________________________________________________________________________________

Massey Ferguson 6480 Tractor hydrostatic steering 80/205cm3

The Massey Ferguson 6480, 6485, 6445 Tractor steering system is of the

dynamic type (constant 0.5l /min flow rate - 6 bar standby pressure).

Its control principle is of the Load Sensing (LS) type.

The orbitrol steering unit type is displayed on an adhesive plate

located below the steering unit.

The steering unit has no mechanical links, other than the steering

column itself, between the steering wheel and steering ram.

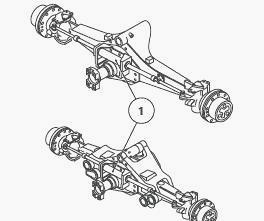

The system comprises the following main

components:

- a pressurised oil feed from the variable displacement pump;

- a steering unit that can be, according to the type of front axle: OSPDF 80/205 cm3, OSPDF 80/240 cm3;

- a double acting steering ram (1).

The Massey Ferguson 6485, 6445, 6480 Tractor steering unit is supplied

via the priority block(s) (depending on version) by the high flow rate

high pressure circuit.

This circuit also supplies the integrated spool (18) and the two gears

(27)(28), (30)(31).

When the steering wheel is turned, the necessary flow of oil is directed

to the corresponding side of the steering ram. The other side of the ram

is connected to the gearbox selector cover return ports.

In the event of a variable displacement pump failure, only the steering

unit gear (27) (28) acts as a manual pump, thus allowing the tractor to

continue to be steered.

This operation, performed without hydraulic assistance, obviously

requires significant effort to turn the steering wheel.

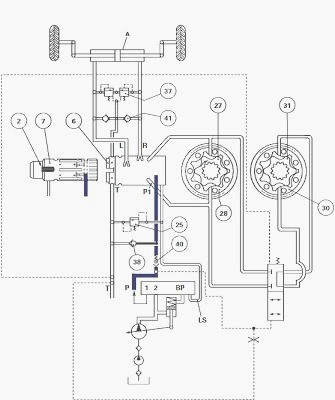

Fig.35

Description of the MF 6480, 6485, 6445

Tractor steering unit

The steering unit comprises:

- two gears of different capacity, each consisting of a rotor and a

stator. These two gears are mechanically coupled to a drive shaft,

itself connected to the steering column;

- a spring centred supply sleeve;

- an integrated spool in the body (19).

The steering unit comprises five ports:

- pressure;

- return to the selector cover;

- two supplies (left and right) to the steering ram;

- Load Sensing

The circuit is protected by a safety valve, two shock valves and two

suction valves.

The principle of Load Sensing

Massey Ferguson 6480, 6485, 6445 Tractor

Steering unit

The LSD steering unit possesses a fifth LS port.

This port is connected:

- either to the closed steering unit circuit when steering is in neutral

position;

- or with the pressure supply line when the steering wheel is turned.

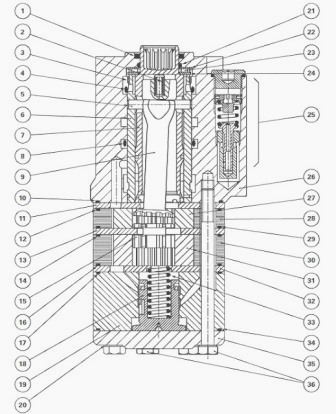

Fig.36. Parts list

(1) Lip seal (2) Centring springs (3) Bush (4) O’ring (5) Cotter pin (6)

Sleeve (7) Spool valve (8) O’ring (9) Link shaft (10) O’ring (11) Plate

(12) O’ring (13) Plate (14) O’ring (15) Spacer (16) O’ring (17) O’ring

(18) Integrated spool (19) Spool body (20) Seals (21) O’ring (22) Washer

(23) Needle bearing (24) Washer (25) Relief valve (26) Orbitrol steering

unit (27) Rotor (gear type 80 cm3) (28) Stator (gear type 80 cm3) (29)

O’ring (30) Stator (gear type 205 cm3 or 240 cm3) (31) Rotor (gear type

205 cm3 or 240 cm3) (32) Plate (33) Spring (34) O’ring (35) Closing

plate (36) Screw

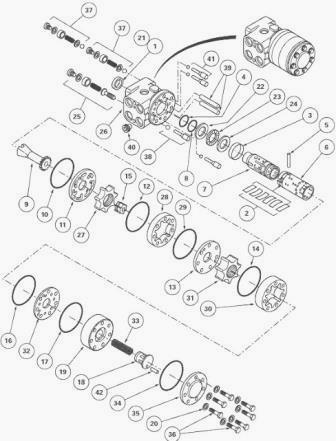

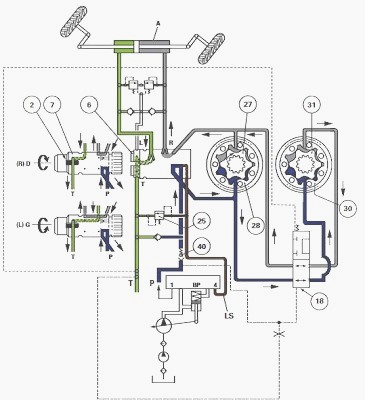

Fig.37. Parts list

(1) Lip seal (2) Centring springs (3) Bush (4) O’ring (5) Cotter pin (6)

Sleeve (7) Spool valve (8) O’ring (9) Link shaft (10) O’ring (11) Plate

(12) O’ring (13) Plate (14) O’ring (15) Spacer (16) O’ring (17) O’ring

(18) Integrated spool (19) Spool body (20) Seals (21) O’ring (22) Washer

(23) Needle bearing (24) Washer (25) Relief valve (26) Orbitrol steering

unit (27) Rotor (gear type 80 cm3) (28) Stator (gear type 80 cm3) (29)

O’ring (30) Stator (gear type 205 cm3 or 240 cm3) (31) Rotor (gear type

205 cm3 or 240 cm3) (32) Plate (33) Spring (34) O’ring (35) Closing

plate (36) Screw (37) Shock valves (38) Non-return valve (39) Spacers

(40) Non-return valve (41) Suction valve (42) Cotter pin

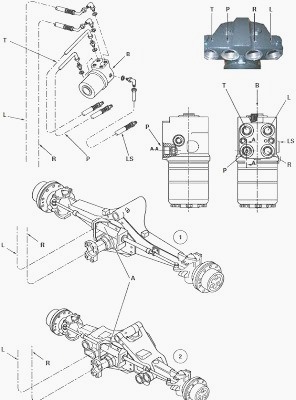

Layout of channels and ports

Fig.38. Parts list / Legend

1 - CARRARO fixed 4 WD front axle, 2 - CARRARO suspended 4 WD front

axle, A - Double acting steering ram, B - Location of steering column, L

- Supply to left- hand union of the steering ram, LS - Signal to

variable displacement pump, P - Pressure, R - Supply to right-hand union

of the steering ram, T - Return to housing via gearbox selector cover

Neutral position (engine running)

In this position the spool valve (7) is centred in relation to the

sleeve (6) by the springs (2) (Fig. 7). The channels P1, L, R are not

supplied. The oil coming from the variable displacement pump via channel

(2) is directed in priority to the Orbitrol unit via channel (1).

With the steering in a neutral position, there is no flow in this

channel. The circuit is closed centre. Two shock valves (37) and two

suction valves (41) are located in ports L and R of the spool valve.

The shock valves (37) protect the circuit between the MF 6480, 6485,

6445 Tractor steering ram and the spool valve from eventual pressure

overloads caused by shocks to the wheels.

The suction valves (41) allow the oil released by the shock valves (37)

to pass from the right-hand channel to the left-hand channel or vice

versa depending on the movement of the piston inside the steering ram.

Fig.39. Legend

A - Double acting steering ram, BP - Priority block(s), L - LH hydraulic

port of the steering ram, LS - Signal, P - Pressure, P1 - Supply to

metering devices (stators (28) (30) and rotors (27) (31)), R - RH

hydraulic port of the steering ram, T - Return

Steering on lock position (engine running)

Fig.40

Action on the steering wheel (to the left or right) (Fig. 8) produces an

angular displacement of the spool valve (7) in relation to the sleeve

(6) and the opening of the closed Orbitrol circuit.

A pilot pressure coming from the Orbitrol arrives in channel (4) and

allows the passing into channel (1) of the flow necessary to the

integrated spool (18) and the stator metering devices (stators (28) (30)

and rotors (27) (31)).

The rotors (27) (31) are driven in rotation and force towards the ram a

quantity of oil that is proportional to the degree of rotation. The

rotation of rotors (27) (31) is equal to that of the steering wheel.

Example: Let us suppose that the steering wheel is turned by 5°. An

angular displacement of 5° of the spool valve (7) is produced in

relation to the sleeve (6). The rotors (27) (31) are driven in rotation

as long as they are supplied with pressurised oil.

They drive with them the link shaft (9) and the sleeve (6). When the

latter have turned 5°, the spool valve (7) and the sleeve (6) are once

again centred by the springs (2). The rotors cease to be supplied and

stop. This same reasoning applies to greater angles.

The quantity of oil delivered by the Massey Ferguson MF 6485, 6480, 6445

Tractor steering unit to the steering ram A is therefore proportional to

the rotational angle of the steering wheel.

Depending on whether a left-hand or right-hand lock is applied, the

spool valve (7) directs the oil discharged by the metering devices

(stator (28) (30) and rotor (27) (31)) towards the L or R port.

During rotation, the sleeve (6) ensures the synchronous communication of

the cavities in the metering device with the circuit from the pump, on

the one-hand, and the circuit to the steering rams, on the other hand.

A non-return valve (40) is screwed into the supply port of the steering

unit . This valve is one-way. It prevents excessive pressure exerted to

the front wheels from being transmitted to the pump when the steering

lock is applied.

If the pressure in the steering circuit is too high, the relief valve

(25), located in the steering unit, opens and the excess pressure is

released to channel T.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader