________________________________________________________________________________

PTO clutch Massey Ferguson tractors

- MF 3000-3100 Service and Repair

- MF 5400-5600 Service and Repair

- MF 6100-6200 Service and Repair

- MF 6400-6600 Service and Repair

- MF 7400-7700 Service and Repair

The power take-off PTO clutch, fitted at the front of the rear axle

housing, is driven by a splined shaft located inside the engine clutch

input shaft, which rotates integral with the engine flywheel. The PTO

clutch control shaft traverses: the gearbox primary shaft, the

Speedshift, the reverse shuttle and the intermediate shaft.

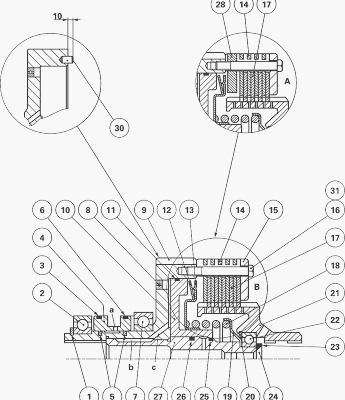

The MF 3060/3070/3090 tractor clutch consists

of:

- a unit (9), supported by two ball bearings (2) (7) separated by a

sleeve (4) centred in a bore of the centre housing. The sleeve (27)

supports the ball bearing (22), the drive hub (21) and the piston (10).

- a bell (15) including a set of discs (17) and intermediate plates (14)

is fixed onto the unit. The unit (9) comprises external helical teeth

that drive the hydraulic pump gear. The bearings and discs are

lubricated. Depending on the model, the clutch has either 4 or 5 discs.

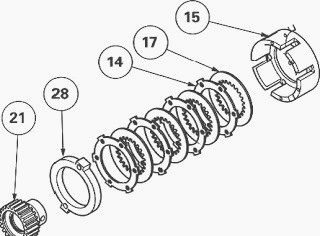

On the 4-disc version (Fig.1), a special spacer (28) is fitted in place

of the missing disc and spacer.

Clutch engaged position

A 17 bar hydraulic system supplies the clutch via a PTO proportional

solenoid valve located on the right-hand hydraulic cover plate. Oil

enters the unit (9) via channels a and c and chamber b. It pushes the

piston (10) which compresses the discs (17) against the intermediate

plates (14).

As the intermediate plates are attached to the bell (15) by lugs and the

discs (17) are attached to the hub (21), the drive is transmitted to the

drive hub (21) in which the intermediate shaft controlling the PTO

driving gear is located.

At the same time, the pressure acting on the PTO brake piston is cut,

allowing the 540 and 1000 rpm gears of the PTO lower shaftline to turn

freely. When engaging the clutch, the discs are cooled and lubricated.

PTO brake position

When the supply is cut, the spring (18) pushes the piston back against

the unit (9). When the knob located in the cab is in the PTO brake

position, the ON/OFF solenoid

valve for the PTO brake directs the oil towards the top cover plate,

which is fitted at the rear of the tractor.

Pressure acts on a piston that pushes the bearing cup on the rear

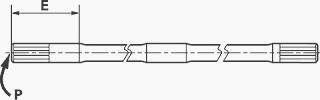

bearing cone, progressively immobilising the driving gear. Fit the

longer end "E" or the paint mark "P"

on the clutch control shaft so that it is facing towards the input

housing (Fig.71).

Fig.72. Parts list

(1) Circlip, (2) Bearing, (3) "O" ring, (4) Sleeve, (5) Seal rings, (6)

"O" ring, (7) Bearing, (8) Valve, (9) Clutch unit, (10) Piston, (11) "O"

ring, (12) Belleville progressivity washers, (13) Support, (14)

Intermediate plates A: 4-disc clutch B: 5-disc clutch, (15) Bell, (16)

Screw, (17) Discs, (18) Spring, (19) Spring seat, (20) Snap ring, (21)

Drive hub, (22) Bearing, (23) Washer, (24) Screw (25) "O" ring, (26) "O"

ring, (27) Sleeve, (28) Special spacer (4-disc version only), (30) Pins,

(31) Treated washers

Removing and refitting the PTO clutch

(2-speed version)

Remove the right-hand hydraulic cover plate.

Remove the PTO top cover plate located at the rear of the MF

3060/3070/3090 tractor, the driving gear and the intermediate Shaft.

Take off the retaining screw (3) from the clutch (1) using a combination

wrench (for cutting and shaping as needed). Remove the latter and the

spring (5).

Check and clean the components. Replace any defective parts.

Check that the "O" rings (2) and (4) are not damaged.

Install the spring (5) in the port of the PTO shaft and refit the clutch

(1) by moving it fully forwards using a lever to compress the spring in

order to fit the screw (3).

Clean and smear the screw (3) with Loctite 542 and tighten to 50 - 70

Nm.

Install the intermediate shaft, the driving gear and the top cover

plate.

Install the right-hand hydraulic cover plate.

Check for the correct operation of the clutch, PTO brake and linkage.

Check tightness:

- of the mating faces (spool valve support, top cover plate, right-hand

hydraulic cover plate)

- Hydraulic unions

Removing and refitting the Massey

Ferguson 3060/3070/3090 tractor PTO clutch (4-speed version)

On 4-speed version tractors (economy), removal of the PTO clutch is the

same as the 2-speed version.

The only difference relates to the parts to be removed for access (i.e.

driving gears and intermediate shaft).

Remove the right-hand hydraulic cover plate.

Remove the PTO top cover plate located at the rear of the tractor, the

driving gear and the intermediate shaft.

Take off the retaining screw (3) of the clutch using the same equipment

as that used for the 2-speed version. Remove clutch and spring (5).

Check and clean the components. Replace any defective parts.

Check that the "O" rings (2) and (4) are not damaged.

Place spring (5) in the port of the PTO shaft and refit the clutch (1)

by moving it fully forwards using a lever to compress the spring in

order to fit the screw (3).

Clean and smear the screw with Loctite 542 and tighten to 50 - 70 Nm.

Install the intermediate shaft, the driving gear and the rear cover

plate.

Install the right-hand hydraulic cover plate.

Check correct operation of the clutch and power take-off brake.

Check tightness:

- of the mating faces (spool valve support, top cover plate, right-hand

hydraulic cover plate)

- Hydraulic unions

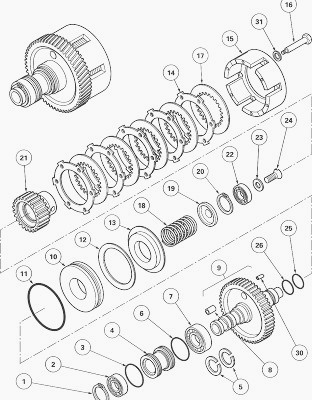

Disassembling and reassembling the

Massey Ferguson 3060/3070/3090 tractor clutch

Take off the screws (16) and washers (31).

Remove the bell (15), discs (17) and intermediate plates (14).

Place the clutch unit (9) into a vice equipped with protective jaws.

Remove the "O" rings (3) (6).

Remove the circlip (1).

Extract the bearing (2) with the sleeve (4).

Take off the seal rings (5) and extract the bearing (7)

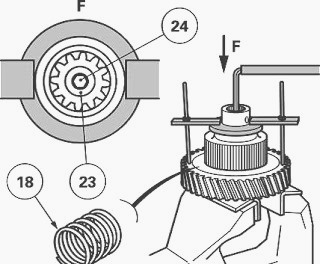

Hold the spring (18) using a makeshift tool (Fig.3).

Take off the screw (24) and remove the washer (23) (Fig.3). Gradually

decompress the spring using the tool.

Remove the drive hub (21), the spring seat (19), the spring (18), the

support (13) and the Belleville washer (12).

Take off the snap ring (20).

Extract the bearing (22).

Take out the piston (10) by hitting the clutch unit on a block of wood.

Take off the "O" rings (11) (25) (26).

The valve (8) is crimped onto the clutch unit (9). Check that the

bearing moves freely by rapidly shaking the unit up and down several

times. The sleeve (27), smeared with Loctite 648, is fitted using the

press. If disassembly is necessary, make sure that there is no Loctite

blocking the channel when reassembling. Two pins (30) are fitted in the

unit (9) 10 mm from the face.

Check and clean the components and replace those that are defective.

Using a suitable fixture and a press, fit the bearing (7) home against

the shoulder.

Place seal rings (5) into their grooves and hook their ends, making sure

that they turn freely.

Slide the sleeve (4) over the rings and avoid damaging them. Turn the

larger sleeve diameter towards the bearing (7).

Using a suitable fixture and a press, fit the bearing (2) up against the

shoulder of the unit (9).

Position the circlip (1).

Replace and lubricate the "O" rings (11) (25) (26).

Lubricate the sleeve (27) and the piston (10) and fit it into the unit

using a plastic hammer.

Using a suitable fixture and a press, fit the bearing (22) into the hub

(21) and refit the snap ring (20).

Install the Belleville washer (12), the support (13), the spring (18),

the spring seat (19) and the drive hub (21).

Compress the spring (18) with the tool (Fig.3), fit the washer (23) and

tighten the screw (24) smeared with Loctite 270 to a torque of 24 - 28

Nm.

Position the spacer (if fitted), intermediate plates and discs on the

hub (21).

Position the bell (15) in the two pins (30). Fit the screws (16) each

fitted with a washer (31), lightly smeared with Loctite 270, and tighten

to 15 - 18 Nm.

Manually check that the discs and intermediate plates are not obstructed

in any way.

Lubricate and fit the "O" rings (3) (6). The rings have different

diameters. Install the clutch.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader