________________________________________________________________________________

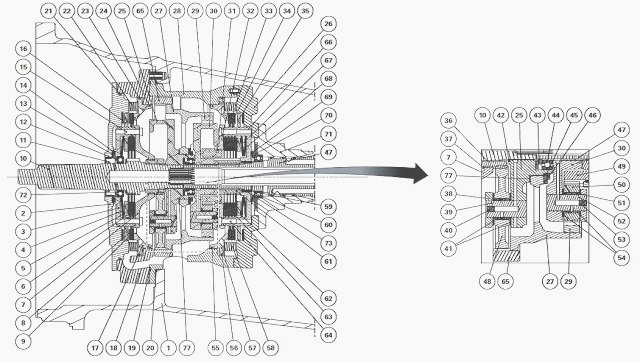

Massey Ferguson 5608, 5609 gearbox - Powershift module

Drain the transmission oil. Split the Massey Ferguson 5608, 5609 tractor between the engine and the gearbox.

Remove: either the complete gearbox (if servicing is to be carried out

on the whole transmission assembly) or only the Powershift module from

the unit, leaving the mechanical unit coupled to the rear axle (if

servicing is to be carried out on the Powershift module or reverse

shuttle only)

Remove:

- all hydraulic pipes fitted to the unit housing.

- the unit control hydraulic unit with its connecting pipes.

- the union and the lubrication pipe of the Powershift module.

- the PTO shaft.

If the whole unit has been removed, separate the Powershift module from

the mechanical gearbox. Rig up four makeshift legs on which to set the

unit vertically.

Use an M14 screw or threaded rod, and weld on a nut to ensure a minimum

distance of 120 mm between the unit and the work surface.

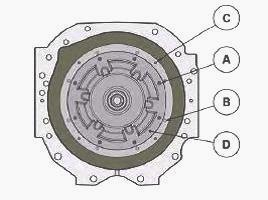

Unscrew the two diametrically opposed screws (A) and replace them with

two shackles to sling the gearbox. do not remove screws (C). They hold

the front

epicyclic gear train housing (D) in place.

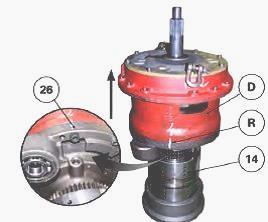

Sling the MF 5608, 5609 gearbox Powershift module using the shackles.

Make a mark (R) on the housings to ensure the modules are refitted

correctly.

Install the Powershift module on a supporting fixture positioned on the

forward clutch.

Take out the screws holding the cover (26) on the housing (D).

Using the sling, lift and separate the front part of the Powershift

module.

During this step, the brake, the clutch and the rear planet carrier stay

on the Power Shuttle.

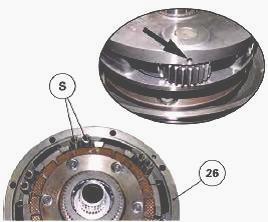

Sling the Powershift module. Check that the return springs (S) are

present in the cover (26).

Carry out step in reverse order, aligning the two parts using the mark

(R).

Take care when inserting the planetary gears in the Powershift module

brake piston (57).

Install the cover screws (26) to the Powershift module, after smearing

them with Loctite 242 or equivalent. Tighten the screws to a torque of

66 Nm.

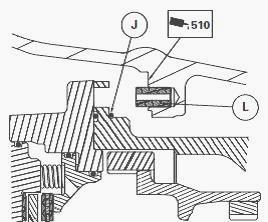

Clean the mating faces then apply Loctite 510 or equivalent sealing product. Reinstall the "O" ring (J). Grease it lightly and Install it on the Powershift module.

Sling the

reverse shuttle and Powershift module assembly.

Install the assembly in the unit housing. Lower the sling, aligning the

centring pin (L) with the port. Reinstall the screws (B) of the housing

(D).

Removing the Powershift module

Remove the piston (57) and the springs (58). Place the section with the

reverse shuttle on a suitable supporting fixture, with the cover (26)

and planet carrier (30)

facing upwards. Remove the planet carrier (30).

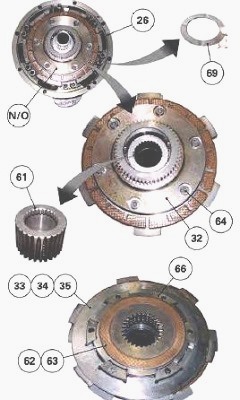

To remove the planetary gears. Take out the clutch O/brake N assembly

from the cover (26). Retain the friction washer (69). Remove the clutch

hub (61). Take out

the screws (64) to remove the clutch cover (32).

Mark the order of the discs and brake/clutch thrust plates before

removing them. Mark the direction and remove the Belleville washers (67)

and (68).

If necessary, take out the needle bearing (73) of the clutch housing

(66).

Place the front part of the Massey Ferguson 5609, 5608 gearbox

Powershift module facing downwards on a suitable supporting fixture.

Make a mark (G) on the

housings (28) and (18).

Remove the screws from the housings (28) and (18), then remove the

housing (28). Take out and discard the "O" rings (74) and (75) on the

housing pilot ports.

Discard "O" ring (19) and "O" ring (76).

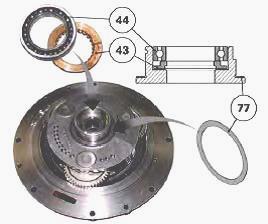

Remove the ring gear carrier assembly (27), the two ring gears (29) and

(65), with the front planet carrier. Remove the circlip (46). Separate

the front planet carrier

from the ring gears. Retain the spacer (45). Remove the bearing (44),

the washer (77) and the spacer (43) from the planet carrier (25).

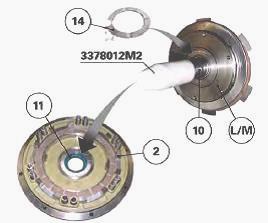

To remove the planetary gears. Place the housing (18) on the shims, with

the input shaft (10) facing upwards. Place service tool on the input

shaft (10) so as to

protect the lip seal (11). Unscrew the cover screws (2) of the housing

(18). Remove the cover (2) and retain the springs (22). Discard the "O"

ring (21).

Remove the brake piston (17) from the housing (18). Discard the "O"

rings (23) and (24). Remove the friction washer (13). Remove the lip

seal (11). Remove the

clutch M/brake L assembly from the housing (18). Remove the friction

washer (14) and the snap ring (42).

Place the clutch M/brake L assembly on a supporting fixture. Take out

the screws (15) to remove the clutch cover (7).

If necessary, take out the snap ring (37) to separate the sun gear (36)

from the clutch cover (7). Mark the order of the discs and brake/clutch

thrust plates. Remove

the discs (5) and thrust plates (6) of clutch M and the discs (8) and

thrust plates (9) of brake L.

Remove the junction plate (16). Mark the

assembly order then

remove the input shaft (10), the Belleville washer (4), the spring

washer (72) and the bearing (12).

Install the Powershift module

Ensure all parts are in good condition. Ensure the clutch pilot ports

and lubricating ports are clean. Install a new oiled "O" ring on the

Powershift module cover.

In the cover (2), fit a new lip seal (11) smeared with grease on the

inside and oiled on the outside. Install the springs in the housings.

Install a disc on the cover.

If the MF 5608, 5609 brake discs or clutch discs have been replaced,

they must be soaked for approximately one hour in a transmission oil

bath.

Install the friction washer (13), with the grease removed and smeared

with Loctite 648 or equivalent.

Install the Belleville washer (4), the ball bearing (12) and the spring

washer (72) on the clutch housing (3). Slide on the shaft (10). Install

the junction plate (16), the

clutch discs (5) and thrust plates (6), and a brake disc (8) and thrust

plate (9) on the clutch housing (3).

Reinstall the clutch cover (7). Install the screws (15) smeared with

Loctite 242. Tighten to a torque of 33 Nm. Install the snap ring (42) on

the shaft (10). Install the

friction washer (14) smeared with grease on the clutch housing (3).

Install service tool on the input shaft (10) so as to protect the lip

seal (11). Install clutch M /brake L on the cover (2), paying attention

to the lip seal (11). Place the

cover (2) on a supporting fixture to position the input shaft (10).

Replace the last disc (8) of brake L. Install the brake piston (17) with

new, oiled "O" rings (23) (24), in the housing(18). Reinstall the

housing (18) on the cover (2).

Install the cover screws smeared with Loctite 242. Tighten to a torque

of 29-37 Nm. Place the planet carrier (25) on the input shaft (10).

Turn the planetary gears (48) to engage them with the sun gear (36) and

line up the splines of the planet carrier on the shaft. Insert the

spacer (43,) which should be

smeared with grease, and the ball bearing (44) in the planet carrier

(25). Install the friction washer (77).

Position the ring gears (29) (65) and ring gear carrier (27) assembly on

the planet carrier (25). Install the spacer (45) and the circlip (46).

Smear new "O" rings (76)

and (19) with miscible grease and Install them on the housing (28).

Using a sling, position housing (28) on housing (18).

Make sure that the "O" rings are correctly positioned. Install and

tighten the housing screws (18) and (28), smeared with Loctite 242.

Insert the brake piston (57),

fitted with two new oiled "O" rings (55) (56), in the housing (28).

Install two shims in the housing (28) to hold the ring gears and the

planet carrier in place during assembly of the module and the reverse

shuttle. Check that the

needle bearing (73) is present in the MF 5609, 5608 clutch housing (66).

Check its condition and change it if necessary.

Install the friction washer (69), smeared with grease, on the cover

(26). Install a brake disc (33). Install the clutch housing (66) on the

cover (26), followed by the hub

(61), the Belleville washers (67) (68) and the junction plate (35).

Install the clutch discs (63) and thrust plates (62).

If the brake discs or clutch discs have been replaced, they must be

soaked for approximately one hour in a transmission oil bath. Install

the brake discs (33) and

thrust plates (34).

Install the clutch cover (32), the screws (64), smeared with Loctite

242, and tighten them to a torque of 33 Nm. Install the springs (58) in

the cover (26). Install the

planet carrier (30) on the output shaft (47). Reinstall the Powershift

module on the reverse shuttle.

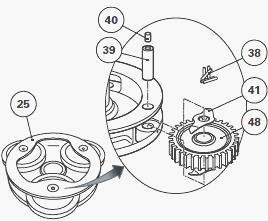

Disassembling and reassembling the planetary gears

The planetary gear pins are fitted already tightened in the thickest

part of the planet carriers. The pins comprise lubricating ports that

must be positioned facing the

corresponding ports on the planet carrier.The disassembly principle is

the same for all planet carriers.

The following example applies to planetary gears in the front epicyclic

gear train of the Powershift module. Place the planet carrier (25) in a

vice equipped with

protective jaws. Using a suitable press and fixture, drive out the pins

(39) from the planet carrier (25), pushing from the side where the

planet carrier is thickest.

Take out the planetary gear and retain the friction washers (41) and

bearing needles (38). Clean all the parts, check their condition and

replace any that are

defective. Ensure the lubricating ports of the planet carriers and pins

are clean.

The pins of the planetary gears (39) are blocked by plugs (40). Check

that the plugs are present. Install new ones if any are missing. Prepare

the planetary gears.

Install the bearing needles in the planetary gears using miscible

grease. Place the planet carrier on a suitable supporting fixture.

Install the planetary gear (48) with the needle bearing (38) and the two

friction bearings (41). Insert the pin (39), then drive it in, using a

suitable press and fixture.

Insert the pin until it is flush with the planet carrier surface. Check

that the planetary gears rotate freely.

Reinstall the PTO shaft (33). Clean and check the condition of the

Massey Ferguson 5608, 5609 gearbox hydraulic control unit.

Check for the presence of "O" rings in the hydraulic unit ports. If the

"O" rings have to be replaced, oil them slightly. Apply Loctite 510 or

an equivalent sealing

product to the mating face of the unit. Reinstall the connecting pipes,

then the hydraulic control unit. Install the screws.

Assemble the gearbox and the engine and rear axle. Top up the

transmission oil level. Carry out a clutch calibration procedure. Carry

out road tests to check the

operation of the gearbox. Check the operation of the hydraulics and make

sure that there are no leaks.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader