________________________________________________________________________________

Onan B48G Carburetor

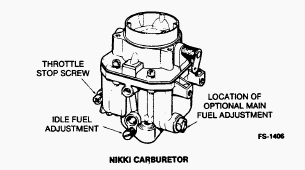

Onan B48G Nikki Carburetor

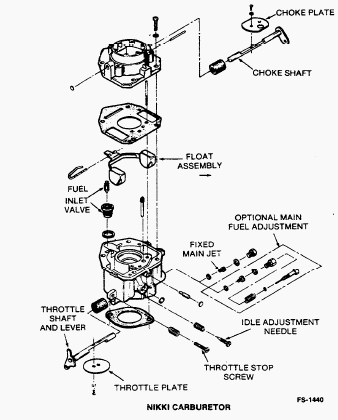

Removal and Disassembly

Remove air cleaner and hose. Disconnect governor and throttle linkage,

choke control and fuel line from carburetor. Remove the four intake

manifold cap screws and lift complete manifold assembly from engine.

Remove carburetor from intake manifold.

Nikki carburetor limited idle adjustment - Remove main jet and idle

adjustment needle. Remove attaching screws and separate upper and lower

carburetor sections. Carefully note position of float assembly parts,

then pull out retaining pin and float assembly. Remove needle valve.

Onan B48G Nikki Carburetor - Cleaning and

Repair

Soak all metal components not replaced in carburetor cleaner. Do not

soak non-metal floats or other non-metal parts. Follow the cleaning

manufacturer’s recommendations. Clean all carbon from the carburetor

bore, especially where the throttle and choke plates seat. Be careful

not to plug the idle or main fuel ports. Dry out all passages with low

pressure air (35 PSI).

Avoid using wire or other objects for cleaning which may increase the

size of critical passages. Check the condition of the adjustment needle;

replace if damaged. Replace float if loaded with fuel or damaged. Check

the choke and throttle shafts for excessive play in their bore. This

condition may necessitate replacement of the carburetor. Replace old

components with new parts.

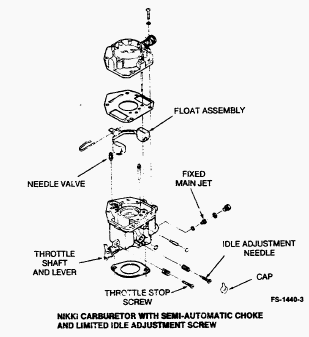

Nikki limited idle adjustment - Reassembly and

Installation

- Install needle valve, main jet, and float assembly.

- Make sure float pivot pin is properly placed and float moves freely

without binding.

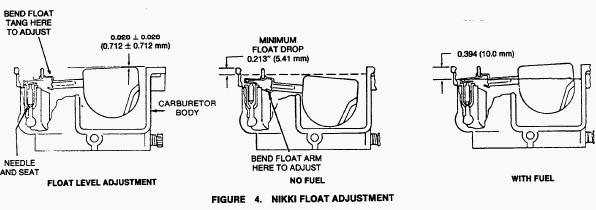

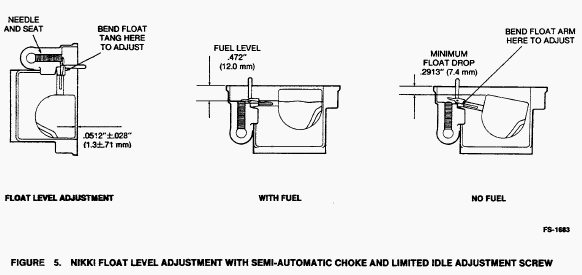

- Turn carburetor on its side and measure float level. Adjust float

level only if necessary.

- Measure float drop (the distance from the top of carburetor body to

top of float). Adjust only if necessary.

- Position gasket on lower carburetor section and install upper

carburetor section.

- Install idle adjustment screw, throttle stop screw, and fixed main jet

plug.

- Mount carburetor on intake manifold and install assembly on engine.

- Mount air cleaner assembly. Connect air intake hose, breather hose,

fuel line, vacuum line, and throttle linkage.

- Adjust carburetor and governor according to directions given in this

section.

Onan B48G - Nikki Carburetor Adjustment

The carburetor idle and main mixture were set for maximum efficiency at

the factory and should normally not be disturbed. If adjustments seem

necessary, first be sure the ignition system is working properly and

governor sensitivity is properly adjusted. If adjustment is needed,

proceed as follows and refer to figures. Overtightening the mixture

adjustment screw will cause carburetor damage. Turn mixture adjustment

screw in only until light tension can be felt.

These initial adjustments will permit engine to start and warm up prior

to final adjustment.

Onan B48G Nikki carburetor mixture

screw settings

Turn idle mixture screw in until lightly seated, then back idle mixture

screw out 3/4 turn. On engines equipped with main fuel adjustment, turn

main mixture screw in until lightly seated then back the main mixture

screw out 1-1/4 to 1-1/2 turns.

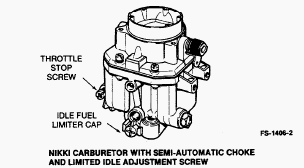

Onan B48G Nikki carburetor with

semi-automatic choke and limited idle adjustment screw

No initial mixture adjustments are required. When replacing idle mixture

screw, turn in until lightly seated, then turn screw back out 1-1/4

turns. Replace limiter cap with the plastic stop approximately centered.

Start the engine and allow it to warm up thoroughly (at least 10

minutes). Move the engine speed control to the slow position. Bend or

turn the low speed stop on the governor so the throttle stop screw on

the carburetor controls engine speed. Adjust throttle stop screw to

obtain the following rpm: Nikki carburetor 1000 rpm.

Determine the best idle mixture setting by first turning the idle

adjustment screw in until engine speed drops and then outward until

engine speed drops again. Over a narrow range between these two

settings, engine speed remains at its highest. Set the adjustment screw

about 1/8 turn outward (rich) from the midpoint of this range.

Readjust throttle stop screw to obtain the RPM specified in step 3 and

release the governor arm. Adjust governor low speed stop for 1100 ± 100

rpm idle. Move the engine speed control to the fast position. Bend the

high speed stop on the governor so the engine runs at the equipment

manufacturer’s recommended speed.

Check the main mixture adjustment (optional on some carburetors) by

rapidly accelerating the engine from idle to full speed. The engine

should accelerate evenly and without hesitation. If it does not, turn

the main adjustment screw out in 1/8 turn increments until the engine

accelerates smoothly, but do not turn it out more than 1/2 turn beyond

the original setting.

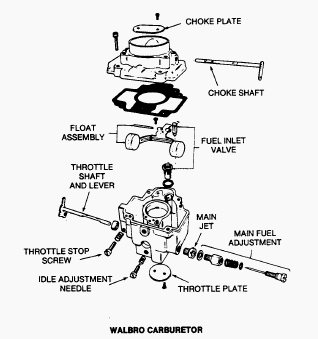

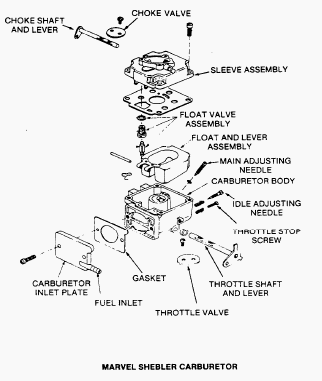

Onan B48G Marvel Schebler and Walbro

Carburetors

Removal and Disassembly

- Remove air cleaner and hose.

- Disconnect governor and throttle linkage, choke control and fuel line

from carburetor.

- Remove the four intake manifold cap screws and lift complete manifold

assembly from engine.

- Remove carburetor from intake manifold.

- Remove throttle and choke plate retaining screws and plates. Pull out

throttle and choke shafts.

- Remove main adjustment and idle adjustment needles.

- Remove attaching screws and separate upper and lower carburetor

sections.

- Carefully note position of float assembly parts, then pull out

retaining pin and float assembly.

- Remove needle and unscrew needle valve seat.

Cleaning and Repair

Soak all metal components not replaced in carburetor cleaner. Do not

soak non-metal floats or other non-metal parts. Follow the cleaning

manufacturer’s recommendations. Clean all carbon from the carburetor

bore, especially where the throttle and choke plates seat. Be careful

not to plug the idle or main fuel ports. Dry out all passages with low

pressure air (35 PSI).

Avoid using wire or other objects for cleaning which may increase the

size of critical passages. Check the condition of the adjustment needle;

replace if damaged. Replace float if loaded with fuel or damaged. Check

the choke and throttle shafts for excessive play in their bore. This

condition may necessitate replacement of the carburetor. Replace old

components with new parts.

Reassembly and Installation

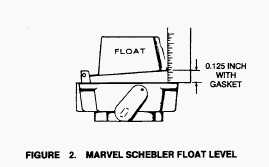

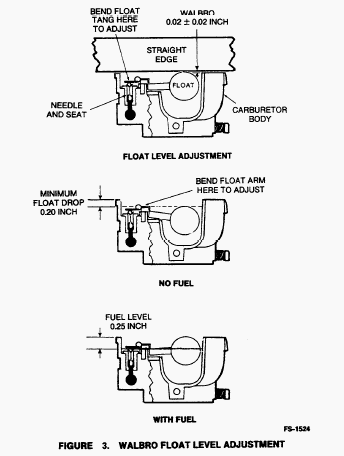

Install needle valve and seat, main jet and float assembly. Make sure

that float pivot pin is properly placed and that float moves freely

without binding. Gently push float tang down until needle just seats.

Measure float level. Adjust float level if necessary. Release float tang

and measure float drop. This is the distance from top of carburetor body

to top of float. When checking float level and float drop, measure to

float body, not seam.

Position gasket on carburetor and attach carburetor sections together

with screws. Slide in throttle shaft and install plate using new screws.

Before tightening the screws, the plate must be centered in the bore. To

do so, back off the throttle stop screw as necessary and completely

close the throttle lever. Seat the plate by tapping with a small

screwdriver, then tighten screws. Install the choke shaft and plate in

the same manner.

Install idle adjustment screw, throttle stop screw, and fixed main jet

plug or optional main fuel adjustment needle. Mount carburetor on intake

manifold and install assembly on engine. Mount air cleaner assembly.

Connect air intake hose, breather hose, fuel line, vacuum line, and

throttle linkage. Adjust carburetor and governor according to directions

given in this section.

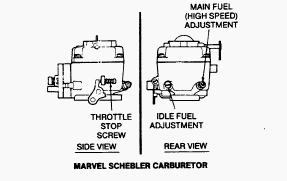

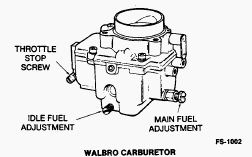

Onan B48G - Marvel Schebler and Walbro

Carburetor Adjustment

These initial adjustments will permit engine to start and warm up prior

to final adjustment. Marvel Schebler carburetor mixture screw settings:

Turn both mixture screws in until lightly seated, then back the idle

mixture screw out 1 turn and the main mixture screw out 1-1/4 turns.

Walbro carburetor mixture screw settings: Turn idle mixture screw in

until lightly seated, then back idle mixture screw out 1-1/8 turns. On

engines equipped with main fuel adjustment, turn main mixture screw in

until lightly seated then back the main mixture screw out 1-1/2 turns.

Start the engine and allow it to warm up thoroughly (at least 10

minutes). Move the engine speed control to the slow position. Bend or

turn the low speed stop on the governor so the throttle stop screw on

the carburetor controls engine speed. Adjust throttle stop screw to

obtain the following rpm: Marvel Schebler carburetor without governor

low speed adjustment screw 1200 rpm, with governor low speed adjustment

screw 1100 rpm.

Walbro carburetor 1000 rpm. Determine the best idle mixture setting by

first turning the idle adjustment screw in until engine speed drops and

then outward until engine speed drops again. Over a narrow range between

these two settings, engine speed remains at its highest. Set the

adjustment screw about 1/8 turn outward (rich) from the midpoint of this

range.

Readjust throttle stop screw to obtain the RPM specified in step 3 and

release the governor arm. Adjust governor low speed stop for 1100 ± 100

rpm idle. Move the engine speed control to the fast position. Bend the

high speed stop on the governor so the engine runs at the equipment

manufacturer’s recommended speed. Check the main mixture adjustment

(optional on some carburetors) by rapidly accelerating the engine from

idle to full speed. The engine should accelerate evenly and without

hesitation. If it does not, turn the main adjustment screw out in 1/8

turn increments until the engine accelerates smoothly, but do not turn

it out more than 1/2 turn beyond the original setting.

Governor adjustment

Onan B48G engines equipped with variable speed governors are adapted for

use where a wide range of speed settings are desired. Engine speed is

controlled at any given point between minimum and maximum by simply

shifting the throttle lever on the control panel until the desired speed

is reached. Engines equipped with fixed speed governors are generally

used where a single constant speed is required.

Engine speed is controlled by adjusting governor spring tension. The

fixed and variable speed governor give an automatic decrease in

sensitivity when the speed is increased. The result is good stability at

all speeds. A reliable instrument for checking engine speed is required

for accurate governor adjustment. Engine speed can be checked with a

tachometer.

Check the governor arm, linkage, throttle shaft, and lever for binding

condition or excessive slack and wear at connecting points. A binding

condition at any point will cause the governor to act slowly and

regulation will be poor. Excessive looseness may cause a hunting

condition and regulation could be erratic. Work the arm back and forth

several times by hand while the engine is idling to check for above

conditions.

If the variable speed governor is hunting or not operating properly,

adjust as follows. Disconnect linkage from one of holes. Push linkage

and governor arm as far back (toward carburetor) as they will go.

Holding linkage and governor arm toward direction of carburetor, insert

end of linkage into whichever hole in governor arm lines up the closest.

If between two holes, insert in next hole out.

To adjust fixed speed governor: Adjust governor link length so that with

the engine stopped and tension on the governor spring, the stop on the

throttle shaft assembly almost touches the stop on the side of the

carburetor. On side pull governors the governor spring is set by the

factory in the third hole of the governor arm (Third hole from pivot).

On front pull governors the governor spring is set by the factory in the second hole of the governor arm adapter (Second hole from pivot). To increase sensitivity, move spring loop into a hole closer to the pivot. To decrease sensitivity, move spring loop into a hole farther away from the pivot. After sensitivity has been set, recheck the low speed rpm setting. Adjust if necessary.

________________________________________________________________________________

________________________________________________________________________________________

| KOHLER ENGINES SPECS AND SERVICE DATA |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KAWASAKI ENGINES SPECS AND SERVICE DATA |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| BRIGGS AND STRATTON ENGINES SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| HONDA ENGINES SPECS AND SERVICE DATA |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

CH12.5

CH12.5 CH14S

CH14S CH15S

CH15S CH16

CH16 CH18S

CH18S CH23S

CH23S CH25S

CH25S CH640S

CH640S CH730S

CH730S CH750S

CH750S CV15S

CV15S CV16S

CV16S CV18S

CV18S CV20S

CV20S CV22S

CV22S CV23S

CV23S CV25S

CV25S CV490S

CV490S CV491S

CV491S CV730S

CV730S CV740S

CV740S K161

K161 K181

K181 K241

K241 K301

K301 K321

K321 K341

K341 K361

K361 M18

M18 M20

M20 SV470S

SV470S SV530S

SV530S SV540S

SV540S SV590S

SV590S SV600S

SV600S SV710

SV710 SV715

SV715 SV725S

SV725S SV730S

SV730S SV735

SV735 FA210

FA210 FA210D

FA210D FB460V

FB460V FC150V

FC150V FC290V

FC290V FC420V

FC420V FC540V

FC540V FD501V

FD501V FD590V

FD590V FD620D

FD620D FD731V

FD731V FD750D

FD750D FH430V

FH430V FH500V

FH500V FH531V

FH531V FH580V

FH580V FH601V

FH601V FH680V

FH680V FS541V

FS541V FS600V

FS600V FS651V

FS651V FX651V

FX651V FX691V

FX691V FX730V

FX730V FH541V

FH541V FH641V

FH641V FH661V

FH661V FH721V

FH721V FS730V

FS730V 252707

252707 253707

253707 282707

282707 286707

286707 303777

303777 28N707

28N707 28M707

28M707 28Q777

28Q777 28R707

28R707 28S777

28S777 311707

311707 31A607

31A607 31C707

31C707 31N707

31N707 31Q777

31Q777 31R977

31R977 31R777

31R777 31P777

31P777 31P977

31P977 350777

350777 402707

402707 422707

422707 42A707

42A707 331777

331777 331877

331877 G50

G50 G100

G100 GC135

GC135 GC160

GC160 GC190

GC190 GS190

GS190 GX100

GX100 GX120

GX120 GX160

GX160 GX200

GX200 GXV120

GXV120 GXV160

GXV160 GXV270

GXV270 GXV340

GXV340 GXV390

GXV390 GXV610

GXV610 GCV520

GCV520 GCV530

GCV530 GXV620

GXV620 GXV630

GXV630 GCV145

GCV145 GCV160

GCV160 GCV170

GCV170 GCV190

GCV190 GCV200

GCV200 GSV190

GSV190 GX110

GX110 GX140

GX140 GV100

GV100 GXV140

GXV140