________________________________________________________________________________

Kubota B3150, B3200, B3350 - Transmission and PTO

Kubota B3150, B3200, B3350 Transmission -

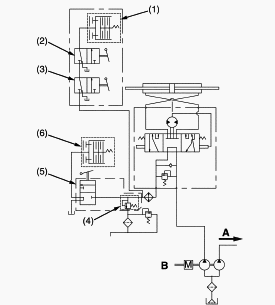

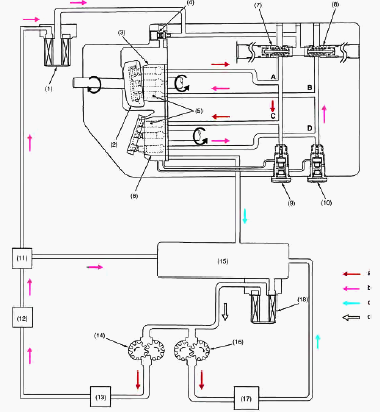

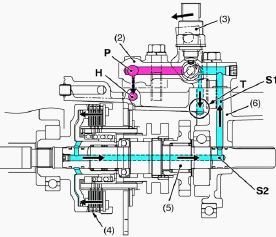

Hydraulic Circuit

Hydrostatic Transmission

1 - Bi-Speed Turn Clutch, 2 - Bi-Speed Turn Valve 2, 3 - Bi-Speed Turn

Valve 1, 4 - Regulating Valve, 5 - Independent PTO Valve, 6 -

Independent PTO Clutch, A - To 3-Points Hitch, B - HST

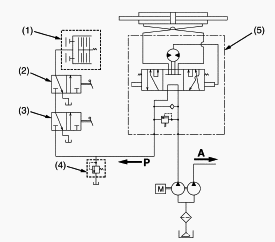

Manual Transmission

1 - Bi-Speed Turn Clutch, 2 - Bi-Speed Turn Valve 2, 3 - Bi-Speed Turn

Valve 1, 4 - Regulating Valve, 5 - Power Steering Controller, A - To

3-Points Hitch, P - From Pump Port

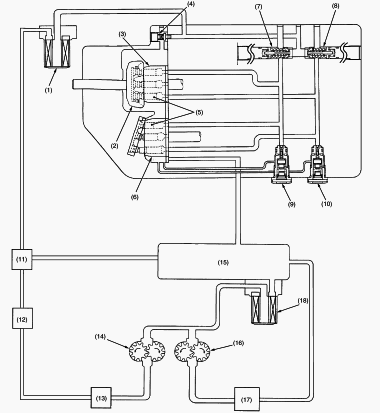

Kubota B3150, B3200, B3350 Transmission - Oil

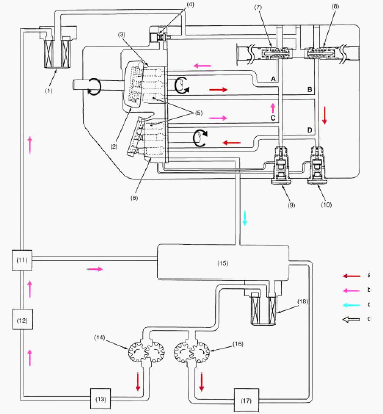

Flow And Valves

1 - Oil Filter Cartridge (for HST), 2 - Swashplate, 3 - Cylinder Block

(for Pump), 4 - Charge Relief Valve, 5 - Piston, 6 - Cylinder Block (for

Motor), 7 - Check and High Pressure Relief Valve (for Forward), 8 -

Check and High Pressure Relief Valve (for Reverse), 9 - Neutral Valve

(for Forward), 10 - Neutral Valve (for Reverse), 11 - Independent PTO

Control Valve, 12 - Oil Cooler, 13 - Power Steering, 14 - Hydraulic Pump

(for Power Steering, Independent PTO, HST), 15 - Oil Tank, 16 -

Hydraulic Pump (for 3-points Hitch), 17 - Hydraulic Control Valve (for

3-points Hitch), 18 - Oil Filter Cartridge

The pump and the motor are joined in a closed hydraulic circuit. Most of

oil circulates with in the main oil circuit. A little oil lubricates and

oozes out from the clearance between the moving parts in the case. Then

oil in the main oil circuit of the HST needs to be supplied a want. So

all of oil fed from hydraulic pump flow to hydraulic transmission for

charging and cooling. The charge oil aids smooth operation of pistons

for pump and motor. The charge oil passed to charge relief valve port.

The rest of oil passed through the charge relief valve into the HST

housing. And overflow oil from HST housing return to the transmission

case.

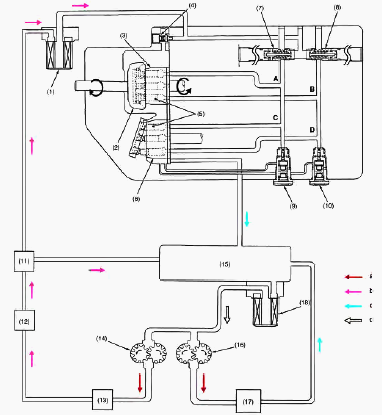

Neutral

1 - Oil Filter Cartridge (for HST), 2 -

Swashplate, 3 - Cylinder Block (for Pump), 4 - Charge Relief Valve, 5 -

Piston, 6 - Cylinder Block (for Motor), 7 - Check and High Pressure

Relief Valve (for Forward), 8 - Check and High Pressure Relief Valve

(for Reverse), 9 - Neutral Valve (for Forward), 10 - Neutral Valve (for

Reverse), 11 - Independent PTO Control Valve, 12 - Oil Cooler, 13 -

Power Steering, 14 - Hydraulic Pump (for Power Steering, Independent

PTO, HST), 15 - Oil Tank, 16 - Hydraulic Pump (for 3-points Hitch), 17 -

Hydraulic Control Valve (for 3-points Hitch), 18 - Oil Filter Cartridge,

A - Pump A Port, B - Pump B Port, C - Motor C Port, D - Motor D Port, a

- High Pressure Oil, b - Low Pressure Oil, c - Free Oil, d - Suction Oil

When the speed control pedal (HST pedal) is in "Neutral", the variable

swashplate is right-angles to the pump pistons. And the pump pistons

only rotate with cylinder block (pump) without reciprocating. Since the

oil is not being pumped to the motor, the cylinder block (motor) is

stationary. And the output shaft does not rotate.

Forward

1 - Oil Filter Cartridge (for HST), 2 -

Swashplate, 3 - Cylinder Block (for Pump), 4 - Charge Relief Valve, 5 -

Piston, 6 - Cylinder Block (for Motor), 7 - Check and High Pressure

Relief Valve (for Forward), 8 - Check and High Pressure Relief Valve

(for Reverse), 9 - Neutral Valve (for Forward), 10 - Neutral Valve (for

Reverse), 11 - Independent PTO Control Valve, 12 - Oil Cooler, 13 -

Power Steering, 14 - Hydraulic Pump (for Power Steering, Independent

PTO, HST), 15 - Oil Tank, 16 - Hydraulic Pump (for 3-points Hitch), 17 -

Hydraulic Control Valve (for 3-points Hitch), 18 - Oil Filter Cartridge,

A - Pump A Port, B - Pump B Port, C - Motor C Port, D - Motor D Port, a

- High Pressure Oil, b - Low Pressure Oil, c - Free Oil, d - Suction Oil

When the speed control pedal (HST pedal) is stepped on and set to

"Forward", the variable swashplate is tilted as shown in figure above.

As the pump cylinder block rotates with the input shaft, oil is forced

out of pump port A at high pressure. As pressure oil from the pump

cylinder block enters to motor port C, the pistons, which align with

port C, are pushed against the swashplate and slide down the inclined

surface. Then the output shaft rotates with the motor cylinder block.

This drives the machine forward and the angle of pump swashplate

determines the output speed. As the motor cylinder block continues to

rotate, oil is forced out of motor port D at low pressure and retunes to

the pump port B.

Reverse

1 - Oil Filter Cartridge (for Hydrostatic

Transmission), 2 - Swashplate, 3 - Cylinder Block (for Pump), 4 - Charge

Relief Valve, 5 - Piston, 6 - Cylinder Block (for Motor), 7 - Check and

High Pressure Relief Valve (for Forward), 8 - Check and High Pressure

Relief Valve (for Reverse), 9 - Neutral Valve (for Forward), 10 -

Neutral Valve (for Reverse), 11 - Independent PTO Control Valve, 12 -

Oil Cooler, 13 - Power Steering, 14 - Hydraulic Pump (for Power

Steering, Independent PTO, HST), 15 - Oil Tank, 16 - Hydraulic Pump (for

3-points Hitch), 17 - Hydraulic Control Valve (for 3-points Hitch), 18 -

Oil Filter Cartridge, A - Pump A Port, B - Pump B Port, C - Motor C

Port, D - Motor D Port, a - High Pressure Oil, b - Low Pressure Oil, c -

Free Oil, d - Suction Oil

When the speed control pedal (HST pedal) is stepped on and set to

"Reverse", the variable swashplate is tilted as shown in figure above.

As the pump cylinder block rotates with the input shaft, oil is forced

out of pump port B at high pressure. As pressure oil from the pump

cylinder block enters to motor port D, the pistons, which align with

port D, are pushed against the swashplate and slide down the inclined

surface. Then the output shaft rotates with the motor cylinder block.

This drives the machine reward and the angle of pump swashplate

determines the output speed. As the motor cylinder block continues to

rotate, oil is forced out of motor port C at low pressure and retunes to

the pump port A.

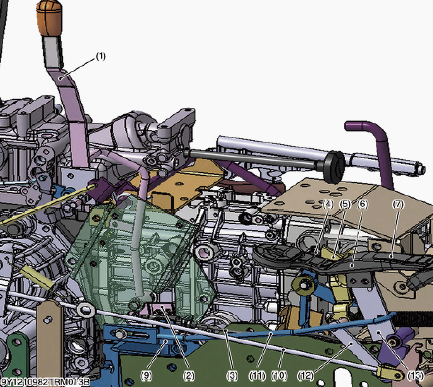

Kubota B3150, B3200, B3350 Tractor -

Transmission Linkage

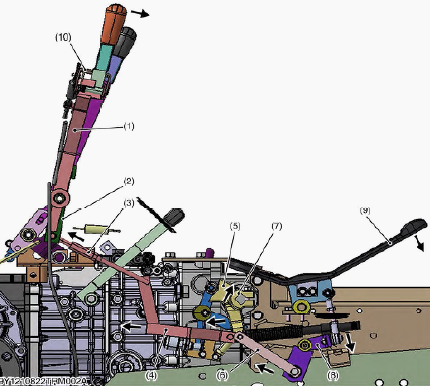

Cruise Control Linkage (Tractors with Cab)

1 - Cruise Control Lever, 2 - Cruise Link Lever, 3 - Cruise Rear Rod, 4

- Cruise Front Rod, 5 - Neutral Holder, 6 - HST Plate, 7 - Trunnion

Shaft, 8 - HST Lever, 9 - HST Pedal, 10 - Release Lever

Cruise control system mainly consists of cruise control lever holding

section and cruise control releasing section. When the cruise control

lever (1) is set to the desired position, the bottom end of the cruise

link lever (2) turns clockwise. The control lever (1) pulls the cruise

rear rod (3). The cruise rear rod (3) pulls the cruise front rod (4).

The cruise front rod (4) pulls the neutral holder (5). The HST plate (6)

is pulled by the cruise front rod (4). Since the neutral holder (5)

turns clockwise, the trunnion shaft (7) directly attached to the neutral

holder (5) turns clockwise. On the other hand, since the HST plate (6)

pulls the HST lever (8) and the HST pedal (9). The HST pedal (9) is

turned to the front side. On the other hand, since release lever (10)

engage with tooth of lever guide RH, the cruise control lever (1) is

held at the desired cruise position until the brake pedals will be

depressed by an operator.

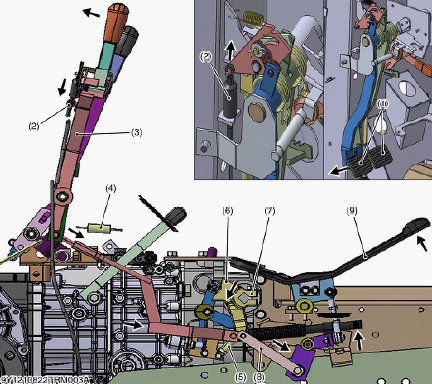

Cruise Control Release

1 - Brake Pedal, 2 - Cruise Cable, 3 - Cruise Control Lever, 4 - Return

Spring, 5 - Return Spring, 6 - Neutral Holder, 7 - Trunnion Shaft, 8 -

HST Plate, 9 - HST Pedal

Cruise control release is done by depressing the brake pedals (1). When

an operator depresses the brake pedal (1), the cruise cable (2) is

pulled by the brake pedals (1). At the time, the cruise control lever

(3) is free. The cruise control lever (3) is returned to "NEUTRAL"

position by the return spring (4). On the other hand, the return spring

(5) pulls the neutral holder (6). The neutral holder (6) and the

trunnion shaft (7) turns counterclockwise. Since the neutral holder (6)

is connected to the HST plate (8), the HST plate (8) is pushed to the

front side. The HST plate (8) pushes the HST pedal (9) to return to

"NEUTRAL" position.

Cruise Control Linkage (ROPS Models)

1 - Cruise Control Lever, 2 - Cruise Lock 1, 3 - Release Wire, 4 -

Roller, 5 - Neutral Holder, 6 - Trunnion Shaft, 7 - HST Pedal, 8 - Brake

Pedal, 9 - Cruise Lock 2, 10 - Brake Rod, 11 - Cruise Rod, 12 - HST

Plate, 13 - Hydrostatic Transmission Lever

When depressing the HST pedal (7) to "Forward", the HST lever (13), the

cruise rod (11) and the cruise lock 2 (9) moves forward. And when the

cruise control lever (1) is set to the desired position, the cruise lock

1 (2) is locked to the cruise lock 2 (9) and travelling speed is held to

the desired speed.

When depressing the brake pedals, the release wire (3), the cruise

control lever (1) and the cruise lock 1 (2) moves back. And the cruise

lock 1 (2) release from the cruise lock 2 (9). Cruise lock is changed

from "ON" to "OFF" position. Since the cruise lock is kept "OFF", the

neutral holder turns counterclockwise, and the roller is returned to

"Neutral" position. The HST pedal (7) also returns to "Neutral" position

and the tractor stops.

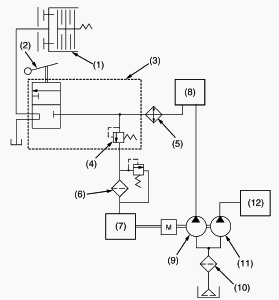

Kubota B3150, B3200, B3350 Tractor -

Independent PTO

Hydraulic Circuit

1 - PTO Clutch, 2 - Independent PTO Lever, 3 - Independent PTO Control

Valve, 4 - Relief Valve, 5 - Oil Cooler, 6 - Oil Filter Cartridge (for

HST), 7 - HST, 8 - Power Steering, 9 - Hydraulic Pump (for HST, Power

Steering and Independent PTO), 10 - Oil Filter Cartridge, 11 - Hydraulic

Pump (3-Points Hitch), 12 - 3-Points Hitch

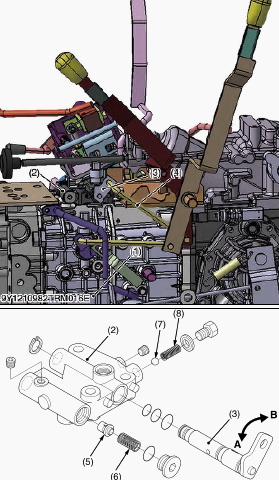

Independent PTO Control Valve

1 - Transmission Case, 2 - Independent PTO Control Valve, 3 - PTO Arm, 4

- Control Rod, 5 - Poppet, 6 - Spring, 7 - Ball, 8 - Spring, A - PTO arm

"OFF" position, B - PTO arm "ON" position

Independent PTO control valve (2) is located at transmission case (1).

The independent PTO control valve (2) consists of PTO arm (3), poppet

(5), ball (7) and etc. The PTO arm (3) is connected to control rod (4)

and the independent PTO lever. The PTO arm (3) is moved to "OFF" or "ON"

position by the independent PTO lever. Oil passage in the PTO arm (3) is

turned by the independent PTO lever. When the PTO arm (3) is moved to

"OFF" position, oil in the independent PTO control valve does not flow

to the oil passage. When the PTO arm (3) is moved to "ON" position, oil

in the independent PTO control valve flow to the oil passage. Poppet (5)

and spring (6) operate as a relief valve.

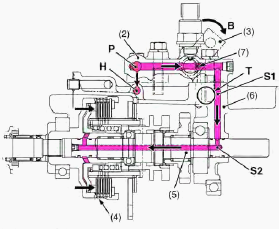

Independent PTO Lever Engaged

When the independent PTO lever is shifted to the "ENGAGED" position, the

PTO arm (3) is turned to "ON" position. Hydraulic oil from P port flows

through oil passage (7) of the PTO arm (3), oil passage S1 in the

transmission case (6) and oil passage S2 in the PTO clutch shaft (5) to

the PTO clutch (4). Since the piston of the PTO clutch (4) is pushed by

pressurized oil, clutch discs and clutch plates are pushed, and the PTO

clutch (4) is engaged.

2 - Independent PTO Control Valve, 3 - PTO Arm, 4 - PTO Clutch, 5 - PTO

Clutch Shaft, 6 - Transmission Case, 7 - Oil Passage (in the PTO Arm), P

- Pump Port, H - HST Port, T - Tank Port, S1 - Oil Passage (in the

Transmission Case), S2 - Oil Passage (in the PTO Clutch Shaft)

Independent PTO Lever Disengaged

When the independent PTO lever is shifted to the "DISENGAGED" position,

the PTO arm (3) is turned to "OFF" position. Hydraulic oil is stopped at

the PTO arm (3). This oil flows to the HST port. Oil in the PTO clutch

(4) and the PTO clutch shaft (5) drains through oil passage S2, S1 and T

port to the transmission case.

2 - Independent PTO Control Valve, 3 - PTO Arm, 4 - PTO Clutch, 5 - PTO

Clutch Shaft, 6 - Transmission Case, P - Pump Port, H - HST Port, T -

Tank Port, S1 - Oil Passage (in the Transmission Case), S2 - Oil Passage

(in the PTO Clutch Shaft)

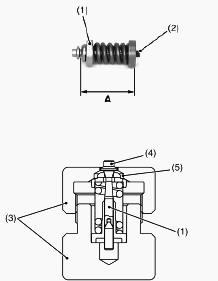

Kubota B3150, B3200, B3350 Transmission -

Checking And Adjusting

Readjustment of Relief Valve (HST doesn't work due to its

loose hex. socket head screw)

1 - Relief Valve Assembly, 2 - Hexagon Socket Head Screw, 3 - Relief

Valve Assembling Tool, 4 - Poppet, 5 - Valve Seat

Measure the pre-adjustment distance "A". Compress the spring of the

relief valve with a relief valve assembling tool (3). Then, find the

distance "A" by turning the poppet (4) with a screwdriver. The distance

"A" changes by about 0.5 mm (0.0197 in.) per one turn of the poppet (4).

Repeat the same operation a few times to find the distance "A" as it is

difficult to acquire at the first time. After finding the distance "A",

hold the setscrew (6) to a vice and fasten the hexagon socket head screw

(2) with specified torque. On this occasion, use a copper plate, etc.

for the vice jaws not to damage the setscrew (6). Install the relief

valve in the HST. Check the relief pressure. The distance "A" is for

refresh only. Make sure to check the relief pressure after readjustment.

The pressure changes by 1.47 MPa (213.3 psi) per 0.1 mm (0.0039 in.) in

distance "A". Relief valve readjusting pressure - 31.4 to 35.3 MPa (4551

to 5120 psi). Distance "A" - 37.9 to 38.0 mm (1.4921 to 1.4960 in).

Kubota B3150, B3200, B3350 - Hydrostatic

Transmission Service

Motor Shaft and Pump Shaft

Pull out the pump shaft from the HST housing case. Check the oil seal

surface the bearing surface and the bearing. If the shaft is rough or

grooved, replace it. If the bearing is worn, replace it. Motor Shaft -

Pull out the motor shaft from the HST housing case. Check the oil seal

surface the bearing surface and the bearing. If the shaft is rough or

grooved, replace it. If the bearing is worn, replace it.

Cylinder Block Bore and Pistons

Lift all the pistons gently with the retainer plate. Check the pistons

for their free movement in the cylinder block bores. If the piston or

the cylinder block bore is scored, replace cylinder block assembly. Do

not interchange pistons between pump and motor cylinder block. Pistons

and cylinder blocks are matched. Piston Slipper and Retainer Plate -

Check the slipper for flatness. If rounded, replace piston. Measure the

thickness of piston slipper. If the measurement is less than the

allowable limit, replace the piston. Check the lubricant hole for

clogging. Thickness of slipper - 3.00 mm (0.118 in).

Cylinder Block Face and Trunnion Shaft Cover

Check the polished face of cylinder block for scoring. If scored,

replace cylinder block assembly. Check the spring for breakage. If

broken, replace cylinder block assembly. Trunnion Shaft Cover - Check

the bearing for scratches and excessive wear. If worn or scored, replace

it. Check the oil seal and the O-rings for damage.

Valve Plate and Center Section Face

Check the engagement of the valve plate and the anchor pin. Pushing the

valve plate against the anchor pin, lift it to remove. Check the valve

plate for foreign particles. Clean the valve plate and dry with

compressed air. Check the valve plate for scratches, wear and erosion.

If worn or scored, replace it.

Thrust Plates and Bearing Surface

Check the thrust plate for scratches and excessive wear. If worn or

scored, replace it. Check the bearing surface of trunnion shaft

(swashplate) for scratches and excessive wear. If worn or scored,

replace it.

Center Section Oil Seals and Bearings

Check the oil seals for damage. Check the needle bearings for wear. If

the needle bearings and oil seals are worn, replace all seals and needle

bearings. After checking, coat the bearing with hydrostatic transmission

oil and the oil seal lip with grease.

Check and High Pressure Relief Valve

Check the valve plug and valve for scratches and damage. Check the valve

seat in the port block for damage. Check the spring for breakage and

wear. If anything unusual, replace the check and high pressure relief

valve assembly.

Neutral Valve and Charge Relief Valve

Check the holes of the valve body and the neutral valve for clogging. If

clogged, open hole with compressed air. Replace the O-rings and the

backup ring for scratches and damage. Check the springs for breakage and

wear. If the valve surface is scored, replace it. If anything is

unusual, replace it. Charge Relief Valve - Check the spring for breakage

and wear. If it is unusual, replace it.

Cylinder Block Bore and Pistons

Lift all the pistons gently with the retainer plate. Check the pistons

for their free movement in the cylinder block bores. If the piston or

the cylinder block bore is scored, replace cylinder block assembly.

Clearance between piston and bore - 0.02 mm (0.0008 in). Allowable limit

- 0.04 mm (0.0016 in).

Kubota B3150, B3200, B3350 - Independent PTO

Clutch Service

Bearing Check

Hold the inner race, and push and pull the outer race in all directions

to check for wear and roughness. Apply transmission fluid to the

bearing, and hold the inner race. Then, turn the outer race to check

rotation. If there is any defect, replace it.

Clutch Disc Wear

Measure the clutch disc thickness with vernier calipers. If the

thickness is less than the allowable limit, replace it. Clutch disc wear

- 1.70 to 1.90 mm (0.067 to 0.075 in). Allowable limit - 1.55 mm (0.061

in).

Steel Plate and Pressure Plate Wear

Measure the steel plate thickness with vernier calipers. Measure the

pressure plate thickness with vernier calipers. If the thickness is less

than the allowable limit, replace. Steel plate wear (without hole) -

0.95 to 1.05 mm (0.0374 to 0.0413 in). Allowable limit - 0.8 mm (0.031

in). Steel plate wear (with holes, with holes and rubber plugs) - 1.15

to 1.25 mm (0.045 to 0.049 in). Allowable limit - 1.10 mm (0.043 in).

Pressure plate wear - 1.95 to 2.05 mm (0.0768 to 0.0807 in). Allowable

limit - 1.8 mm (0.071 in).

Piston Return Spring Free Length and Tension

Measure the free length of the piston return spring with vernier

calipers. Place the piston return spring on a spring compression tester

and compress to the specified length, and read the gauge. If the

measurement is less than the allowable limit, replace. Piston / return

spring free length - 34.5 mm (1.36 in). Piston return spring tension -

614.2 N / 17.8 mm.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605