________________________________________________________________________________

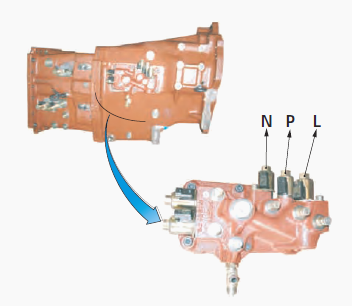

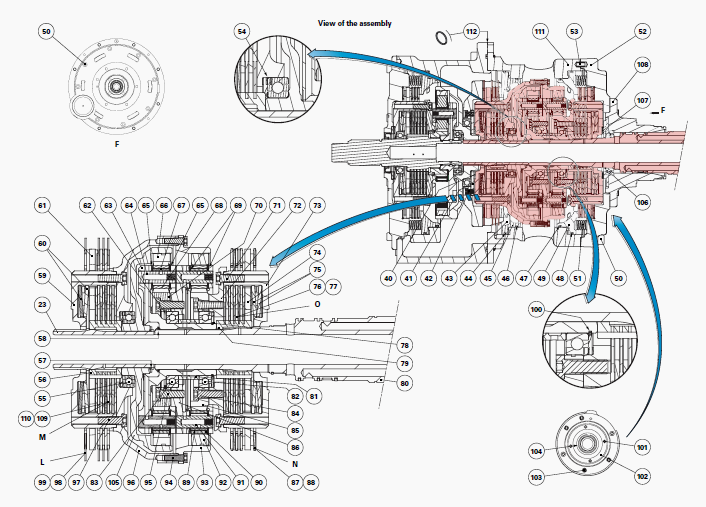

Massey Ferguson 7622, 7624 Dyna 6 Transmission - Powershift module

Massey Ferguson 7622, 7624 Dyna 6 transmission (GBA15 gearbox)

Powershift module is housed inside a housing located between the engine

and the gearbox. It provides six ratios at the gearbox input for

shifting under load.

Operating principle of the Powershift module

and its control

MF 7622, 7624 Powershift module comprises:

- the multiplier module

- the Dynashift module.

The multiplier module

The multiplier module is controlled by proportional solenoids valves N

and P.

It comprises:

- a standard epicyclic gear train;

- a clutch;

- a brake.

Direct drive (ratio 1/1)

The sun gear is attached to the planet carrier via the clutch. Drive

enters via the planet carrier and exits via the ring gear.

Overdrive MF 7624, 7626 transmission (ratio 1.423/1)

The sun gear is immobilised on the gearbox housing by the brake. It

allows the engine speed to go into overdrive when ratios E and F are

engaged.

The Dynashift module

The Dynashift module provides four ratios for shifting under load - A,

B, C and D - controlled by proportional solenoid valves L and N.

It

comprises:

- two standard epicyclic gear trains (primary and secondary);

- two brakes;

- two clutches.

Drive enters and exits via the primary epicyclic gear train. The

clutches/brakes operate on the secondary epicyclic gear train ring gear

and sun gear at an opportune

moment in order to modify the rotational speed of the primary sun gear,

thus creating ratios A, B, C and D of the Dynashift module.

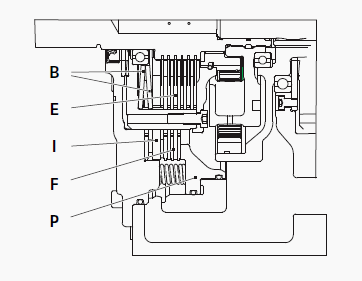

The clutches/brakes that select the multiplier module ratios and the

Dynashift module ratios are each controlled by a piston P. When a brake

is engaged, the related

clutch is disengaged, and vice versa.

Control pistons P operate act both on brake discs F and on junction

plate I. When piston P is under pressure, plate I pushes back Belleville

washers B of clutch E.

When the pressure is released, Belleville washers B push piston P back

via junction plate I and tightens clutch discs E.

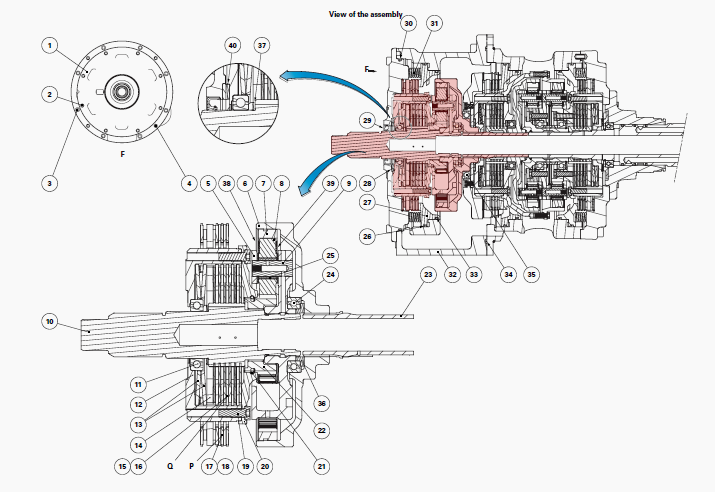

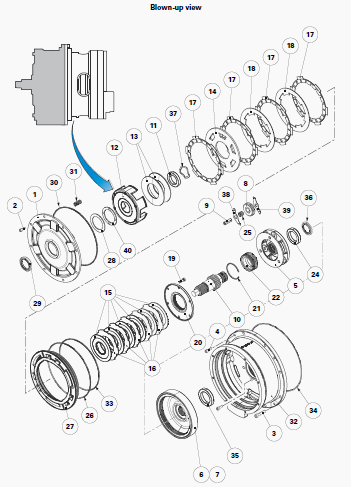

Multiplier module

(1) Cover plate, (2) Screw, (3) Screw, (4) Screw, (5) Planet carrier,

(6) Ring gear carrier, (7) Ring gear, (8) Planet gear, (9) Planet gear

pin, (10) Input shaft, (11) Ball

bearing, (12) Clutch Q bell housing, (13) Belleville washers, (14)

Clutch Q/brake P junction plate, (15) Clutch Q discs, (16) Clutch Q

intermediate plates, (17) Brake

P discs, (18) Brake P intermediate plates, (19) Screw, (20) Clutch Q

cover plate, (21) Snap ring, (22) Sun gear, (23) Dynashift module input

shaft, (24) Ball bearing,

(25) Planet gear needle rollers, (26) "O" ring, (27) Brake P piston,

(28)Washer, (29) Lip seal, (30) "O" ring, (31) Spring, (32) Multiplier

module housing, (33) "O" ring

(34) "O" ring, (35) Ball bearing, (36) Splined washer (bronze), (37)

Waved washer (spring), (38) Wear plate, (39) Wear plate, (40) Friction

washer

Massey Ferguson 7624, 7622 Powershift module control

The Powershift module ratio can be changed via:

- the multifunctional Power Control lever located on the left underneath

the steering wheel;

- the other lever fitted to the right-hand armrest.

In basic operating mode, ratios are shifted in Speedmatching mode. The

most suitable ratio under load is then selected automatically when

shifting range.

Depending on the option, ratio shifting can be completely automatic.

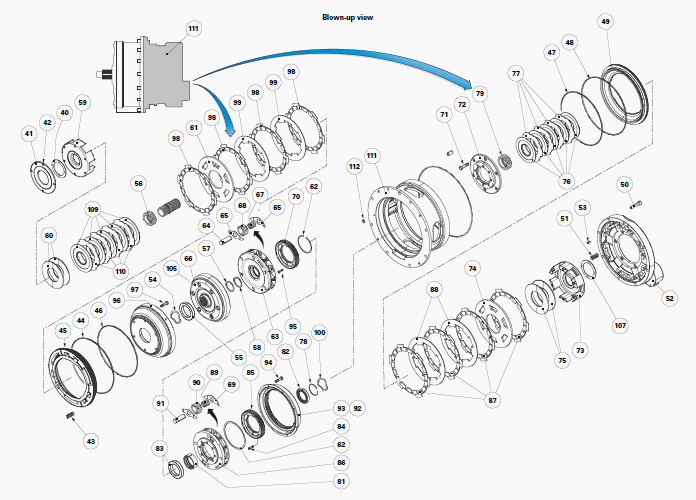

Dynashift module

(40) Friction washer, (41) Thrust washer, (42) Screw, (43) Location of

springs, (44) "O" ring, (45) Brake L piston, (46) "O" ring, (47) "O"

ring, (48) "O" ring, (49)

Brake N piston, (50) Screw, (51) Spring, (52) Rear cover plate of

Dynashift, (53) Dowel, (54) Waved washer (spring), (55) Ball bearing,

(56) Clutch M hub, (57)

Circlip, (58) Snap ring, (59) Clutch M bell housing, (60) Belleville

washers, (61) Clutch M/brake L junction plate, (62) Snap ring, (63)

Primary planet carrier, (64)

Planet gear pin, (65) Wear plates, (66) Primary ring gear, (67) Primary

planet gear needle rollers, (68) Primary planet gear, (69) Wear plates,

(70) Primary sun gear,

(71) Screw, (72) Clutch O cover plate, (73) Clutch O bell housing, (74)

Clutch O/brake N junction plate, (75) Belleville washers, (76) Clutch O

discs, (77) Clutch O,

intermediate plates, (78) Snap ring, (79) Clutch O hub, (80) Shaft/bell

housings, (81) Spacer, (82) Ball bearing, (83) Ball bearing, (84) Screw,

(85) Secondary sun

gear, (86) Secondary planet carrier, (87) Brake N discs, (88) Brake N

intermediate plates, (89) Secondary planet gear needle rollers, (90)

Secondary planet gear,

(91) Planet gear pin, (92) Secondary ring gear, (93) Secondary ring gear

carrier, (94) Screw, (95) Screw, (96) Secondary ring gear/bell housing,

(97) Screw, (98)

Brake L disc, (99) Brake L intermediate plates, (100) Waved washer

(spring), (101) Screw, (102) Thrust plate, (103) Screw, (104) Snap ring,

(105) Primary bell

housing, (106) Bearing with sealed face, (107) Friction washer, (108)

Bush, (109) Clutch M discs, (110) Clutch M intermediate plates, (111)

Dynashift module

housing, (112) "O" ring

Removing and refitting the Powershift module

Disconnect the MF 7622, 7624 tractor between housing (C) of the robotic

gearbox and housing of the Powershift module (C1).

Separate housing C1 from the engine.

Remove the hydraulic control unit located to the right of housing C1

together with its connecting pipes.

From housing C1 remove: the PTO shaft; the reverse layshaft; the reverse

driven gear.

Stabilise housing C1 of the Powershift module in a vertical position on

wooden blocks.

Removal

Unscrew three screws (2) from the multiplier cover plate. In their

place, fit locally obtained flanges B using screws V with the correct

thread length.

Unscrew the eight M10 screws V2 without working on the M8 screws V1.

Unscrewing the M8 screws would cause the Powershift module to separate,

which is not desired.Sling the Powershift module.

To remove the Powershift module from housing C1, proceed as follows:

- Using a suitable sling and hoist, lift the Powershift module slightly

out of housing C1.

- Turn the Powershift module so that lug O of the reverse layshaft gear

is positioned between the two bosses B.

- Tilt the Powershift module steeply towards lug O and continue to lift

it so that it enters groove A (approx. D 310 mm) of housing C1.

- Definitively remove the Powershift module from housing C1.

Remove and discard seal J. Place the Powershift module in a vertical

position on a suitable support S.

Refitting

Lightly smear "O" ring J with miscible grease. Fit it into the groove of

the Powershift module housing (111).

Check that dowel P is present on housing C1. Clean mating face F of the

Powershift module and that of housing C1.

If mating face F of housing C1 was chipped or deformed during the

removal of the Powershift module, smooth it off with fine sandpaper.

To refit the Powershift module in housing C1, proceed as follows:

- Use flanges B and the sling used during removal.

- Mark the location of dowel P with a line of paint on housing C1 and on

the Powershift module.

- Position the Massey Ferguson 7622, 7624 Powershift module at the

opening of groove A of housing C1, positioning lug O of the reverse

layshaft gear between the

two bosses B.

- Tilt the Powershift module steeply towards lug O and continue to lower

it so that it enters groove A of housing C1.

- When it has entered the groove of housing C1, continue to lower the

Powershift module slowly, turning it gently to bring it into position

with the paint lines made

previously. Definitively refit the Powershift module in housing C1.

Screw the eight M10 screws V2. Tighten to 57-77 Nm. On the multiplier

cover plate: Unscrew screws V.

Remove the locally obtained flanges B. Screw in the original screws (2).

Tighten to a torque of 37 Nm.

Stabilise front housing C1 of the Powershift module in a horizontal

position. Refit: the reverse driven gear; the reverse layshaft; the PTO

shaft.

Clean the mating faces: of the hydraulic cover plate; of the hydraulic

control cover plate on housing C1. Check that transfer pipes T are

present.

Lightly smear the mating face of the hydraulic cover plate on housing C1

with Loctite 510 or equivalent.

Do not block low-pressure hydraulic port O (approx. 21 bar) supplying

ranges 1 to 4 of the robotic gearbox.

Refit the hydraulic control unit. Screw in the screw. Tighten to 57-77 Nm. Fit housing C1 to the engine. Reconnect the tractor between housing C of the robotic gearbox and housing C1 of the Powershift module.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader