________________________________________________________________________________

Massey Ferguson 3095, 3125 Tractor Gearbox – Speedshift

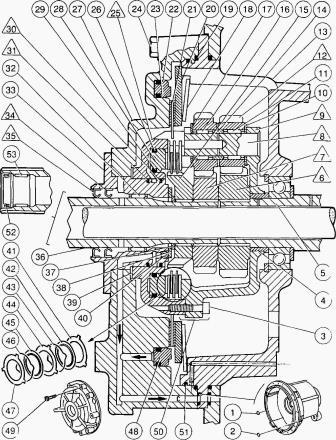

The speedshift unit is mounted at the front of the Massey Ferguson 3095,

3080, 3105, 3125 gearbox input. It is a hydraulically operated

gearchange device which provides two different input ratios to the main

gearbox.

It does this by means of:

- a multidisc hydraulic clutch,

- an epicylic gear train consisting of a planetary carrier with three

twin planetary gears, an input sun gear and an output sun gear,

- a system for braking the planetary carrier hydraulically. The design

of the speedshift allows the ratios to be changed on the move, even

under full load, without declutching.

Different versions

The following versions can be obtained as a function of the number of

teeth on sun gears 6 and 7 and the order in which they are fitted: 30

km/h or 40 km/h version/version with super creeper gears.

Fig. 3

30 Kph and super creeper version : stepdown 40 Kph version : stepup

(Fig. 3) - in this mode (Fig. 3), there is no supply to the hydraulic

components and the

speedshift operates as a purely mechanical transmission.

Oil in chamber of pistons (28) and (48) returns to the housing via the

gallery C and the solenoid. The drive from the hollow primary shaft (36)

is transmitted to the input

sun gear 7 by the splines which secure the gear to the shaft. Sun gear R

drives the compound planetary gears 12 which are mounted to rotate

freely on spindles 8.

The planetary gears in turn drive the output sun gear 6, which is

splined to the hollow secondary shaft (5). in one of the following

ratios: 30km/h 1.26 stepdown - 40km/h

1.26 stepup - super creeper 7.8 stepdown.

Since no hydraulic pressure is applied, the planetary carrier assembly

(50) is locked against rotation by a Belleville spring disc (18) which

applies pressure to pressure

plate (20) and thus stops disc (21) from turning, the latter being

locked to the planetary carrier assembly in rotation by splines.

Hydraulic operation - direct transmission

The range is changed by actuating the solenoid valve. which then feeds

hydraulic oil to the chambers behind pistons (48) and (28)

simultaneously.

Braking piston (48) is then applied to pressure plate (20), which

compresses the Belleville spring disc (18), thus releasing disc (21) and

the planetary carrier assembly

(50). At the same time clutch piston (28) clamps together pressure

plates (41), (44), (47) and the discs (42), (45) which are driven by hub

(15).

Since the pressure plates are secured to the planetary carrier by three

lugs, drive is transmitted from the primary input shaft (36) to the hub

(15) and from there to the

clutch assembly which transmits it to the planetary carrier (50).

The primary shaft (36) and the planetary gear and sun gear assembly turn

at the same speed as the secondary shaft (5) thus giving direct

transmission in the ratio of

1/1.

Front cover operations

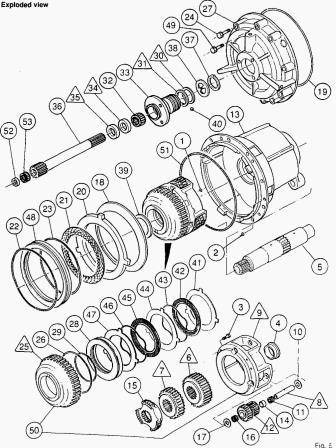

Fig.5

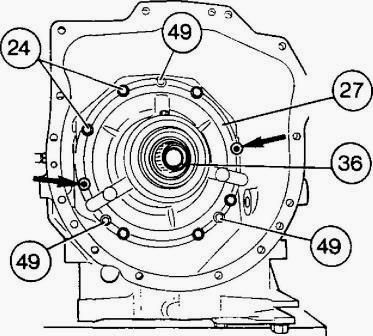

Removing the front cover tractors:

- Split the tractor between the engine and gearbox Massey Ferguson 3125

Tractor

- Split the tractor between the engine and gearbox.

- Remove the PTO shaft. Withdraw seal (52).

- Remove the bleed and supply pipes to the clutch assembly.

- Drain the gearbox only of oil. Unscrew bolts (24) (Fig.6).

- Screw two pilot pins into the gearbox housing in diametrically opposed

positions (Fig.6).

- Unscrew the three bolts (49) a little at a time, taking them in order

(Fig.6).

- Remove cover (27) together with shaft (36) (Fig.6). Discard O-rings

(1) and (2), (19) and (51).

- In anticipation of future rationalisation of the design of the

speedshift, the former 6-lugged friction disc has been replaced by one

with 40 internal splines.

- The hydraulic cover and the planetary carrier cover, and the bolts for

securing them, have also been replaced by new covers and bolts adapted

to the design with the

splined disc.

- Take out disc (21), pressure plate (20), Belleville spring disc (18)

and planetary carrier assembly (50).

Fig.6

Disassembling the front cover:

- Extract circlip (37) and take out lug washer (38).

- Withdraw shaft (36) from the front of the cover.

- Take out needle-roller bearing (53).

- Remove washer (39).

Massey Ferguson 3095, 3050 Tractor:

- Take out the clutch slave cylinder assembly

- You are advised not to take the release bearing out of the slave

cylinder to avoid damage to the seals.

- Withdraw the release bearing from the slave cylinder for a distance of

approx. 40 mm, take off the bellows.

- Unscrew the three bolts holding the cylinder in place.

Massey Ferguson 3125, 3115 Tractor:

Take out the clutch stave cylinder assembly - Unscrew the bolts holding

me slave cylinder assembly in place and take the assembly out. Withdraw

piston (48) from

the cover.

All tractors:

- Remove seals (22) and (23) and discard them.

- MF 3095, 3125 tractors, new speedshift rings made of PTFE rather than

cast iron and with gaps increased to 2.1/2.4 mm were introduced as from

serial no.

N155012.

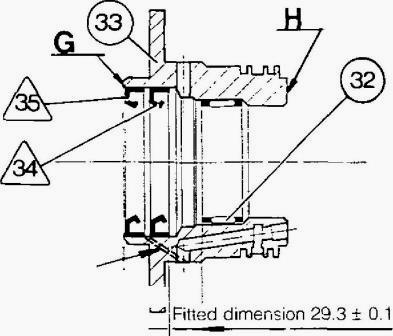

- Remove seal rings 30 and 31 (discard these rings).

- Remove lip seals 34 and 35 and discard them.

- Take out needle-roller bearing (32) and discard it.

- Drive ring carrier (33) out of cover (27) (Work from the rear of the

ring carrier using a plasticiaced mallet as a drift).

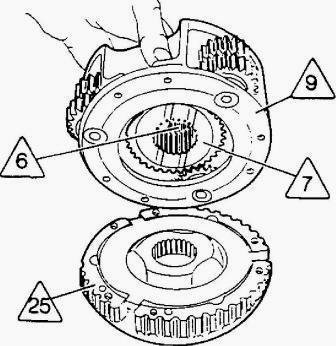

- Separating planetary carrier and cover assembly.

- Place the planetary carrier assembly (50) down on a bench (with the

planetary carrier cover 9 on top).

- Unscrew bolts (3).

- Separate planetary carrier cover 9 from hydraulic cover 25 while

holding sun gears 6 and 7 in position in planetary carrier cover

(Fig.9).

Fig.9

Disassembling planetary carrier assembly

Take out the 1st sun gear:

- H36 tooth in 30 km/h version

- (6) 30 tooth in 40 km/h version

- (7) 30 tooth in super creeper version - Mark the direction in which

the lubricating grooves in the sun gear should face when the gear is

refitted.

Drive out spindles 8 with a drift and a mallet.

Take out the planetary gears 12.

Take out needle-roller bearings (11) and (16). spacers (14), and washers

(10) and (17).

Take out the second sun gear:

- (6) 39 tooth in 30 km/h version (7) 36 tooth in 40 km/h version

- (6) 39 tooth in supper creeper version (Fig.2) . Bush (4) is a force

fit in planetary carrier cover 9.

Disassembling the hydraulic cover:

- Take out splined hub (15).

- Take out pressure plate (41), disc (42), spring washer (43). pressure

plate (44), disc (45), spring washer (46) and pressure plate (47).

- Withdraw piston (28) from cover 25.

- Remove O-rings (26) and (29) and discard them. In the supper creeper

version, cover 25 and piston (28) differ from those in the 30 and 40

km/h versions.

The cross-sectional area of the piston is greater and this means that

the diametric cutouts in the cover are larger.

Reassembling the planetary trier:

- Glean and check the parts and replace any which are faulty.

- Lubricate the needle-roller bearings. Check that the oilways in

spindles 8 are not blocked, m/h version

- Fit the 39 tooth sun gear 6 into the planetary carrier cover. km/h

version.

- Fit the 36 tooth sun gear 7 into the planetary carrier cover.

- Fit the tooth sun gear 6 into the planetary carrier cover.

- In all versions, fit the gear so that the lubricating grooves in it

are facing towards face F of the planetary carrier cover. Fit a

needle-roller bearing (11), a spacer (14)

and a needle-roller bearing (16) into a planetary gear 12V

Fit an assembled planetary gear into the cover, with the following gears

closer to face F in the respective cases:

- 21 tooth: 30 km/h version

- 18 tooth: 40 km/h version

- 27 tooth: super creeper version.

The planetary gear is marked with three punch marks made in a single

face. Each punch mark indicates two teeth which line up. Fit washers

(10) and (17).

Line up the planetary gear and washers with a locating rod made up

locally : diameter = 16 mm, length = 80 mm.

Insert spindle 8 into the unobstructed bore in face F and drive it home

with a mallet until it is slightly recessed below the face.

The oilway opening onto the circumference of spindle 8 must face

outwards. The oilway opening onto the end face of spindle 8 must face

towards face F of the

planetary carrier cover.

Repeat procedures to fit the other two planetary gears.

The marks (punch marks) on the three planetary gears must line up with

the centre on line spaced 120P apart. Once fitting of the spindles I8\

has been completed,

re-check that the marks on the planetary gears line up as above.

If the marks do not line up properly, this will cause damage to the

speedshift.

Fit the following sun gears in the respective versions :

- (7) 36 tooth: 30 km/h version

- (6) 39 tooth: 40 km/h version

- (7) 30 tooth: super creeper version

In all versions, fit the gear so that the lubricating grooves in it are

facing towards face F of the cover.

Reassembling the hydraulic cover:

- Clean and check the parts and replace any which are faulty.

- Make sure that the three openings into the 17 bar passage in the

hydraulic cover /2S\are not blocked.

- Lubricate O-rings (26) and (29) and fit them to piston (28).

- Lubricate the faces against which the piston seals bear in the

hydraulic cover.

- Place the piston in the cover with the grooves facing towards the

operator.

- Tap the piston (28) gradually home into the cover by working

progressively round its face with a plastic-faced mallet.

- Once the piston is fitted, check that no pieces have been detached

from the O-rings.

- Refit the splined hub (15) making sure it is correctly orientated.

- Refit pressure plate (47), spring washer (46), disc (45), pressure

plate (44), spring washer (43), disc (42) and pressure plate (41).

- Place the gaps in spring washers (43) and (46) in diametrically

opposed positions.

Reassembling the planetary carrier assembly:

- Screw two pilot pins into the hydraulic cover 25 in diametrically

opposed positions.

- Fit the planetary carrier cover 9 to the hydraulic cover 25, while

holding the sun gears 6 and 7 in position.

- Position the two covers so that the balancing marks (milled grooves or

paint lines) are as far away from each other as possible.

- Refit bolts (3). Bolts must be tightened to a torque of 10-14 Nm.

- Tap spindles 8 in with a pin punch so that they butt against the

hydraulic cover 25V

- Check: that discs (42) and (45) are not compressed / that planetary

gears 12 and sun gears 6 and 7 can turn freely.

- Fit planetary carrier assembly (50) to shaft (5).

- Fit Belleville spring disc (18).

- Fit pressure plate (20) into housing (13).

- Apply three spots of grease («Amber Technical" or equivalent) to the

lugs on the pressure plate.

- Engage friction disc (21) onto the planetary carrier assembly.

Reassembling the front cover:

Fig.20

- Clean the mating face and the rest of the cover. Make sure that the 17

bar passage and the lubricating passage are not blocked.

- Fit seals (22) and (23) to piston (48).

- Lubricate the surfaces in the speedshift cover against which the

piston seals bear.

- Position the piston on the cover with its grooves facing towards the

operator.

- Tap piston (48) gradually home into the cover by working progressively

round its face with a plastic-faced mallet.

- Once the piston is fitted, check that no pieces have been detached

from the O-rings.

- Clean the ring carrier and its mating face (check that the 17 bar

passage and the lubricating pas-sage are not blocked). Ball (40) is

crimped into the ring carrier.

Position (Fig.20) :

- needle-roller bearing (32) at 29.3 ± 0.1 mm from faceG - seal 34 at

43.8 mm from face H

- wide seal 35 at 0.3 - 0.8 from face G.

Use a press and a suitable press tool to position the bearing and seals

perpendicular to the axis of the ring carrier.

- Having fitted seals 34 and /35, check that the two pressure-relief

passages are not blocked.

- Apply a gasketing compound (Loctite Masterjoint 510 or equivalent) to

the mating face of the cover to allow the ring carrier (33) to be

fitted.

- Screw two pilot pins (1) into the cover. Engage the ring carrier in

the cover bore.

- Check that the openings of the 17 bar passage and the lubricating

passage in the ring carrier match up with the passages in the cover.

- Tap the ring carrier home in the cover. Lubricate seals 34 and 35V

MF 3095 Tractor:

- Refit the clutch slave cylinder assembly.

- Apply Loctite 241 to the three bolts and tighten them to torques of: 8

mm;25 - 35 Nm / 50 - 70 Nm.

- Refit the bellows and push in the release bearing.

- Refit the clutch slave cylinder assembly.

- Apply Loctite 241 to the bolts which hold the clutch slave cylinder

assembly in place and tighten them to the following torques : 8 mm;25-35

Nm 10 mm/50 - 70 Nm.

MF 3095, 3125 tractors:

- Fit needle-roller bearing (1) so that it is 15-16 mm from the front

face of the shaft.

- Lubricate shaft (36) and insert it in ring carrier (33) from the

front.

- Make sure that the lubricating passages in the shaft are not blocked.

- Cover the splines in the shaft temporarily to avoid damage to seals 34

and 35.

- Refit washer (38) and circlip (37).

- Refit rings 30 and 31 and make sure that they turn freely in the

grooves.

- Having made this check, remove the rings, preform them by reducing

them to approximately 1 /3 of their original diameter, and coat them

with miscible grease

(Amber Technical or equivalent) to ensure that they will be held in

position effectively when the front cover is being refitted.

- Fit the rings into their respective grooves, making sure that : they

do not project from the circumference of the ring carrier, their ends

are correctly overlapped.

- Even the slightest damage to the rings may give rise to leaks followed

by pressure dropping in operation.

- Grease washer (39) and fit it into cover (27).

- Fit new O-rings (1) and (2), (19) and (51).

- Check that the locating pin is present in the reversing mechanism

housing and that the two pilot pins are fitted.

Refitting the front cover:

- Fit front cover (27) together with shaft (36).

- Use the PTO shaft to make mating-up easier (only when fitting on

tractor).

- Check that the 17 bar and lubricating passages in the cover match up

with the openings in the housing.

- Refit bolts (24) and tighten them to a torque of 45 - 60 Nm.

- Fit bolts (49) and tighten them to a torque of 25 -35 Nm.

- Reconnect the supply and bleed pipes to the clutch slave cylinder

assembly.

- Re-unite the tractor between engine and gearbox.

Massey Ferguson 3125 tractors:

- Top up the oil in the housing,

- Bleed the clutch circuit.

- Carry out a road test on the speedshift control.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader