________________________________________________________________________________

Dry disc diaphragm clutch of Massey Ferguson 5455, 5465 Tractor

The Massey Ferguson 5455, 5465, 5460 Tractor dry clutch consists of :

- a thrust bearing carrier (2) and thrust ball bearing (1),

- a diaphragm mechanism (9),

- a bladed friction disc (6).

It is controlled by a power assisted master cylinder supplied by the

tractor low pressure (17 bar) hydraulic system.

Massey Ferguson 5455, 5465, 5460

Tractor clutch construction

The hydraulic slave device / thrust bearing carrier assembly is attached

to the Speedshift input unit cover plate at the front of the gearbox.

The thrust bearing carrier supports the bearing. It is controlled by the

hydraulic slave device assembly.

The tractor clutch thrust bearing is:

- sealed: the ball bearing races are lubricated for life and designed to

be lubricated constantly when rotating;

- held in permanent contact with the tractor clutch mechanism by springs

(13) located behind each piston (3).

This design avoids undue pedal clearance:

- automatically centred when the engine starts running.

Each piston (3) is guided in its cylinder by rings (11). Piston /

cylinder tightness is ensured by composite seals (12) (24).

Composite seals comprise a sealing ring (12) held under constant

pressure against a piston (3) by an "O" ring (24). Any dust created by

the friction of the disc (6) is driven from the rims of the pistons (3)

by wiper seals (10).

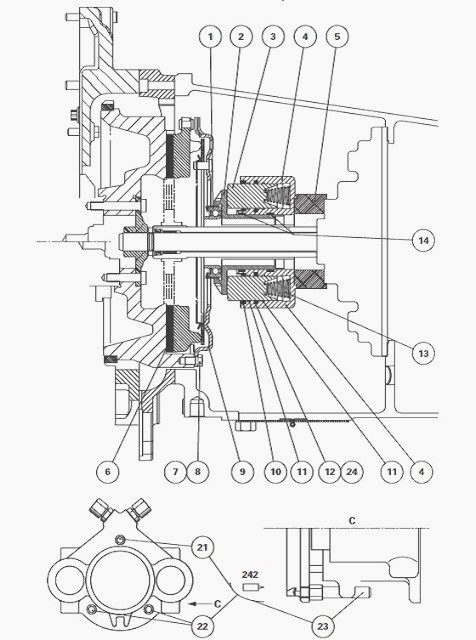

Fig.50. Parts list

(1) Clutch thrust bearing, (2) Thrust bearing carrier, (3) Pistons, (4)

Hydraulic slave device assembly, (5) Spacer, (6) Friction disc, (7)

Screw, (8) Dowel, (9) Mechanism, (10) Wiper seals, (dust seals) (11)

Guide rings, (13) Springs, (12) Sealing ring (composite), (14) Guide

rings, (21) Screw, (22) Screw, (24) "O" ring (composite), (23) Guide pin

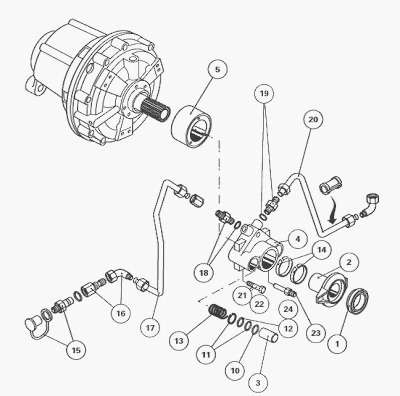

Fig.51. Parts list

(1) Clutch thrust bearing, (2) Thrust bearing carrier, (3) Pistons, (4)

Hydraulic slave device assembly, (11) Guide rings, (10) Wiper seals

(dust seals), (12) Sealing ring

(composite), (13) Springs, (14) Guide rings, (15) Bleed or pressure

connector, (16) Unions, (17) Pipe, (18) Union and seal, (19) Union and

seal, (20) Supply pipe, (21)

Screw, (23) Guide pin, (22) Screw, (24) "O" ring (composite)

Clutch disengaged position

The dry Massey Ferguson 5455, 5465, 5460 Tractor clutch is controlled by a standard clutch pedal that

acts on a master cylinder via a rod. The quantity of oil moved by the

master cylinder piston causes the thrust bearing carrier and its bearing

to move. The diaphragm mechanism is then compressed and the clutch disc

released.

Clutch engaged position

When the pedal is released, the pressure drops in the slave cylinders.

The tractor clutch mechanism diaphragm forces:

- the thrust bearing carrier and its bearing to return to position;

- the clutch mechanism pressure plate to move forwards.

The friction disc (6) is then locked between the pressure plate and the

engine flywheel. This allows drive to be transmitted from the engine to

the gearbox.

Removing and refitting the diaphragm

mechanism and friction disc

Disconnect the Massey Ferguson 5455, 5465, 5460 Tractor between

the engine and the gearbox.

Fully insert centring tool in the friction disc and hub of the engine

flywheel PTO shaft. This prevents the friction disc (6) from falling

off.

Gradually and evenly loosen and remove opposing screws (7) from the

mechanism (9).

Remove the mechanism and the friction disc (6). The friction disc can

have five or six blades depending on the tractor power.

Remove dust from the engine flywheel. Clean it with a solvent.

Check for any signs of wear, scratches, surface cracks, buckling or

overheating on the mechanism and on the engine flywheel. Replace

defective parts.

Lightly smear the splines of the PTO shaft hub (1) with AS767 grease or

equivalent. The hub (1) is located in the engine flywheel.

Check that the dowels (8) are present on the engine flywheel.

Install the following onto the engine

flywheel:

- the friction disc (6),

- centring tool,

- the clutch mechanism (9).

Turn the thick part "E" of the friction disc (6) towards the clutch

mechanism (9).

Lightly smear the thread of the screws (7) with Loctite 270 or

equivalent. Gradually screw in the screws. Tighten the screws equally in

diametrically opposed pairs to a torque of 50 - 70 Nm.

Take off centring tool.

Reconnect the tractor between the engine and the gearbox.

Replacing the MF 5455, 5465, 5460

Tractor clutch thrust Bearing

Disconnect the tractor between the engine and the gearbox.

Take out the thrust bearing carrier and its bearing from the hydraulic

slave device assembly.

Moderately compress the clips of the thrust ball bearing cage (3) using

a screwdriver. Separate the cage (3) from the thrust bearing carrier

(2).

Remove the spring washer (4).

Remove the thrust ball bearing (1).

Check the condition of the ball bearing in the thrust bearing and ensure

its tightness by checking there is no grease on the operating zone.

Replace the ball bearing if unsure of its condition. Never soak the ball

bearing in solvent. If required, wipe it with a dry cloth.

On the thrust bearing carrier (2), fit :

- the thrust ball bearing (1),

- the spring washer (4).

Manually compress the cage (3). Engage its clips in the thrust bearing

carrier groove.

Check:

- the rotation of the ball bearing in the thrust bearing,

- the radial movement of the thrust bearing.

Check that the guide rings (14) are present and fitted correctly.

Lightly grease the strut of the thrust bearing carrier (2) with clean

transmission oil.

Return the thrust bearing carrier into the hydraulic slave device

assembly (4).

There may be stiffness when returning the thrust bearing carrier into

the assembly. Move the thrust bearing to and fro several times.

Removing and refitting the hydraulic

slave device assembly

Disconnect the MF 5455, 5465, 5460 Tractor between the engine and

the gearbox.

Remove the supply pipe (20) and bleed pipe or pressure connector pipe

(17) from the hydraulic slave devices.

If required, remove the thrust bearing carrier (2) from the hydraulic

slave device assembly (4).

Take out the screws (21) and (22).

Manually hold the pistons (3) in position. Take off the hydraulic slave

device (4) / spacer (5) assembly.

If no work is to be carried out on the pistons, ensure that they are not

separated from the slave cylinders.

Clean the tapped holes in the Speedshift cover plate and the thread of

the screws (21) and (22).

Screw an M8 guide stud "G" of sufficient length into the top hole of the

front cover plate in the position of screw (21).

Lightly smear the thread of the screws (21) and (22) with Loctite 242 or

equivalent.

Turn the spacer (5). Position it against the Speedshift front cover

plate. Manually hold the pistons of the hydraulic slave device assembly

in place. Slide the hydraulic slave device assembly (4) onto the guide

stud "G" (Fig. 8). Position the hydraulic slave device assembly up

against the spacer.

Fit the screws (21) (L = 95 mm) and (22) (L = 75 mm), respecting their

length depending on their positioning on the hydraulic slave device

assembly. Take out the guide stud. Tighten the screws to a torque of

25-35 Nm. If removed, refit the thrust bearing carrier (2) in the

hydraulic slave device assembly (4).

Reconnect the Massey Ferguson 5455, 5465, 5460 Tractor Tractor between the

engine and the gearbox.

Ensure the hydraulic pipes (17) and (20) do not leak through the cover

located under the front of the gearbox.

Replacing the guide rings and piston

seals of the hydraulic slave device assembly

Disconnect the tractor between the engine and the gearbox.

Remove the hydraulic slave device assembly.

Take the pistons (3) out of the slave cylinders (4). Recover the springs

(13). Pair the pistons with their respective cylinders if they are to be

reused.

From the cylinders extract:

- the wiper seal or dust seal (10),

- the first guide ring (11),

- the composite seal (12) (24),

- the second guide ring (11).

From the hydraulic slave device assembly

extract:

- the guide rings (14).

The seals and rings should be discarded, regardless of their function

(wiper, guide or sealing).

If necessary, unscrew the pin (23) of the thrust bearing carrier (2).

If disassembled, lightly smear the thread of the pin (23) with Loctite

242 or equivalent. Screw in and tighten the pin to a torque of 25 - 35

Nm.

Carefully clean the hydraulic slave device assembly and each seal

groove. The grooves must be cleaned without using sharp or pointed

tools.

Ensure that:

- the bleed and supply lines on the slave device assembly are not

obstructed,

- there are no scratches in the cylinder bores or on the pistons.

Replacing the guide rings (14) of the

hydraulic slave device assembly

Preform a guide ring (14) by reducing its diameter by approximately one

third. Fit it into the lower groove of the central bore in the hydraulic

slave device assembly (4).

Preform a second guide ring (14) as described above. Fit it into the top

groove of the central bore in the hydraulic slave device assembly (4).

Composite seal of a slave cylinder

Preform a guide ring (11) by reducing its diameter by approximately one

third. Fit it into the lower groove of the slave cylinder (4).

Lubricate and fit an "O" ring (24), without twisting it, into the

intermediate groove of the slave cylinder (4). Form a composite seal

(12) without creating any sharp angles.

Fit this seal manually and evenly against the "O" ring (24). The lip of

the composite seal (12) should be turned towards the pressure chamber of

the slave cylinder.

Preform a second guide ring (11) as described above. Fit it into the top

groove of the slave cylinder.

Use the same assembly method to replace the guide rings (11) and

composite seal (12) (24) in the second slave cylinder.

Calibrating the guide rings (11) and

composite seal (12) (24) of a slave cylinder

Calibration consists of helping guide rings and the composite seal

return to their initial shape after they become misshapen at assembly.

Calibration should be carried out before fitting the wiper seal (10).

Lightly lubricate the guide rings (11) and sealing ring (12) inside the

slave cylinder with clean transmission oil.

Take an original piston (3). Ensure it shows no signs of knocks or deep

scratches on its rim or entry chamfer.

Place the piston in the slave cylinder: the piston chamfer must be

turned towards the pressure chamber.

Partially insert the piston into the slave cylinder by gently tapping on

its top surface with a plastic hammer.

Rotate the piston several turns.

Remove the piston by striking the back of the slave cylinder with a

plastic hammer. Visually check the appearance of the guide rings (11)

and sealing ring (12).

Use the same calibration method for the guide rings (11) and composite

seal (12) (24) in the second slave cylinder. Install the wiper seals

(10).

Replacing a slave cylinder wiper seal

Lightly smear the rim of the wiper seal (10) with Loctite 270 or

equivalent. Fit the wiper seal in the front counterbore of the slave

cylinder (4) using a press and a suitable fixture. The lip of the wiper

seal should be turned towards the front of the slave cylinder.

Remove any traces of Loctite after fitting.

Use the same fitting method to replace the wiper seal (10) of the second

slave cylinder.

Assembling pistons

Ensure there are no signs of knocks or deep scratches on the rim or

chamfer "C" of each piston (3).

Lightly lubricate the guide rings (11), the composite seal (12) (24) and

the wiper seal (10) of the slave cylinders with clean transmission oil.

Fit the springs (13) on the locating pin of each piston.

Insert each piston (3)/spring (13) assembly into each slave cylinder (4)

by gently tapping the top surface of the piston with a plastic hammer.

Check that the pistons move correctly when fitted.

The pistons must not resist manual pressure. They should return with

almost no effort due to their return springs (13). If one or two

piston(s) lock, find the cause of the problem.

Refit the hydraulic slave device assembly.

Reconnect the MF 5455, 5465, 5460 Tractor between the engine and the gearbox.

Bleed the hydraulic mechanism of the engine clutch. If required, check

its pressure (approximately 10 bar) on the diagnostics connector located

on the front right-hand side of the gearbox.

Bleeding the clutch system

The tractor clutch is controlled via the clutch pedal by a master

cylinder/slave cylinder assembly and the tractor's 17 bar hydraulic

system. After dismantling the control system, the circuit must be bled.

Park the tractor on a flat surface.

Put the transmission lever into neutral and apply the hand brake.

Check the transmission oil level. Adjust as necessary.

Bleeding the Massey Ferguson 5455,

5465, 5460 Tractor clutch by pumping the clutch pedal

This bleeding method requires two people.

Rig up a makeshift transparent hose on one end, and the other end inside

in a container. Connect the hose on the clutch bleed nipple located on

the right-hand side at the front of the Gearbox.

Start the engine. Set the engine speed between 1200 and 1500 rpm.

Assisted by an operator, pump the clutch pedal until there are no more

bubbles in the transparent hose.

When no further bubbles leave the system, keep the pedal depressed,

disconnect the transparent hose and then release the clutch pedal.

Check the bleeding. The pedal should be firm. If the pedal is too

spongy, perform another bleeding Operation.

Check the clutch operation.

Bleeding the Massey Ferguson 5455,

5465, 5460 Tractor clutch using

hydraulic pressure

A male quick connector is fitted as standard on the 5 bar line of the

left-hand hydraulic cover plate. It facilitates bleeding of the clutch

system.

Rig up a makeshift hose.

Using this hose, connect the 5 bar quick connector located on the

left-hand cover plate of the rear axle with the clutch bleed nipple

located on the right-hand side at the front of the gearbox.

Start the engine. Wait for about two minutes then disconnect the bleed

hose whilst the engine is running. Check the bleeding. The pedal should

be firm. If the pedal is too spongy, perform another bleeding operation.

Check the clutch operation.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader