________________________________________________________________________________

Kawasaki FB460V Carburetor

Kawasaki FB460V Carburetor Operation

In the choke or start position, the choke valve is closed, and the only

air entering the engine enters through opening around the valve. As the

starting device is operated to start the engine, the air pressure in the

carburetor is reduced as air drawn into the engine.

Since the air passage is blocked by the choke valve, fuel is drawn from

the main nozzle and from both idle fuel discharge ports and mixes with

the air that passes through the throttle valve. This makes a very rich

fuel mixture required to start a cold engine.

At idle a relatively small amount of fuel is required to operate the

engine. The throttle is almost closed, shutting off the fuel supply from

all except the one idle fuel discharge orifice, so that the suction

created by the engine draws fuel only from that orifice. During

intermediate operation, second and third orifices are uncovered as the

throttle valve opens, and more fuel is allowed to mix with the air

flowing into the engine.

During high speed operation, the throttle valve is fully opened. Air

flows through the carburetor at high speed. The venturi, which decreases

the air passage through carburetor, further accelerates the air flow.

This high speed movement of the air decreases the air pressure, and fuel

is drawn into the air stream through the main nozzle that opens into

venturi, mining with the air in the air passage.

As the engine load increases, air is automatically bled into the main

nozzle through the air jet located in the air horn. This allows fuel to

be metered freely from the main nozzle and to be facilitated

atomization.

General Specifications

Main Jet (FB460V-AS) - #112.5

Main Jet (FB460V-BS) - #115

Pilot Jet - #47.5 / #47.5

Pilot Screw (Turn out) - 1-1/8

Float Valve - 1.5 mm (0.059 in.)

Low Idle Speed - 1350 to 1450 rpm

Fast Idle Speed - 3275 to 3425 rpm

Float Level - Float parallel to carburetor body-to-bowl mating surface.

Kawasaki FB460V Carburetor Adjustment

Adjust idle mixture

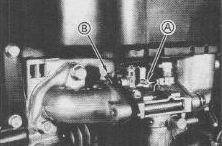

Air cleaner must be assembled to engine. Turn idle mixture screw (B) in

until it just seats, then back it out 1-1/8 turns. Do not turn the screw

in too far. The pointed end of valve seat is susceptible to damage.

Start and allow engine to warm. Move throttle lever on equipment to

"IDLE POSITION".

Use a tachometer and adjust throttle stop screw (A) to obtain 1350 to

1450 rpm by turning it in or out while holding the end of the screw

against carb body. Adjust idle mixture screw (B) by turning clockwise

(lean) or counterclockwise (rich) to obtain the peak of idling. Turn

idle mixture screw (B) back out 1/4 turn more. Use a tachometer and

readjust throttle stop screw (A) to obtain and satisfy specified 1350 to

1450 rpm idling. Stop the engine.

Removal and Disassembly

Before removing for repair, check for signs of air leakage, or mounting

gaskets that are loose, deteriorated, or otherwise damaged. Do not bent

the links or stretch. Pull carb free, and gently twist carb. to free

link rod. Remove governor link rod and link spring. Disassemble carb.

Kawasaki FB460V Carburetor

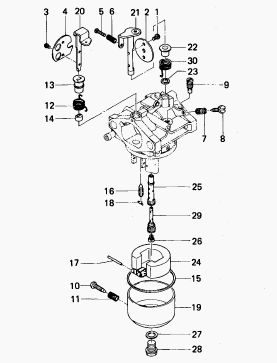

Disassembly: 1 - Screw, 2 - Throttle valve, 3 - Screw, 4

- Choke valve, 5 - Screw, 6 - Spring, 7 - Spring, 8 - Pilot screw, 9 -

Pilot jet, 10 - Drain screw, 11 - Spring, 12 - Spring, 13 - Ring, 14 -

Ring, 15 - Gasket, 16 - Needle valve, 17 - Float pin, 18 - Clip, 19 -

Float chamber, 20 - Choke shaft, 21 - Throttle shaft, 22 - Ring, 23 -

Seal, 24 - Float, 25 - Main nozzle, 26 - Main jet, 27 - Washer, 28 -

Bolt, 29 - Bleed pipe, 30 - Spring

Cleaning and Inspect

Place carb body and parts in PT503 cleaner or its equivalent. Do not put

gaskets and plastic parts in cleaner. Parts should remain in cleaner for

1 or 2 hours. Remove and rinse with solvent. Rinse carb body in hot

water to neutralize corrosive action of cleaner on aluminum. Dry parts

with compressed air. Be sure all holes are open. Do not use rags or

paper to dry parts. Lint may plug hole or passages.

Inspect carb body for damage. Flange sealing surfaces should be smooth

and free of burrs and nicks. Replace gasket if necessary. Inspect pilot

screw and drain screw for wear at the seating surface. Inspect for weak

springs. Inspect main jet, bleed pipe, main nozzle and pilot screw for

damage. Inspect inlet needle valve for wear or damage at the seating

surface. Inspect clip for damage. Inspect the other parts of carburetor

for wear, damage.

Assembly and Installation

Reassembly is the reverse of removal. Note the following points: Install

main nozzle, bleed pipe, and main jet by turning clockwise into

carburetor body. Do not over tighten screws. Install pilot screw

(mixture screw) and spring finger tight. Install pilot jet screw by

turning it clockwise into carb body.

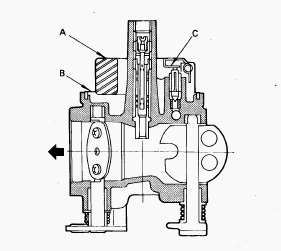

Do not over tighten. Install float and float pin. Do not push on float

or, inlet needle valve when adjusting float level. When carburetor is

upside down, float surface (A) must be parallel to carburetor body (B).

To adjust float surface angle, bend tang (C) with needle-nose pliers.

Install throttle linkages and choke linkage on carburetor. Install

breather connector on intake pipe. Assembly gaskets, heat shield plate,

carburetor, gasket and intake pipe. Install carb assembly on inlet pipe

with through bolts.

________________________________________________________________________________

________________________________________________________________________________________

| KOHLER ENGINES SPECS AND SERVICE DATA |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KAWASAKI ENGINES SPECS AND SERVICE DATA |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| BRIGGS AND STRATTON ENGINES SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| HONDA ENGINES SPECS AND SERVICE DATA |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

CH12.5

CH12.5 CH14S

CH14S CH15S

CH15S CH16

CH16 CH18S

CH18S CH23S

CH23S CH25S

CH25S CH640S

CH640S CH730S

CH730S CH750S

CH750S CV15S

CV15S CV16S

CV16S CV18S

CV18S CV20S

CV20S CV22S

CV22S CV23S

CV23S CV25S

CV25S CV490S

CV490S CV491S

CV491S CV730S

CV730S CV740S

CV740S K161

K161 K181

K181 K241

K241 K301

K301 K321

K321 K341

K341 K361

K361 M18

M18 M20

M20 SV470S

SV470S SV530S

SV530S SV540S

SV540S SV590S

SV590S SV600S

SV600S SV710

SV710 SV715

SV715 SV725S

SV725S SV730S

SV730S SV735

SV735 FA210

FA210 FA210D

FA210D FB460V

FB460V FC150V

FC150V FC290V

FC290V FC420V

FC420V FC540V

FC540V FD501V

FD501V FD590V

FD590V FD620D

FD620D FD731V

FD731V FD750D

FD750D FH430V

FH430V FH500V

FH500V FH531V

FH531V FH580V

FH580V FH601V

FH601V FH680V

FH680V FS541V

FS541V FS600V

FS600V FS651V

FS651V FX651V

FX651V FX691V

FX691V FX730V

FX730V FH541V

FH541V FH641V

FH641V FH661V

FH661V FH721V

FH721V FS730V

FS730V 252707

252707 253707

253707 282707

282707 286707

286707 303777

303777 28N707

28N707 28M707

28M707 28Q777

28Q777 28R707

28R707 28S777

28S777 311707

311707 31A607

31A607 31C707

31C707 31N707

31N707 31Q777

31Q777 31R977

31R977 31R777

31R777 31P777

31P777 31P977

31P977 350777

350777 402707

402707 422707

422707 42A707

42A707 331777

331777 331877

331877 G50

G50 G100

G100 GC135

GC135 GC160

GC160 GC190

GC190 GS190

GS190 GX100

GX100 GX120

GX120 GX160

GX160 GX200

GX200 GXV120

GXV120 GXV160

GXV160 GXV270

GXV270 GXV340

GXV340 GXV390

GXV390 GXV610

GXV610 GCV520

GCV520 GCV530

GCV530 GXV620

GXV620 GXV630

GXV630 GCV145

GCV145 GCV160

GCV160 GCV170

GCV170 GCV190

GCV190 GCV200

GCV200 GSV190

GSV190 GX110

GX110 GX140

GX140 GV100

GV100 GXV140

GXV140