________________________________________________________________________________

Massey Ferguson 5610, 5430 hydraulic system - Open centre

The Massey Ferguson 5400-5600 series tractors

open centre hydraulic system (100 l/min) comprises two separate systems:

- low flow rate system supplied by a gear pump located on the internal

face of the left-hand transmission cover plate.

- high flow rate system supplied by two gear pumps located on the

internal face of the right-hand transmission cover plate.

The pumps suck transmission oil from the common tank formed by the

centre housing and the gearbox. A 150 micron suction strainer ensures

filtration during

suction.

A 15 micron main filter, and a blockage indicator are fitted to

the low flow rate system upstream of the Orbitrol steering spool valve.

The pumps are driven

by the ring gear of the PTO clutch unit.

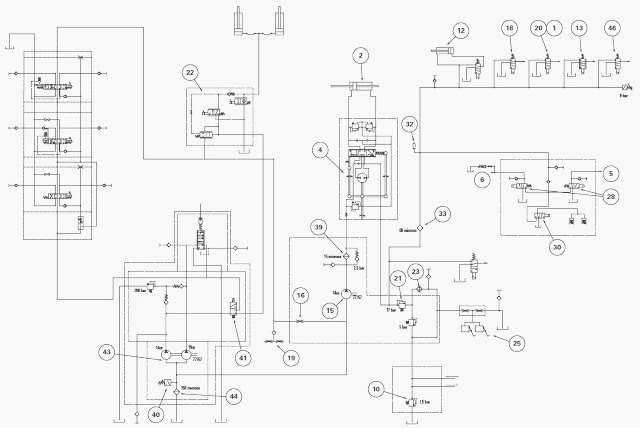

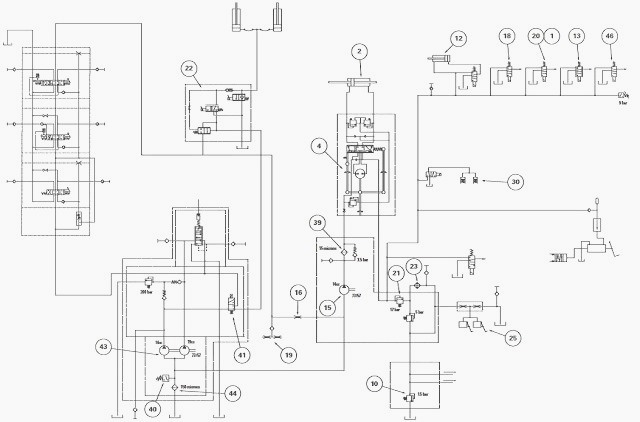

System schematic diagrams Low-pressure system, low flow rate

The Massey Ferguson 5613, 5410 low-pressure hydraulic system is supplied

by a gear pump that provides the pressure to the following equipment:

- the steering,

- the cooling system,

- the lubrication system,

- the transmission components operating under 17 bar.

Hydraulic flow

After supplying the Orbitrol steering spool valve as required, the oil

is directed to the left-hand cover plate attached to the centre housing.

This cover plate performs

several low-pressure functions.

It ensures:

- operating pressure for the various transmission components via a 17

bar valve fitted downstream from the Orbitrol unit,

- cooling and lubrication of the gearbox and connected components,

- pressure for the brake master cylinders (excluding MERITOR master

cylinders).

MF 5610, 5613 transmission components

The 17-bar system supplies, in parallel, the various transmission

functions via solenoid valves flanged on the reverse shuttle clutch

unit, on the Speedshift control

and in the main channel of the right-hand cover plate.

None of these

functions has priority and they may be activated simultaneously. The

reverse shuttle solenoid

valves are proportional. The other solenoid valves are non-proportional.

The functions supplied by the low flow rate system are as follows:

- the hydrostatic steering,

- the Hare / Tortoise range shifting (Hi / Lo),

- the differential lock (front and rear),

- the 4WD clutch,

- the Speedshift,

- The clutch control valve,

- the clutch unit of the reverse shuttle,

- the power take-off system,

- clutch,

- brake,

- front PTO (depending on option).

Cooling and lubrication

When the various components of the transmission are supplied, the

left-hand cover plate directs oil towards the cooler when it is hot, or

directly towards to the

gearbox and PTO when it is cold.

The lubrication pressure is maintained

by a valve set to 1.5 bar and fitted on the front left-hand side of the

gearbox.

Pressure for brake master cylinders - Only unassisted master cylinders

receive pressure from the hose connected upstream to the 1.5 bar valve.

High-pressure system, high flow rate

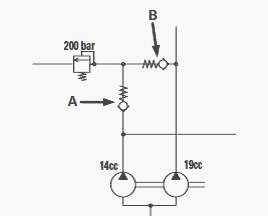

The Massey Ferguson 5410, 5430 high-pressure hydraulic system has two

pumps (19 cc and 14 cc), used respectively for the linkage and for

auxiliary hydraulics.

The flow rates of these two pumps can be coupled to use the auxiliary

spool valves only. Coupling is performed by a solenoid valve controlled

from the cab by a

button.

The solenoid valve is located on the rear axle right-hand cover plate.

When the pump flow rates are coupled, linkage is locked in position. It

can only be used once

the flows have been uncoupled and linkage reactivated.

The 19cc pump supplies:

- the trailer brake valve, as a priority,

- the auxiliary spool valves

The 14cc pump supplies:

- the linkage spool valve.

Coupled 19cc + 14cc pumps

When the pumps are coupled, they supply the auxiliary spool valves

through the coupling solenoid valve (41).

The 19cc pump always supplies the trailer brake valve as a priority (if fitted). The oil not used by the trailer brake spool valve supplies the auxiliary spool valves fitted to the rear of the linkage cover plate.

Surplus

spool and linkage valve flows return to the pump inlet manifold via a

restrictor, without passing through the 150 micron filter.

A safety valve, set to 200 bar, is fitted in the pump discharge channel

on the right-hand cover plate to protect the high pressure system. Two

non-return valves (A

and B) are fitted to the pump system to isolate the pumps from each

other towards the safety valve.

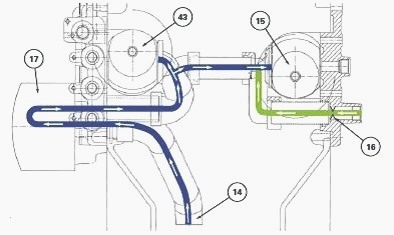

MF 5610, 5613 Pump suction system

The pumps, located inside the left- and right-hand cover plates, suck

the oil through the 150 micron strainer (17). A tube connects the

suction manifolds of the two

pumps (15)(42).

The left-hand cover plate supports the oil return, which

opens into the low pressure pump manifold (15) through a restrictor

(16).

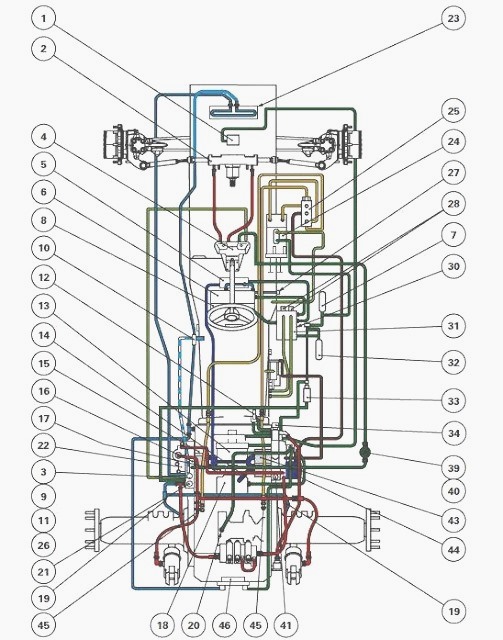

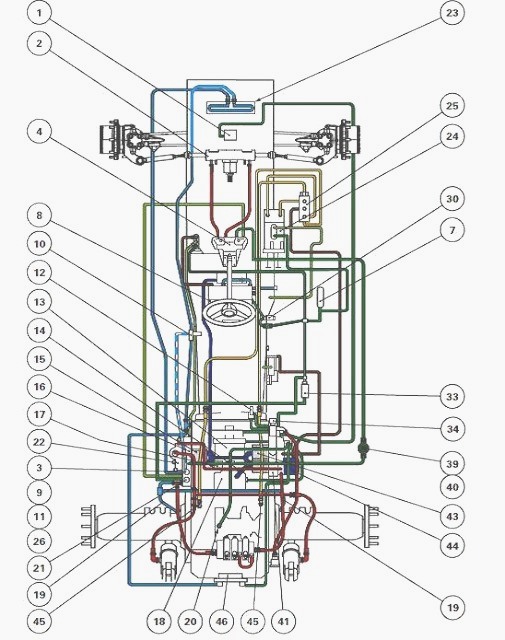

Layout of the main Speedshift and Power Shuttle system components

Parts list

(1) Front differential lock (2) Steering ram (3) Cooling system pressure

connector (4) Hydrostatic spool valve (Orbitrol) (5) Forward clutch

(reverse shuttle) (6)

Reverse clutch (reverse shuttle) (7) Accumulator (assisted master

cylinders) (8) Speedshift mechanism (9) Left-hand cover plate

(10) 1.5 bar valve (11) Temperature switch (12) Hare/Tortoise mechanism

(13) PTO clutch (14) Pump suction pipe (15) Low-pressure system

hydraulic pump (16)

Restrictor (17) Suction strainer (Reverse shuttle clutch lubrication

pump) (18) 4WD clutch (19) Brake lubrication pipes (20) Rear

differential lock (21) 17 bar valve

(22) Linkage spool valve (23) Oil cooler (24) Brake master cylinders

(25) FTE valve (26) Bleed connector (27) Diagnostics connector (reverse

shuttle lubrication)

(28) Reverse shuttle proportional solenoid valves

(30) Speedshift solenoid valve (31) Gearbox control unit (32)

Accumulator (33) 60 micron filter (34) Solenoid valves (Hare / Tortoise,

Differential lock, PTO, PTO

brake, 4WD) (39) 15 micron filter (40) Blockage indicator (41) Pump

coupling solenoid valve (43) High-pressure system hydraulic pumps (19cc

+ 14cc) (44) 150

micron suction strainer

(45) Left and right-hand brakes (46) PTO brake

Layout of the main Speedshift and mechanical reverse shuttle system

components

Parts list

(1) Front differential lock (2) Steering ram (3) Cooling system pressure

connector (4) Hydrostatic spool valve (Orbitrol) (7) Accumulator

(assisted master cylinders)

(8) Speedshift mechanism (9) Left-hand cover plate (10) 1.5 bar valve

(11) Temperature switch (12) Hare/Tortoise mechanism (13) PTO clutch

(14) Pump suction

pipe (15) Low-pressure system hydraulic pump (16) Restrictor (17)

Suction strainer (Reverse shuttle clutch lubrication pump)

(18) 4WD clutch (19) Brake lubrication pipes (20) Rear differential lock

(21) 17 bar valve (22) Linkage spool valve (23) Oil cooler (24) Brake

master cylinders (25)

FTE valve (26) Bleed connector (30) Speedshift solenoid valve (33) 60

micron filter (34) Solenoid valves (Hare / Tortoise, Differential lock,

PTO, PTO brake, 4WD)

(39) 15 micron filter (40) Blockage indicator (41) Pump coupling

solenoid valve (43) High-pressure system hydraulic pumps (19cc + 14cc)

(44) 150 micron suction

strainer (45) Left and right-hand brakes (46) PTO brake

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader