________________________________________________________________________________

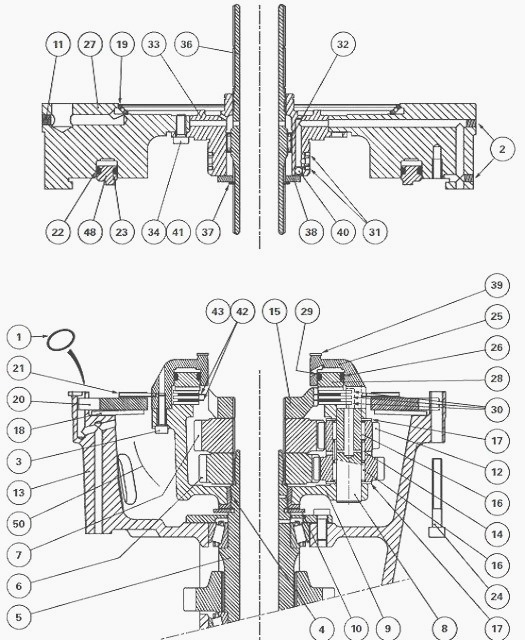

MF 5450, 5455 Power Shuttle Speedshift - Removing and install

Removing, splitting and disassembling the

planet carrier assembly

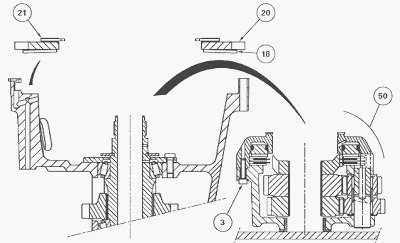

Remove the brake disc (21), thrust plate (20), Belleville washer (18)

and planet carrier assembly (50).

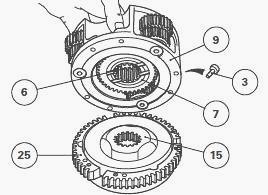

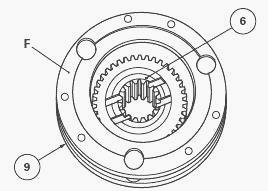

Put the planet carrier assembly on a workbench with the unit (9) turned

upwards. Remove the screws (3). Separate the unit (9) from Massey

Ferguson 5450, 5455

hydraulic cover plate (25) while holding sun gears (6) and (7).

The text and figures in this section concern the disassembly of a planet

carrier for a forward speed of 40 kph. Remove the input sun gear (7),

visually identifying the

direction of the lubricating grooves.

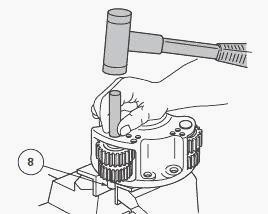

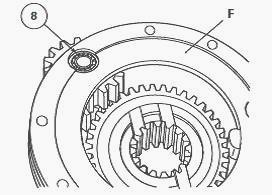

Drive out the pins (8) using a drift and a hammer. The pins are fitted

tight in the thickest part of the planet carrier with the lubrication

hole turned towards the

hydraulic cover plate (25). Remove the planet gears (12).

Recover needle roller bearings (16), spacers (14) and washers (17).

Remove the output sun gear (6).

Disassembling the MF 5455, 5450 hydraulic cover plate

Remove the splined hub (15). Remove the intermediate plates (30), discs

(42) and spring washers (43).

The clutch consists of:

- two friction discs;

- two spring washers;

- three intermediate plates.

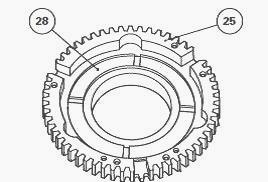

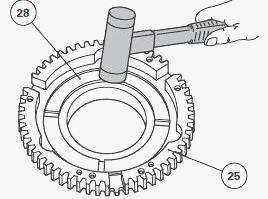

Remove the piston (28) by lightly tapping the cover plate (25) on a

wooden block or using a jet of compressed air. Remove the seals (26) and

(29) and discard

them.

Reassembling the planet carrier

Clean and check all components. Replace those that are defective.

Lubricate the needle roller bearings (16). Make sure that the radial

holes and axial channel for

the lubrication of pins (8) are not blocked.

Massey Ferguson 5455, 5450 Tractor speed can be between 30 and 40 kph.

Each speed is obtained by turning the planet gears and sun gears of the

Speedshift

epicyclic gear train. The sun gears have different numbers of teeth: sun

gear (6): 36 teeth/ sun gear (7): 39 teeth.

The text and figures in this section concern the reassembly of a planet

carrier for a forward speed of 40 kph. Put the output sun gear (6) in

the unit (9), turning the

sun gear lubricating grooves towards face "F" of the unit.

Install the needle roller bearings (16), separated by a spacer (14) in a

planet gear (12). Put an "assembled" planet gear in the unit, the

18-tooth gear turned.

Each

double planet gear is identified with one, two or three punchmarks on

one of its faces which is not necessarily the 18-tooth gear. In this

case, make the same marks

on the aforementioned gear using an appropriate pen. A punchmark

corresponds to the alignment of two teeth. Position the washers (17).

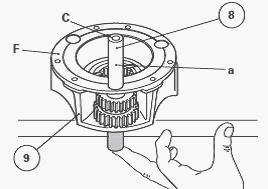

Centre the planet gear and washers with a guide pin O 16 mm, L = 80 mm.

Insert the pin (8) into the free bore on face "F" of the unit (9)

Install it partially set back,

with the radial lubricating hole "a" turned outwards and the end of

central channel "C" turned towards face "F".

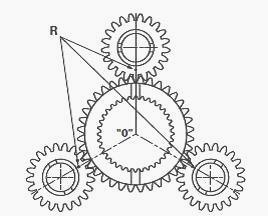

Repeat steps to assemble the two other planet gears. During these

operations, position the three planet gears according to marks "R" so

that they run in a line

corresponding with "O".

After final assembly of the pins (8), check again that the marks are

correctly aligned. Incorrect alignment may make it impossible to

assemble combined parts or

cause damage to the epicyclic gear train. Install the input sun gear (7)

with the lubricating groove turned towards the output sun gear (6).

Install the MF 5450, 5455 tractor hydraulic cover plate

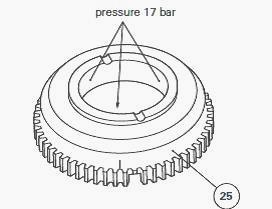

Clean and check all components. Replace those that are defective. Make

sure that the three holes of the 17-bar channel on the hydraulic cover

plate (25) are not

blocked. Install the lubricated seals (26) and (29) and onto the piston

(28).

Lubricate the mating faces of piston seals in the hydraulic cover plate.

Position the piston in the cover plate, turning the grooves towards the

operator. Install the

piston (28) using a plastic hammer, gradually and alternately striking

around the circumference of the piston.

Check that there are no fragments of "O" rings after fitting. Install

the splined hub (15). Install an intermediate plate (30), a disc (42)

and a spring washer (43).

Continue stacking parts, ending with an intermediate plate. Arrange the

cut section of spring washers in opposite directions.

Assembling the planet carrier

Screw two diametrically opposed guide studs in the Massey Ferguson 5450,

5455 hydraulic cover plate (25). Assemble the planet carrier unit (9) on

the hydraulic

cover plate (25) while holding the sun gears (6) and (7).

Position the unit and the cover plate so that the balancing marks

(ground in marks) are on opposite sides as far as possible. Reinstall

the screws (3). They must be

tightened to a torque of 14 - 20 Nm.

Strike pins (8) definitively

against the hydraulic cover plate (25) with a pin punch. Check: the

discs (42) are not compressed; the

planet gears (12) and sun gears (6) and (7) turn freely.

Install the planet carrier assembly (50) on the shaft (5). Position the

Belleville washer (18). Position the thrust plate (20) in the housing

(13). Install the brake disc (21)

on the planet carrier assembly.

Assembling and install the MF 5450, 5455 tractor front cover plate

Clean the cover plate. Make sure that the 17-bar channel and the

lubrication channel are not blocked. Check that the sealing rivets (2)

and (11) are present. Install

the seals (22) and (23) on the piston (48). Lubricate the mating faces

of the piston seals in the cover plate (27).

Position the piston in the cover plate, turning the grooves towards the

operator. Install the piston (48) using a plastic hammer, gradually and

alternately striking

around the circumference of the piston. Check that there are no

fragments of "O" rings after fitting.

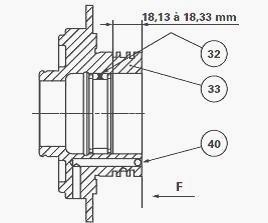

If work is necessary on the ring carrier (33):

- check that the channels are not blocked and that the ball bearing (40)

is correctly crimped in its port.

- If necessary, Install the needle roller bearing (32) 18.13 to 18.33 mm

from face "F";

- position the ring carrier on the cover plate, making sure that the low

pressure (17 bar) and lubrication holes correspond respectively with

those on the cover plate;

- Install and tighten screws (34) and (41), lightly smeared with Loctite

242 or similar, to a torque of 25 - 35 Nm.

Check that the lubrication holes on the shaft (36) are not blocked.

Slide the shaft in the ring carrier. Reinstall the washer (38) and

circlip (37). Test-Install the new

rings (31), making sure they turn freely in the grooves. After this

check, remove the rings and smear with miscible grease.

Install the rings in their respective grooves, making sure:

- that they do not exceed the circumference of the ring carrier;

- their ends overlap correctly. The slightest damage to rings may cause

a leak followed by a pressure drop and incorrect operation of the

Speedshift.

Smear the washer (39) with grease and Install it on the ring carrier

(33). Reinstall the new seals (1) on the housing (13). Reinstall the

shaft (36), ring carrier (33) and

front cover plate (27) assembly using the same procedure as for removal.

Install and tighten the screws (24) to a torque of 36 - 46 Nm, with the

thread lightly

smeared with Loctite 242 or similar.

Remove the makeshift lifting tool. Reinstall the Power Shuttle reverse

clutch. Reinstall the input unit and the Power Shuttle forward clutch.

Reinstall the spacer.

Reconnect the tractor between the engine and the gearbox.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader