________________________________________________________________________________

Kubota B2601, B26, B26TLB - Transmission

Kubota B2601, B26, B26TLB Hydrostatic

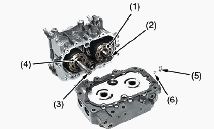

Transmission - Front Case

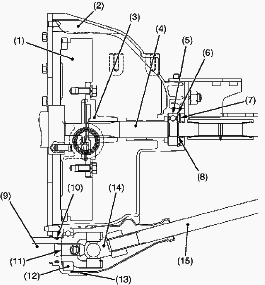

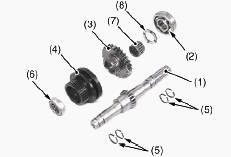

In Kubota B2601, B26, B26TLB tractors, clutch disc is not installed. The

input flange (3) is installed on the clutch shaft (4). Power from the

engine is transmitted through the input flange (3) to the clutch shaft

(4) and HST pump shaft.

1-Flywheel, 2-Clutch Housing, 3-Input Flange, 4-Clutch Shaft, 5-Ball

Bearing, 6-Circlip, 7-Oil Seal, 8-Circlip, 9-Front Drive Shaft,

10-O-ring, 11-Circlip, 12-Ball Bearing, 13-O-ring, 14-Universal Joint,

15-Rear Drive Shaft

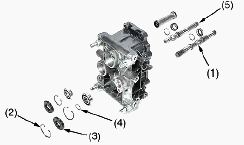

Kubota B2601, B26, B26TLB HST - Speed Set

Linkage

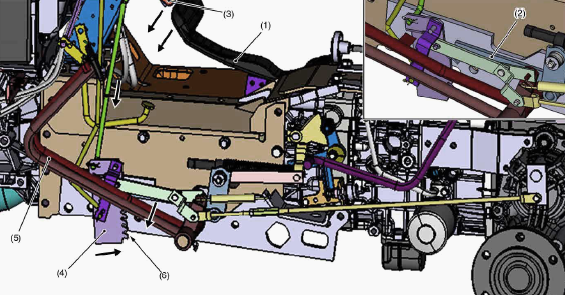

Speed Set

1-HST pedal, 2-Lever, 3-Speed Set Lever, 4-Speed Set Holder, 5-Brake

Pedal, 6-Tooth

The speed set device mainly consists of HST pedal holding section and

HST pedal releasing section. When the HST pedal (1) is see to the

desired position, the lever (2) turns counter clockwise. The speed set

lever (3) to the "ON" position. The speed set holder (4) turns counter

clockwise. On the other hand, sine lever engage with tooth (6) of speed

set holder (4), the HST pedal (1) is held at the desired set position

until the brake pedals (5) will be depressed by an operator.

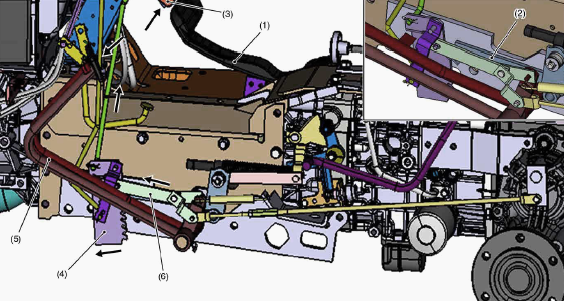

Speed Set Release

1-HST pedal, 2-Lever, 3-Speed Set Lever, 4-Speed Set Holder, 5-Brake

Pedal, 6-Brake Link

The speed set release is done by depressing the brake pedals (5). When

an operator depresses the brake pedal (5), the brake link (6) is pushed

by the brake pedals (5). When brake link (6) is pressed, the speed set

holder (4) is released. If you step on the HST pedal on the forward

acceleration side, the speed set device will disengage.

Kubota B2601, B26, B26TLB Hydrostatic

Transmission - Checking And Adjusting

Readjustment of Relief Valve (When the HST

does not work due to its loose hexagon socket head screw)

Measure the pre-adjustment Relief Valve Length. Compress the spring of

the relief valve with a relief valve assembling tool. Then, find the

Relief Valve Length by turning the poppet with a screwdriver. The Relief

Valve Length changes by about 0.5 mm (0.0197 in.) per one turn of the

poppet. Repeat the same operation a few times to find the Relief Valve

Length as it is difficult to acquire at the first time. After finding

the Relief Valve Length, hold the setscrew to a vice and fasten the

hexagon socket head screw with specified torque. On this occasion, use a

copper plate, etc. for the vice jaws not to damage the setscrew. Install

the relief valve in Kubota B2301, B2601, B26, B26TLB HST. Check the

relief pressure. The Relief Valve Length is for refresh only. Make sure

to check the relief pressure after readjustment. If the relief pressure

does not fall within the readjustment pressure range, repeat the

processes of the above item 1 onward. Tightening torque Hex. socket head

screw - 24.5 to 29.5 Nm / 18.1 to 21.7 lbf-ft. Relief valve readjusting

pressure - 23 to 25 MPa / 3400 to 3600 psi. Relief Valve Length

Reference value 38.5 to 38.6 mm / 1.516 to 1.519 in.

Adjusting Neutral

Disengage the front wheel drive lever. (Drive only rear wheels). Lift

the rear of the tractor so that the rear wheels are off the ground and

operate Kubota B2301, B2601, B26, B26TLB engine at low idling and drive

only rear wheels. Slightly loosen the neutral adjuster setting screw.

Rotate the neutral adjuster clockwise so the rear wheels turn reverse.

Then rotate it counterclockwise until wheels stop completely. Put a mark

on the center frame aligning the groove on neutral adjuster. Rotate the

neutral adjuster counterclockwise so the rear wheels turn forward. Then

rotate it clockwise until wheels stop completely. Put a mark on the

center frame aligning the groove on neutral adjuster. Hold the neutral

adjuster so its groove is at the middle of the marks and tighten the

setting screw. When the wheels tend to turn forward, rotate neutral

adjuster clockwise. When the wheels tend to turn reverse, rotate neutral

adjuster counterclockwise.

Kubota B2601, B26, B26TLB - Dismounting the

Step and Floor Seat

HST Pedal, Floor Mat and Front Cover

Remove the HST pedal mounting bolts. Remove the HST pedal. Remove the

lower adjusting knob. Remove the front cover. Remove the floor mat. ROPS

- Disconnect the tail light connectors and turn signal light connectors.

Remove the tail lights. Remove the spring pins. Remove the bolt. Remove

the upper frame from lower frames. Remove the ROPS mounting bolts and

the lower frames.

Seat and Fenders

Remove the seat and the lever grips. Disconnect the electrical socket

connector. Remove the fender LH. Remove the fender RH. Remove the both

side steps and seat under cover. Disconnect the seat switch connector.

Remove the seat support.

Hydraulic Pipes and Others

Remove the clamps. Disconnect the suction pipe and delivery pipe.

Disconnect the loader valve pipes. Disconnect the independent PTO pipe.

Remove the right side brake rod and sub frame. Remove the left side

brake rod and sub frame. Disconnect the HST pedal switch connector.

Remove the frame support plate and spring. Remove the HST damper and

plate. Front loader valve pipe joint - 48 to 70 Nm / 36 to 51 lbf-ft.

3-point hitch delivery pipe joint bolt - 48 to 70 Nm / 36 to 51 lbf-ft.

Frame support plate mounting bolt (M12) - 64 to 74 Nm / 48 to 54 lbf-ft.

Sub frame mounting bolt (M12) - 80 to 90 Nm / 59 to 66 lbf-ft. Sub frame

mounting bolt (M14) - 126 to 150 Nm / 93.0 to 110 lbf-ft. Sub frame

mounting bolt (M10) - 40 to 45 Nm / 30 to 34 lbf-ft.

Kubota B2601, B26, B26TLB - Front Case and HST

Disassembly and Assembly

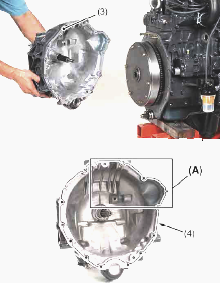

Clutch Housing

1.Bolt, 2.Engine Rear-End Plate, 3.Front Case, 4.Groove (for liquid

gasket), A.Front Case Corner

Support the engine securely. Remove the front case mounting bolts.

Remove the front case from engine. Front case mounting nut for aluminum

material (M8) - 17.7 to 20.5 Nm / 13.1 to 15.1 lbf-ft. Front case

mounting bolt for aluminum material (M10) - 39.3 to 44.1 Nm / 29.0 to

32.5 lbf-ft.

Clutch Shaft and Ball Bearing

Remove the oil seal. Remove the circlip. Remove the clutch shaft from

the front case.

Kubota B2601, B26, B26TLB Hydrostatic

Transmission Assembly

1.HST Assembly, 2.HST Assembly Mounting Bolt, 3.O-ring, 4.Groove (for

Liquid Gasket)

Remove the HST mounting bolts. Separate the HST assembly from the

transmission. Install the O-ring to the transmission case. Tightening

torque HST assembly mounting bolt (M10, aluminum) - 39.3 to 44.1 Nm /

29.0 to 32.5 lbf-ft.

Plate Push Rod, Neutral Arm and Neutral Holder

Remove the plate push rod. Remove the spring. Remove the neutral arm

mounting bolt. Loosen the bolt of the neutral holder. Remove the neutral

holder.

Center Section

Remove the center section mounting hex. bolts. Separate the HST housing

from the center section. Use a new gasket. Install the poppet to the

center section. Do not drop the spring. Check the knock pin. Hold the

gasket with the hex. bolts not to drop the gasket.

Oil Seals and Needle Bearings

Remove the needle bearing. Remove the oil seals. Center section mounting

hex. bolt (M10, aluminum) - 49 to 59 Nm / 37 to 43 lbf-ft.

Check and High Pressure Relief Valve

Remove the valve plug with a hex. wrench. Remove the spring and the

valve.

HST Housing Case Cylinder Blocks

1.Cylinder Block (Pump), 2.Pump Shaft, 3.Motor Shaft, 4.Cylinder Block

(Motor), 5.Spring, 6.Poppet

Remove the cylinder blocks from the pump shaft and the motor shaft.

Install the poppet to the center section, not to drop it. Install the

spring to the HST housing side.

Piston and Spring

Remove the pistons with the spring. Install the piston to its original

position of the cylinder block.

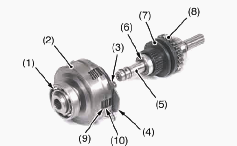

Motor Shaft and Pump Shaft

1.Pump Shaft, 2.Circlip, 3.Oil Seal, 4.Circlip, 5.Motor Shaft

Remove the circlip and oil seal from the HST housing. Remove the circlip

from the pump shaft. Remove the pump shaft. Remove the motor shaft.

Replace the used oil seal with a new one.

Trunnion Shaft

Remove the circlip and oil seal from the HST housing. Remove the circlip

from the trunnion shaft. Remove the swash plate. Strike out the trunnion

shaft slightly with a plastic hammer and remove the trunnion shaft.

Charge Relief Valve - Remove the spring and poppet. Check the spring for

breakage and wear.

Kubota B2601, B26, B26TLB - Independent PTO

Clutch and Mid-PTO

Installing PTO Clutch Shifter

Install the spring and the ball to transmission. Push the ball by finger

from the inside of the transmission case. Push the PTO shift arm ball

guide into the transmission case. Push the PTO shift arm ball guide with

the PTO shift arm. Install the PTO cotter to the PTO shift arm. Align

the PTO cotter to the groove of the PTO shifter.

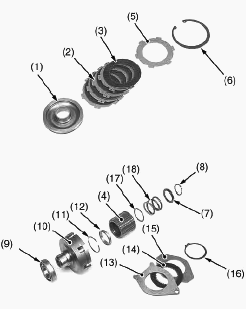

PTO Clutch Case

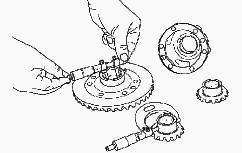

1 - Ball Bearing, 2 - PTO Clutch Case, 3 - Brake Plate 4, 4 - Brake

Plate 2, 5 - PTO Clutch Shaft, 6 - Thrust Bearing, 7 - PTO Shifter, 8 -

25T Mid PTO-gear, 9 - Clutch Disc, 10 - Clutch Plate

Remove the external circlip from the spline boss. Remove the internal

circlip from the PTO clutch case. Remove the clutch discs and the clutch

plates from the PTO clutch case. Remove the ball bearing from the PTO

clutch case with a puller. When removing the circlip, use an adequate

size circlip pliers.

PTO Clutch Spring

Set the PTO clutch spring compressor to the PTO clutch case. Tighten the

nut and remove the external circlip. Remove the spring collar and the

PTO clutch spring.

PTO Clutch Discs and Brake

1.Clutch Piston, 2.Clutch Plate, 3.Clutch Disc, 4.Spline Boss,

5.Pressure Plate, 6.Internal Circlip, 7.Spring Collar, 8.External

Circlip, 9.Ball Bearing, 10.PTO Clutch Case, 11.Circlip, 12.Ball

Bearing, 13.Brake Plate, 14.PTO Brake Disc, 15.Brake Plate, 16.External

Circlip, 17.Bearing Collar, 18.Spring

After removing the inner circlip from the PTO clutch case, remove the

pressure plate. Remove the clutch discs and clutch plates. Remove the

external circlip from the spline boss. Remove the brake plate, the brake

discs and the brake plate. After removing the external circlip and the

spring.

Spline Boss Circlip

Push the circlip with a small screw driver through the small hole of the

spline boss. Lift the circlip with a screw driver not to damage it.

Install the circlip holding it by hands.

PTO Shaft

1 - PTO Clutch Shaft, 2 - Ball Bearing, 3 - 26T Mid-gear, 4 - PTO

Shifter, 5 - Seal Ring, 6 - Thrust Bearing, 7 - Needle Bearing, 8 -

Collar

Remove the thrust bearing and the PTO shifter not to damage the seal

rings located at the PTO shaft front side. Remove the seal rings located

at the PTO shaft rear side. Remove the ball bearing with a puller. Check

all seal rings. If the seal ring is damaged, replace it. Check the

direction of the thrust bearing and install the thrust bearing.

Mid-Gear and Idle Shaft

Remove the idle shaft from the transmission case using a screw driver.

Remove the mid-gear from the transmission case. Remove the ball bearings

and the internal circlip from the mid-gear. Install the internal circlip

to the inner groove of the mid-gear.

Mid-PTO Case and Mid-Gear Shaft

Remove the mid-PTO case mounting bolts. Remove the mid-PTO case from the

transmission case. Remove the mid-PTO oil seal from the mid-PTO case

using a screw driver not to damage it. Remove the internal circlip.

Remove the mid-gear shaft with the ball bearings. Remove the bearing

from the mid-gear shaft. If the mid-PTO oil seal is damaged, worn or

scratched, replace it. Apply grease to the lip and the outer of the

mid-PTO oil seal. After installing the mid-gear, apply liquid gasket to

the joint surface of transmission case and the mid-PTO case.

Kubota B2601, B26, B26TLB HST - Transmission

Case Servicing

Checking Bearing

Hold the inner race, and push and pull the outer race in all directions

to check for wear and roughness. Apply transmission fluid to the

bearing, and hold the inner race. Then, turn the outer race to check

rotation. If there is any problem, replace it. Clutch disc wear - 1.70

to 1.90 mm / 0.067 to 0.075 in. Steel plate wear - 1.15 to 1.25 mm /

0.045 to 0.049 in. Pressure plate wear - 1.95 to 2.05 mm / 0.0768 to

0.0807 in. Piston / return spring free length - 44.0 mm / 1.73 in.

Piston return spring tension: 638.7 N / 26 mm, 143.6 lbf / 1.02 in.

Clearance between Shift Fork and Shift Gear

Groove

Insert the fork into the shift gear groove and measure the clearance

with a feeler gauge. If the clearance exceeds the allowable limit,

replace it.

Differential Gear

Clearance between Differential Case (Spiral

Bevel Gear) and Differential Side Gear

Measure the differential side gear boss O.D. with an outside micrometer.

Measure the differential case I.D. and the spiral bevel gear I.D. with

an inside micrometer, and calculate the clearance. If the clearance

exceeds the allowable limit, replace damage parts.

Clearance between Differential Pinion Shaft

and Differential Pinion

Measure the differential pinion shaft O.D. with an outside micrometer.

Measure the differential pinion I.D. with an inside micrometer, and

calculate the clearance. If the clearance exceeds the allowable limit,

replace damage parts. Clearance between shift fork and shift gear groove

- 0.10 to 0.35 mm / 0.004 to 0.014 in. Clearance between differential

case (spiral bevel gear) and differential side gear - 0.025 to 0.066 mm

/ 0.0010 to 0.0026 in. Differential case I.D - 32.000 to 32.025 mm /

1.2598 to 1.2608 in. Spiral bevel gear I.D - 32.000 to 32.025 mm /

1.2598 to 1.2608 in. Differential side gear O.D - 31.959 to 31.975 mm /

1.2582 to 1.2589 in. Clearance between differential pinion shaft and

differential pinion - 0.048 to 0.084 mm / 0.0019 to 0.0033 in.

Differential pinion I.D - 16.032 to 16.050 mm / 0.63119 to 0.63188 in.

Differential pinion shaft O.D - 15.966 to 15.984 mm / 0.62859 to 0.62929

in.

Backlash between Differential Pinion and

Differential Side Gear

Secure the differential case with a vise. Set the dial indicator (lever

type) with its finger on the tooth of the differential side gear. Press

differential pinion and side gear against the differential case. Hold

the differential pinion and move the differential side gear to measure

the backlash. If the backlash exceeds the allowable limit, adjust with

differential side gear shims. Thickness of shims: 0.80 mm (0.0315 in.),

1.00 mm (0.0394 in.), 1.20 mm (0.0472 in.). Backlash between

differential pinion and differential side gear 0.1 to 0.3 mm / 0.004 to

0.0012 in.

Backlash between Spiral Bevel Pinion and

Spiral Bevel Gear

Set the dial indicator (lever type) with its finger on the end of spiral

bevel pinion. Move the spiral bevel pinion back and forth to each end

and measure the side clearance. If the side clearance exceeds the

factory specifications, adjust with the shims at front end of spiral

bevel pinion. Set the dial indicator (lever type) with its finger on the

tooth surface of bevel gear. Measure the backlash by fixing the spiral

bevel pinion and moving bevel gear by hand. If the backlash exceeds the

factory specifications, adjust with the shims at bearing holder and

differential case. Adjust the backlash properly by repeating the above

procedure. Movement of spiral bevel pinion shaft at shaft directions - 0

mm / 0 in. Backlash between spiral bevel pinion and spiral bevel gear -

0.10 to 0.30 mm / 0.0039 to 0.0012 in.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605