________________________________________________________________________________

Kubota B6200, B7200 - Hydrostatic Transmission

Kubota B6200HST, B7200HST Tractor -

Transmission System

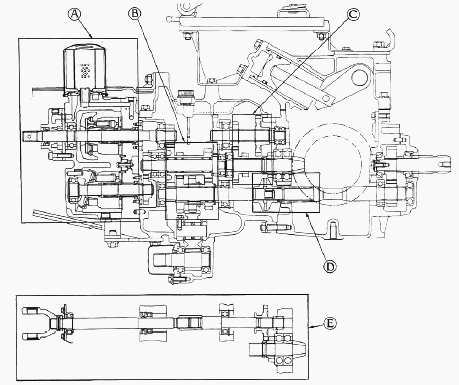

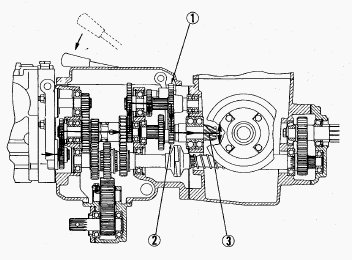

A - Hydrostatic transmission, B - PTO shift section (1-2-N), C -

High-low gear shift section, D - One-way clutch cam section, E - Front

wheel drive section (Engaged - Disengaged)

The transmission consists of HST (Hydrostatic Transmission) and a series

of gears shown in pic. It offers the most suitable speeds for traveling

and operation by combination of them. And power is transmitted to the

front or rear axles and the PTO shafts, which are classified

respectively as the traveling system and PTO system. The traveling

system consists of the HST (A), high-low gear shift section (C) and

front wheel drive section (E). The traveling speeds are selected by the

operation of the speed control pedal and the high-low gear shift lever.

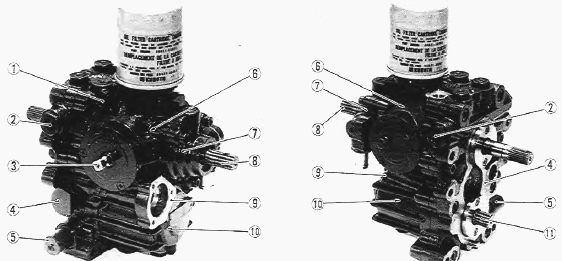

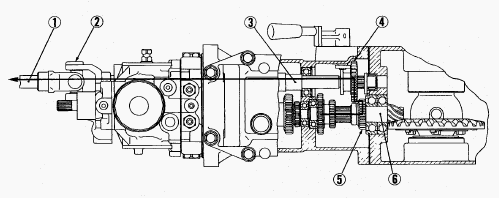

1 - Charge Relief Valve, 2 - Neutral Valve, 3 - Trunnion Shaft W Port

Block, 5 - High Pressure Relief Valve, 6 - Variable Displacement Piston

Pump, 7 - Charge Pump, 8 - Input Shaft, 9 - Case, 10 - Fixed

Displacement Piston Motor, 11 - Output Shaft

1-Oil Filter Cartridge, 2-Joint, 3-Thrust Plate, 4-P3 Port, 5-Trocoid

Rotor Assembly, 6-Charge Pump Case, 7-Input Shaft, 8-Oil Seal, 9-Ball

Bearing, 10-Case, 11-Ball Bearing, 12-Fixed Swashplate, 13-Piston,

14-Cylinder Block, 15-Drain Plug, 16-Valve Plate, 17-Variable

Swashplate, 18-Piston, 19-Cylinder Block, 20-Port Block, 21-Valve Plate,

22-Variable Displacement Piston Pump, 23-Oil Seal, 24-Case Relief Valve,

25-Fixed Displacement Piston Motor, 26-Oil Seal, 27-Output Shaft

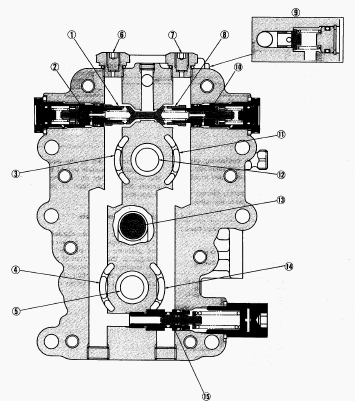

1-Check Valve, 2-Neutral Valve (Forward), 3-Pump Kidney Port A, 4-Motor

Kidney Port C, 5-Output Shaft, 6-P1 Port, 7-P2 Port, 8-Check Valve,

9-Charge Relief Valve, 10-Neutral Valve (Reverse), 11-Pump Kidney Port

В, 12-Input Shaft, 13-Case Relief Valve, 14-Motor Kidney Port D, 15-High

Pressure Relief Valve

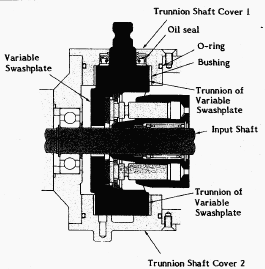

Variable Swashplate

This pump is variable displacement one. The angle of its swashplate can

be varied so that the volume and pressure of oil pumped by the pistons

can be changed or the direction of oil flow can be reversed. The

swashplate is moved around the trunnion shaft with the neutral holder,

by stepping on the speed control pedal linked to the neutral holder.

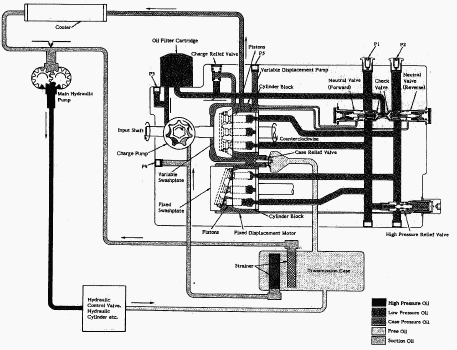

Kubota B6200, B7200 Transmission - Oil Flow

and Valves

P1. Port for checking high pressure (forward), P2. Port for checking

high pressure (reverse), P3. Port for checking case pressure, P4. Port

for checking vacuum, P5. Port for checking case pressure

The pump and motor are joined in a closed hydraulic loop and most of oil

circulates within the main oil circuit. A little oil lubricates and

oozes out from the clearance between the moving parts to the case. Then

oil in the main oil circuit of the hydrostatic transmission needs to be

supplied a want. So all of oil fed from the main hydraulic pump flows to

the hydrostatic transmission for charging. Only return oil from the

hydraulic cylinder drops to the transmission case. The charge oil aids

smooth operation of piston pump and motor. The rest of the oil passes

through the charge relief valve into the case. Then the oil passes to

the main hydraulic pump through a cooler.

Neutral Valve

The neutral valves in the main oil circuit lines are open and pass the

oil to the case when in neutral, and the oil pressure in their lines

becomes low. And when the oil pressure in the high pressure line

increases to a specified pressure, the neutral valve closes. Valve

operating pressure - 3.24 MPa (469 psi).

High Pressure Relief Valve

The high pressure relief valve between the two lines in the main oil

circuit monitors the oil pressure in each line. When excessively high

pressure is built up in one line, it opens and flows the oil into

another line. Valve operating pressure - 22.5 to 24.5 MPa (3270 to 3560

psi).

Case Relief Valve

The case relief valve monitors the oil pressure in the hydrostatic

transmission case. When the oil pressure rises, it opens and flows the

oil directly to the transmission case, so that the oil may not leak

against the sealings. Valve operating pressure - 170 to 230 kPa (24 to

32 psi).

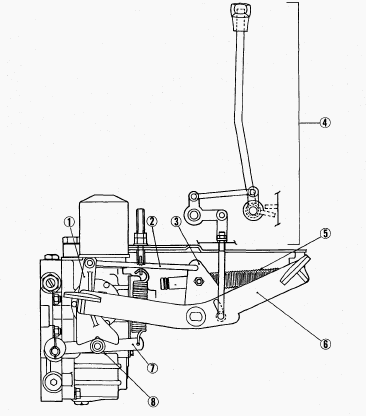

Kubota B6200, B7200 Transmission - Control

Linkage

1-Neutral Holder, 2-Speed Control Rod, 3-Rod Guide, 4-Speed Set Device,

5-Damper, 6-Speed Control Pedal, 7-Neutral Holder Arm, 8-Roller

The speed control pedal (6) and the trunnion shaft of variable

swashplate are linked with the rod guide (3), the speed control rod (2)

and the neutral holder (1). As the front footrest of the pedal is

depressed, the swashplate rotates and forward traveling speed increases.

Depressing the rear footrest increases reverse speed. The roller (8) on

the neutral holder arm (7) hanged with spring seats the detent of the

neutral holder (1) so that the neutral holder returns to neutral. Then,

the swashplate is returned to neutral with the neutral holder, when the

pedal is released. The damper (5) connected to the rod guide (3)

restricts the movement of the linkage to prevent abrupt operation or

reversing. The speed set device (4) linked to the rod guide (3) enables

the linkage not to return to neutral and to keep a certain forward speed

while the speed control pedal (6) is released. On B6200, this device is

installed as optional.

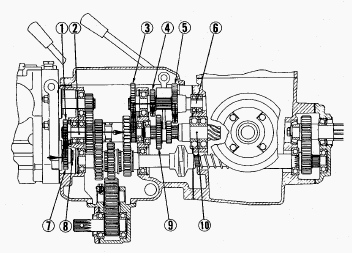

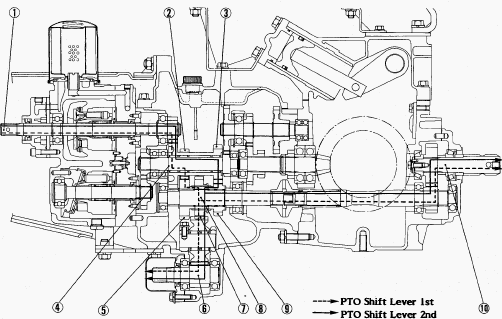

Kubota B6200HST, B7200HST Tractor - Mechanical

Transmission

High-Low Gear Shift Section

Mechanical transmission receives engine power from the output shaft of

hydrostatic transmission and selects high or low gear, and transmits the

power to differential.

Neutral

1 - 14T Gear, 2 - 2nd Shaft, 3 - 24T Gear, 4 - 15T Gear, 5 - 23T Gear, 6

- 4th Shaft, 7 - 16T Gear, 8 - Output Shaft, 9 - 20T-12T Gear, 10 -

Spiral Bevel Pinion

High or low speed is obtained by shifting 20T-12T gear (9) splined to

spiral bevel pinion (10). When in neutral, neither 15T gear (4) nor 23T

gear (5) meshes with 20T-12T gear (9) on spiral bevel pinion (10).

Engine power is transmitted to the output shaft (8) of hydrostatic

transmission, to which 16T gear (7) is splined. 16T gear (7) and 14T

gear (1) are in mesh. 14T gear (1) is splined to 2nd shaft (2). Integral

11T gear on 2nd shaft (2) and 24T gear (3) are in mesh. 24T gear (3) is

splined to 4th shaft (6). To 4th shaft (6), 15T gear (4) and 23T gear

(5) are also splined. Spiral bevel pinion (10) is not driven.

Low

1 - 15T Gear, 2 - 20T-12T Gear, 3 - Spiral Bevel Pinion

20T-12T gear (2) is shifted and 20T gear meshes with 15T gear (1)

splined to spiral bevel pinion (3). Then power is transmitted to

differential.

High

1 - 23T Gear, 2 - 20T-12T Gear, 3 - Spiral Bevel Pinion

20T-12T gear (2) is shifted and 12T gear meshes with 23T gear (1)

splined to spiral bevel pinion (3). Then power is transmitted to

differential.

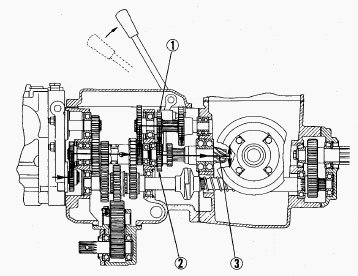

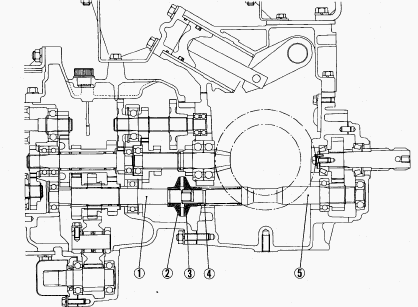

Front Wheel Drive Section (4WD-Type)

1 - Drive Shaft, 2 - Universal Joint, 3 - Front Wheel Drive Shaft, 4 -

24T Gear, 5 - 16T Gear, 6 - Spiral Bevel Pinion

The front wheel drive is used when greater traction power is required or

to prevent the tractor from being pushed during rotary tilling of hard

soil. 2-wheel drive or 4-wheel drive is selected by changing position of

24T gear (4) on the front wheel drive shaft (3) with the front drive

lever. When the front drive lever is set to "Disengaged", 24T gear is in

neutral and power is not transmitted to the front drive shaft. When the

front drive lever is set to "Engaged", 24T gear slides rearward to

engage with 16T gear (5) on the spiral bevel pinion shaft (6).

Therefore, the front drive shaft is actuated to drive the front wheels.

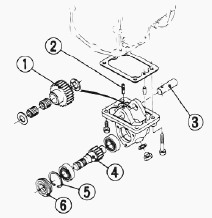

Kubota B6200, B7200 - PTO Shift Section

PTO system is independent of HST. Engine revolution is directly

transmitted to the 2nd shaft (4).

1 - Input Shaft of HST, 2 - 14T Gear, 3 - 18T Gear, 4 - 2nd Shaft, 5 -

21T Gear, 6 - Mid PTO Shaft, 7 - 21T Gear, 8 - 3rd Shaft, 9 - 17T Gear,

10 - Rear PTO Shaft

Neutral - The 14T gear (2) meshes with the 21T gear (5)

on the 3rd shaft (8). And the 18T gear (3) meshes with the 17T gear (9)

on the 3rd shaft (8), too. But the 21T gear (5) and the 17T gear (9)

unite with needle bearing in itself, they run idle on the 3rd shaft (8).

Then the 3rd shaft (8) is not driven.

1st Position - The 21T gear (7) splined to the 3rd

shaft (8) is shifted forward, and then the 3rd shaft (8) is rotated.

Rear PTO shaft (10) speed is 540 rpm at an engine speed of 2517 rpm. Mid

PTO shaft (6) speed is 1546 rpm at an engine speed of 2517 rpm.

2nd Position - The 21T gear (7) shifted to the 3rd

shaft (8) is shifted rearward, and then the 3rd shaft (8) is rotated.

Rear PTO shaft (10) speed is 858 rpm at an engine speed of 2517 rpm. Mid

PTO shaft (6) speed is 2456 rpm at an engine speed of 2517 rpm.

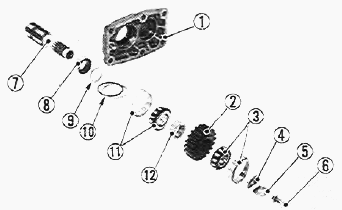

Kubota B6200, B7200 One-Way Clutch Cam Section

1 - 3rd Shaft, 2 - Clutch Cam, 3 - Clutch Cam, 4 - Cam Spring, 5 - 5th

Shaft

The one-way clutch cam is also called an overrunning clutch. It is

composed of a pair of clutch cams (2), (3) and a cam spring (4). One of

the clutch cams is splined to the 3rd shaft (1), and the other is

splined to the 5th shaft (5). These two clutch cams are engaged with

each other by the force of the cam spring. As long as the 3rd shaft is

rotating faster than the 5th shaft, these two clutch cams will remain

engaged, and the 5th shaft is driven.

Kubota B6200, B7200 - Transmission Service

Transmission Oil Change

Remove the drain plugs to drain transmission oil. Screw in the drain

plugs. Fill new oil up to the upper line on the dipstick

Transmission Oil Filter Cartridge Replacement

The oil filter cartridge must be replaced after initial 50 hours and

every 200 service hours. Remove the bolts which secure the cover. Remove

the oil filter cartridge by using the filter wrench. Lightly tighten the

screw by using a screwdriver. Apply a slight coat of oil onto the

cartridge gasket. To install the new cartridge, screw it in by hand.

Over tightening may cause deformation of rubber gasket. After the new

cartridge has been replaced, the transmission oil level will become a

little lower. Make sure that the transmission oil does not leak through

the seal. Check the oil level.

Kubota B6200, B7200 Hydrostatic Transmission (HST)

Remove the propeller shaft from the 1st shaft. Remove the drive shaft

from the front wheel drive shaft (4WD type only). Remove the HST

mounting screws, and remove the HST. After inserting the spring pin to

the 1st shaft and drive shaft, lock the spring pin with a wire. HST

mounting screw (Tightening torque) - 48 to 56 Nm (35.4 to 41.2 ft-lbs).

Control Valve and Top Link Bracket

Remove the control valve with the feedback rod (4WD type). Remove the

control valve with the check rod (2WD type). Remove the top link

bracket. Use care not to damage the О-rings on the control valve.

Control valve mounting screw (B6200HST, B7200HST 4WD type) - 16.7 to

21.6 Nm (12.3 to 15.9 ft-lbs). Control valve mounting screw (B6200HST,

B7200HST 2WD type) - 16.7 to 21.6 Nm (12.3 to 15.9 ft-lbs). Top link

bracket mounting screw - 39.2 to 64.7 Nm (28.9 to 47.7 ft-lbs).

Separating Transmission Case

Remove the bolt. Remove the fork shaft lock screw. Remove the

transmission case mounting nuts, and separate the transmission case.

Apply liquid gasket (Three Bond 1102 or equivalent) to both sides of new

gasket. Transmission case mounting nut (Tightening torque) - 39.2 to

64.7 N-m (28.9 to 47.7 ft-lbs).

Case and Case Relief Pressure Checking

Remove the 1/4 plug from port, with care not to allow any particle of

sealing tape enter into the port. Install the long connector to port

with sealing tape on its thread. Install the threaded joint to long

connector with the gasket between them. Install the cable, threaded

joint in relief valve set pressure tester and low pressure gauge to

threaded joint in order. Run the engine at 2600 to 2700 rpm. Place the

high-low shift lever in neutral. Release the speed control pedal to set

in neutral. After measuring the case pressure, remove the eye joint from

port and plug the port with 3/8 screw to measure the case relief

pressure.

Kubota B6200HST, B7200HST - Mid-PTO

1 - 24T Gear, 2 - Screw, 3 - Shaft, 4 - 11T Gear Shaft, 5 - Cover, 6 -

Oil Seal

Separate the mid-PTO case from the transmission case. Remove the mid-PTO

case cover (5). Remove the screw (2) and pull out the mid-PTO counter

shaft (3) and remove the 24T gear (1). Draw out the 11T gear shaft (4)

with the bearing on it. After tapping the spring pin (2) into the shaft

(3), remove the shaft (3) and the 24T gear (1). Remove the oil seal (6)

and the external snap ring (5). Draw out the 11T gear shaft (4) with the

bearing on it. Mid-PTO case cover to case - 14 to 20 Nm (10 to 14

ft-lbs). Mid-PTO case to transmission case - 48 to 56 Nm (35 to 41

ft-lbs).

PTO Shaft

1. Rear Cover, 2. 18T Gear, 3. Taper Roller Bearing, 4. Washer, 5. Lock

Washer, 6. Screw, 7. PTO Shaft, 8. Bushing, 9. PTO Collar, 10. PTO Shim,

11. Taper Roller Bearing, 12. PTO Collar

Flatten the lock washer (5). Remove the screw (6), plain washer, lock

washer (5), washer and straight pin. Tap out the PTO shaft (7) to the

rear. Replace the lock washer with a new one, and be sure to adjust the

turning torque of PTO shaft. Lock the screw with the lock washer after

adjusting the turning torque. Tightening torque Screw - 18.6 to 32 Nm

(13.7 to 23.9 ft-lbs).

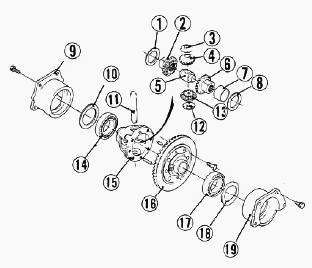

Differential Assembly

1.Shim, 2.Differential Side Gear, 3.Differential Pinion Collar,

4.Differential Pinion, 5.Thrust Collar, 6.Differential Side Gear, 7.Ring

Gear Bushing, 8.Shim, 9.Differential Bearing Holder (RH),

10.Differential Side Shim, 11.Differential Pinion Shaft, 12.Differential

Pinion Collar, 13.Differential Pinion, 14.Bearing, 15.Differential Case,

16.Ring Gear, 17.Bearing, 18.Differential Side Shim, 19.Differential

Bearing Holder (LH)

Remove the left and right differential bearing holders (19), (9). Take

out the differential assembly from the differential gear case. Install

the differential assembly, noting the number of differential side shims

(10), (18).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605