________________________________________________________________________________

Kubota B2301, B2311, B2231 - Transmission

Kubota B2301, B2311, B2231 - Transmission

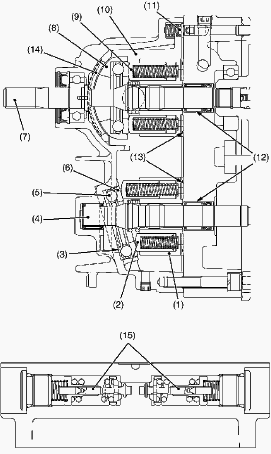

Assembly Parts

1-Cylinder Block (Motor), 2-Piston, 3-Thrust Collar, 4-Motor Shaft,

5-Thrust Ball Bearing, 6-Thrust Collar, 7-Pump Shaft, 8-Swashplate,

9-Piston, 10-Cylinder Block (Pump), 11-Charge Relief Valve, 12-Needle

Bearing, 13-Valve Plate, 14-Cradle Bearing, 15-Check and High Pressure

Relief Valve,

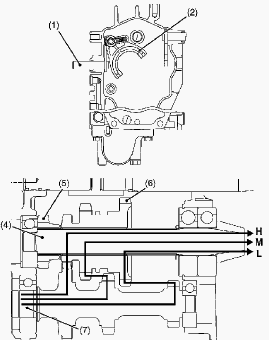

Range Gear Shift

1. Range Gear Shift Lever, 2. Range Shift Fork, 3. Range Shift Arm, 4.

6T Bevel Pinion Shaft, 5. 13T Gear (for Front Wheel Drive), 6.

14T-21T-29T Gear, 7. 23T-16T-14T Sub Shaft, L - LOW Range, M - MID

Range, H - HIGH Range

Range gear shift lever (1) is located at left side fender. Range gear

shift lever (1) can select three speed range, low speed, mid speed and

high speed. Range gear shift lever (1) and 14T-21T-29T gear (6) are

linked with range shift arm (3) and range shift fork (2) etc. Three

range gear shifts are selected by shifting the 14T-21T-29T gear (6) on

6T bevel pinion shaft to 23T-16T-14T sub shaft (7).

Low Speed Position: 14T of 23T-16T-14T Sub Shaft (7) - 29T of

14T-21T-29T Gear (6) - 6T Bevel Pinion Shaft (4).

Middle Speed Position: 16T of 23T-16T-14T Sub Shaft (7) - 21T of

14T-21T-29T Gear (6) - 6T Bevel Pinion Shaft (4).

High Speed Position: 23T of 23T-16T-14T Sub Shaft (7) - 14T of

14T-21T-29T Gear (6) - 6T Bevel Pinion Shaft (4).

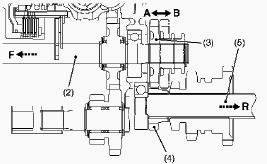

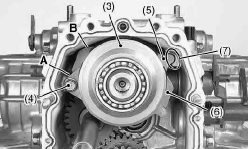

Front Wheel Drive Section

1 - Front Wheel Drive Lever, 2 - Front Wheel Drive Shaft, 3 - 20T

Shifter Gear, 4 - 13T Gear, 5 - 6T Bevel Pinion Shaft, A - 4WD Position,

B - 2WD Position, F - Power to Front Wheels, R - Power to Rear Wheels

Front wheel drive lever (1) is located at the right side fender. Front

wheel drive lever (1) and shifter are linked. 20T shifter gear (3) is

located on the front wheel drive shifter (2). 2-wheel drive or 4-wheel

drive is selected by changing the position of 20T shifter gear (3)

reverse or forward. When the font wheel drive lever (1) is set to "4

Wheel Drive" position, 20T shifter gear (3) slides forward, meshes the

13T gear (4) on the 6T bevel pinion shaft (5). In this state, power from

the 6T bevel pinion shaft (5) is transmitted through 20T shifter gear

(3) to the front wheel drive shaft (2) and the front wheels.

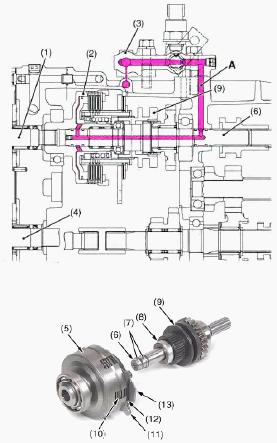

Kubota B2301, B2311, B2231 Tractor - Independent PTO

Independent PTO Clutch

1 - HST Pump Shaft, 2 - Independent PTO Clutch, 3 - Independent PTO

Control Valve, 4 - HST Motor Shaft, 5 - Case, 6 - PTO Clutch Shaft, 7 -

Seal, 8 - Bearing, 9 - Shifter, 10 - Clutch Discs and Plates, 11 - Brake

Plate 4, 12 - Brake Disc, 13 - Brake Plate 2

Independent PTO clutch (2) is located behind the HST pump shaft (1) in

the transmission case. Independent PTO clutch (2) is operated with

pressured hydraulic oil forced from the independent PTO control valve

(3). When independent PTO lever is shifted to "ENGAGED" position,

hydraulic oil is forced through the transmission case inner passage (A)

and PTO clutch shaft (6) to PTO clutch. In this state, power from HST

pump shaft is transmitted through independent PTO clutch (2) to

independent PTO clutch shaft (6). When independent PTO lever is shifted

to "DISENGAGED" position, hydraulic oil is not forced to the PTO clutch.

In this state, power from HST pump shaft (1) is not transmitted to

independent PTO clutch shaft (6).

Independent PTO Control Valve Checking

Disconnect the OPC switch connector and remove the seat. Remove the

plate. Remove the 3-point hitch lowering speed knob. Remove the plug

with a hexagon wrench. Install the adapter to the independent PTO

control valve. Connect the cable and the pressure gauge to the adapter.

Reassemble the plate. Start the engine and set at the maximum speed.

(Pressure at "ENGAGED" position) Move the independent PTO lever to

"ENGAGED" position A. Measure the pressure. (Pressure at "DISENGAGED"

position). Move the independent PTO lever to position B. Measure the

pressure. If the pressure is not the factory specifications, adjust

setting pressure with (the adjusting) shims. Independent PTO valve

setting pressure (ENGAGED position) - 1.1 to 1.5 MPa (160 to 218 psi).

Independent PTO valve setting pressure (DISENGAGED position) - 0 MPa (0

psi).

Kubota B2301, B2311, B2231 Independent PTO Troubleshooting

PTO Clutch Slip

Operating pressure is low - Check PTO control valve setting pressure.

Inspect clutch disc or plate. Replace PTO clutch or other parts.

Independent PTO control valve malfunctioning - Check PTO control valve

setting pressure. Inspect or replace poppet or PTO control valve.

Clutch disc or drive plate excessively worn - Check PTO control valve

setting pressure. Inspect or replace clutch disc or plate.

Deformation of piston or return plate - Inspect return plate or piston.

Replace return plate or piston.

PTO Shaft Does Not Rotate

PTO clutch malfunctioning Solution order - Check PTO control valve

setting pressure. Replace PTO clutch or other parts.

PTO Clutch Operating Pressure is Low

Transmission oil improper or insufficient - Check transmission oil.

Relief valve malfunctioning - Replace poppet.

PTO Clutch Drags

Brake plate excessively worn - Replace brake plate. Return spring weaken

or broken - Inspect or replace return spring.

Kubota B2301, B2311, B2231 Hydrostatic Transmission - Checking And

Adjusting

Charge Relief Pressure

Remove the cover. Remove the plug from P1 port (reverse) or P2 port

(forward). Install the adaptor to P1 port or P2 port. Install the cable

and low pressure gauge to the adaptor. Start the engine and warm the oil

before testing. Change the range gear shift lever to "NEUTRAL" position.

Operate engine at the rated speed. Release the foot from the HST pedal.

Read the low pressure gauge to measure the charge relief pressure. If

the measurement is not same as factory specification, check the charge

relief valve and the related hydraulic components. Low pressure gauge is

2.9 MPa (30 kgf/cm2, 427 psi) full scale. Charge pressure - 0.4 to 0.6

MPa / 60 to 80 psi. Checking port plug - 29 to 44 Nm / 21.7 to 32.5

lbf-ft.

High Pressure Relief Valve (Reverse)

Remove the cover. Remove the plug from P1 port (reverse). Install the

adaptor to P1 port. Install the cable and high pressure gauge. Start the

engine and warm the oil before testing. Check to see that parking brake

is applied. Place the range gear shift lever to "HIGH" position. Operate

the engine at the rated speed. Depress the rear side pedal of the HST

pedal. Read the high pressure gauge to measure the high pressure relief

valve pressure. If the measurement is not the same as factory

specification, check the check and high pressure relief valve assembly.

High pressure gauge is 40 MPa (400 kgf/cm2, 5800 psi) full scale. Oil

temperature: 50 C (122 F). Check and high relief pressure - 23 to 25 MPa

/ 3400 to 3600 psi. Checking port plug - 29 to 44 Nm / 21.7 to 32.5

lbf-ft.

High Pressure Relief Valve (Forward)

Remove the cover. Remove the plug from P2 port (forward). Install the

adaptor to P2 port. Install the cable and high pressure gauge. Start the

engine and warm the oil before testing. Check to see that parking brake

is applied. Place the range gear shift lever to "HIGH" position. Operate

the engine at the rated speed. Depress the front side pedal of the HST

pedal. Read the high pressure gauge to measure the high pressure relief

valve pressure. If the measurement is not same as factory specification,

check the check and high pressure relief valve assembly.

Kubota B2301, B2311, B2231 - PTO Clutch Case and Front Wheel Drive Shaft

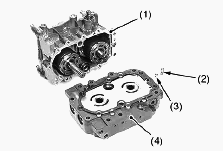

Separating Transmission Case and PTO Clutch Case

1 - Transmission Case, 2 - Differential Case, 3 - PTO Clutch Case, 4 -

PTO Brake Plate 4 Mounting Bolt, 5 - PTO Brake Plate 4, 6 - PTO Brake

Plate 2, 7 - Transmission Case Groove, A - Position, B - Position

Remove the transmission case mounting bolts. Separate the transmission

case from the differential case. Remove the PTO brake plate 4 mounting

bolt. Install the PTO brake plate 4 to the transmission case groove

securely.

Bevel Pinion Shaft

Remove the bevel pinion shaft assembly and range gear shaft assembly

from the transmission case. Remove the spacer. Install the spacer to the

transmission case. Install the bevel pinion shaft assembly and range

gear shaft assembly. Transmission case mounting bolt (M10) and nut -

39.3 to 44.1 Nm / 29.0 to 32.5 lbf-ft. Hydraulic cylinder mounting bolt

(M10) and nut - 39.3 to 44.1 Nm / 29.0 to 32.5 lbf-ft.

Sub Gear Shaft Assembly

Remove the circlip from the sub gear shaft. Remove the sub gear shaft

assembly from the transmission case.

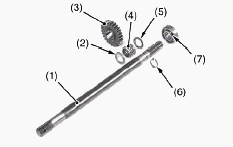

4WD Shaft

1.4WD Shaft, 2.Collar, 3.26T Gear, 4.Needle Bearing, 5.Collar,

6.Circlip, 7.Ball Bearing

Remove the circlip from the 4WD shaft. Remove the 4WD gear from the 4WD

shaft. Remove the 4WD shaft with the 26T gear. Remove the 26T gear and

the ball bearing.

4WD Shift Lever

Remove the bolt and the washer with rubber. Install the 4WD gear to the

4WD shaft. Install the 4WD shaft arm to the 4WD gear. Install the

O-rings to the 4WD shift arm.

Kubota B2301, B2311, B2231 Tractor - Differential Gear Section

Rear Axle Case and Rear PTO Cover

Remove the rear axle mounting bolts. Remove the left rear axle case and

the right rear axle case from the differential case. Remove the rear PTO

cover mounting bolts and the rear PTO cover. Apply liquid gasket to the

joint surface of the rear axles cases and the rear PTO cover.

Differential Bearing Holder (RH)

Remove the differential holder mounting bolts. Remove the differential

holder and shims. 0.2 mm (0.008 in.) shim / 0.5 mm (0.020 in.) shim.

Rear axle case (LH and RH) mounting bolt for aluminum material (M10) -

39.3 to 44.1 Nm / 29.0 to 32.5 lbf-ft. Rear PTO cover mounting bolt for

aluminum material (M10) - 39.3 to 44.1 Nm / 29.0 to 32.5 lbf-ft.

Differential bearing holder mounting bolt for aluminum material (M8) -

17.7 to 20.5 Nm / 13.1 to 15.1 lbf-ft.

Differential Gear Assembly

Remove the internal circlip from the differential case. Remove the

shims. Remove the differential gear assembly from the differential case.

When reassembling: 0.5 mm (0.020 in.), shim 0.6 mm (0.024 in.), shim 0.7

mm (0.028 in.), shim 0.8 mm (0.031 in.).

Differential Side Gear and Differential Pinion

Put parting marks on the differential pinion and the differential side

gear. Tap out the dowel pin. Remove the differential pinion shaft.

Remove the differential pinion, differential side gear and shim. Install

the differential pinion and differential side gear, aligning the parting

marks.

Kubota B2301, B2311, B2231 Tractor - Hydrostatic Transmission Service

Pump Shaft

Pull out the pump shaft from the HST housing case. Check the oil seal

surface, the bearing surface and the bearing. If the shaft is rough or

grooved, replace it. If the bearing is worn, replace it.

Cylinder Block Face

Check the polished face of cylinder block for scoring. If scored,

replace cylinder block assembly.

Valve Swash Plate Bearing Face

Check the swash plate bearing for scratches and excessive wear. If worn

or scored, replace it. Apply liquid lock to the screw.

Thrust Collars, Thrust Ball Bearing and Swash Plate Surface

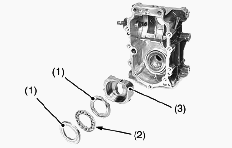

1-Thrust Collar, 2-Thrust Ball Bearing, 3-Swash Plate

Check the thrust collar for scratches and excessive wear. If worn or

scored, replace it. Check the thrust ball bearing surface for scratches

and excessive wear. If worn or scored, replace it. Check the swash plate

for scratches and excessive wear. If worn or scored, replace it.

Thrust collars and Thrust Ball Bearing (Motor Side)

Check the thrust collars for scratches and excessive wear. If worn or

scored, replace it. Check the thrust ball bearing for scratches and

excessive wear. If worn or scored, replace it.

Center Section Oil Seals and Bearings

Check the oil seals for damage. Check the needle bearings for wear. If

the needle bearings and oil seals are worn, replace all seals and needle

bearings. After checking, coat the bearing with hydrostatic transmission

oil and the oil seal lip with grease. Tightening torque: Screw (M3) -

1.5 Nm / 1.1 lbf-ft.

Check and High Pressure Relief Valve

Check the valve plug and valve for scratches and damage. Check the valve

seat in the port block for damage. Check the spring for breakage and

wear. If anything unusual, replace the check and high pressure relief

valve assembly.

Charge Relief Valve

1-HST Housing, 2-Spring, 3-Poppet, 4-Center Section

Check the spring for breakage and wear. If it is unusual, replace it.

Cylinder Block Bore and Pistons

Check the pistons for their free movement in the cylinder block bores.

If the piston or the cylinder block bore is scored, replace cylinder

block assembly. Do not interchange pistons between pump and motor

cylinder block. Pistons and cylinder blocks are matched.

Kubota B2301, B2311, B2231 - Independent PTO Clutch Service

Checking Bearing

Hold the inner race, and push and pull the outer race in all directions

to check for wear and roughness. Apply transmission fluid to the

bearing, and hold the inner race. Then, turn the outer race to check

rotation. If there is any problem, replace it. Valve plug - 59 to 78 Nm

/ 44 to 57 lbf-ft. Clearance between piston and bore - 0.02 to 0.03 mm /

0.0008 to 0.001 in.

Clutch Disc Wear

Measure the clutch disc thickness with vernier calipers. If the

thickness is less than the allowable limit, replace it.

Steel Plate and Pressure Plate Wear

Measure the steel plate thickness with vernier calipers. Measure the

pressure plate thickness with vernier calipers. If the thickness is less

than the allowable limit, replace.

Piston Return Spring Free Length and Tension

Measure the free length of the piston return spring with vernier

calipers. Place the piston return spring on a spring compression tester

and compress to the specified length, and read the gauge. If the

measurement is less than the allowable limit, replace.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605