________________________________________________________________________________

Massey Ferguson 3050, 3060, 3080, 3125 Rear Axle - Lift cover

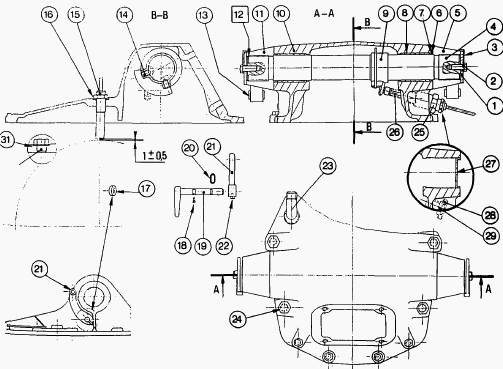

The lift cover is mounted on the upper face of the rear axle housing.

The shaft (4) which has the two lift arms (5) and (11) splined to it is

supported by bushes (8). Cam (9) on the lift shaft (4) provides the

means for sensor (26) to monitor position of lift arms. This information

is transmitted to the Electronic Linkage Control (ELC) system. To ensure

correct play between the lift arms and the cover, shims are fitted on

the left hand end of the shaft. The rear face of the lift cover supports

the auxiliary spool valves. The vehicle speed sensor (15) is screwed in

the front oi the cover. The cover also supports lever (21) for economy

(4 speed) PTO.

Parts list - (1) Washer, (2) Bolt, (3) Retainer, (4)

Lift shaft, (5) Right-hand lift arm, (6) Nylon ring, (7) O-ring, (8)

Bush, (9) Cam, (10) Lift cover, (11) Left-hand lilt arm, (12) Shim(s),

(13) Bush, (14) Set screw, (15) Vehicle speed sensor, (16) Nut, (17) Cup

plug (2-speed PTO), (18) Screw (4-speed PTO), (19) Control finger

(4-speed PTO), (20) О-ring (4-speed PTO), (21) Lever (4-speed PTO), (22)

Screw (4-speed PTO), (23) Elbow connector, (24) Bolt, (25) Nut, (26)

Position sensor, (27) Cup plug, (28) Threaded plug, (29) Seal, (30)

Threaded plug, (31) Seal

Massey Ferguson 3050, 3060, 3080, 3125 - Lift

Cover Removal and Disassembly

Removal

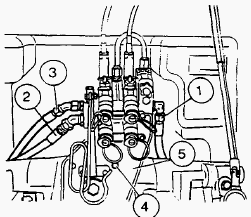

Remove the sheet metal. Remove the rear fastening screws to the cab

(remove only the central and lower screws to the guard plates to gain

access to the cab fastening screws). Raise the cab. Place a block

between the cab and the trumpets. Disconnect: the supply hose to the

spool valve; supply hose to the lift valve; return hose. Remove the

bolts for the spool valve support. Remove the support swinging the

assembly out of the way, without disconnecting the controls.

Disconnect: vehicle sensor wire assembly (Autotronic, Datatronic);

position sensor wire assembly; differential lock pipe; cable (4-speed

PTO, if fitted); cable(shiftable PTO, if fitted). Unscrew the pipe at

both ends and remove the support for the trailer brake connector if

fitted. Remove the upper pins from the rams and lift rods. Remove the

fastening bolts for the cover. The PTO control cable supports (depending

on the version) are fixed by the bolts for the cover. Lift there over

and remove it.

Disassembly

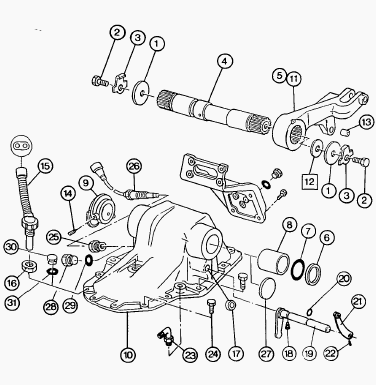

Place the cover on a work bench. Remove the elbow connector. Unscrew the

nut (16) and remove the vehicle speed, sensor (15). Unscrew the nut (25)

and remove the position sensor (26). For MF 3050, 3060, 3080, 3065,

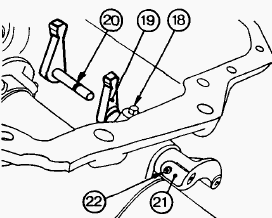

3070, 3095, 3120, 3125 tractors equipped with economy 4-speed, carry out

operations. Undo the Allen screw (22) in the lever (21). Undo the screw

(18).

Remove the control finger (19). Remove the O-ring (20). Flatten tabs

locking the bolts (2) retaining the lift arms. Undo the screws. Remove

the washers (1). Remove the shim(s). Remove the lift arms (5) and (11).

Remove the nylon rings (6) and the O-rings (7). Remove the set screws

(14) in the cam (9). Withdraw the lift shaft (4) from the cover. Remove

the cam (9). Withdraw the bushes (8). Remove the cup plug (17) (2-speed

PTO).

Massey Ferguson 3050, 3060, 3080, 3125 - Lift

Cover Reassembly

The bushes (13) are mounted with Loctite 648 at a distance of 40.50 mm

from the face. Clean and check the parts. Replace any which are

defective. Clean the joint faces of the lift cover and of the spool

valve support. Fit the bushes in the cover. Fit the cup plug (17)

smeared with Loctite 542 flush with the cover (2-speed PTO). Mount the

lift shaft (4) and the cam (9) in the cover. Ensure that the direction

of the shaft and the position of the cam are correct. Tighten the set

screws (14) smeared with Loctite 241 to a torque of 5 Nm.

Apply this torque so as not to deform the cam. Position the O-rings (7)

and the nylon rings (6). Note: Protect the splines of the shaft.

Lubricate the О-rings before mounting. Grease the splines of the shaft

(4) (Anti-Seize Grease or equivalent). Fit the lift arm (5) (sensor

side), the washer (1). the retainer (3) and the screw (2). Grease the

face of the cover (Anti-Seize Grease or equivalent) before fitting the

arms. Tighten the screw (2) so as to align two flat sides of the screw

head with the two tabs of the retainer(3). Bend back the tabs.

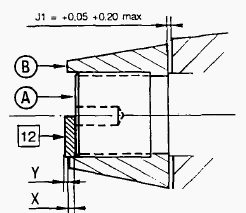

Carry out shimming of the shaft (4) to obtain: J1 = +0.05 to +0.20

maximum. Mount the arm (11), the washer (1) and the bolt (2). Grease the

face of the cover (Anti-Seize Grease or equivalent) before mounting the

arm. Tighten the bolt so as to position the lift arms (5) and (11)

correctly on the shaft. Remove the bolt (2) and the washer (1) at the

left end of the shaft. Measure the distance between face A of the shaft

and face В of the arm using a depth gauge. By measuring dimension X,

determine the thickness of spacers Y needed to obtain: J1 = +0.05 to

+0.20 maximum. J1 = X + Y.

Mount the previously selected shims, the washer (1), the retainer (3)

and the bolt (2). Tighten the bolt (2) so as to align two flat sides of

the screw head with the two tabs of the retainer (3). Bend back the

tabs. For MF 3050, 3060, 3080, 3065, 3070, 3095, 3120 tractors equipped

with economy 4-speed PTO, carry out operations. Refit the finger (19).

Mount the O-ring (20) from the exterior side of the cover. Smear the

screws (18) and (22) with Loctite 241 and tighten. Check that the

control functions smoothly. Fit the elbow connector (23).

Massey Ferguson 3050, 3060, 3080, 3125 - Lift

Cover Refitting

Clean the joint face of the cover on the rear axle housing. Smear the

joint face with a sealing compound (Master Joint 510 Loctite or

equivalent). Lift cover into position. When refitting the cover, ensure

that the supply pipe of the differential lock and the control finger

(4-speed economy PTO) engage properly in their respective positions.

Mount the supports for the PTO control cables (depending on the version)

and fit the bolts (24) of the cover (10).

Tighten to the following torque: 12 mm diameter bolt = 72-96 Nm, 16 mm diameter bolt = 160-200 Nm. A heavy-duty cover and five new bolts (24) has been released on MF 3125 tractor. The tightening torque of 16 mm diameter bolts is 240-320 Nm instead of 160-200 Nm. Refit the upper pins to the rams and lift rods.

Refit the trailer brake valve support if fitted. Retighten the pipe at both ends. Refit: differential lock supply pipe (3); cable (4) (4-speed PTO, if fitted); cable (5) (shiftable PTO, if fitted). Fit the vehicle speed sensor (15) with Loctite 577 Sensor Sealing or equivalent (Autotronic, Datatronic tractors). Screw in the speed sensor into contact with the crown wheel, without forcing it.

Unscrew the sensor 3/4 of a turn so as to obtain a clearance of approx.

1 mm between the sensor and the crown wheel. Tighten the nut (16)

moderately. Connect the sensor. Fix the harness assembly with a clip.

Clean the joint face of the spool valve support. Coat the joint face of

the spool valve support with a sealing compound (Master Joint 510

Loctite or equivalent). Refit the support and spool valve assembly.

Smear the thread of the two lower screws (4) with Loctite 510. Fit and

tighten the bolts (4) in the spool valve support to a torque of 50-70

Nm. Reconnect: supply hose (1) to the spool valve; supply hose (3) to

the lift valve; return hose (2). Adjust the PTO control (4-speed) and

the PTO control (shiftable). Remove the blocks between the cab supports

and the trumpets. Position the cab. Refit the rear fastening screws of

the cab.

Tighten the nuts to 27-35 Nm and the lock-nuts smeared with Loctite 270 to 13-20 Nm. Refasten the guard plates. Fit and adjust the position sensor. Smear the thread of the sensor (26) with a sealing compound (Hylomar or equivalent), then screw in the sensor a few turns and connect the harness. Start the engine. Using the external control, make sure that the lift arms are in the fully raised position (relief valve blowing).

Stop the engine, then make a mark on the cover and on one arm. Screw in the sensor (without forcing it) until it meets the cam (9) and unscrew by approximately one turn (1.5 mm). Fix the harness. Start the engine. Using the internal control, lower and raise the lift arms. Check the position of the moving mark on the arm. The difference between the two marks should be approx. 3 mm. If the difference is greater than 3 mm, unscrew the sensor slightly. If the difference is less than 3 mm, retighten the sensor slightly.

Tighten the nut (25) to a torque of 25 Nm using a suitable spanner. Check for leaks: at the joint between the lift cover and the spool valve support, at the hydraulic connectors. Refit the sheet metal. Version without lift - The holes of the shaft (4) are plugged with caps (27) sealed with Loctite 542. The position sensor (26) is replaced with a threaded plug (28) equipped with a seal (29). Version without Autotronic - The vehicle speed sensor (15) is replaced with a threaded plug (30) equipped with a seal (31).

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS MAINTENANCE |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| MF TRACTORS TROUBLESHOOTING | ||||

| 1652 | 1749 | 2620 | 2725 | 2805 |

| 3050 | 3120 | 3640 | 3709 | 4245 |

| 4455 | 5320 | 5455 | 5613 | 6150 |

| 6280 | 6480 | 6615 | 7618 | 7720 |

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS 130

130 133

133 145

145 155

155 158

158 165

165 175

175 185

185 188

188 230

230 254

254 254S

254S 284S

284S 294

294 353

353 290

290 362

362 375

375 390

390 398

398 399

399 590

590 690

690 1010

1010 1030

1030 1020

1020 1150

1150 2620

2620 2640

2640 2645

2645 1540

1540 2660

2660 3065

3065 3095

3095 3650

3650 3680

3680 4255

4255 4355

4355 4370

4370 3630

3630 3635

3635 4245

4245 4445

4445 4609

4609 4710

4710 5435

5435 5475

5475 5610

5610 5711

5711 6150

6150 6170

6170 6180

6180 6270

6270 6290

6290 6445

6445 6499

6499 6614

6614 6713

6713 7465

7465 7495

7495 7614

7614 7622

7622 7715

7715 7726

7726 8210

8210 8270

8270 8650

8650 8727

8727 GC1705

GC1705 1464 Loader

1464 Loader 1466 Loader

1466 Loader 1040 Loader

1040 Loader 1070 Loader

1070 Loader 905 Loader

905 Loader 906 Loader

906 Loader 915 Loader

915 Loader 916 Loader

916 Loader 921 Loader

921 Loader 926 Loader

926 Loader 931 Loader

931 Loader 933 Loader

933 Loader 936 Loader

936 Loader 938 Loader

938 Loader 939 Loader

939 Loader 940 Loader

940 Loader 941 Loader

941 Loader 945 Loader

945 Loader 946 Loader

946 Loader 948 Loader

948 Loader 949 Loader

949 Loader 950 Loader

950 Loader 951 Loader

951 Loader 955 Loader

955 Loader 956 Loader

956 Loader 958 Loader

958 Loader 960 Loader

960 Loader 961 Loader

961 Loader 965 Loader

965 Loader 966 Loader

966 Loader 968 Loader

968 Loader 975 Loader

975 Loader 976 Loader

976 Loader 978 Loader

978 Loader 985 Loader

985 Loader FL.3114 X

FL.3114 X FL.3419 X

FL.3419 X FL.3522

FL.3522 FL.3615

FL.3615 FL.3619

FL.3619 FL.3817

FL.3817 FL.3819

FL.3819 FL.3823

FL.3823 FL.4018

FL.4018 FL.4121

FL.4121 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader FL.4125

FL.4125 FL.4227

FL.4227 FL.4124

FL.4124 FL.4220

FL.4220 FL.4323

FL.4323 FL.4327

FL.4327 FL.4621

FL.4621 FL.4624

FL.4624 FL.4628

FL.4628 FL.5033

FL.5033 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader 1010

1010 1020

1020 1030

1030 1035

1035 1040

1040 1045

1045 1080

1080 1085

1085 1120

1120 1125

1125 1140

1140 1160

1160 1165

1165 1180

1180 1190

1190 1205

1205 1210

1210 1215

1215 1220

1220 1225

1225 1230

1230 1233

1233 1235

1235 1240

1240 1260

1260