________________________________________________________________________________

1106 Perkins motor - Turbocharger (Repair operations)

Removal Procedure (Side Mounted)

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting and repair of

the product. Be prepared to collect the fluid with suitable containers

before opening any compartment or disassembling any component containing

fluids. Dispose of all fluids according to local regulations and

mandates. Disconnect the air hose for the turbocharger inlet and for the

turbocharger outlet. If the turbocharger has a remote wastegate

solenoid, disconnect the hose to the solenoid from the turbocharger.

Disconnect the exhaust pipe. If the turbocharger has an exhaust elbow,

remove the exhaust elbow.

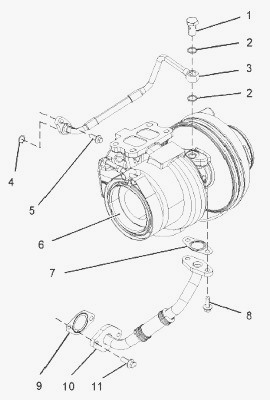

Follow Steps to remove the tube assembly (4) for the oil feed. Remove

the setscrew (5). Remove the banjo bolt (1) and remove the two sealing

washers (2). Discard the sealing washers. Remove the tube assembly (3)

from the cylinder block. Remove the O-ring seal (4) from the tube

assembly. Discard the O-ring seal. Plug the port for the oil feed to the

turbocharger with a suitable plug. Remove the tube assembly (10) for the

oil drain. Remove the two setscrews (11). Remove the two setscrews (8)

and remove the tube assembly (10) from the turbocharger (6). Remove the

joint (7) and remove the joint (9). Discard the joints.

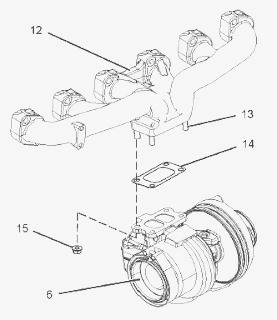

Remove the four nuts (15) from the turbocharger (6) and remove the

turbocharger (6) from the exhaust manifold (12). Ensure that the weight

of the turbocharger is supported as the nuts are loosened. Remove the

joint (14). Discard the joint. If necessary, remove the four studs (13)

from the exhaust manifold (12).

Removal Procedure (Top Mounted)

Disconnect the air hose for the turbocharger inlet and for the

turbocharger outlet. If the turbocharger has a remote wastegate

solenoid, disconnect the hose to the solenoid from the turbocharger.

Disconnect the exhaust pipe. If the turbocharger has an exhaust elbow,

remove the exhaust elbow.

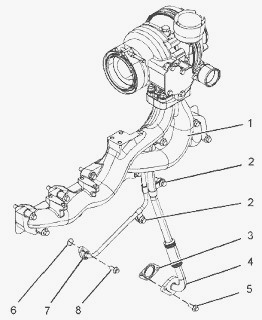

Remove the two setscrews (5) in order to disconnect the tube assembly

(4) from the cylinder block. Remove the joint (3). Discard the joint.

Remove the setscrew (8) in order to disconnect the tube assembly (7)

from the cylinder block. Remove the fasteners for the tube clips (2).

Loosen the four nuts (11). Refer to Illustration. Remove the exhaust

manifold (1) and the assembly of the turbocharger from the cylinder

head.

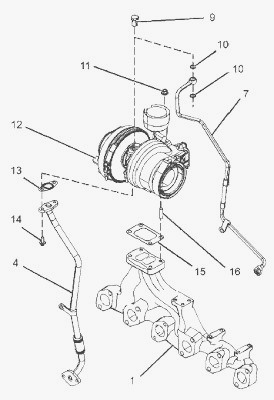

Remove the banjo bolt (9) and remove the tube assembly (7) for the oil

feed from the turbocharger (12). Remove the two sealing washers (10).

Discard the sealing washers. Remove the O-ring seal (6) from the tube

assembly (7). Refer to Illustration. Discard the O-ring seal. Remove the

two setscrews (14) and remove the tube assembly (4) for the oil drain

from the turbocharger (12). Remove the joint (13). Discard the joint.

Remove the four nuts (11) and remove the turbocharger (12) from the

exhaust manifold (1). Remove the joint (15) from the exhaust manifold

(1). Discard the joint. If necessary, remove the four studs (16) from

the exhaust manifold (1).

Disassemble and Assemble Procedures

Disconnect the pipe for the boost sensor (7) at the actuator (6). Remove

the circlip (1) that retains the actuator rod (4). Remove the actuator

rod (4) from the pin (2). Remove the nuts (5) from the bracket (3).

Remove the actuator (6) from the bracket (3). Do not attempt to

disassemble the turbocharger cartridge assembly or wastegate. Do not

remove the compressor wheel. The turbocharger cartridge assembly and the

wastegate are not field serviced, and should be replaced only as a unit.

Install the actuator (6) to the bracket (3). Install the nuts (5) to the

bracket (3). Tighten the nuts to a torque of 5 Nm (44 lb in). Connect

the bottom of the actuator (6) to a suitable air supply with an accurate

gauge. Operate the arm of the actuator by hand in order to check that

the valve is free to move. Push the arm of the wastegate valve toward

the actuator (6) and hold the arm in position. Slowly apply air pressure

to the actuator (6) until the pin (2) will fit into the actuator rod

(4). Install the circlip (1) into the groove in the pin (2). Do not

apply an air pressure of more than 205 kPa (29 psi) to the actuator.

High pressures may damage the actuator. Install the pipe for the boost

pressure (7) to the actuator (6).

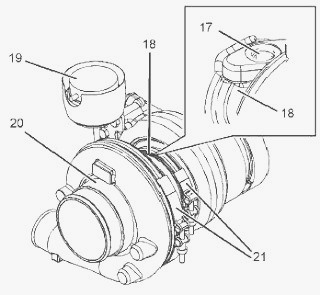

Installation Procedure (Side Mounted)

Ensure that the turbocharger is clean and free from damage. Inspect the

turbocharger for wear. If any part of the turbocharger is worn or

damaged, the complete turbocharger must be replaced. Test the wastegate

actuator (19) for correct operation. If the wastegate actuator is

damaged or the wastegate actuator does not operate within the specified

limits, the wastegate actuator must be replaced.

Clean the mating surfaces of the exhaust manifold (12). If necessary,

install the four studs (13) to the exhaust manifold. Tighten the studs

to a torque of 18 Nm (13 lb ft). Install a new joint (14) to the exhaust

manifold (12). Position the turbocharger (6) on the exhaust manifold.

Ensure that the turbocharger is correctly oriented. Install the four

nuts (15). Tighten the nuts to a torque of 44 N·m (32 lb ft). If a new

turbocharger is installed, the bearing housing (18) and the compressor

housing (20) must be oriented to the correct positions.

Loosen the two band clamps (21) sufficiently in order to allow the

housings to rotate. If the band clamps are damaged, replace the band

clamps. Carefully turn the bearing housing (18) until the port for the

oil feed (17) is upward. Rotate the compressor housing (20) until the

compressor outlet is in the correct position. Ensure that the band

clamps (21) are correctly oriented. Tighten the band clamps finger

tight.

Ensure that the tube assemblies (3) and (10) are clean and free from

damage. Replace any damaged components. Position a new joint (7) and the

two setscrews (8) onto the tube assembly (10). Install the tube assembly

(10) to the turbocharger (6). Tighten the setscrews (8) finger tight.

Position a new joint (9) between the flange of the tube assembly (10)

and the cylinder block. Install the two setscrews (11) finger tight. If

a new turbocharger has been installed, check that the orientation of the

bearing housing (18) is correct. If the orientation of the bearing

housing is not correct, rotate the bearing housing until the tube

assembly (10) fits correctly. Tighten the two band clamps (21) to a

torque of 13 Nm (9.6 lb ft). Tighten the setscrews (8) and (11) to a

torque of 22 Nm (16 lb ft).

Remove the plug from the oil inlet port (17). Lubricate the turbocharger

bearings with clean engine oil through the oil inlet port. Rotate the

wheel of the compressor several times in order to lubricate the

bearings. Use Tooling in order to lubricate a new O-ring seal (4).

Install the O-ring seal (4) to the tube assembly (3). Install the banjo

bolt (1) and two new sealing washers (2) to the tube assembly (3).

Install the tube assembly (3) to the cylinder block and to the

turbocharger (6). Tighten the banjo bolt (1) finger tight.

Install the setscrew (5) finger tight. Ensure that the tube assembly (3)

fits correctly. Tighten the banjo bolt (1) to a torque of 20 Nm (14 lb

ft). Tighten the setscrew (5) and (11) to a torque of 22 Nm (16 lb ft).

If the turbocharger has an exhaust elbow, install the exhaust elbow.

Connect the exhaust pipe. If the turbocharger has a remote wastegate

solenoid, connect the hose for the solenoid to the turbocharger. Connect

the air inlet hose and connect the air outlet hose to the turbocharger.

Installation Procedure (Top Mounted)

Ensure that the turbocharger is clean and free from damage. Inspect the

turbocharger for wear. If the turbocharger is worn, the complete

turbocharger must be replaced. Test the wastegate actuator (19) for

correct operation. If the wastegate actuator is damaged or the wastegate

actuator does not operate within the specified limits, the wastegate

actuator must be replaced. Clean the mating surfaces of the exhaust

manifold (1). If necessary, install the four studs (16) to the exhaust

manifold. Tighten the studs to a torque of 18 Nm (13 lb ft). Support the

exhaust manifold during installation of the turbocharger. Install a new

joint (15) to the exhaust manifold (1).

Position the turbocharger (12) on the exhaust manifold (1). Install the

four nuts (11). Tighten the nuts to a torque of 44 Nm (32 lb ft). If a

new turbocharger is installed, the bearing housing (18) and the

compressor housing (20) must be oriented to the correct positions.

Loosen the two band clamps (21) sufficiently in order to allow the

housings to rotate. If the band clamps are damaged, replace the band

clamps. Carefully turn the bearing housing (18) until the port for the

oil feed (17) is upward. Rotate the compressor housing (20) until the

compressor outlet is in the correct position. Ensure that the band

clamps (21) are correctly oriented. Tighten the band clamps finger

tight.

Ensure that the tube assemblies (4) and (7) are clean and free from

damage. Replace any damaged components. Position a new joint (13) and

the two setscrews (14) onto the tube assembly (4). Install the tube

assembly (4) to the turbocharger (12). Tighten the setscrews (14) finger

tight. Remove the plug from the oil inlet port (17). Lubricate the

turbocharger bearings with clean engine oil through the oil inlet port.

Rotate the wheel of the compressor several times in order to lubricate

the bearings. Install the banjo bolt (9) and two new sealing washers

(10) to the tube assembly (7). Use Tooling in order to lubricate a new

O-ring seal (6). Install the O-ring seal (6) to the tube assembly (7).

Install the tube assembly (7) to the turbocharger (12). Tighten the

banjo bolt (9) finger tight.

Install the exhaust manifold (1) and the assembly of the turbocharger to

the cylinder head. Install the setscrew (8) finger tight. Ensure that

the tube assembly (7) fits correctly. Position a new joint (3) between

the flange of the tube assembly (4) and the cylinder block. Install the

two setscrews (5) finger tight. If a new turbocharger has been

installed, check that the orientation of the bearing housing (18) is

correct. If the orientation of the bearing housing is not correct,

rotate the bearing housing until the tube assemblies (4) and (7) fit

correctly. Tighten the two band clamps (21) to a torque of 13 Nm (9.6 lb

ft). Tighten the banjo bolt (9) to a torque of 20 Nm (14 lb ft). Tighten

the setscrew (5) and (8) to a torque of 22 Nm (16 lb ft). Install the

fasteners for the tube clips (2) to the cylinder block.

If the turbocharger has an exhaust elbow, install the exhaust elbow.

Connect the exhaust pipe.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader