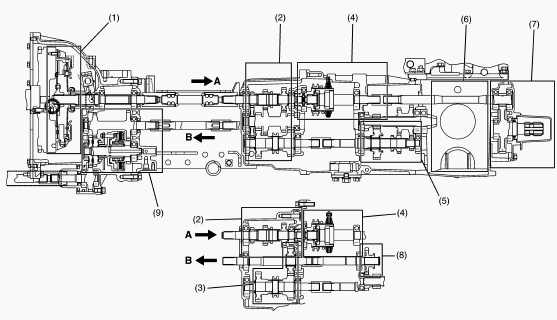

Manual Transmission (with Bi-Speed Turn and without Mid-PTO Model): 1 -

Main Clutch Section, 2 - Main Gear Shift Section, 3 - Shuttle Shift

Section, 4 - Mechanical PTO Clutch Section, 5 - Range Gear Shift

Section, 6 - Differential Gear Section, 7 - Rear PTO Gear Section, 8 -

Front Wheel Drive Gear Section, 9 - Bi-Speed Turn Gear Section, A - From

Front Case, B - To Bi-Speed Turn Gear Section

Main Gear Shift Section

Main shift section consists of three speeds.

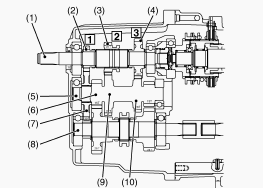

1 - First Shift Shaft, 2 - 13T F1 Gear, 3 - 23T F2 Gear (Shifter), 4 -

29T F3 Gear, 5 - 15T-32T-26T-13T Shaft, 6 - 15T Gear, 7 - 30T F1 Gear, 8

- Shuttle Shaft, 9 - 32T Gear, 10 - 26T Gear

1st Speed Gear - The 23T F2 gear (shifter) (3) slides to the engine

side. The 23T F2 gear (shifter) (3) meshes to the 13T F1 gear (2). The

power is transmitted as follows. First shift shaft (1) - 23T F2 gear

(shifter) (3) - 13T F1 gear (2) - 30T F1 gear (7) - 15T-32T-26T-13T

shaft (5).

2nd Speed Gear - The 23T F2 gear (shifter) (3) meshes to the 32T gear

(9) of the 15T-32T-26T-13T shaft (5). The power is transmitted as

follows. First shift shaft (1) - 23T F2 gear (shifter) (3) - 32T gear

(9) / 15T-32T-26T-13T shaft (5).

3rd Speed Gear - The 23T F2 gear (shifter) (3) slides to the mechanical

PTO clutch side. The 23T F2 gear (shifter) (3) meshes to the 29T F3 gear

(4). The power is transmitted as follows. First shift shaft (1) - 23T F2

gear (shifter) (3) - 29T F3 gear (4) - 26T gear (10) / 15T-32T-26T-13T

shaft (5).

Shuttle Gear Shift Section

The power shifted in the main gear shift section is transmitted from the

15T-32T-26T-13T shaft (2) to the shuttle shaft (3). The shuttle shift

gears are the sliding mesh gears. The reverse shaft is the front wheel

drive shaft (8). The 27T gear (9) on the front wheel drive gear (8) is a

reverse gear.

1 - First Shift Shaft, 2 - 15T-32T-26T-13T Shaft, 3 - Shuttle Shaft, 4 -

28T Gear, 5 - Shifter, 6 - 24T Gear, 7 - 13T Gear, 8 - Front Wheel Drive

Shaft, 9 - 27T Gear, F - Forward, R - Reverse, A - To High-Low Range

Gear Section

Forward - When shifting the shuttle lever to “Forward”, the shifter (5)

slides to the 28T gear side. The shifter (5) meshes to the 28T gear (4).

The power is transmitted as follows. 15T-32T-26T-13T shaft (2) / 15T

gear (2) - 28T gear (4) - shifter (5) - shuttle shaft - Hi-Low range

gear section.

Reverse - When shifting the shuttle lever to “Reverse”, the shifter (5)

slides to the 24T gear side. The shifter is transmitted as follows.

15T-32T-26T-13T shaft (2) / 13T gear (7) - 27T gear (9) on the front

wheel drive shaft (8) - 24T gear (6) - shifter (5) - shuttle shaft (3) -

High-low range gear section.

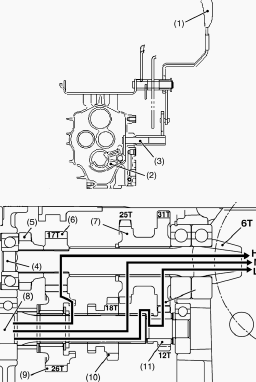

Range gear shift section

Range gear shift lever (1) is located at left side fender. Range gear

shift lever (1) can select three speed range, low speed, mid speed and

high speed. Range gear shift lever (1) and 18T shifter gear (10) are

linked with range shift arm (3) and range shift fork (2) etc. Three

range gear shifts are selected by shifting the 18T shifter gear (10) on

the sub shaft (8) to 17T gear (6) and 25T-31T gear (7) on 6T bevel

pinion shaft (4).

1 - Range Gear Shift Lever, 2 - Range Shift Fork, 3 - Range Shift Arm, 4

- 6T Bevel Pinion Shaft, 5 - 13T Gear (for Front Wheel Drive), 6 - 17T

Gear, 7 - 25T-31T Gear, 8 - Sub Shaft, 9 - 26T Gear, 10 - 18T Shifter

Gear, 11 - 12T Gear, L - LOW Range, M - MID Range, N - Neutral Position,

H - HIGH Range

Low Speed Position - Sub shaft (8) - 18T shifter gear (10) - 12T gear

(11) - 31T of 25T-31T gear (7) - 6T bevel pinion shaft (4).

Middle Speed Position - Sub shaft (8) - 18T shifter gear (10) - 25T of

25T-31T gear (7) - 6T bevel pinion shaft (4).

High Speed Position - Sub shaft (8) - 18T shifter gear (10) - 26T gear

(9) - 17T gear (6) - 6T bevel pinion shaft (4).

Kubota B2050, B2350, B2650 Tractor - Power Take Off

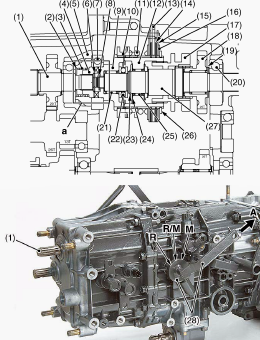

Mechanical PTO Clutch

The PTO shift lever (1) is located at left side fender. The PTO

positions are selected to three positions, the “Rear PTO” position (R),

the “Rear PTO/ the mid-PTO” position (R/M) and the “Mid-PTO” position

(M). The PTO section is separated to two sections. The front PTO section

is located in the main speed shift case. The rear PTO is the mechanism

PTO assembly and is located in the transmission case. The shifter (17)

is connected mechanically to the PTO select lever. When the mechanical

PTO clutch lever is shifted to “ON (Engaged)” position, the mechanical

PTO clutch lever sides front and meshes to the one-way clutch spline

boss (21). Since the PTO brake spline boss (12), the power is

transmitted from the one-way clutch spline boss through the shifter (10)

to the PTO brake spline boss (12).

1 - First Shift Shaft, 2 - Collar (1.8), 3 - Overrunning Clutch Spring,

4 - One-way Clutch Cam, 5 - Bearing Holder, 6 - Cir-clip, 7 - Ball

Bearing, 8 - Cir-clip, 9 - One-way Clutch Spline Boss, 10 - Shifter (PTO

ON/OFF), 11 - PTO Brake Spring, 12 - PTO Brake Spline Boss, 13 - Brake

Plate 2, 14 - Brake Disk, 15 - Brake Plate 3, 16 - Brake Plate 1, 17 -

PTO Shifter, 18-25T Mid-gear, 19 - Collar (20), 20 - Ball Bearing, 21 -

Needle Bearing, 22 - Thrust Ball Bearing, 23 - Cir-clip, 24 - Thrust

Collar, 25 - Needle Bearing, 26 - Cir-clip, 27 - PTO Clutch, 28 - PTO

Shift Lever, 29 - PTO ON/OFF Shift Folk, a - One-way Clutch Section, A -

Connected to the PTO Select Lever, R - REAR PTO position, R/M - REAR PTO

/ MID PTO position, M - MID-PTO Position

PTO Brakes

When the mechanical PTO clutch lever is shifted to “OFF (Disengaged)”

position, the shifter slides to the PTO brake spring side. The shifter

does not mesh to the one-way clutch spline boss, and the power is not

transmitted from the one-way clutch spline boss (9) to the PTO brake

spline boss. Since the PTO brake spring pushed the brake prates and the

PTO brake disks, the PTO brake is engaged at this moment.

Kubota B2050, B2350, B2650 Tractor - Rear PTO

When the PTO shift lever is set to “Rear PTO” position (R), the PTO

shifter slides to “Rear PTO” position (R). The PTO shifter meshes to the

spline of the PTO clutch shaft. The power is transmitted from the first

shift shaft to the PTO clutch shaft as follows. First shift shaft -

One-way clutch cam - One-way clutch spline boss - shifter (PTO ON/OFF) -

PTO brake spline boss - PTO shifter - PTO clutch shaft.

Rear PTO / Mid PTO

When the PTO shift lever is set to “Rear PTO/Mid-PTO” position, the PTO

shifter slides to “Rear PTO/Mid-PTO” position (R/M). The PTO shifter

meshes to both the spline of the PTO clutch shaft and the spline of the

25T mid-PTO gear. The power is transmitted from the first shift shaft to

both the rear PTO and the mid-PTO as follows. To Rear PTO: First shift

shaft - One-way clutch cam - One-way clutch spline boss - shifter (PTO

ON/OFF) - PTO brake spline boss - PTO shifter - PTO clutch shaft - to

rear PTO. To Mid PTO: First shift shaft - One-way clutch cam - One-way

clutch spline boss - shifter (PTO ON/OFF) - PTO brake spline boss - PTO

shifter - 25T mid-gear - 26T gear - to mid-PTO.

Mid PTO

When the PTO shift lever is set to “Mid-PTO” position, the PTO shifter

slides to “Mid-PTO” position (M). The PTO shifter meshes to the spline

of the 25T mid-gear. The power is transmitted from the first shift shaft

to the mid-PTO.

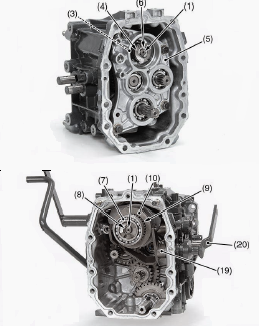

Kubota B2050, B2350, B2650 - Clutch

1 - Engine Flywheel, 2 - Clutch Disc, 3 - Clutch Cover, 4 - Pressure

Plate, 5 - Diaphragm Spring, 6 - Clutch Rod, 7 - Clutch Release Fork, 8

- Clutch Release Bearing, 9 - Clutch Release Hub, 10 - Clutch Shaft, 11

- Pressure Plate Assembly

Kubota B2050, B2350, B2650 - Transmission Service

Bi-Speed Turn Clutch

Clutch Disk and Clutch Plate -

Measure the clutch disk thickness with a Vernier calipers. Measure the

clutch plate thickness with a Vernier calipers. If the thickness is less

than the allowable limit, replace it. If the bearing is worn, replace

it. Bi-Speed Turn clutch disk thickness - 1.70 to 1.90 mm (0.067 to

0.075 in). Bi-Speed Turn clutch disk plate thickness - 1.95 to 2.05 mm

(0.0768 to 0.0807 in).

Mechanical PTO Clutch

PTO Clutch Shaft -

Check the needle bearings. Check the needle bearing surfaces of the PTO

clutch shaft. Check the needle bearing surfaces of the one-way clutch

spline boss, the PTO brake spline boss and the 25T mid-PTO gear. If the

PTO clutch shaft is rough or grooved, replace it. If the needle bearing

is wore, replace it. The one-way clutch spline boss, the PTO brake

spline boss or the 25T mid-PTO gear is worn, replace it.

PTO Brake Disk and Brake Plate 1

Measure the PTO brake disk thickness with a Vernier calipers. Measure

the brake plate thickness with a Vernier calipers. If the thickness is

less than the allowable limit, replace it. PTO brake disk thickness -

1.70 to 1.90 mm (0.067 to 0.075 in). Mechanical PTO brake plate 1

thickness - 1.95 to 2.05 mm (0.0768 to 0.0807 in).

Kubota B2050, B2350, B2650 - Mechanical PTO Clutch Assembly

Separating Transmission Case from Differential Case

Remove the transmission mounting bolts and nuts. Separate the

transmission case from the differential case. Install the coupling to

the mechanical PTO clutch shaft. Apply the liquid gasket. Tighten the

transmission mounting bolts and the nuts to the specified torque.

Removing One-Way Clutch Spline Boss

Remove the circlip from the PTO clutch shaft. Remove the one-way clutch

spline boss with the bearing. Remove the needle bearing and the thrust

ball bearing.

Removing PTO ON-OFF Shift Fork and PTO Shift Arm

Remove the circlip from the PTO clutch shaft. Remove the circlip the PTO

ON-OFF arm shaft. Remove the shifter and the PTO clutch spring. Remove

the bolt and the washer from the transmission case. Remove the PTO shift

arm. Install the PTO cotter to the groove of the PTO shifter securely.

Install the ball and the spring to the transmission case using the

special ball guide.

Removing and Disassembling Mechanical PTO Clutch Assembly

Remove the rear PTO shifter from the PTO clutch shaft. Disassemble the

mechanical PTO clutch assembly. Check the mechanical PTO clutch assembly

parts the damage and wear, replace it.

Kubota B2050, B2350, B2650 Tractor - Separating Engine From Clutch housing

Draining Transmission Fluid

Place oil pan underneath the transmission case, and remove the drain

plugs. Drain the transmission fluid. Reinstall the drain plug. Fill new

oil from port after remaining the filling plug up to the upper notch on

the dipstick. After running the engine for new minutes, stop it and

check the oil level again, it low, add oil prescribed level.

Transmission fluid capacity -

Manual transmission (without Bi-Speed Turn) - 15 L. Manual transmission

(with Bi-Speed Turn) - 16.5 L.

Bonnet, Side Cover and Battery Cord

Open the bonnet and remove the front grille. Disconnect the battery

negative cord. Disconnect the head light connectors and remove the

bonnet side covers. When disconnecting the battery cords, disconnect the

grounding cord first. When connecting, positive cord first.

Hydraulic Hoses from Power Steering Cylinder

Disconnect the hydraulic hoses from the power steering cylinder.

Removing the snap pin and disconnect the bi-speed rod.

Fuel -

Disconnect the fuel hose from the fuel filter. Drain the fuel to the

fuel tank completely.

Steering Wheel, Meter Panel, Shuttle Lever and Panel Lower Cover

Remove the steering wheel cap. Remove the steering wheel mounting nut.

Remove the steering wheel with a steering wheel puller. Remove the

accelerator lever grip and the steering boot. Disconnect the hour meter

cable and wiring harness connectors. Remove the meter panel not to

damage with the steering shaft. Remove the shuttle lever. Remove the

panel lower cover.

Fuel Tank

Disconnect the leads from the fuel tank. Disconnect the overflow hoses

from the fuel tank. Remove the shutter plate and the fuel tank.

Key Stop Solenoid and Hydraulic Delivery Pipe

Remove the key stop solenoid connector. Remove the engine stop solenoid

using a small size ratchet handle, the extension joint, the universal

joint and the thinner socket (10 mm). Remove the hydraulic delivery pipe

mounting nuts. Slide the hydraulic delivery pipe. Loosen the hose band.

Disconnect the suction hose from the hydraulic pump. Apply the liquid

gasket to the joint face of the key stop solenoid and the engine.

Steps (4-cylinder Engine, ROPS Model)

Remove the bolts and the nut. Remove the brake spring from the step

(RH). Remove the brake spring and the clutch spring from the step (LH).

Sub-Frames (4-cylinder Engine Model)

Place the rigid jack under the rear axle shaft. Remove the transmission

oil filter cartridge. Loosen the sub-frame mounting bolts. Remove the

sub-frames.

Separating Engine with Front Axle

Reinstall the rear tires. Support the transmission with a disassembling

stand. Hook the engine with a hoist. Place the disassembling stand under

the main frame. Disconnect the power steering hoses. Loose the hydraulic

inlet hose band. Disconnect the hydraulic inlet hose from the hydraulic

pump. Disconnect the hydraulic delivery pipe from the hydraulic pump.

Disconnect the wiring leads from the alternator, the engine oil pressure

switch and the starter motor. Disconnect the wiring harness and the

power steering hoses from the engine body. Remove the docking bolts

between the engine and the front case. Align the spline between the

front wheel drive shaft and the universal joint securely.

Separating the Clutch Assembly

Remove the clutch assembly from the flywheel. Direct the shorter end of

the clutch disc boss toward the flywheel. Apply molybdenum disulphide to

the splines of clutch disc boss. Install the pressure plate, noting the

position of straight pins. Align the center of clutch disc and flywheel

by inserting the clutch center tool. Do not allow grease and oil on the

clutch disc facing.

Clutch and Clutch Release Fork

Remove the external snap ring at the end of clutch rod shaft and remove

the clutch release fork and the release bearing with release bearing

holder.

Set the clutch release fork and the release bearing with the release

folk spring in the correct direction.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605