________________________________________________________________________________

Kubota B7400, B7500, B7510, B7610 - HST Transmission

Kubota B7400, B7500, B7510, B7610 -

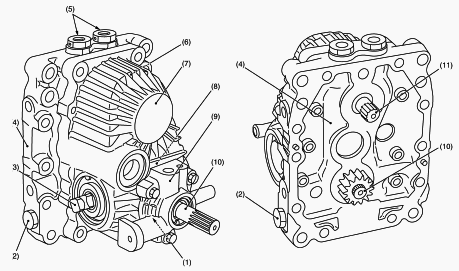

Hydrostatic Transmission Components

1.Charge Relief Valve, 2.Check and High Pressure Relief Valve,

3.Trunnion Shaft, 4.Center Section, 5.Neutral Valve, 6.Fixed

Displacement Piston Motor, 7.Housing, 8.Variable Displacement Piston

Pump, 9.Charge Pump, 10.Input Shaft (Pump Shaft), 11.Output Shaft

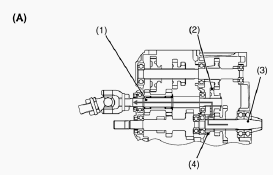

Front Wheel Drive System

1 - Front Wheel Drive Shaft, 2 - Shifter Gear 20T, 3 - Spiral Bevel

Pinion Shaft, 4 - Gear 13T

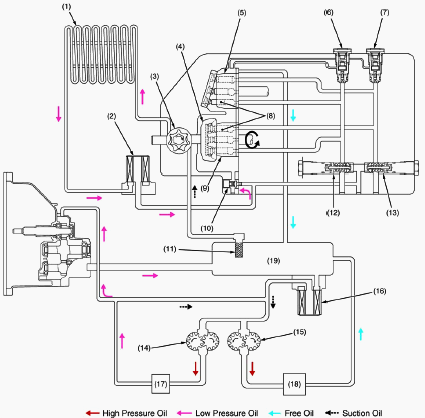

Kubota B7400, B7500, B7510, B7610 HST - Oil

Flow

1.Oil Cooler, 2,16-Oil Filter, 3.Charging Pump, 4.Swash Plate, 5.Motor

Cylinder Block, 6.Neutral Valve (Forward), 7.Neutral Valve (Reverse),

8.Piston, 9.Pump Cylinder Block, 10.Charge Relief Valve, 11.Oil

Strainer, 12.Check and High Pressure Relief Valve (Forward), 13.Check

and High Pressure Relief Valve (Reverse), 14.Power Steering Hydraulic

Pump, 15.Main Circuit Hydraulic Pump, 17.Controller of Power Steering,

18.Hydraulic Control Valve, 19.Transmission Case

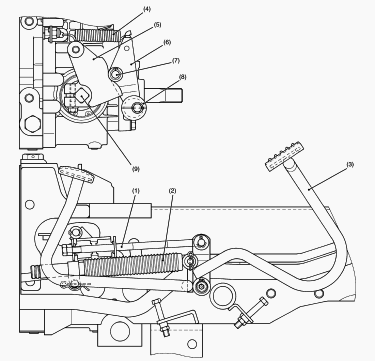

Kubota B7400, B7500, B7510, B7610 Hydrostatic

Transmission - Control Linkage

1 - Speed Control Rod Assembly, 2 - Damper, 3 - Speed Control Pedal, 4 -

Spring, 5 - Neutral Holder, 6 - Neutral Holder Arm, 7 - Roller, 8 -

Neutral Adjuster, 9 - Trunnion Shaft

The speed control pedal (3) and the trunnion shaft (9) of variable

swashplate are linked with the speed control rod (1) and the neutral

holder (5). As the front footrest of the pedal is depressed, the

swashplate rotates and forward travelling speed increased. Depressing

the rear footrest increases reverse speed. The roller (7) on the neutral

holder arm (6) is held with spring seats the detent of the neutral

holder (5) so that the neutral holder returns to neutral. Then, the

swashplate is returned to neutral with the neutral holder, when the

pedal is released. The damper (2) connected to the speed control pedal

restricts the movement of the linkage to prevent abrupt operation or

reversing.

Kubota B7400, B7500, B7510, B7610 - HST

Transmission Removal

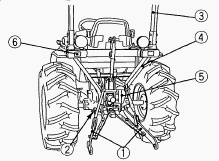

Roll-Over Protective Structures (ROPS) and 3

Point Hitch

1.Lower Link, 2.3-Point Hitch Shaft, 3.ROPS Top Frame, 4.ROPS Frame,

5.PTO Shaft Cover, 6.Tail Lamp

Disconnect the wire harness of tail lamps. Remove the ROPS frame top

(3). Remove the lower link (1) and the collar from the 3-point hitch

shaft (2). Remove the both sides reflectors (6) with frame. Remove the

both sides fender mounting screws. Remove the PTO shaft cover (5) and

connecting plate. Remove the ROPS left, right frames and 3-point hitch

shaft (2). Connecting plate mounting screw 47.1 to 56.9 Nm / 34.7 to

42.0 ft-Ibs. ROPS frame and frame top mounting bolt and nut 149.1 to

179.5 Nm / 109.9 to 132.4 ft-Ibs. ROPS frame mounting screw - 77.5 to

90.1 Nm / 57.2 to 66.5 ft-Ibs. 3-Point hitch shaft setting screw - 14.7

to 19.6 Nm / 10.8 to 14.5 ft-Ibs. 3-Point hitch shaft setting screw lock

nut - 43.0 to 47.0 Nm / 31.7 to 35.4 ft-Ibs.

Seat, Fender, Steering Wheel, Panel, Step and

Others

Remove the seat, seat adjuster, lowering speed adjusting knob, seat

under cover and fender cover. Remove the position control lever grip,

front wheel drive lever grip and bi-speed turn lever grip (Bi-speed Turn

Type). Remove the fender RH. Remove the mid-PTO gear shift lever grip,

rear PTO shift lever grip and range gear shift lever grip or Hi-Lo shift

lever grip. Remove the fender LH. Loosen the lock nuts and disconnect

the bi-speed turn cable (Bi-speed Turn Type). Remove the fender stay and

bi-speed turn lever as a unit (Bi-speed Turn Type). Remove the cruise

control lever grip, lever guide, tool box and fender stay. Remove the

steering wheel, panel and panel under cover. Remove the fuel tank frame

set screws and fuel tank stay. Remove the clutch and brake springs. Lift

up the fuel tank frame and then remove the steps. Disconnect the speed

set rod, HST release rod and brake pedal link. Place the jack under the

transmission case, and then set the rigid rack under the rear axles.

Remove the tires.

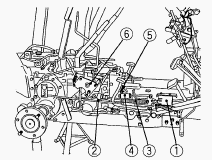

HST Pedal

1-Spring Stay, 2-Brake Rod RH, 3-Damper, 4-Speed Control Rod Assembly,

5-Speed Control Rod Screw, 6-Cruise Control Assembly,

Remove the brake springs and spring stay (1). Remove the brake rod RH

(2). Remove the cruise control assembly (6). Remove the damper (3) and

speed control rod assembly (4). Remove the HST pedal. Remove the speed

control rod screw (5) from the neutral holder.

Sub Frame RH, HST Delivery Pipe and Hydraulic

Pipes

Remove the sub frame RH. Remove the pips clamps and pipe joint bolt.

Remover the HST safety switch holder with neutral rod. Disconnect the

HST delivery pipe. Remove the brake rod RH. Remove the connecting pipe.

Remove the HST suction pipe. Remove the sub frame RH. Remove the

hydraulic oil filter assembly and pipes.

Separating Transmission Case from Center Frame

and Hydrostatic Transmission

1-HST Delivery Pipe, 2-Universal Joint, 3-Front Wheel Propeller Shaft,

4-Neutral Spring, 5-Spring Holder, 6-Spring Hook

Separate transmission case and center frame. Remove the propeller shaft,

front wheel drive shaft (1) and HST delivery pipe (2). Remove the

neutral spring (4) and remove the spring holder (5). Separate the HST

from transmission case. Apply liquid gasket (Three Bond 1208D or

equivalent) to joint face of the HST and transmission case. When

inserting the spring pins, face their splits in the direction at a right

angle to the universal joint and propeller shaft. Apply grease to the

spline of the HST pump shaft, front wheel propeller shaft, universal

joint and ball coupling. Spring holder mounting screw 39.2 to 44.1 Nm /

28.9 to 32.5 ft-Ibs. HST and center frame mounting screw and nut - 62.8

to 72.6 Nm / 46.3 to 53.5 ft-Ibs.

Separating Hydraulic Cylinder, Rear Axle Cases

and Others

Remove the front wheel drive lever. Remove the differential lock pedal

support. Remove the top link bracket LH and remove the hydraulic

cylinder. Remove the rear axle case and drawbar frame. Apply liquid

gasket to joint face of the differential case to hydraulic cylinder and

rear axle cases.

Separating Mid-PTO Case, Transmission Case and

Differential Case

Remove the mid-PTO case mounting screws and separate the mid-PTO case

and transmission case. Remove the transmission case mounting screws and

nuts and separate the differential case and transmission case with

middle case as a unit. Apply liquid gasket (Three Bond 1208D or

equivalent) to joint face of the transmission case and differential

case.

Kubota B7500HST, B7510HST, B7610HST -

Transmission Checking And Adjusting

Adjusting Neutral

Disengage the front wheel drive lever (Drive only rear wheels). Lift the

rear of the tractor so that the rear wheels are off the ground and run

the engine at low idling and drive only rear wheels. Slightly loosen the

neutral adjuster setting screw. Rotate the neutral adjuster clockwise so

that rear wheels turn reverse. Then rotate it counterclockwise until

wheels stop completely. Put a mark on the center frame aligning the

groove on neutral adjuster. Rotate the neutral adjuster counterclockwise

so the rear wheels turn forward. Then rotate it clockwise until wheels

stop completely. Put a mark on the center frame aligning the groove on

neutral adjuster. Hold the neutral adjuster so its groove is at the

middle of the marks and tighten the setting screw. When the wheels tend

to turn forward, rotate neutral adjuster clockwise. When the wheels tend

to turn reverse, rotate neutral adjuster counterclockwise.

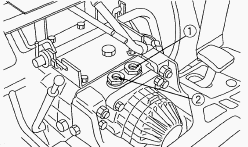

Charge Relief Pressure and High Relief

Pressure

1-Neutral Valve (Forward), 2-Neutral Valve (Reverse)

Remove the lowering speed adjusting knob and dipstick, then remove the

seat under cover. Assemble the HST adaptor A and threaded joint with

O-ring and back up ring. Charge Relief Pressure - Remove the neutral

valve assembly one side (forward (1) or reverse (2)) then install the

assembled HST adaptor A to its neutral valve port. Install the cable and

low pressure gauge to HST adaptor A. Change the range gear shift lever

to Low position. Start the engine and run it at the maximum speed. Read

the low pressure gauge to measure the charge relief pressure. If the

measurement is not same as factory specification, check the charge

relief valve and related hydraulic components. High Relief Pressure -

Remove the neutral valve assembly forward (1), then install the

assembled HST adaptor A to its neutral valve port. Install the cable and

high pressure gauge to HST adaptor A. Change the range gear shift lever

to High position. Start the engine and run it at the maximum speed.

Depress the speed control pedal forward and read the high pressure gauge

to measure the forward high relief pressure. Stop the engine and change

the installation of HST adaptor A and pressure gauge from forward

neutral valve port to reverse. Start engine and repeat above method (4.

and 5.) to measure the reverser high relief pressure. If the measurement

is not same as factory specification, check the high pressure relief

valve and related hydraulic components. Charge relief pressure (Oil

temperature at 50C) - 500 to 800 kPa / 73 to 116 psi. High relief

pressure (Oil temperature at 50C) - 30.9 to 31.9 MPa / 4480 to 4622 psi.

Tightening torque: Neutral valve cap screw - 58.8 to 68.6 Nm / 43.4 to

50.6 ft-Ibs.

Neutral Valve Actuation Test

Disengage the front wheel drive lever. Disconnect the brake rod, one

side. Lift the rear of tractor, one side. Set the engine speed to 1500

rpm. Shift the range gear shift lever to Hi position. Move the HST pedal

from the forward to the neutral position make sure that the tire comes

to stop. Check the same way for the movement from rearward to the

neutral position. In this time, make sure that the neutral range of HST.

If the tire fail to stop or neutral range is point, check the each

neutral valve.

Kubota B7500HST, B7510HST, B7610HST -

Differential Gear Case Disassembly

PTO Shaft

Remove the PTO cover mounting screws and remove the PTO cover assembly.

Apply liquid gasket (Three Bond 12080 or equivalent) to joint face of

differential gear case and PTO cover.

Differential Gear Assembly

Remove the bearing holder mounting screws and remove the bearing holder.

Take out the differential gear assembly. Install the differential gear

assembly, noting the number of shims in the differential case left side

and bearing holder side.

Spiral Bevel Gear

Remove the spiral bevel gear UBS screws. Remove the spiral bevel gear

from differential case. Apply liquid lock to the spiral bevel gear UBS

screws.

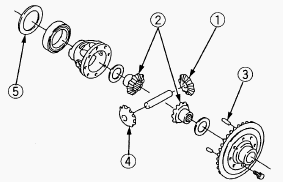

Differential Side Gear and Differential Pinion

1-Differential Pinion, 2-Differential Side Gear, 3-Dowel Pin,

4-Differential Pinion, 5-Shim

Put parting marks on the differential pinion and the differential side

gear. Tap out the dowel pin. Remove the differential pinion shaft.

Remove the differential pinion, differential side gear and shim. Install

the differential pinion and differential side gear, aligning the parting

marks.

Kubota B7400, B7500, B7510, B7610 -

Hydrostatic Transmission Service

Valve Plate

Check the engagement of the valve plate and the anchor pin. Pushing the

valve plate against the anchor pin, lift it to remove. Check the valve

plate for foreign particles. Clean the valve plate and dry with

compressed air. Check the valve plate for scratches, wear and erosion.

If worn or scored, replace. After checking, coat them with hydrostatic

transmission oil.

Thrust Plate and Swashplate

Check the thrust plate for scratches and excessive wear. If worn or

scored, replace. Check the bearing surface of trunnion shaft

(swashplate) for scratches and excessive wear. If worn or scored,

replace.

Trunnion Shaft Cover

Check the bearing for scratches and excessive wear. If worn or scored,

replace. Check the oil seal and the O-rings for damage. After checking,

coat the bearings with hydrostatic transmission oil, and the oil seal

lip and the O-rings with grease.

Oil Seals and Bearings for Shaft

Remove the internal snap ring and check the oil seals for damage. Check

the bearings for wear. If the bearings are worn, replace. After

checking, coat the bearing with hydrostatic transmission oil and the oil

seal lip with grease.

Check and High Pressure Relief Valve

Check the valve plug and valve for scratches and damage. Check the valve

seat in the port block for damage. Check the spring for breakage and

wear. If anything unusual, replace the check and high pressure relief

valve assembly.

Neutral Valve

Check the holes of the valve body and the neutral valve for clogging. If

clogged, open hole with compressed air. Check the O-rings and the backup

ring for scratches and damage. Check the springs for breakage and wear.

If the valve surface is scored, replace. If anything unusual, replace

Kubota B7500HST, B7510HST, B7610HST -

Differential Gear Service

Clearance between Differential Case (Spiral

Bevel Gear) and Differential Side Gear

Measure the differential side gear boss O.D. with an outside micrometer.

Measure the differential case I.D. and the spiral bevel gear I.D. with

an inside micrometer, and calculate the clearance. If the clearance

exceeds the allowable limit, replace faulty parts. Clearance between

differential case (spiral bevel gear) and differential side gear - 0.025

to 0.066 mm (0.00098 to 0.00260 in). Differential case I.D. - 32.000 to

32.025 mm (1.25984 to 1.26082 in). Spiral bevel gear I.D. - 32.000 to

32.025 mm (1.25984 to 1.26082 in). Differential side gear O.D. - 31.959

to 31.975 mm (1.25823 to 1.25886 in).

Clearance between Differential Pinion Shaft

and Differential Pinion

Measure the differential pinion shaft O.D. with an outside micrometer.

Measure the differential pinion I.D. with an inside micrometer, and

calculate the clearance. If the clearance exceeds the allowable limit,

replace faulty parts. Clearance between differential pinion shaft and

differential pinion - 0.016 to 0.045 mm (0.00063 to 0.00177 in).

Differential pinion I.D. - 16.000 to 16.018 mm (0.62992 to 0.63063 in).

Differential pinion shaft O.D. - 15.973 to 15.984 mm (0.62886 to 0.62929

in).

Backlash between Differential Pinion and

Differential Side Gear

Secure the differential case with a vise. Set the dial indicator (lever

type) with its finger on the tooth of the differential side gear. Press

differential pinion and side gear against the differential case. Hold

the differential pinion and move the differential side gear to measure

the backlash. If the backlash exceeds the allowable limit, adjust with

differential side gear shims. Backlash between differential pinion and

differential side gear - 0.1 to 0.3 mm (0.004 to 0.012 in). Allowable

limit - 0.4 mm (0.016 in).

Backlash between Spiral Bevel Pinion and

Spiral Bevel Gear

Set the dial indicator (lever type) with its finger on the end of spiral

bevel pinion. Move the spiral bevel pinion back and forth to each end

and measure the side clearance. If the side clearance exceeds the

factory specifications, adjust with the shims at front end of spiral

bevel pinion. Set the dial indicator (lever type) with its finger on the

tooth surface of bevel gear. Measure the backlash by fixing the spiral

bevel pinion and moving bevel gear by hand. If the backlash exceeds the

factory specifications, adjust with the shims at bearing holder and

differential case. Adjust the backlash properly by repeating the above

procedure.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605