________________________________________________________________________________

Kubota B2100, B21, B7300 - Hydrostatic Transmission

Kubota B21, B2100, B7300 Tractor -

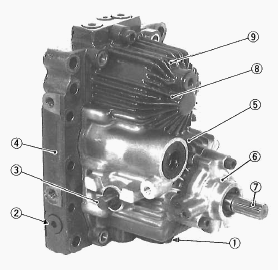

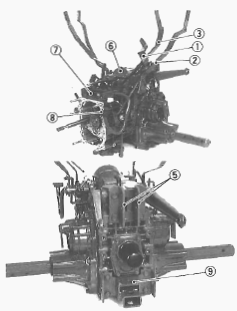

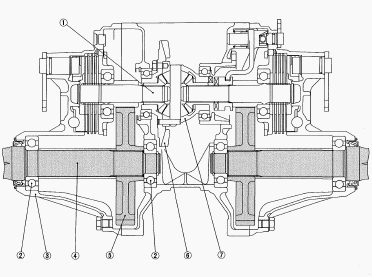

Transmission Components

1 - Charge Relief Valve, 2 - Check and High Pressure Relief Valve, 3 -

Trunnion Shaft, 4 - Center Section, 5 - Variable Displacement Piston

Pump, 6 - Charge Pump, 7 - Input Shaft (Pump Shaft), 8 - Housing, 9 -

Fixed Displacement Piston Motor

The hydrostatic transmission consists of a variable displacement piston

pump and a fixed displacement piston motor. Convenient single lever

control permits simple operation of the vehicle, starting, stopping,

increasing or decreasing speeds, changing direction of travel, and even

going up or down hills.

Pump and Motor

Pump and motor cylinder, each containing pistons, are connected by

lines. Cylinders and lines are filled with oil. Pistons ride against

swashplates located in pump and motor. In the pump, as the cylinder

rotates, pistons move across the sloping face of swashplate and slide in

or out of their cylinder bores. The oil, forced out by the pump pistons,

causes the motor pistons to slide out of their cylinder bores. In the

motor, sliding out of the cylinder and moving across the sloping face of

swashplate, the pistons rotate the cylinder.

Oil Flow and Valves

The pump and motor are joined in a closed hydraulic loop and most of oil

circulates within the main oil circuit. A little oil lubricates and

oozes out from the clearance between the moving parts of the case. Then

oil in the main oil circuit of the HST needs to be supplied a want. The

combined oil flow from the power steering circuit and HST charge pump

are flows into the HST for charging. The charge oil aids smooth

operation of piston pump and motor. The charge oil passes through the

oil cooler and transmission oil filter to charge relief valve port. The

rest of oil passes through the charge relief valve into the HST housing.

Oil from the hydraulic cylinder and overflow oil from HST housing return

to the transmission case.

Charge Relief Valve

While pumped and filtered oil flows into the main oil circuit through

the check valves, excessive oil passes to the case through the charge

relief valve.

Check and High Pressure Relief Valve

The check and high pressure relief valves monitor the oil pressure in

each line of the main oil circuit. In neutral, both valves are open and

charging oil enters into the main oil circuit through the valves. At

normal operation, the check valve in the high pressure side is closed

and it pushes and opens the another one. When excessively high pressure

is built up in one line, the high pressure relief valve located in this

line is open and the oil flows into another line.

Control Linkage

The speed control pedal and the trunnion shaft of variable swashplate

are linked with the speed control rod and the trunnion control lever

assembly. As the front footrest of the pedal is depressed, the

swashplate rotates and forward travelling speed increases. Depressing

the rear footrest increases reverse speed. The roller on the trunnion

lever holder with spring seats the detent of the trunnion arm so that

the trunnion lever returns to neutral. Then, the swashplate is returned

to neutral with the trunnion control lever assembly, when the pedal is

released. The damper connected to the speed control pedal restricts the

movement of the linkage to prevent abrupt operation or reversing. The

speed set lever linked to the speed control pedal enables the linkage

not to return to neutral and to keep a certain forward speed while the

speed control pedal is released.

Kubota B2100, B21, B7300 HST - PTO System

Rear-PTO Shift Section

Besides neutral, one kind of power flow are available by operating the

PTO shift lever to shift positions of 17T shifter gear (2) for rear-PTO.

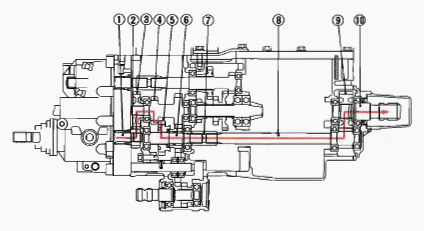

1 - HST Pump Shaft, 2 - 14T Gear, 3 - 27T Gear, 4 - 2nd Gear Shaft with

13T and 18T Gear, 5 - 17T Shifter Gear, 6 - 3rd Shaft, 7 - Coupling, 8 -

5th Shaft with 11T Gear, 9 - 24T Gear, 10 - Rear-PTO Shaft.

Rear-PTO Shift Lever ON position

HST Pump Shaft (1) - 14T Gear (2) - 27T Gear (3) - 2nd Gear Shaft with

13T Gear (4) - 17T Shifter Gear (5) - 3rd Shaft (6) - Coupling (7) - 5th

Shaft with 11T Gear (8) - 24T Gear (9) - Rear-PTO Shaft (10).

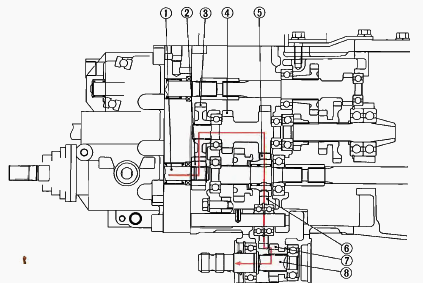

Mid-PTO Section

Besides neutral, one kind of power flow are available by operating the

PTO shift lever to shift positions of shifter (5) or 11T shifter gear

(7) for mid-PTO.

1 - HST Pump Shaft, 2 - 14T Gear, 3 - 27T Gear, 4 - 2nd Gear Shaft with

13T and 18T Gear, 5 - 13T Gear, 6 - 19T Gear, 7 - 11T Shifter Gear, 8 -

Mid-PTO Shaft.

Mid-PTO Shift Lever ON Position

HST Pump Shaft (1) - 14T Gear (2) - 27T Gear (3) - 2nd Gear Shaft with

18T Gear (4) - 13T Gear (5) - 19T Gear (6) - 11T Shifter Gear (7) -

Mid-PTO Shaft (8).

Kubota B21, B2100, B7300 - Clutch

Separating the Clutch Assembly

Remove the clutch assembly from the flywheel. Direct the shorter end of

the clutch disc boss toward the flywheel. Apply molybdenum disulphide to

the splines of clutch disc boss. Install the pressure plate, noting the

position of straight pins. Align the center of clutch disc and flywheel

by inserting the clutch center tool.

Clutch Rod and Clutch Release Fork

Remove the clutch pedal rod. Remove the external snap ring at the end of

clutch rod and remove the clutch release fork and release bearing with

release hub. Set the clutch release fork and release hub with set spring

in the correct direction.

Kubota B21, B2100, B7300 HST - Clutch

Replacement Service

Backlash between Clutch Disc and Clutch Shaft

Mount the clutch disc onto the propeller shaft. Hold the propeller shaft

so that it does not rotate. Slightly move the disc and measure the

displacement around disc edge. If the measurement exceeds the allowable

limit, replace clutch disc. Displacement around disc edge - 2.0 mm

(0.079 in).

Clutch Disc Wear

Measure the depth from clutch disc surface to the top of rivet at least

10 points with a depth gauge. If the depth is less than the allowable

limit, replace. If oil is sticking to the clutch disc, or disc surface

is carbonized, replace clutch disc. Depth to river top - 0.3 mm (0.012

in).

Pressure Plate Flatness

Place a straightedge on the pressure plate and measure clearance with a

feeler gauge at several points. If the clearance exceeds allowable

limit, replace pressure plate. When the pressure plate is worn around

its outside and its inside surface only is in contact with the

straightedge, replace it even if the clearance is within the allowable

limit. Clearance between pressure plate and straightedge - 0.2 mm (0.008

in).

Checking Pressure Plate and Diaphragm

Check the pressure plate and if scratched on its surface, correct with

sandpaper or replace it. Check the diaphragm for cracks and scratches.

If defects are found, replace it.

Checking Clutch Release Bearing

Check the clutch release bearing. If surface is worn excessively, or

abnormal sounds occur, replace it.

Kubota B2100, B21, B7300 Transmission -

Checking And Adjusting

Neutral

Disengage the front wheel drive lever (Drive only rear wheels). Lift the

rear of the tractor so that the rear wheels are off the ground and run

the engine at low idling and drive only rear wheels. Depress the one end

of speed control pedal and release, and do the same at the other end. If

the rear wheels do not stop turning, adjust as following procedure.

Before loosen the neutral adjuster setting screw, be sure to insert the

screw driver to hole of neutral adjuster. This mean prevent to comes out

neutral adjuster at adjusting window.

Adjusting Neutral

Disconnect the brake rod RH. Remove the HST pedal damper. Loosen the

neutral adjuster setting screw. When rear wheels tend to turn forward -

Rotate the neutral adjusting lever clockwise so that the rear wheels

turn reverse. Then rotate it counterclockwise until wheels stop

completely. When rear wheels tend to turn reverse - Rotate the neutral

adjusting lever counterclockwise so that the rear wheels turn forward.

Then rotate it clockwise until wheels stop completely.

Oil Pressure in Hydrostatic Transmission

Clean and clear the work area and fully engage the parking brake.

Measure the following oil pressures using HST adaptors.

Check and High Relief Pressure

Remove the 8 mm (0.31 in.) hex socket head plug from P1 or P2 port (P1

is for forward and P2 is for reverse). Assemble the HST adaptor and

threaded joint with the gasket between them. Install the assembled HST

adaptor and threaded joint to P1 (forward) or P2 (reverse) port. Install

the cable threaded joint in relief valve set pressure tester and high

pressure gauge to threaded joint in order. Run the engine at 2600 rpm.

Place the high-low shift lever in high. Depress the speed control pedal

approx. 10 mm (0.39 in.) which rotates the trunnion shaft 0.087 rad

(5.0°).

Kubota B21, B2100, B7300 - Transmission Case

Disassembly

Charge Pump Housing and Spacer

Remove the charge pump mounting hex. socket head screw, and remove the

charge pump assembly from the HST housing. Remove the charge pump spacer

from the charge pump assembly.

Center Section

Remove the external snap ring and 14T gear. Remove the center section

mounting hex. socket head screw. Lift and remove the center section from

the HST housing. Place a new gasket on the housing. Press the cylinder

block (motor side) by hand then softly reinstall the counter section. Be

careful the pistons for come off from the cylinder block. Install the

snap ring with its rounded edge facing the gear so that its sharp edge

in the groove keep itself in place against the face.

Check and High Pressure Relief Valve

Remove the hex. socket head plug and remove the spring and relief valve

assembly. Take care not to damage the O-ring On the plug.

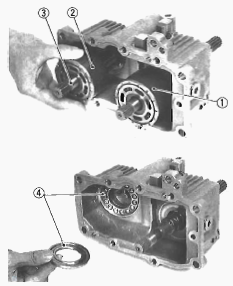

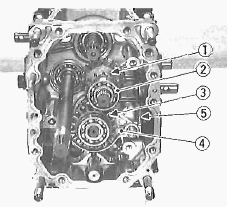

Cylinder Block Assembly and Thrust Ball Bearing

1.Cylinder Block Assembly (Pump Side), 2.Cylinder Block Assembly (Motor

Side), 3.Motor Shaft, 4.Thrust Ball Bearing

Lay the housing on its side. Remove the cylinder block assembly (pump

side) (1). Remove the cylinder block assembly (motor side) (2) with the

motor shaft (3). Remove the thrust ball bearing (4). Apply clean

hydrostatic transmission oil to thrust ball bearing, cylinder block and

piston.

Swashplate

Remove the swashplate from the housing. Remove the thrust plate, thrust

roller bearing and thrust washer from the swashplate. Apply clean

hydrostatic transmission oil to the thrust roller bearing. Place the

swashplate into the housing, align the groove of swashplate and slot

guide by keeping the slot guide from moving with a screw driver.

Slot Guide, Cradle Bearing and Trunnion Arm

Remove the slot guide from the trunnion arm. Remove the cradle bearing

from the housing. Remove the trunnion arm. Remove the oil seal with a

screw driver. Apply clean hydrostatic transmission oil to journal

bearing, trunnion arm and cradle bearing.

Pump Shaft

Remove the internal snap ring. Tap the pump shaft with a plastic hammer

slightly to slide out it from the housing.

Charge Relief Valve

Remove the charge relief valve plug. Remove the spring and charge relief

corn. If shims are placed at the bottom of the relief valve plug bore,

place them as they are. Take care not to damage the a-ring on the relief

plug.

Separating Hydraulic Cylinder and Rear Axle Case

1 - Aux. Speed Change Lever, 2 - Rear-PTO Shift Lever, 3 - Mid-PTO Shift

Lever, 4 - Connecting Plate, 5 - Top Link Bracket, 6 - Hydraulic

Cylinder Assembly, 7 - Differential Lock Pedal Support, 8 - Differential

Lock Pedal, 9 - Drawbar Frame

Remove the external snap ring and remove the auxiliary speed change

lever (1) with rod, rear-PTO shift lever (2) and mid-PTO shift lever

(3). Remove the hook and connecting plate (4). Remove the top link

bracket (5). Remove the hydraulic cylinder mounting screws and dismount

the hydraulic cylinder assembly (6). Disconnect the differential lock

rod and remove the differential lock pedal support (7) with differential

lock pedal (8). Remove the drawbar frame mounting screws and remove the

drawbar frame (9). Apply liquid gasket to joint face of the differential

case and the rear axle case, differential case and the hydraulic

cylinder.

Separating Mid-PTO Case and Transmission Case

Remove the mid-PTO case mounting screws and separate the mid-PTO case

from transmission case. Remove the transmission case mounting screws and

nuts and separate the transmission case from the differential case.

Apply liquid gasket to joint face of the transmission case, differential

case and mid-PTO case.

Bearing Holder

Remove the external snap ring and remove the 27T gear. Remove the

bearing holder mounting screws and remove the bearing holder.

2nd Gear Shaft and 17T Shifter Gear

1 - 2nd Gear Shaft, 2 - Bearing, 3 - 17T Shifter Gear, 4 - Shift Fork, 5

- Shift Lever

Remove the 2nd gear shaft (1) with bearings. Remove the bearing (2), 17T

shifter gear (3) and shift fork (4) with shift rod. Remove the shift

lever (5).

Middle Shaft and 3rd Shaft

Tap out the middle shaft and remove the 19T gear with bearing. Draw out

the 3rd shaft with 13T gear. When assembling the 19T gear, face the

chamber side to the rear. When installing the needle bearings into the

13T gear, apply transmission oil to the needle bearings.

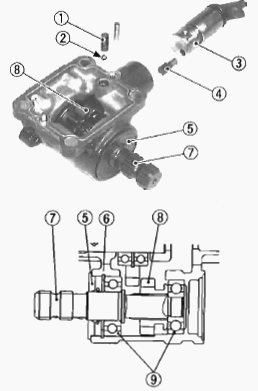

Mid-PTO Shaft

1 - Spring, 2 - Ball, 3 - Shift Arm, 4 - Shifter, 5 - Oil Seal, 6 -

Internal Snap Ring, 7 - Mid-PTO Shaft, 8 - 11T Shifter Gear, 9 - Bearing

Remove the spring (1) and ball (2). Draw out the dowel pi n and remove

the shift arm (3) with shifter (4). Remove the oil seal (5) and internal

snap ring (6). Remove the mid-PTO shaft (7) with 11T shifter gear (8)

and bearings (9). Apply grease to lip and outer of oil seal.

Front Wheel Drive Shaft

Remove the external snap ring and remove the 20T shifter gear. Draw out

the front wheel drive shaft to the front.

4th Gear Shaft and Spiral Bevel Pinion Shaft

Remove the spiral bevel pinion shaft with 15T-29T shifter gear, 13T

gear. Remove the 4th gear shaft with 18T gear. When installing the

spiral bevel pinion shaft, be sure to install the shim.

Kubota B21, B2100, B7300 HST - Transmission

Case Service

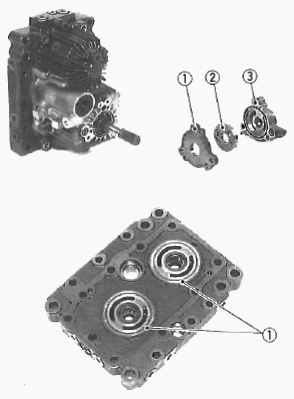

Charge Pump

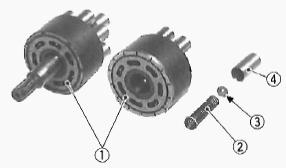

1.Spacer, 2.Gerotor Assembly, 3.Charge Pump Housing

Check the charge pump housing (3), spacer (1) and the gerotor assembly

(2) for scratches and wear. If scratch or worn, replace the charge pump

complete assembly.

Center Section

Check the surface of center section for scratches or wear. If deep

scratch or excessive wear is found, replace the center section.

Check and High Pressure Relief Valve

Check the valve for scratches and damage. Check the valve seat in the

center section for damage. Check the spring for breakage and wear. If

anything unusual, replace the high pressure relief valve complete

assembly.

Cylinder Block Assembly

1.Cylinder Block, 2.Spring, 3.Spring Seat, 4.Piston

Check cylinder blocks (1) and pistons (4) for scratches and wear. If

deep scratch or excessive wear is found, replace the cylinder block

assembly. Check that the piston (4), spring (2) and spring seat (3) are

in each cylinder bore. Check the pistons for their free movement in the

cylinder block bores. If the piston or cylinder block bore is scored,

replace the cylinder block assembly.

Thrust Washer, Thrust Roller Bearing and Thrust Plate

Check the thrust roller bearing for scratches and excessive wear. If

worn, replace. Check the thrust plate for scratches and excessive wear.

If worn or scored, replace.

Pump Shaft

Check the seal surface, the bearing surface and the bearing. If the

shaft is rough or groove, replace. If the bearing is worn, replace.

Needle Bearing and Oil Seal

Check the oil seals for damage. Check the needle bearings for wear. If

the oil seals and bearings are worn, replace them.

Charge Relief Valve

Check the charge relief cone and the seat in the housing for damage. If

defects are found, replace them.

Bearing Check

While holding the inner race, push and pull the outer race in all

directions to check for wear and roughness. Apply transmission oil to

the bearing and hold the inner race. For needle bearing, lay the needle

rollers to check for any damage and wear. Replace it if defects are

found.

Clearance between Shift Fork and Shift Gear Groove

Insert the fork into the shift gear groove and measure the clearance

with a feeler gauge. If the clearance exceeds the allowable limit,

replace it. Clearance between shift fork and shift gear groove - 0.10 to

0.35 mm (0.004 to 0.014 in).

Clearance between 13T Gear and 3rd Shaft

Measure the 13T gear I.D. with an inside micrometer, and then 3rd shaft

O.D. with an outside micrometer. Measure the O.D. of two needles in the

needle bearing with an outside micrometer. Clearance is the difference

between the gear I.D. and the sum of shaft O.D. and two needle O.D. If

the clearance exceeds the allowable limit, replace. Clearance between

13T gear and 3rd shaft - 0.007 to 0.046 mm (0.0003 to 0.0018 in). 3rd

shaft O.D. - 21.987 to 22.000 mm (0.8656 to 0.8661 in). 13T gear I.D. -

28.007 to 28.021 mm (1.1026 to 1.1032 in). Needle O.D. - 2.994 to 3.000

mm (0.1179 to 0.1181 in).

Kubota B21, B2100, B7300 - Differential Case

Service

Clearance between Differential Case and Differential Side Gear

Measure the differential side gear boss O.D. with an outside micrometer.

Measure the differential case I.D. and the spiral bevel gear I.D. with

an inside micrometer. If the clearance exceeds the allowable limit,

replace it. Clearance between differential case and differential side

gear - 0.025 to 0.066 mm (0.0016 to 0.0029 in). Differential case I.D. -

32.000 to 32.025 mm (1.2598 to 1.2608 in). Differential side gear O.D. -

31.959 to 31.975 mm (1.2582 to 1.2589 in). Spiral bevel gear I.D. -

32.000 to 32.025 mm (1.2598 to 1.2608 in).

Clearance between Differential Pinion Shaft and Differential Pinion

Measure the differential pinion shaft O.D. with an outside micrometer.

Measure the 'differential pinion I.D. with an inside micrometer. If the

clearance exceeds the allowable limit, replace it. Clearance between

differential pinion shaft and differential pinion 0.016 to 0.045 mm

(0.0006 to 0.0018 in). Differential pinion shaft O.D. - 15.973 to 15.984

mm (0.6289 to 0.6293 in). Differential pinion I.D. - 16.000to 16.018 mm

(0.6299 to 0.6306 in).

Backlash between Differential Pinion and Differential Side Gear

Secure the differential case with a vise. Set the dial indicator (lever

type) with its finger on the tooth of the differential side gear. Press

differential pinion and side gear against the differential case. Hold

the differential pinion and move the differential side, gear to measure

the backlash. If the backlash exceeds the allowable limit, adjust with

differential side gear shims. Backlash between differential pinion and

differential side (Allowable limit) - 0.4mm (0.016 in).

Backlash between Spiral Bevel Pinion and Spiral Bevel Gear

Set the dial indicator (lever type) with its finger on the end of spiral

bevel pinion. Move the spiral bevel pinion back and forth to each end

and measure the side clearance. If the side clearance exceeds the

factory spec., adjust with the shims at front end of spiral bevel

pinion. Set the dial indicator (lever type) with its finger on the tooth

surface of bevel gear. Measure the backlash by fixing the spiral bevel

pinion and moving bevel gear by hand. If the backlash exceeds the

factory spec., adjust with the shims at bearing holder and differential

case. Adjust the backlash properly by repeating the above procedures.

Side clearance of spiral bevel pinion - Less than 0.15 mm (0.006 in).

Backlash between spiral bevel pinion and spiral bevel gear - 0.10 to

0.20mm (0.0039 to 0.0080 in).

Kubota B21, B2100, B7300 Tractor - Rear Axle

The rear axles are the semi floating type with ball bearings (2) between

the rear axle (4) and the rear axle case (3), which supports the rear

wheel load as well as transmitting power to the rear wheels. The

differential (7) automatically controls the revolution of right and left

wheels when the rear wheels encounter unequal road resistance during

turning.

1 - Differential Gear Shaft, 2 - Ball Bearing, 3 - Rear Axle Case, 4 -

Rear Axle, 5 - Spur Gear, 6 - Spiral Bevel Gear, 7 - Differential

Separating Rear Axle Case from Differential Gear Case

Drain the Transmission Fluid

Place oil pans underneath the transmission case. Remove the four drain

plug. Drain the transmission oil. Reinstall the four drain plugs. Fill

up from filling port after removing plug until reaching the gauge. After

running the engine for few minutes, stop it and check the oil level

again. Add the oil to prescribed level if it is not correct level.

Rear Wheel

Place a jack under the transmission case. Loosen the rear wheel cotter

setting bolt and nut. Take out the wheel hub pin. Take out the rear

wheel. When refitting or adjusting a wheel, tighten the bolts to the

following torques then recheck after driving the tractor 200 m (200

yards) and there after daily check service.

Rear Axle Case

Disconnect the differential lock rod. Disconnect the brake rod. Remove

the rear axle case mounting screw. Separate the rear axle case from

differential gear case. Apply liquid gasket to joint face of the rear

axle case and differential gear case after eliminate the water, oil and

stuck liquid gasket.

Separating Hydrostatic Transmission

Tap out the spring pins and remove the universal joint with front wheel

propeller shaft. Remove the neutral adjuster setting screw and loosen

the trunnion control lever mounting bolt and nut. Then remove the

trunnion control lever assembly. Remove the hydrostatic transmission

mounting screws and nuts, and separate the hydrostatic transmission from

the transmission case. When assembling the neutral spring bracket,

adjust the clearance between nut and bracket. Apply liquid gasket to

joint face of the HST and transmission case. When inserting the spring

pins, face their splits in the direction parallel to the universal joint

Differential Gear Case

5th Gear Shaft and Rear-PTO Shaft

Remove the ternal snap ring and one-way clutch cam (Manual Transmission

Type). Remove the rear-PTO cover mounting screw and remove the rear-PTO

cover assembly. Apply liquid gasket to joint face of differential case

and rear-PTO cover. Do not tighten the rear-PTO cover mounting screws

before reassembling the differential case and transmission case.

Removing Differential

Remove the bearing holder mounting screws and remove the differential

bearing holder. Remove the differential assembly. Install the

differential assembly, noting the number of shims in the differential

case left side and differential bearing holder.

Differential Side Gear and Differential Pinion

Put parting marks on the differential pinion and the differential side

gear. Tap out the dowel pin. Remove the differential pinion shaft.

Remove the differential pinion, differential side gear and shim. Install

the differential pinion aligning the parting marks.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605