________________________________________________________________________________

Belarus Tractor Clutch Adjustments

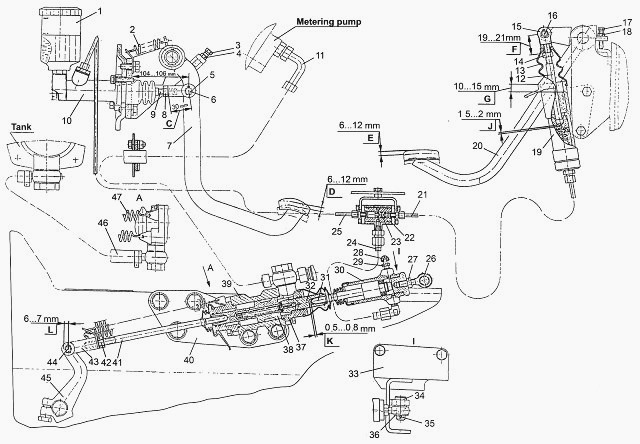

Adjusting the clearance between the piston and

the piston lifter (9) of the clutch master cylinder (10) (for forward

motion):

- Set the initial position of the pedal (7) by means of the adjusting

bolt (3) and fork (5) having kept the dimension “B”;

- Adjust the clearance between the piston lifter (9) and the piston of

the clutch master cylinder (10) by means of the fork (5).

When doing this, the travel of the pedal (7) from the initial position

to the moment of contact of the piston lifter (9) with the piston as

measured at the center of the pedal boot shall correspond to the

dimension “G”;

- Tighten the nuts (4, 8) and fix the pin (6) with a cotter pin;

Adjusting the clearance “J” between the piston

and the piston lifter (12) of the master cylinder (19) (for working in

the reverse mode):

- Remove the boot (13);

- Unlock the piston lifter (12);

- Screw the piston lifter (12) of the master cylinder (19) into the fork

(15) having kept the dimension “F”;

- Tighten the nut (14) and refit the boot (13);

- Adjust the free travel of the pedal (20) as measured at the center of

the boot to the dimension “E” by turning the bolt (17) in and out for

ensuring the clearance between the piston lifter (12) and the piston of

the master cylinder (19);

- tighten the locknut (18);

Adjusting the clearance “K” between the piston

lifter (31) of the service cylinder (30) and piston lifter (32) of the

hydraulic booster (39):

- Dismantle the clutch master cylinder (30) from the bracket (33) having

removed the pin (34);

- Set the piston lifter (31) in the cylinder (30) to the rightmost

position until it rests against the cover;

- Move the cylinder (30) until it contacts the piston lifter (32) of the

hydraulic booster (39) without effort and align the holes of the support

(26) with those of the bracket (33) by turning the support (26) in or

out; then screw the support in by 1/2 revolutions and refit the pin

(34);

- Tighten the locknut (27) and fix the pin (34) with a cotter pin;

Adjusting the free travel of the clutch

release shifter:

- Remove the two release springs (47);

- Disconnect the rod (41) from the lever (45) having removed the pin

(44);

- Unlock the fork (43);

- Move the rod (41) to the right until the piston (38) of the hydraulic

booster (39) rests against the cover (37), turn the lever (45)

counter-clockwise until the release bearing rests against the release

levers and align the holes of the lever with those of the fork by

rotating the fork (43); then turn the fork in by 5...5.5 revolutions

(dimension “L”) and connect the same with the lever by means of the pin

(44);

- tighten the nut (42), fix the pin (44) with a cotter pin and refit the

two release springs (47).

Bleed air from the MTZ Belarus Tractor hydraulic clutch control system.

Bleeding the air from the hydraulic

clutch control system

Prior to bleeding, fill the reservoir (1) of the master cylinder for

forward motion (10) and the equalizing chamber of the master cylinder

for reverse (19) with brake fluid.

Bleed air from the hydraulic system in the

forward motion. To do this:

- Fill the reservoir (1) with brake fluid to the mark “MAX”;

- Remove the protective cap (28) from the cylinder (30) and fit a rubber

hose onto the head of the bypass valve (29). Dip another end of the

rubber hose into a vessel with brake fluid;

- Step on the clutch pedal several times; while holding down the pedal,

turn out the bypass valve (29) by quarter of revolution to release the

excess fluid brake with air bubbles into the vessel with brake fluid;

- Turn in the bypass valve (29) and release the clutch pedal;

- Bleed air from the system until the air bubbles in the released brake

fluid disappear completely;

- Remove the hose and refit the protective cap (28);

- Check the brake fluid level in the reservoir (1) and add it as

necessary.

Bleed air from the hydraulic system in the

reverse mode. To do this:

- Remove the boot (13) of the master cylinder (19);

- Check the brake fluid level in the equalizing chamber of the master

cylinder (19), which shall not be below dimension “G” from the top edge

of the equalizing chamber;

- The procedure of bleeding air from the hydraulic system is similar to

that for the forward motion.

Check the bleeding of air from the hydraulic system.

When bleeding air from the Belarus MTZ Tractor

hydraulic system:

- for forward motion: maintain the brake fluid level in the tank (1)

between the marks “MIN” and “MAX”;

- for reverse mode: maintain the brake fluid level in the equalizing

chamber of the master cylinder (19) to be not below the dimension G from

the top edge of the equalizing chamber.

When performing the clutch adjustment, ensure the coaxiality of the

hydraulic booster (39) and service cylinder (30) by shifting the bolts

of the brackets (33), (40) before tightening them.

If the adjustment is performed correctly, the pedal (7) being released

shall be positioned according to the dimension “B”. When the pedal (7)

is completely depressed, the piston lifter (9) shall move to the value

“C” and the lever (45) on the radius 105 mm shall move to 24…26 mm.

After checking the Belarus Tractor clutch

adjustments of the clutch, the smoothness of the clutch disengagement

should be checked. To do this:

- Start the engine and set its rotational speed to 1400±100 rpm;

- Tighten the parking brake;

- Step on the clutch pedals as far as they will go and shift in the GB

gears after at least 5 s. The shifting of the gears shall be smooth,

without foreign noises.

If not so, check the adjustments once again.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader