________________________________________________________________________________

Massey Ferguson 7616, 7618 Dyna 6 Transmission - GBA15 gearbox

Massey Ferguson 7618, 7616 gearbox (GBA-15) provides four basic synchronised ratios and six ratios for shifting under load.

The 24 ratios can be engaged manually or automatically inforward and

reverse position, without using the clutch pedal. The gearbox is divided

into two sections: front housing and rear housing.

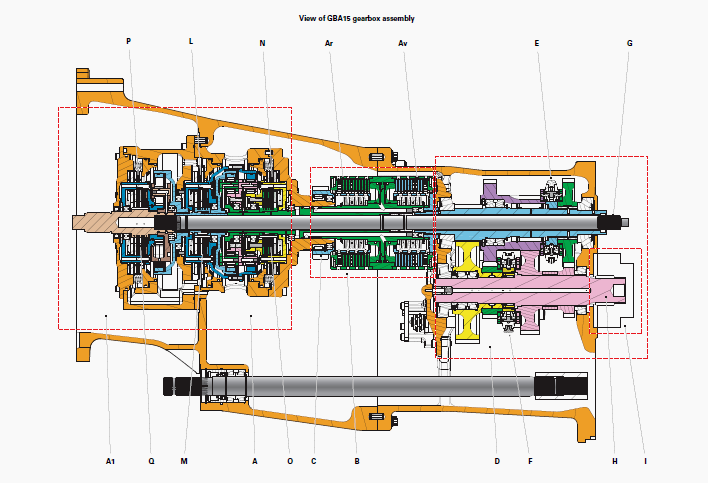

View of the gearbox assembly

A - Dynashift module with multiplier module A1, Ar - Reverse multidisc

clutch, Av - Forward multidisc clutch, B - Power Shuttle, C - Reverse

driving gear, D - Main

gearbox with four robotic ranges, E - Double cone synchroniser for

3rd/4th, F - Double cone synchroniser for 1st/2nd, G - Power take-off

shaft, H - Main gearbox

output shaft, I - Creeper gearbox (if fitted), L - Brake, M - Multidisc

clutch, N - Brake, O - Multidisc clutch, P - Brake, Q - Multidisc clutch

Fitted behind the engine, the front housing supports:

- the multiplier module to obtain two ratios for shifting under load;

- the Dynashift module with four ratios for shifting under load;

- the PowerShuttle.

The multiplier module and the Dynashift module make up the Powershift

module.

Fitted behind the front housing, the rear housing supports:

- the main gearbox with its four robotically-controlled mechanical

ratios;

- the creeper gearbox.

MF 7616, 7618 Multiplier module

The multiplier module is fitted at the GBA15 gearbox input. It allows

multiplier module ratios to be obtained by overincreasing respectively

two ratios of the Dynashift

module.

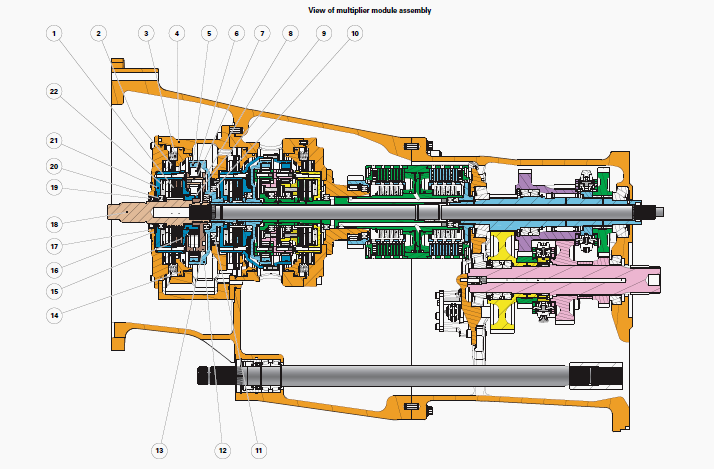

Multiplier module

(1) Clutch Q disc/intermediate plate assembly, (2) Brake P

disc/intermediate plate assembly, (3) Spring, (4) Multiplier module

housing, (5) Ring gear, (6) Planetary

gear, (7) Needle bearing, (8) Pin, (9) Sun gear, (10) Ball bearing, (11)

Ball bearing, (12) Ring-gear carrier, (13) Planet carrier, (14) Brake

piston, (15) Clutch cover,

(16) Friction washers, (17) Cover, (18) Input shaft, (19) Lip seal, (20)

Ball bearing, (21) Clutch bell housing, (22) Belleville washers

The multiplier module includes:

- an epicyclic gear train;

- a brake;

- a multidisc clutch.

The brake piston, supplied by a proportional solenoid valve (with ON/OFF

control), locks the brake discs.

The thrust plate moves forwards at the

same time,

compressing the two Belleville washers to release the multidisc clutch.

The two multiplier module ratios are 1/1 and 1.423/1.

MF 7618, 7616 Dynashift module

This Dynashift-module provides four ratios for shifting under load plus

ratios in combination with the multiplier module.

The Dynashift module includes two epicyclic gear trains:

- the primary epicyclic gear train, the main module component;

- the secondary epicyclic gear train, used to control the speed of the

primary sun gear. This gear train is controlled hydraulically by the

brakes via two proportional

solenoid valves (with ON/OFF control) and two multidisc clutches under

pressure from the Belleville washers.

Massey Ferguson 7616, 7618 gearbox PowerShuttle

The PowerShuttle is located in the centre of the gearbox. It connects

the Dynashift module to the main gearbox.

The Power Shuttle includes:

- two multidisc clutches (front and rear) located back to back and

controlled by two proportional solenoid valves with PWM control;

- a mainshaft providing the reversing function.

Main gearbox

The main gearbox has four ranges selected by two robotically-controlled

double cone synchronisers (electrohydraulic).

The main gearbox input drive is supplied by the multiplier.

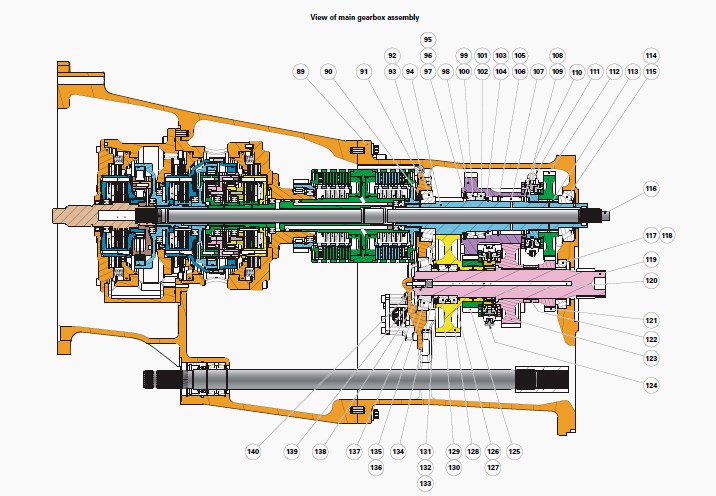

Main gearbox

(89) Gearbox housing, (90) Shim(s), (91) Compartment, (92) Bearing cup,

(93) Bearing cone, (94) Primary shaft, (95) Circlip, (96) Thrust washer,

(97) Shim(s), (98)

1st/3rd double pinion, (99) Bearing cup, (100) Bearing cone, (101)

Bearing cone, (102) Bearing cup, (103) Spacer, (104) Circlip, (105)

Circlip, (106) Thrust washer,

(107) Needle bearing, (108) Thrust washer, (109) Circlip, (110) Special

circlip, (111) 3rd/4th double cone synchroniser, (112) 4th driving gear,

(113) Ring, (114)

Bearing cup, (115) Bearing cone, (116) Power take-off shaft, (117)

Bearing cone, (118) Bearing cup, (119) Output shaft, (120) Needle

bearing, (121) 4th driven

pinion, (122) Spacer, (123) 3rd driven pinion, (124) 1st/2nd double cone

synchroniser, (125) 1st driving gear, (126) Bearing cone, (127) Bearing

cup, (128) 2nd gear

pinion, (129) Bearing cup, (130) Bearing cone, (131) Circlip, (132)

Thrust washer, (133) Shim(s), (134) Special spacer, (135) Bearing cup,

(136) Bearing cone, (137)

Shim(s), (138) Spring, (139) "O" ring, (140) Lubrication pipe

Dynashift and PowerShuttle modules

The four main gearbox ranges are automated. All ratios may be engaged or

disengaged automatically by the tractor electronic control without

intervention by the

driver.

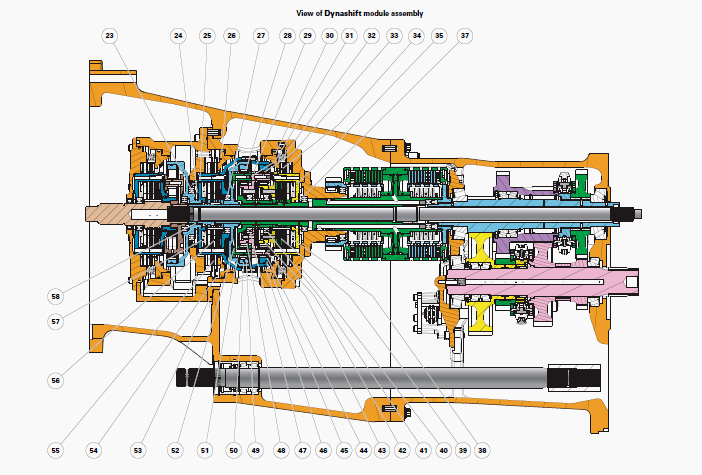

MF 7616, 7618 Dynashift module

(23) Thrust plate, (24) Friction washer, (25) Clutch bell housing, (26)

Brake piston, (27) Ball bearing, (28) Needle bearing, (29) Secondary

planet carrier, (30) Brake

piston, (31) Pin, (32) Spring, (33) Needle bearing, (34) Brake N

disc/intermediate plate assembly, (35) Clutch bell housing, (37)

Friction washer, (38) Belleville

washers, (39) Clutch O disc/intermediate plate assembly, (40) Rear

cover, (41) Ball bearing, (42) Secondary sun gear, (43) Pin, (44)

Planetary gear, (45)

Secondary ring gear, (46) Secondary ring-gear carrier, (47) Ball

bearing, (48) Primary sun gear, (49) Planetary gear, (50) Primary ring

gear, (51) Primary ring-gear

carrier, (52) Primary planet carrier, (53) Dynashift module housing,

(54) Spring emplacement, (55) Brake L disc/intermediate plate assembly,

(56) Clutch M

disc/intermediate plate assembly, (57) Belleville washers, (58) Primary

shaft

Creeper gearbox

A unit mounted on the main gearbox output shaft is used to obtain slow

forward speeds.

This mechanically-controlled unit encloses a traditional

final drive giving a

reduction of 4/1.

Lubrication

The lubricating oil is directed by the tractor hydraulic circuit.

It penetrates the two ports located to the left of the main gearbox and PowerShuttle housings respectively.

It lubricates the bearings, pinions and synchroniser hubs via axial channels and ports.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader