________________________________________________________________________________

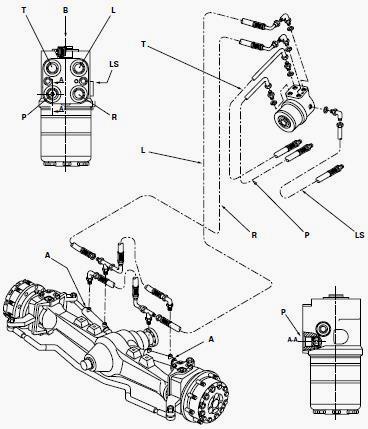

Massey Ferguson 8280 Tractor hydrostatic steering for 4WD

The steering system on Massey Ferguson 8280, 8270 tractor is of the

dynamic type (constant flowrate of 0.5 l/min, standby pressure of 6

bar). There is no mechanical linkage between the steering wheel and the

steering rams. Its control principle is of the Load Sensing type.

The main components of the circuit are:

- pressurised oil feed from the priority block(s) (depending on version)

supplied by the variable displacement pump,

- an Orbitrol steering distribution valve of the closed centre OSPD.LS

100 - 260 type with twin stator rotors mounted in by-pass.

- two double acting steering rams connected in parallel and mounted on

the 4WD front axles - ZF APL 5052

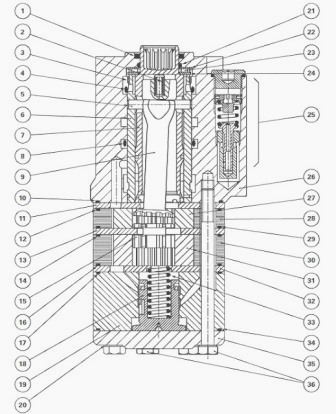

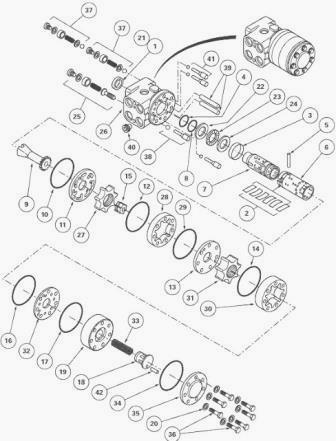

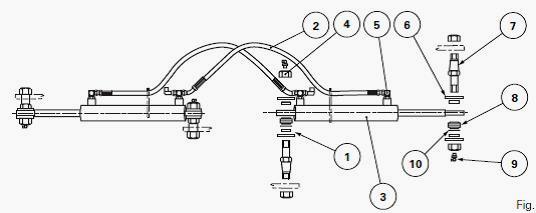

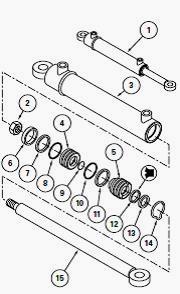

Fig.36/37. MF 8280, 8270 tractor steering construction (Parts

list)

(1) Lip seal, (2) Centring springs, (3) Bush, (4) O’ring, (5) Pin, (6)

Sleeve, (7) Spool valve, (8) O’ring, (9) Linkage shaft, (10) O’ring,

(11) Plate, (12) O’ring, (13) Plate, (14) O’ring, (15) Spacer, (16)

O’ring, (17) O’ring, (18)Integrated spool, (19) Spool body, (20) Seals,

(21) O’ring, (22) Washer, (23) Needle bearings, (24) Washer, (25)

Discharge valve, (26) Block, (27) Rotor (100 cm3), (28) Stator (100

cm3), (29) O’ring, (30) Stator (160 cm3), (31) Rotor (160 cm3), (32)

Plate, (33) Spring, (34) O’ring, (35) Closing plate, (36) Bolts, (37)

Shock valves, (38) Non-return valve, (39) Spacers, (40) One-way valve,

(41) Suction valve, (42) Pin

Disassembling and reassembling the

distribution valve (Orbitrol)

Disassembly MF 8280, 8270 tractor steering

- Remove the distribution valve from the Massey Ferguson 8280, 8270

tractor.

- Place the distribution valve in a vice fitted with plastic jaw

protectors.

- Mark the location of bolts (36). Remove the bolts along with seals

(20).

- Take off the closing plate (35), the O’ring (34), the body (19), the

integral spool (18) and spring (33).

- Remove the O’ring (17). Locate the position of plate (32) and remove

it.

- Remove O’ring (16). Remove stator (30) and rotor (31). Take out the

O’ring (14).

- Locate and remove plate (13).

- Remove spacer (15), stator (28), rotor (27). Locate and remove plate

(11). Take out O’ring (10).

- Take out the splined linkage shaft (9).

- Unscrew the threaded socket and recover the ball from the non-return

valve (38).

- Take out the two pins and the two balls from the Massey Ferguson 8280,

8270 tractor spool valve suction valves (41).

- Extract the sleeve assembly (6) and spool valve (7) by pushing on it

and checking that pin (5) lies along the horizontal axis.

- Take out washers (22) (24), the needle bearings (23) and bush (3) from

the sleeve / spool valve assembly.

- Take out pin (5) and centring springs (2) by pressing on one of their

ends. Separate sleeve (6) from spool valve (7).

- Unscrew the plug of the discharge valve (25). Using an 8 mm Allen key,

disassemble the threaded bush and remove the seal, spring and valve (the

inserted valve seat cannot be removed).

- Unscrew the two plugs from the shock valves (37), remove the seals.

Using a 6 mm Allen key, disassemble the threaded bushes and take out the

springs, the balls and their seats (the inserted valve seats cannot be

removed).

- Extract the oil tightness seal (1) and O’ring (21).

- Disassemble the check valve (40).

Reassembly MF 8280, 8270 tractor steering

- Check and clean all components, replace any parts found to be

defective. Lubricate the components with clean transmission oil before

reassembly.

- Refit the check valve (40). Fit seal (1), O’ring (21) and the bush.

- Fit the balls and springs in the housings of the shock valves (37).

Screw in the threaded bushes, place the seals and tighten the plugs.

- In the housing of the discharge valve (25), place the valve and

spring, screw in the threaded bush. Fit the seal and tighten the plug to

a torque of 40 - 60 Nm.

- Introduce the spool valve (6) in sleeve (7). Position the centring

springs (2) according to Figure 37 and fit pin (5).

- Position bush (3) on the sleeve and spool valve assembly so that the

chamfer facilitates assembly in the spool valve.

- Place washers (22) (24), with the chamfer of washer (24) turned

towards the centring springs (2) and placing needle bearing (23) in

between them.

- Assemble the sleeve and spool valve assembly in the spool valve using

a slight oscillatory movement. Take care that pin (5) is held

horizontally.

- In the suction valve housings (41), place the two balls and the two

pins.

- In the non-return valve housing (38), place the ball and screw in the

threaded bush.

- Position the splined linkage shaft (9). Place the O’ring (10), and the

distributor plate (11).

- Fit rotor (27) so that the two cavities "C" lie in the axis of the

slot of splined shaft (9). Place the O’rings (12) (29) on the stator

(28).

- While avoiding moving the rotor (27), fit the stator (28). Then turn

it so that its fixing holes match those in the spool valve.

- Refit rotor (31) on the spacer (15) so that the two cavities "C" lie

in the axis of the slot of splined shaft (9).

- Place O’rings (14) (16) on the stator (30). Fit and move it so that

the fixing holes match those provided in the spool valve.

- Refit plate (32) in the position noted during disassembly.

- Check that the bore of body (19) and the rim of spool (18) are free of

scratches or burs.

- Check that the spool moves normally in the body.

- Slide the spool fitted with its oil tightness components into the

body. Place O’rings (17) (34) and spring (33). Refit the closing plate

(35).

- Refit the new seals (20) and bolts (36) at the emplacement noted

during disassembly.

- Alternately tighten the bolts to a torque of 30 - 35 Nm.

- Using a test bench or an appropriate fixture, check the adjustment and

operation of the spool valve. Refit the spool valve on the tractor.

- Check the oil tightness of the unions.

Fig.58. Layout of channels and ports

Disassembling and reassembling Massey

Ferguson MF 8270, 8280 tractor steering ram

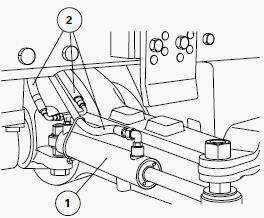

Removal

Fig. 55

- Disconnect the hoses (2), carefully noting their positions (Fig.

55-56)

- Loosen and take off nut (4) holding cylinder (3) on the stub (7)

concerned.

- Repeat the previous operation with the fixing point of the piston rod.

- Remove washers (6), spacers (1), carefully noting their positions.

- Remove the ram(s) (1).

- If necessary, take out the circlip(s), remove the ball joint(s) (8).

Refitting

Fig. 56

- If removed, replace the ball joint(s). Fit the circlip(s). (Fig. 56)

- Refit the ram(s), spacer(s) (1) with the chamfer facing the ball joint

and washers (6).

- Fit and tighten the nut(s) (4) to a torque of 440 Nm. Reconnect the

hose pipes (2).

- Using a grease gun and bearing grease, grease the pins (7).

Disassembly

- Take off snap ring (14) by turning the oil tight stuffing box (5)

using a locally manufactured pin wrench. Take out piston rod (15) from

cylinder (3).(Fig. 57)

- Fix the piston rod in a vice using the end intended for holding the

ball joint.

- Loosen and remove nut (2).

- Remove piston (4) and take off O’ring (9).

- Separate the stuffing box (5) from the shaft (15).

Remove:

- from the piston: oil seal (6), bush (7) and O’ring (8).

- from the oil tight stuffing box: O’ring (10), washer (11), oil seal

(12), oil scraper seal (13).

Fig. 57

Reassembly

- Clean and inspect the components. Replace any found to be

defective.(Fig. 57)

- Check that the bore of the cylinder (3) and the rim of the piston (4)

are free from scratches and that the oil passage ports in the cylinder

are not blocked.

- Carefully refit - on the stuffing box (5): oil seal (12), scraper seal

(13), washer (11) and O’ring (10).

- Lubricate the oil seals, O’rings and oil scraper seal.

- Slide the stuffing box in the correct direction on to the shaft (15)

(Fig. 12).

- Refit with care - on piston (4): O’ring (8), bush (7) and oil seal

(6).

- Place a lubricated O’ring (9) against the shoulder of the shaft (15).

- Slide the piston in the correct direction on to the screw cut end of

shaft (15).

- Carry out operation 56 again to grip the piston rod.

- Discard the used nut (2). Fit and tighten a new nut to a torque of 405

Nm.

- Lubricate the bush (7) and the oil seal (6).

- Slide the shaft assembly (15), stuffing box (5) and piston (4) into

cylinder (3).

- Position the machined groove of the stuffing box opposite that of the

cylinder.

- Fit snap ring (14) using the same method as in operation 55.

- Refit the ram(s) on to the tractor.

- Check the operation and the internal oil tightness of the ram(s).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader