________________________________________________________________________________

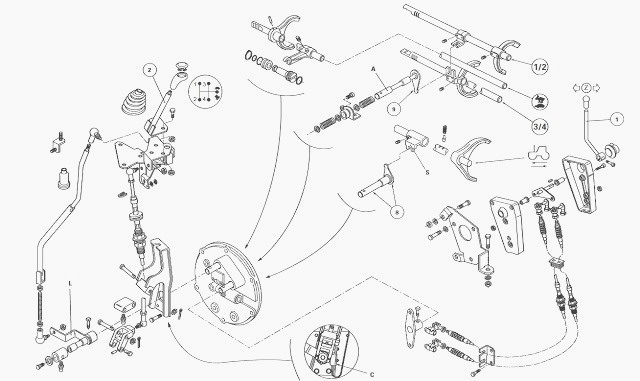

Massey Ferguson 8150, 8160 gearbox - Selector cover

Massey Ferguson 8150, 8160 tractors with a mechanical reverse shuttle

are equipped with either a cab or a platform and a selector cover of

similar construction. For the version with the footstep.

The selector cover, installed on the

right-hand side of the housing on the Heavy gearbox, has two separate

levers providing two different functions:

- front lever - for controlling the reverse shuttle,

- rear lever - for selecting the four basic speeds and the two Hare /

Tortoise ratios (Hi - Lo).

Tractors with cab

- Control lever (1) mounted on the left-hand part of the instrument

panel fascia actuates the reverse shuttle via a control cable.

- Control lever (2) located above and to the right of the console

selects the four basic speeds and also acts on the Hare/Tortoise

function, via a rod and cable.

When the MF 8150, 8160 tractor is stopped, cell “C” mounted on a bracket

on the selector cover informs the user that a gear has remained engaged,

and that the

handbrake is on. The warning is issued by a buzzer located under the

instrument panel surround.

(1) Return ports (2) Grounding lug (3) Screw (4) Temperature probe with

seal. (5) Seal (6) Shouldered ring (7) Selector cover (8) Finger-pin

assembly (reverse

shuttle) (9) Finger-pin assembly (speeds) (10) Grid (11) Screw (12)

Spring (13) Spring cup (14) Spring cup (15) Spring (16) Spring cup (17)

Seal

(18) Shouldered ring (19) Seal(s) (20) Hare / Tortoise switch

Reverse / Forward lever

On Massey Ferguson 8150, 8160 tractors with cabs, lever (1) has the

following positions:

- upwards (forward drive)

- downwards (reverse drive)

Moving lever (1) results in rotation of the pin which is hard-mounted to

finger (8); the follower moves selector “S”.

Gear lever

Selecting 1st / 2nd gear

- Gear lever (2) pushes lever “L” (Fig.70) and engages finger (9) in the

1st / 2nd gear selector fork (Fig.69).

- The first ratio is obtained by moving lever “L” upwards, and the

second ratio by moving it downwards.

Selecting 3rd / 4th gear

- In this configuration, gear lever (2) (Fig.70) is in the intermediate

position; finger (9) integral with shaft “A” is engaged in the 3rd / 4th

gear selector fork (Fig.68).

- The third ratio is obtained by moving lever “L” upwards, and the

fourth ratio by moving it downwards.

Safety interlock - A locking system located on the rear face of the

gearbox, on the end of the selector rails, prohibits accidental gear

shifting.

Hare / Tortoise function

Identification of components

(1) Solenoid valve (2) O’ring (3) Piston (4) Bearing (5) O’rings (6)

Circlip (7) Selector cover

Selecting the Hare / Tortoise range is done with the gear lever in the

neutral position, by pulling lever "L" towards the outside of cover

(Fig. 70). Finger (9) presses

the end of switch (20) (Fig. 68) which informs the electronic system

that the Hare / Tortoise solenoid valve can be switched.

Hare position

Solenoid valve (1) (Fig.71) mounted on selector cover (7) is closed,

which causes a pressure drop in chamber "B".

The constant pressure (17 bar) in chamber "A" is applied to the annular face of piston (3), which moves forward and entrains fork "F1" towards the Hare position under the action of selector "S".

The oil contained in chamber "B"

returns to the sump via the solenoid valve.

Tortoise position

Moving switch (20) (Fig. 68) again causes opening of solenoid valve (1)

(Fig.71). Oil pressurised at 17 bar arrives in chamber "B".

Since the

pressure acting on the

large diameter of the piston is greater than that acting on the annular

face, it forces the piston to retract, driving selector "S" and fork

"F1" towards the Tortoise

position. The oil contained in chamber "A" returns to the 17 bar

circuit.

Removing and refitting the cover

Immobilise the MF 8150, 8160 tractor. Chock the left rear wheel. Set the

handbrake.

Place chocks between the frame and the front axle.

Remove the right rear wheel or set to wide tread. Install an axle stand

if necessary.

Pivot the footstep assembly and battery chest or remove any neighbouring

parts likely to impede removal of the selector cover (depending on

version).

Drain the gearbox.

Disconnect the electrical harnesses on the cover.

Unscrew the tube and hose unions.

Tractors with cabs

Gear control. Disconnect the harness from cell "C" (Fig.70). Remove ball

joint (4). Remove screw (3).

Remove pins (11). Disconnect ball joint (5).

Note the adjustment of cable (6).

Slightly loosen upper nut (12) and

separate the cable from bracket (2). Reverse shuttle control.

Remove clips (1). Note the adjustment of cables (2). Loosen nuts (3).

Separate the cables from bracket (4).

On MF 8160, 8150 tractors fitted with a creeper unit, disconnect control

cable (1).

Remove screws (3), taking care to identify the position of grounding lug

(2).

If installed, remove bracket (2) supporting the creeper control cable.

Release and remove the selector cover.

Clean the mating faces on the gearbox and cover.

Install the following parts:

On the cover: the Hare / Tortoise piston in the "Hare" position

On the gearbox: the Hare / Tortoise fork in the "Hare" position, the 1st

/ 2nd gear and 3rd / 4th-gear selector forks and the reverse shuttle

fork in the neutral position.

Coat the mating face of the gearbox housing with sealing compound

(Masterjoint 510 Loctite or equivalent).

Turn the gear and reversing control linkage on the cover to engage them

in their respective selectors during positioning of the cover on the

gearbox.

Install the bracket for the creeper control cable (if installed).

Position lug (2). Install screw (3) and torque to 34 - 51 Nm.

Depending on the option, reconnect and adjust the creeper gear control.

Reassemble the gear control.

Reassemble the reverse shuttle control.

Use a grease gun to grease the joints of the gear control on the

selector cover.

Install any items previously removed around the cover.

Replace the wheel and torque the screws or nuts depending on the

version.

Service the oil in the sumps and check the level in the sight glass

located on the left-hand of the centre housing.

Remove the chocks between the frame and front axle. Release the handbrake. With the engine running, check passage of all gears and the reverse shuttle. Also check the Hare/Tortoise position.

If necessary, and with

the engine stopped,

adjust the controls.

Check that the buzzer of the safety cell vibrates correctly (contact

set, handbrake on and gear engaged).

Carry out a road test.

Replacing the Hare/Tortoise piston seals

Remove the cover.

Remove circlip (6). Extract piston (3) with bearing (4) and scrap

O’rings (2) and (5).

Clean and check the parts; replace any that are faulty.

Without installing the O’rings on the piston, check that the latter

slides freely in the bore in the cover.

After inspection, lubricate and fit new O’rings.

Install the selector cover. Replacing piston (3), bearing (4) or circlip

(6) implies checking or repeating the setting of selector "S" on the

Hare/Tortoise range.

Disassembling and reassembling the selector mechanisms

Remove the cover and tighten in a soft-jaw vice.

Tractors Massey Ferguson 8160, 8150 with cabs

Remove screws (1) and (4). Remove selector (3), link rod (5) and bracket

(2).

Remove the pin integral with finger (8).

Remove screw (11). Remove the gear control assembly.

Remove cup washers (14) and (16) and spring (15).

Separate the assembly comprising pin and finger (9) from grid (10).

Remove spring cup (13) and spring (12).

If necessary, unscrew and remove Hare/Tortoise switch (20), the threaded

fittings on return ports (1), and temperature probe (4). Recover seal(s)

(19) from the

Hare / Tortoise switch.

Extract seals (5) and (17).

If considered necessary to replace guide rings (6) and (18), lightly

coat the edges of the replacement rings with Loctite 638 or equivalent

and fit them tight so that

they come into contact with the shoulders on the cover.

If removed, reinstall Hare / Tortoise switch (20) with the same number

of seals as removed. Apply a light coat of Loctite 542 to the threads of

the return port and the

temperature probe unions, then refit the unions.

Lightly coat the outside diameter of seals (5) (17) with Loctite 542,

then fit the seals tight onto cover using a suitable fixture.

From the inside of the cover, refit the pin-finger assembly (8) without

damaging the lip of seal (5).

Install reversing linkage (5). Coat the threads of screw (4) with Loctite 241 or equivalent and install the screw. Torque to 30 - 35 Nm. Reassemble spring (12) and spring cup (13) on shaft (9).

Assemble the

shaft with grid (10). Reassemble cup washers (14) (16), with spring (15)

in between.

Install the pin-finger assembly (9) without damaging the lip of seal

(17). Coat threads of screw (11) with Loctite 270 or equivalent. Install

the screw and torque to 25 -

35 Nm.

Positioning bracket

Install bracket (2), observing a clearance of 29 mm between the bracket

and the 22-mm diameter of shaft “A” (Fig. 72). Lightly coat screw (1)

with Loctite 270 or

equivalent, fit the screw and torque to 25 - 35 Nm.

Positioning bracket

This clearance MUST be observed to ensure correct operation of the cell.

Reassemble linkage (3). Coat threads of screw (4) with Loctite 241 or

equivalent, fit the screw and torque to 30 -35 Nm.

Check that the selector mechanisms move freely. Remove the cover from the vice and refit to the Gearbox.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader