________________________________________________________________________________

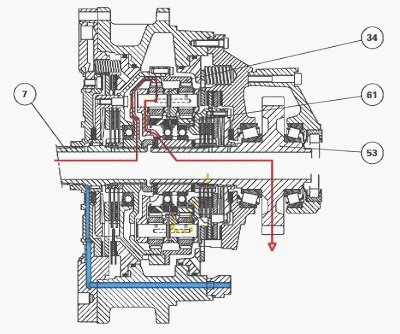

Massey Ferguson 8240, 8250 gearbox - Dynashift with power shuttle

On Massey Ferguson 8240, 8250 tractors the Dynashift can also be mounted on an input unit fitted with a mechanical reverse shuttle.

This section only describes the Dynashift with power shuttle. The operating principles of the two Dynashift versions are similar.

However, housing profile of the Dynashift with power shuttle is

different because of the location of the power shuttle rear clutch and

the driving gear located at the rear end of the housing.

MF 8240, 8250 gearbox dynashift is located between the rear clutch and

the driving gear of the power.

It is a hydraulically controlled gear shift mechanism and provides the

gearbox with four input ratios.

The function is ensured by two epicyclic gear trains associated with two

hydraulic clutches.

Dynashift design enables selection of each of the four ratios while

driving, and under load, without declutching, using a lever mounted to

the left under the steering wheel.

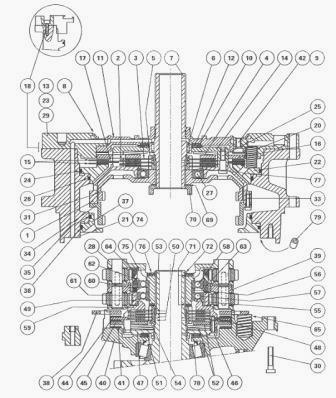

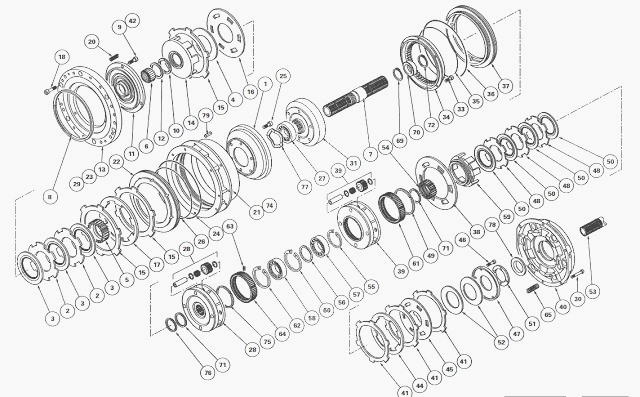

(1) Secondary ring gear carrier (2) Intermediate plates (3) Front clutch

discs (4) Belleville washer (5) Splined hub (6) Needle bearing (7)

Transmission shaft (8) Ring restrictor (9) Screw (10) Friction washer

(11) Bearing (12) Washer (13) Front cover (14) Clutch housing (15) Front

brake discs (16) Thrust plate (clutch - brake) (17) Clutch plate (18)

Screw (20) Springs (21) Spacer casing (22) Front piston (23) Rivet (24)

O’ring (25) Screw (26) O’ring (27) Ball bearing (28) Primary planet

carrier (29) Rivets (30) Screw (31) Primary ring gear (33) Screw (34)

Secondary ring gear (35) O’ring (36) O’ring (37) Rear piston (38) Clutch

plate (39) Secondary planet carrier (40) Cover (41) Rear brake discs

(42) Screw (44) Clutch plate (45) Thrust plate (clutch - brake) (46)

Screw (47) Cover (48) Intermediate plates (49) Retaining ring (50) Rear

clutch discs (51) Friction washer (52) Belleville washers (53) Secondary

shaft (54) Splined hub (55) Circlip (56) Spacer (57) Ball bearing (58)

Ball bearing (59) Rear clutch housing (60) Retaining ring (61) Secondary

sun gear (62) Retaining ring (63) Needles (64) Primary sun gear (65)

Springs (69) Circlip (70) Stop (71) Shim(s) (72) Retaining ring (74)

Rivets (75) Oil splasher (76) Stud washer (77) Spring washer (78) Washer

(79) Locating pin

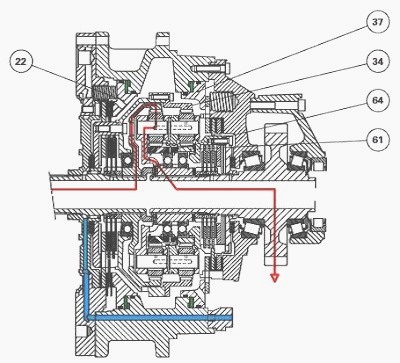

The Dynashift housing is controlled by two solenoid valves mounted on

the clutch unit located on the front right hand side of the gearbox.

The two solenoid valves are controlled by the MF 8240, 8250 tractor’s electronic system.

The Dynashift input unit comprises two epicyclic gear trains: the

primary epicyclic gear train is the input unit’s main component and

transmits the movement of the engine to the gearbox, the secondary

epicyclic gear train controls the speed of the primary sun gear.

Primary epicyclic gear train

The movement comes in via the primary ring gear (31) which is splined

onto the transmission shaft (7).

The ring gear turns at the same speed

as the engine.

The movement exits via the planet carrier (28) which is splined onto the secondary shaft (53).

The primary sun gear (64) is driven by the

secondary epicyclic train.

The speed of this sun gear determines the reduction ratio of the

gearbox.

Secondary epicyclic gear train

This epicyclic gear train is controlled by two Massey Ferguson 8250,

8240 hydraulic clutches and brakes.

The secondary ring gear (34) is:

- either locked onto the transmission shaft (7) by the three clutch

discs (3) and the Belleville washer (4) located in the front part of the

housing,

- or immobilized in relation to the housing by three brake discs (15)

and a piston (22).

- When there is no pressure, the piston (22) is pulled back by the

twelve springs (20) and the Belleville washer (4) by means of the thrust

plate (16).

- When the 17 bar pressure is built up in the circuit, the piston (22)

moves forward and blocks the brake discs (15) while pushing the thrust

plate (16) that

compresses the Belleville washer (4).

Speed of the secondary ring gear is established as follows:

- speed equals engine speed if the front piston is not under pressure.

- speed nil when the front piston is under pressure.

The secondary sun gear (61) is:

- either locked onto the secondary transmission shaft by means of four

clutch discs (50) and two Belleville washers (52) located on the rear

section of the housing,

or immobilized in relation to the housing by means of three brake discs

(41) and a piston (37).

- When there is no pressure, the piston (37) is pushed forward by the

Belleville washers and the six springs (65).

- The 17 bar pressure moves the piston (37) back and locks the brake

discs (41). The piston compresses the Belleville washers (52) by means

of the thrust plate

(45) that releases the secondary MF 8250, 8240 transmission shaft clutch

discs.

- Immobilization of either the secondary ring gear (34) or the secondary

sun gear (61) modifies the speed of the secondary planet carrier (39).

The latter drives the

primary sun gear (64), and this establishes the gearbox reduction ratio.

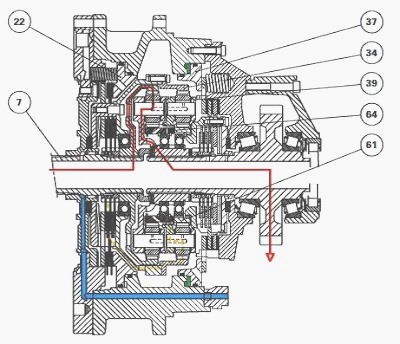

Explanation of the ratios

Ratio A: Reduction 1/1.620

The two pistons (22) (37) are simultaneously under pressure from the 17

bar circuit.

The secondary ring gear (34) is locked onto the casing by means of the

front brake.

The secondary sun gear (61) is locked onto the casing by the rear brake.

Consequently:

- the secondary epicyclic gear train is locked

- the primary sun gear (64) is locked

- the reduction ratio is only set by the primary epicyclic gear train.

- This is standard kinematics, movement comes in via the ring gear and

exits via the planet carrier; the sun gear does not move.

Ratio B: Reduction 1/1.386

Front piston (22) is under pressure.

Front brake locks the secondary ring gear (34) onto the casing.

Rear piston (37) is not under pressure.

The secondary sun gear (61) rotates with the secondary Massey Ferguson

8240, 8250 transmission shaft (53) (clutch engaged).

The secondary planet carrier (39) is rotating at a low speed, driving

the primary sun gear (64).

The rotational speed of the primary planet carrier (28) corresponds to

the speed difference between the primary ring gear (31) and the primary

sun gear (64).

Reduction effect is therefore minor.

Ratio C: Reduction 1/1.1704

Rear piston (37) is under pressure.

The rear brake locks the secondary sun gear (61) onto the casing.

The front piston (22) is not under pressure.

The secondary ring gear (34) rotates with the transmission shaft (7) thereby transmitting a higher speed to the secondary planet carrier (39).

The primary sun gear

(64) is driven by the secondary planet carrier (39) at a higher speed

than in ratio B.

Reduction is therefore lower.

Ratio D: Reduction 1/1 ratio

The two pistons are not under pressure. The two clutches are therefore

engaged.

The secondary ring gear (34) rotates with the transmission shaft (7).

The secondary sun gear (61) is locked on the secondary shaft (53)

thereby mechanically locking the entire system.

The ratio is therefore 1:1 (direct transmission).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader