________________________________________________________________________________

Kubota BX1880, BX2380, BX2680 - Transmission

Kubota BX1880, BX2380, BX2680 - Transmission

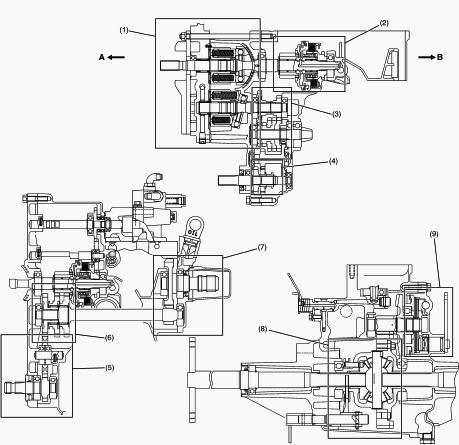

Components

1. Hydrostatic Transmission, 2. PTO Clutch Section, 3. Range Gear Shift

Section, 4. Front Wheel Drive Gear Section, 5. Mid-PTO Section, 6. PTO

Gear Shift Section, 7. Rear PTO Section, 8. Differential Gear Section,

9. Brake Section, A. Front Side, B. Rear Side

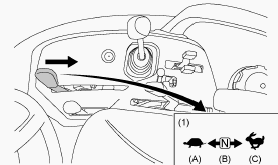

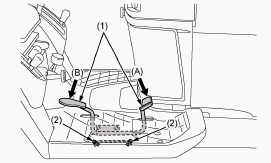

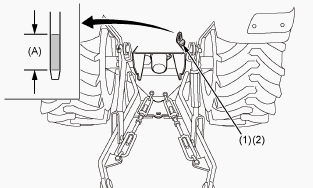

Range gear shift lever (Hi-Lo)

1 - Range gear shift lever (Hi-Lo), A - Low, B - Neutral position, C -

High

You can shift the range gear shift lever only when tractor is completely

stopped. Do not force the range gear shift lever. If it is difficult to

shift the range-gear-shift-lever into the neutral “N” position, you

should attempt the following procedure. Depress the brake pedal firmly

for several seconds. Without reducing the brake pedal force, shift the

range gear shift lever.

If it is difficult to shift the range gear shift lever into the low

position or the high position from the neutral “N” position, you should

attempt the following procedure. Slightly depress the speed control

pedal to rotate the gears inside of transmission. Release the speed

control pedal to the neutral “N” position. Shift the range gear shift

lever.

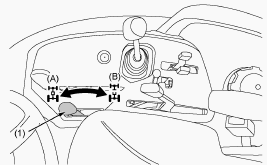

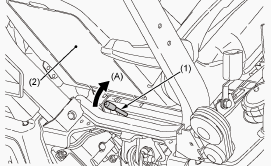

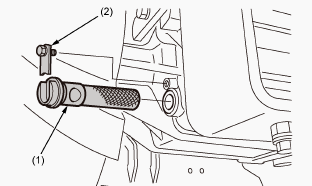

Front wheel drive lever

Use the lever to engage the front wheels with the tractor stopped. Shift

the lever to the on position to engage the front wheel drive. To avoid

damage of transmission, when the front wheel drive lever is not smoothly

shifted, slightly depress forward or rearward on the speed control

pedal.

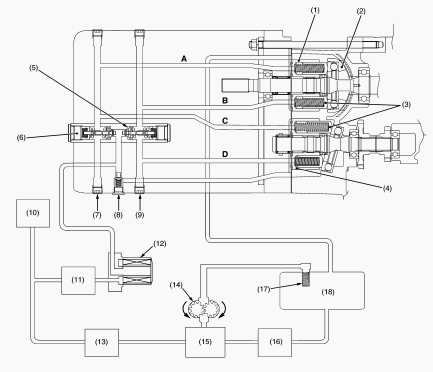

Kubota BX1880, BX2380, BX2680 - Hydrostatic transmission oil flow

1. Cylinder Block (Pump), 2. Swashplate, 3. Piston, 4. Cylinder Block

(Motor), 5. Check and High Pressure Relief Valve (Forward), 6. Check and

High Pressure Relief Valve (Reverse), 7. High Pressure Relief Port Plug

(Forward), 8. Charge Relief Valve, 9. High Pressure Relief Port Plug

(Reverse), 10. PTO Clutch Valve, 11. PTO Relief Valve, 12. Oil Filter

Cartridge, 13. Power Steering Controller, 14. Hydraulic Pump, 15. Flow

Priority Valve (Hydraulic Control Valve), 16. Position Control Valve,

17. Oil Strainer, 18. Transmission Case, A. A Port, B. B Port, C. C

Port, D. D Port

The pump and motor are joined in a closed hydraulic loop and most of oil

circulates within the main oil circuit. A little oil lubricates and

oozes out from the clearance between the moving parts of the case. Then

oil in the main oil circuit of the HST needs to be supplied a want. The

oil from the power steering circuit flows into the HST for charging. The

charge oil aids smooth operation of pistons for pump and motor. The

charge oil passes through the oil filter cartridge to charge relief

valve port. The rest of oil passes through the charge relief valve into

the HST housing. And overflow oil from HST housing return to the

transmission case.

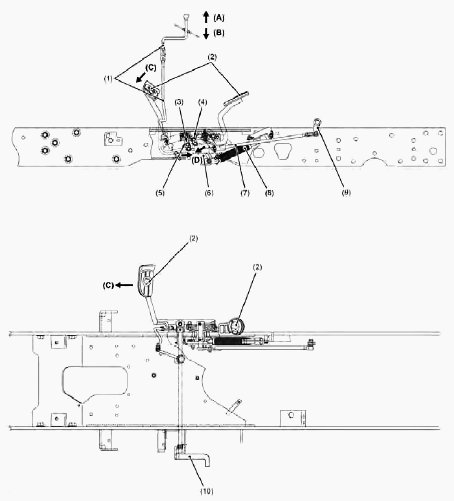

Kubota BX1880, BX2380, BX2680 - Speed set device

Speed set linkage

1 - Speed set rod, 2 - Speed control pedal, 3 - Cruise lock, 4 - Cruise

lock, 5 - Cruise plate, 6 - HST pedal link, 7 - Speed change rod, 8 -

Damper, 9 - Trunnion arm, 10 - Release plate, A - Speed set rod OFF, B -

Speed set rod ON, C - Speed control pedal Forward, D - Cruise lock

Locked

When the brake pedal is depressed, the release plate located under the

brake pedal is pushed down. Since the cruise plate rotates, the cruise

lock and between the cruise plate and the HST pedal link are released.

How to use the speed set device

1 - Speed control pedal, 2 - Stopper bolts, A - Forward, B - Reverse

To engage the speed set device - Accelerate speed to desired level using

the speed control pedal. Push and hold the speed set rod downward to on

position. Release the speed control pedal. Release the speed set rod.

Desired speed will be maintained.

To disengage the speed set device - Depress the brake pedal. If you step

on the speed control pedal on the forward acceleration side, the speed

set device will disengage. The speed set device will not operate in

reverse.

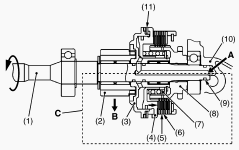

Kubota BX1880, BX2380, BX2680 Tractor - PTO System

PTO Clutch Engaged

1. HST Pump Shaft, 2. Clutch Gear, 3. Clutch Case, 4. Clutch Piston, 5.

Clutch Plate, 6. Clutch Disc, 7. Spring, 8. Spline Boss, 9. O-ring, 10.

Transaxle Case, 11. Brake Disc, A. From PTO Clutch Valve, B. Power to

PTO Shaft, C. PTO Clutch Engaged

The oil from power steering controller flows into the PTO clutch valve.

When the PTO clutch lever is set at the “Engaged” position, the PTO

clutch valve rotates. Oil flows from the oil line through transmission

case to the PTO clutch pack. Oil entering the clutch pack pushes the

clutch piston (4) to engage the clutch pack. Power is transmitted from

the HST pump shaft (1) through the PTO clutch to the clutch gear (2) and

the PTO shafts.

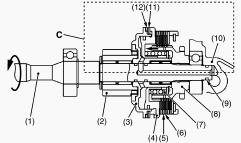

PTO Clutch Disengaged

1. HST Pump Shaft, 2. Clutch Gear, 3. Clutch Case, 4. Clutch Piston, 5.

Clutch Plate, 6. Clutch Disc, 7. Spring, 8. Spline Boss, 9. O-ring, 10.

Transaxle Case, 11. Brake Plate, 12. Brake Disc, C. PTO Clutch

Disengaged

When the PTO clutch lever is set at the “Disengaged” position, the PTO

clutch valve closes the oil passage to the PTO clutch pack. The oil in

the PTO clutch pack drain into the transaxle case (10). Thus the clutch

piston (4) is pushed back by the spring (7). When the clutch piston (4)

is pushed back by the spring (7), the brake plate (11) is also moved to

contract the brake disc (12) so as to stop the rotation and drag of the

PTO shafts.

Stationary PTO

1 - Seat lock lever, 2 - Seat, A - Unlock

To park the tractor and use the PTO system for chipper or pump, for

example, start the PTO system in the following steps. Apply the parking

brake and place blocks at the tires. Make sure that all shift levers are

in their neutral position, and start the engine. Set the PTO select

lever to the Rear-PTO (Rear only) position. Get off the seat and tilt up

it. Move the seat lock lever behind the seat frame in the arrow

direction in the following figure to release the seat lock, and lift the

seat forward. 6. Set the PTO clutch lever to the on (engage) position.

Set the engine speed appropriately to provide recommend rear PTO speed.

Kubota BX1880, BX2380, BX2680 - PTO select lever

Mid PTO

To use the mid PTO, shift the PTO select lever to the mid PTO position

and the PTO clutch lever to the on position. The mid PTO is available

for approved implements.

Mid-Rear PTO

To use the mid PTO and the rear PTO at the same time, shift the PTO

select lever to the mid-rear PTO position and the PTO clutch lever to

the on position.

Rear PTO

To use the rear PTO, shift the PTO select lever to the rear PTO position

and the PTO clutch lever to the on position.

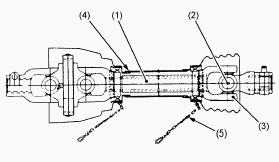

PTO drive shaft

1 - Inner and outer sliding profile tubes, 2 - Journal cross assy, 3 -

Fitting yoke, 4 - Safety guard (in, out), 5 - Chain

When using a PTO drive shaft, read the operator's manual of the

implement before operating the implement. If it is necessary for using

the PTO drive shaft, adjust the length of it. Make sure that the PTO

drive shaft is securely connected at both ends before operating it.

PTO clutch lever

The PTO clutch lever engages or disengages the PTO clutch which gives

the PTO independent control. When you engage the PTO clutch, shift the

PTO clutch lever slowly to avoid damage to the PTO clutch and implement.

Shift the PTO clutch lever to the on position to engage the PTO clutch.

Shift the PTO clutch lever to the off position to disengage the PTO

clutch. The tractor engine will not start if the PTO clutch lever is in

the engaged ON position. When you stand up from the seat with the PTO

clutch lever at the engaged ON position, the engine will stop regardless

of the position of the PTO select lever.

Adjusting the length of PTO drive shaft

To adjust the length of the PTO-drive-shaft, refer to the following

instructions. To adjust the inner and outer guard tubes, hold the half

shafts next to each other in the shortest working position, and mark the

half shafts in the shortest working position of the inner and outer

guard tubes. Shorten the inner and outer guard tubes to the marked

position equally. Shorten the inner and outer sliding profile tubes by

the same length as the inner and outer guard tubes. Round all sharp

edges off, remove burrs, and grease sliding profiles.

Kubota BX1880, BX2380, BX2680 - Transmission Maintenance

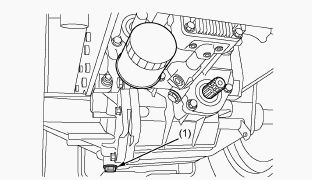

Transmission fluid level check

1 - Oil inlet, 2 - Dipstick, A - Transmission fluid level is acceptable

within this range

To check the transmission fluid level, check the dipstick as the

following procedure. Draw out the dipstick. Wipe the dipstick clean.

Replace the dipstick. Draw the dipstick out again. Check to see that the

transmission fluid level lies between the two notches. If the fluid

level is too low, add new fluid to the prescribed level at the oil

inlet.

Transmission oil filter replacement

Remove the transmission oil filter. Put a film of clean transmission oil

on rubber seal of new oil filter. Tighten the transmission oil filter

quickly until it contacts the mounting surface. Tighten the transmission

oil filter by hand an additional 1/2 turn only. After the new oil filter

has been replaced, the transmission fluid level will decrease a little.

Make sure that the transmission fluid does not leak through the seal,

and check the fluid level. Check the dipstick and refill with oil to

prescribed level. Properly dispose of used oil.

Transmission fluid changing

Transmission fluid capacity - 11.3 L. To drain the used transmission

fluid, remove the drain plug at the bottom of the transmission case and

drain fluid completely into the oil pan. After draining the transmission

fluid, reinstall the drain plug. Clean the transmission strainer. Fill

with new transmission fluid up to the upper notch on the dipstick. After

running the engine for a few minutes, stop it and check fluid level

again. If the transmission fluid level is lower, add it to the

prescribed level. Properly dispose of used transmission fluid.

Transmission strainer cleaning

1 - Transmission strainer, 2 - Filter plate

When changing the transmission fluid, disassemble and rinse the

transmission strainer with nonflammable solvent to completely clean off

filings. When reassembling the transmission strainer, be careful not to

damage the parts. Since the fine filings in the oil can damage the

precision component parts of the hydraulic system, the end of the

suction line is provided with an oil strainer.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605