________________________________________________________________________________

Kubota B3030, B3350, B3150, B7800 - Engine Maintenance

B3030, B3350, B3150, B7800 tractors are equipped with a Kubota V1505

4-cylinder diesel engine.

Kubota B3030, B3350, B3150, B7800 - Separating

Engine

Bonnet, Front Grille, Side Covers and ROPS

Open the bonnet. Remove the pin and the plain washer. Remove the wiring

harness from the bonnet. Remove the hood. Remove the front grille and

the side covers. Remove the ROPS. Install the bush to the bonnet

securely. Install the hood. Don't damage the bonnet when installing it.

Battery

Disconnect the battery negative cable first. Disconnect the battery

positive cable second. Remove the battery. Remove the front hitch.

Hydraulic Hoses from Power Steering Cylinder

Disconnect the hydraulic hoses from the power steering cylinder.

Removing the snap pin and disconnect the bi-speed rod.

Steering Wheel, Meter Panel, Shuttle Lever and

Panel Lower Cover

Remove the steering wheel cap. Remove the steering wheel mounting nut.

Remove the steering wheel with a steering wheel puller. Remove the

accelerator lever grip and the steering boot. Disconnect the hour meter

cable and wiring harness connectors. Remove the meter panel not to

damage with the steering shaft. Remove the shuttle lever. Remove the

panel lower cover. Tighten the steering wheel mounting nut securely.

Fuel Tank

Disconnect the leads from the fuel tank. Disconnect the overflow hoses

from the fuel tank. Remove the shutter plate and the fuel tank.

Key Stop Solenoid and Hydraulic Delivery Pipe

Remove the key stop solenoid connector. Remove the engine stop solenoid

using a small size ratchet handle, the extension joint, the universal

joint and the thinner socket (10 mm). Remove the hydraulic delivery pipe

mounting nuts. Slide the hydraulic delivery pipe. Loosen the hose band.

Disconnect the suction hose from the hydraulic pump. Apply the liquid

gasket to the joint face of the key stop solenoid and the engine.

Final Separating Engine

Reinstall the rear tires. Support the transmission with a disassembling

stand. Hook the engine with a hoist. Place the disassembling stand under

the main frame. Disconnect the power steering hoses. Loose the hydraulic

inlet hose band. Disconnect the hydraulic inlet hose from the hydraulic

pump. Disconnect the hydraulic delivery pipe from the hydraulic pump.

Disconnect the wiring leads from the alternator, the engine oil pressure

switch and the starter motor. Disconnect the wiring harness and the

power steering hoses from the engine body. Remove the docking bolts

between the engine and the front case. Align the spline between the

front wheel drive shaft and the universal joint securely. Tighten the

docking bolts between the engine and the front case securely. Remove the

exhaust pipe. Disconnect the radiator hoses. Remove the front axle frame

mounting bolts. Separate the front axle from the engine.

Kubota B3030, B3350, B3150, B7800 - Engine

Components

Compression Pressure

Run the engine until it is warmed up. Stop the engine and disconnect the

2P connector from the engine stop solenoid. Remove the air cleaner, the

muffler and all injection nozzles. Set a compression tester with the

adaptor to the nozzle hole. While cranking the engine with the starter,

measure the compression pressure. Repeat steps 4 through 6 for each

cylinder. If the measurement is below the allowable limit, apply a small

amount of oil to the cylinder wall through the nozzle hole and measure

the compression pressure again. If the compression pressure is still

less than the allowable limit, check the top clearance, valve and

cylinder head. If the compression pressure increases after applying oil,

check the cylinder wall and piston rings. Check the compression pressure

with the specified valve clearance. Always use a fully charged battery

for performing this test. Variances in cylinder compression values

should be under 10 0/0. Compression pressure - 2.84 to 3.24 MPa (412 to

469 psi). Allowable limit - 2.26 MPa (327 psi).

Top Clearance

Remove the cylinder head. (Do not attempt to remove the cylinder head

gasket.). Move the piston up, and stick a strip of fuse (1.5 mm dia./

0.059 in. dia.), 5 to 7 mm long / 0.197 to 0.276 in. long) on the piston

head at three positions with grease so as to avoid the intake and

exhaust valves and the combustion chamber ports. Lower the piston, and

install the cylinder head and tighten the cylinder head screws to the

specified torque. Turn the crankshaft until the piston exceeds its top

dead center. Remove the cylinder head, and measure the thickness of the

squeezed fuses. If the measurement is not within the factory

specifications, check the oil clearance between the crankpin and

crankpin bearing and between the piston pin and small end bushing. After

checking the top clearance, be sure to assemble the cylinder head with a

new cylinder head gasket. Top clearance - 0.55 to 0.70 mm (0.0217 to

0.0276 in).

Valve Clearance

Valve clearance must be checked and adjusted when engine is cold. Remove

the head cover, the glow plugs and the timing window cover on the clutch

housing. Align the "1TC" mark line on the flywheel and center of timing

window so that the No. 1 piston comes to the compression or overlap top

dead center. Check the following valve clearance marked using a feeler

gauge. If the clearance is not within the factory specifications, adjust

with the adjusting screw. Valve Clearance - 0.145 to 0.185 mm (0.0057 to

0.0073 in).

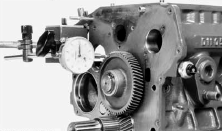

Kubota V1505 - Timing Gear

Set a dial indicator (lever type) with its tip on the gear tooth. Move

the gear to measure the backlash, holding its mating gear. If the

backlash exceeds the allowable limit, check the oil clearance of the

shafts and the gear. If the oil clearance is proper, replace the gear.

Backlash between idle gear 1 and crank gear 0.032 to 0.115 mm / 0.00120

to 0.00453 in.

Backlash between idle gear 1 and cam gear 0.036 to 0.114 mm / 0.00142 to

0.00449 in.

Backlash between idle gear 1 and injection pump gear 0.034 to 0.116 mm /

0.00134 to 0.00457 in.

Backlash between idle gear 1 and idle gear 2 0.033 to 0.117 mm / 0.0013

to 0.0046 in.

Backlash between idle gear 2 and governor gear 0.030 to 0.117 mm /

0.00118 to 0.00461 in.

Idle Gear Side Clearance - Set a dial indicator with its tip on the idle

gear. Measure the side clearance by moving the idle gear to the front

and rear. If the measurement exceeds the allowable limit, replace the

idle gear collar. Idle gear side clearance - 0.050 to 0.150 mm (0.0020

to 0.0059 in). Idle Gear 2 Side Clearance - Set a dial indicator with

its tip on the idle gear. Measure the side clearance by moving the idle

gear to the front and rear. If the measurement exceeds the allowable

limit, replace the idle gear collar. Idle gear 2 side clearance - 0.20

to 0.51 mm (0.0079 to 0.0201 in).

Cylinder Wear

Measure the I.D. of the cylinder at the six positions with a cylinder

gauge to find the maximum and minimum I.D.'s. Get the difference

(Maximum wear) between the maximum and the minimum I.D.'s. If the wear

exceeds the allowable limit, bore and hone to the oversize dimension.

Visually check the cylinder wall for scratches. If deep scratches are

found, the cylinder should be bored. Cylinder liner I.D. - 78.000 to

78.019 mm / 3.01086 to 3.07161 in.

Kubota B3030, B3350, B3150, B7800 -

Lubricating System

Changing Engine Oil

Start and warm up the engine for approx. 5 minutes. Place an oil pan

underneath the engine. To drain the used oil, remove the drain plug at

the bottom of the engine and drain the oil completely. Screw in the

drain plug. Fill new oil up to upper line on the dipstick. When using an

oil of different manufacture or viscosity from the previous one, remove

all of the old oil. Never mix two different types of oil.

Replacing Engine Oil Filter Cartridge

Remove the oil filter cartridge with the filter wrench. Apply a slight

coat of oil onto the cartridge gasket. To install the new cartridge,

screw it in by hand. Over tightening may cause deformation of rubber

gasket. After the new cartridge has been replaced, the engine oil

normally decrease a little. Thus see that the engine oil does not leak

through the seal and be sure to read the oil level on the dipstick.

Then, replenish the engine oil up to the specified level.

Engine Oil Pressure

Remove the engine oil pressure switch, and set a oil pressure tester.

Start the engine. After warming up, measure the oil pressure of both

idling and rated speeds.

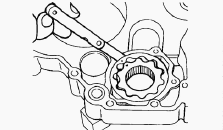

Oil Pump

Rotor Lobe Clearance - Measure the clearance between lobes of the inner

rotor and the outer rotor with a feeler gauge. If the clearance exceeds

the factory specifications, replace the oil pump rotor assembly.

Clearance between Outer Rotor and Pump Body - Measure the clearance

between the outer rotor and the pump body with a feeler gauge. If the

clearance exceeds the factory specifications, replace the oil pump rotor

assembly. Clearance between Rotor and Cover - Put a strip of plastigage

onto the rotor face with grease. Install the cover and tighten the

screws. Remove the cover carefully, and measure the amount of the

flattening with the scale and get the clearance. If the clearance

exceeds the factory specifications, replace oil pump rotor assembly.

Kubota B3030, B3350, B3150, B7800 - Cooling

System

Fan Belt

Fan Belt Tension - Measure the deflection, depressing the belt halfway

between the fan drive pulley and alternator pulley at specified force

(98 N, 10 kgf, 22 Ibs). If the measurement is not within the factory

specifications, loosen the alternator mounting screws and relocate the

alternator to adjust. Deflection - 7 to 9 mm / 0.28 to 0.35 in. Fan Belt

Damage and Wear - Check the fan belt for damage. If the fan belt is

damaged, replace it. Check if the fan belt is worn and sunk in the

pulley groove. If the fan belt is nearly worn out and deeply sunk in the

pulley groove, replace it.

Radiator

Radiator Water Leakage - Pour a specified amount of water into the

radiator. Set a radiator tester and raise the water pressure to the

specified pressure. Check the radiator for water leaks. For water leak

from the pinhole, replace the radiator or repair with the radiator

cement. When water leak is excessive, replace the radiator. Radiator Cap

Air Leakage - Set a radiator tester on the radiator cap. Apply the

specified pressure (88 kPa, 0.9 kgf/cm2, 13 psi), and measure the time

for the pressure to fall to 59 kPa (0.6 kgf/cm2, 9 psi). If the

measurement is less than the factory specification, replace the radiator

cap. Checking Radiator Hose and Hose Clamp - Check to see if radiator

hoses are properly fixed every 200 hours of operation or six months,

whichever comes first. If hose clamps are loose or water leaks, tighten

bands securely. Replace hoses and tighten hose clamps securely, if

radiator hoses are swollen, hardened or cracked. Replace hoses and hose

clamps every 2 years or earlier if checked and found that hoses are

swollen, hardened or cracked.

Flush Cooling System and Changing Coolant

Stop the engine and let cool down. To drain the coolant, open the

radiator drain cock, and remove radiator cap. The radiator cap must be

removed to completely drain the coolant. After all coolant is drained,

close the drain plug. Fill with clean water and cooling system cleaner.

Follow directions of the cleaner instruction. After flushing, fill with

clean water and anti-freeze until the coolant level is just below the

port. Start and operate the engine for few minutes. Stop the engine.

Check coolant level and add coolant if necessary. Install the radiator

cap securely.

Thermostat Assembly

Remove the thermostat cover mounting screws, and remove the thermostat

cover. Remove the thermostat assembly. Apply a liquid gasket only at the

thermostat cover side of the gasket.

Water Pump Assembly

Loosen the alternator mounting bolts, and remove the fan belt. Remove

the fan and fan pulley. Remove the water pump assembly from the gear

case cover. Remove the water pump flange. Press out the water pump shaft

with the impeller on it. Remove the impeller from the water pump shaft.

Remove the mechanical seal. Apply a liquid gasket to the both sides of

gasket. Replace the mechanical seal with new one.

Kubota B3030, B3350, B3150, B7800 - Fuel

System

Cleaning Air Cleaner Element

Remove the air cleaner cover and primary element. Clean the primary

element if: When dry dust adheres to the element, blow compressed air

from the inside turning the element. Pressure of compressed air must be

under 686 kPa (7 kgf/cm2, 99 psi). When carbon or oil adheres to the

element, soak the element in detergent for 15 minutes then wash it

several times in water, rinse with clean water and dry it naturally.

After element is fully dried, inspect inside of the element with a light

and check if it is damaged or not. When replacing the air cleaner

primary element, replace the secondary element as well: Once a year or

after every six times of cleaning, whichever comes first.

Cleaning Fuel Filter

This job should not be done in the field, but in a clean place. Loosen

and remove the fuel filter bowl, and rinse the inside with kerosene.

Take out the filter element and dip it in the kerosene to rinse. After

cleaning, reassemble the fuel filter, keeping out dust and dirt. Bleed

the fuel system. When the fuel filter bowl has been removed, fuel stops

flowing from the fuel tank. If the fuel tank is almost full, however,

the fuel will flow back from the fuel return pipe to the fuel filter.

Before the above checking, make sure the fuel tank is less than

half-full.

Checking Fuel Line

Check to see that all line and hose clamps are tight and not damaged. If

hoses and clamps are found worn or damaged, replace or repair them at

once. The fuel line is made of rubber and ages regardless of period of

service. Replace the fuel pipe together with the clamp every two years

and securely tighten. However if the fuel pipe and clamp are found

damaged or deteriorated earlier than two years, then change or remedy.

After the fuel line and clamp have been changed, bleed the fuel system.

Checking Intake Air Line

Check to see that hoses and hose clamps are tight and not damaged. If

hoses and clamps are found worn or damaged, replace or repair them at

once.

Kubota V1505 - Bleeding Fuel System

Air must removed: When the fuel filter or lines are removed. When tank

is completely empty. After the tractor has not been used for a long

period of time. Bleeding procedure is as follows: Fill the fuel tank

with fuel. Start the engine and run for about 30 seconds, and then stop

the engine.

Injection Timing

Remove the injection pipes. Remove the engine stop solenoid, push in the

control rack of the injection pump by 5 mm (0.2 in.) and hold it at that

position. Turn the flywheel counterclockwise (facing the flywheel) until

fuel flows from the delivery valve holder. Continue to turn the flywheel

slowly, and stop it as soon as the fuel level at the tip of the delivery

valve holder begins to increase. Check to see if the timing angle lines

on the flywheel is aligned with the alignment mark. If the injection

timing is out of adjustment, readjust the timing with shims.

Fuel Tightness of Pump Element

Remove the engine stop solenoid. Remove the injection pipes and glow

plugs. Install the injection pump pressure tester to the injection pump.

Set the speed control lever to the maximum speed position. Turn the

flywheel ten times or more to increase the pressure. If the pressure can

not reach the allowable limit, replace the pump element or injection

pump assembly. Fuel tightness of pump element - 14.7 MPa (2133 psi).

Fuel Valve

Fuel Tightness of Delivery Valve - Remove the engine stop solenoid.

Remove the injection pipes and glow plugs. Set a pressure tester to the

fuel injection pump. Turn the flywheel and raise the pressure to approx.

14.7 MPa (150 kgf/cm2, 2133 psi). Now turn the flywheel back about half

a turn (to keep the plunger free). Maintain the flywheel at this

position and clock the time taken for the pressure to drop from 14.7 to

13.7 MPa (from 150 to 140 kgf/cm2, from 2133 to 1990 psi). Measure the

time needed to decrease the pressure from 14.7 to 13.7 MPa (from 150 to

140 kgflcm2 , from 2133 to 1990 psi). If the measurement is less than

allowable limit, replace the delivery valve. Valve Seat Tightness - Set

the injection nozzle to a nozzle tester. Raise the fuel pressure, and

keep at 12.75 MPa (130 kgflcm2, 1849 psi) for 10 seconds. If any fuel

leak is found, replace the nozzle piece.

Kubota B3030, B3350, B3150, B7800 - V1505

Engine Problems

Low compression

Low cylinder compression will result in insufficient heat being

generated to ignite the fuel and cause hard starting. This is more of a

problem with Kubota V1505 engines. A cold engine compression test should

be performed. Compression should be between 20 to 35 bars, although it’s

more important to have equal pressures, no more than ± 3 bar (50 psi)

between cylinders. Anything below this will cause starting problems.

Low fuel pressure

Low fuel pressure could be either poor fuel supply to the injectors or

the injectors are worn and not holding the fuel pressure. The best way

to diagnose this is to look at the fuel supply in 3 areas. Low pressure

supply from the tank to the fuel injection pump. The supply from the

tank to the injection pump via the lift pump should be about 2 to 5 bar

(30 to 70 psi). Fuel is delivered from the injection pump to the

injectors at approx. 175 atmos. Once the fuel is delivered to the

injectors at the relevant pressure it must lift the needle and spray

finely atomized fuel into the cylinder.

Low cranking speed or Faulty battery

If the Kubota B3030, B3350, B3150, B7800 engine turns over too slowly,

the injection pump can’t generate enough fuel pressure, and the piston

speed will be too low to generate a high enough air temperature to

initiate combustion, causing hard starting problems. This is usually in

the colder months especially if the battery is run down, the tractor has

been left sitting or if the battery terminals are corroded. The battery

should be kept fully charged and all connections in good order.

Thermostart or Glow plugs faulty

The engine relies on the thermostart or glow plugs (If fitted), to heat

the air in the combustion chamber while the engine is being cranked.

Problems in this area will cause starting problems, uneven running and

white smoke when the engine is cold.

Poor or low fuel supply

If there isn’t enough fuel in the tank or there’s a problem with the

fuel pipes being split or kinked the fuel supply can be restricted. The

fuel tank cap breather can sometimes be blocked causing a vacuum in the

tank.

Contaminated fuel

Poor quality fuel and water in the fuel can cause injection pump and

injector failure. Filters and sediment bowls must be changed and drained

regularly. Diesel contaminated with other fuels is a fairly common

problem. Most pump and injectors failures are due to fuel related

issues.

Kubota B3030, B3350, B3150, B7800 - Air in

fuel

Loose or faulty fuel pipe connections can allow air to be drawn into the

system, but dirty fuel filters or a faulty filter head assembly may also

cause fuel supply issues and hard starting. The bolt with the

restriction hole must be in place between the leak off pipe and the

filter head to build up back pressure in the injection pump, the leak

off return pipe must go the bottom of the fuel tank.

Fuel filter or fuel pipes blocked

Dirty fuel containers/tanks/fuel can cause filters in the tank, lift

pump and main filter to become blocked. They must be cleaned or changed

on a regular basis.

Faulty injectors

The greatest cause of injector failure is due to the injectors having

worn needles and nozzles or a build up of carbon. This can cause a poor

spray pattern or fuel Dribble. This results in hard or poor starting.

The injectors should be serviced or replaced at regular intervals.

Diesel additives can help to clean injectors and fuel systems. Over time

the injector springs can weaken.

Fuel pump faulty

Known faults in the pump are: Split diaphragms and leaking, loose or

displaced non-return valves. If the pump is faulty there will be a Low

fuel pressure problem, a split diaphragm will dilute the engine oil with

diesel.

Blocked or Dirty air cleaner

A blocked or dirty air cleaner element can severely restrict air flow to

the Kubota V1505 engine. Whether it’s an oil bath or dry element air

cleaner it must be serviced at regular intervals.

Black Smoke

Faulty injectors. Faulty injector pump. Dirty or blocked air cleaner.

Turbocharger faulty. Problems within the cylinder head or inlet valves

not seating due to a build up of carbon. Over fueling.

White Smoke

Injection pump timing incorrect. Fuel starvation to the injection pump.

Low engine compression. Water in the fuel. Water entering the combustion

chamber. Faulty head gaskets and cracked cylinder liners and heads are a

common cause of water entering the cylinder.

Blue Smoke

Worn cylinder liners or piston rings. Piston rings sticking. Faulty

valves stem seals. Engine over full with engine oil. Dilution of the

engine oil with fuel. Wrong Grade of oil, Too thin. The engine not being

Worked hard enough, all diesel engines need hard work otherwise the

cylinder bores can become Glazed.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES INSTRUCTIONS

INSTRUCTIONS PROBLEMS

PROBLEMS B2320

B2320 B2630

B2630 B2920

B2920 B3300SU

B3300SU BX2360

BX2360 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 BX2660

BX2660 L2501

L2501 L3240

L3240 L3540

L3540 L3940

L3940 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 L4400

L4400 L4600

L4600 L5040

L5040 L5740

L5740 MX4700

MX4700 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 B2710

B2710 BX23S

BX23S B3350

B3350 BX1880

BX1880 L4701

L4701 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 M100GX

M100GX M135GX

M135GX M6040

M6040 M8540

M8540 M95X

M95X LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 M5-091

M5-091 BX2680

BX2680 MX5200

MX5200 BX2380

BX2380 L3901

L3901 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605