________________________________________________________________________________

Massey Ferguson 6614, 6615 tractor electrohydraulic auxiliary spool valves

The Bosch/Rexroth SB23 LS spool valves controlling supply to the Massey

Ferguson 6614, 6615 hydraulic couplers are comprised of: hydraulic and

electrohydraulic part.

An electrohydraulic part comprising:

- an ON/OFF solenoid valve and a 3-way pressure relief valve located on

the end plate of the spool valve block,

- a pilot valve fitted in the electrohydraulic unit.

This section shall concern the hydraulic part only. The Bosch/Rexroth

SB23 LS electric hydraulic control spool valves are supplied by high

flow rate, high pressure

oil from the priority blocks.

When no functions are being activated, the entire flow rate is directed towards the spool valves. When certain functions are being supplied, the excess flow then remains available to the auxiliary spool valves.

The adjustment of the flow rate, expressed as a percentage, may be displayed on the onboard computer (Datatronic) by the operator.

The MF 6614, 6615 tractor electric hydraulic spool valves controlled by a Joystick are fitted with a floating Kick-out position (automatic return to neutral).

The main spool of the spool valve directs oil towards the outlet ports A or B. Each outlet port is linked to the LS pilot line of the variable displacement pump regulating valve via the priority block(s).

The spool valves consist of both electronic and hydraulic components,

the latter containing

spools and valves. Some elements cannot be repaired as spare parts.

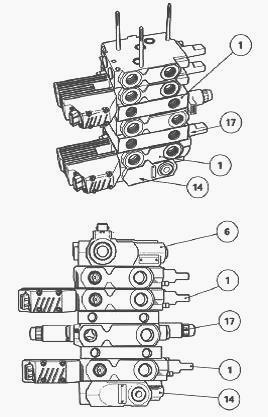

Different types of spool valve block components

A spool valve block can consist of three, four or five of the following

components. It can combine components of similar type of or different

types.

Component a - Electrohydraulic component (Joystick)

Component b - Electrohydraulic component (Dual Control)

Component c - Mechanically controlled component.

(1) Auxiliary spool valves (6) End plate (14) Inlet block (17) Lift

control spool valve (18) ON/OFF solenoid valve (19) Electronic units

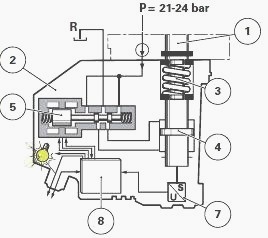

Operation of the pressure relief valve and electrohydraulic unit

When the ON/OFF solenoid valve located on end plate is open, the flow

from the pump is directed to the 3-way pressure relief valve.

The 3-way pressure relief valve supplies the pilot valve with a pressure

of 21 - 24 bar via a pressure balancing valve.

The pilot valve receives a signal from the digital device and moves the

main spool of the auxiliary electric hydraulic spool valve according to

the information

received from the Joystick.

The digital device is informed of the position of the main spool by a

displacement sensor.

The pilot valve and the digital device are housed in the unit fixed

below the spool valve.

The pilot valve is protected from possible oil contamination by a set of

FP filters (25 microns).

Electronic unit (2) channels P and R are connected to channels P1 and R1

of the MF 6614, 6615 auxiliary electrohydraulic spool valve.

(1) Main electric hydraulic valve spool (2) Electrohydraulic unit (3)

Return spring (4) Piston (5) Pilot valve (6) Digital electronic system

(7) Displacement sensor, FP

- Set of filters (25 microns), P - Pressure, R - Return

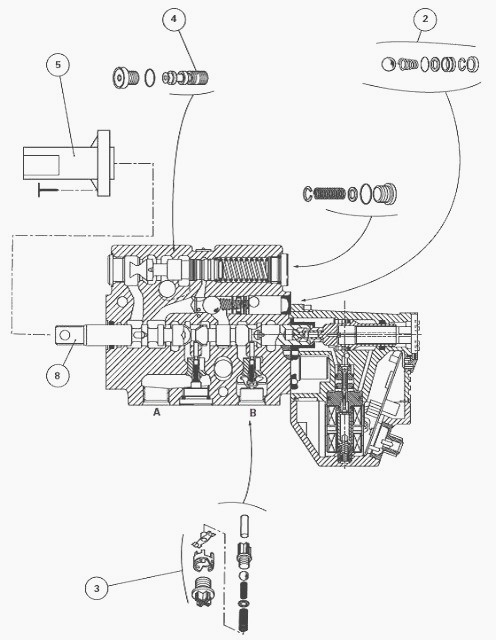

Operation of the auxiliary electric hydraulic spool valve

When the spool is moved electric hydraulically upwards by the pilot

valve, oil penetrates via channel P and travels to the flow regulation

control spool restrictor and

the grooves of the main spool.

The oil is then carried towards a main channel and lifts the ball of valve to enter a chamber. Displacement of the spool simultaneously opens the one-way valve.

The oil flows from the chamber towards port B and returns to the

housing through

port A via the hydraulic slave device. The operating principle is

identical when the spool is electro hydraulically moved down by the

pilot valve.

The oil then flows from the chamber towards port A and returns to the

housing through port B via the hydraulic slave device. The

electrohydraulic spool valves can

be manually controlled using a lever screwed onto the reversing lever.

Layout of components and identification of ports

(1) Main spool (2) Valve (3) Non-return valve (4) Pressure balancing

valve (5) Cover

Spool valve assembly

On Massey Ferguson 6615, 6614 tractors where one or more elements of the

auxiliary spool valves are operated mechanically, take care to

disconnect the link

cable(s) without turning the main spool of the valve a half turn.

Place the lift arms in the low position.

Disconnect:

- on mechanically operated spool valves - control cable, taking the

above reminder into consideration;

- on Joystick or lever operated (Dual Control) spool valves - solenoid

valve, connector(s) linked to the spool valve electrohydraulic unit(s),

marking their position(s).

Removing the spool valves

The spool valve block assembly must be removed complete before working

on it. Any operations carried out on the spool valves require scrupulous

cleanliness.

First correctly clean the spool valves (lift control and auxiliary) and

the areas around them before removing them.

If necessary, remove all the spool valves one after the other and

disconnect the hydraulic connections as they are removed.

Removing the lift control spool valve

Take off the supply and return pipes.

Disconnect the connectors of the lifting and lowering solenoid valves.

The brown connector is connected to the right-hand solenoid valve used to lower the lift control.

Remove the spool valve assembly.

Remove lift control spool valve.

Removing the inlet block

In order to fit the MF 6615, 6614 auxiliary spool valves in horizontal

position, it is necessary to remove the spool valve block assembly.

Loosen the P – R and LS unions, disconnect the hydraulic union and

electrical connectors, and remove the spool valve block. Remove the

inlet block.

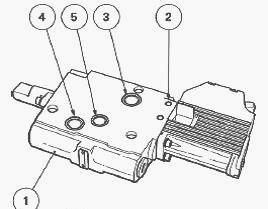

Install the spool valves

Wipe clean the mating faces of the inlet block, the lift control spool

valve, the auxiliary spool valves and the end plate.

Check that each

element is perfectly flat.

Check the tightness of the studs on the inlet block.

Position the new seals (2) (3) (4) and (5) on each element of the

distribution block (1).

Assemble the distribution block on the workbench by superposing the

elements and following the assembly procedure.

Reinstall fit the complete block on the Massey Ferguson 6614, 6615

tractor.

Reconnect the hydraulic pipes and electrical connectors.

Reconnect:

On mechanically operated spool valves

- the lifting and lowering solenoid valve connectors in accordance with

marks made during removal,

- the control cable(s);

On Joystick or lever operated (Dual Control) spool valves

- the lifting and lowering solenoid valve connectors in accordance with

marks made during removal,

- the connector(s) linked to the electrohydraulic unit(s), according to

marks made during removal,

- the solenoid valve located on the end plate.

Start the engine, place the lift control arms in the low position.

At each position, check the operation of:

- the hydraulic system.

- electronic system.

Check the oil tightness of the spool valves and hydraulic unions.

Assembly procedure

To obtain the correct assembly of seals (2) to (5), the reassembly of

each spool valve must be carried out vertically on the workbench.

In this order, stack the input unit, an auxiliary spool valve, a support

block, the lift control valve, an additional support block, and the

auxiliary spool valves.

Place a steel ruler R thrust against face F of the distribution block so

as to align the fixing points equally and correctly.

Tighten the nuts to a torque of 30 - 33 Nm. After the assembly of the spool valves, carry out the reassembly operations.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader