________________________________________________________________________________

Massey Ferguson 6480 Tractor Removable PTO shaft

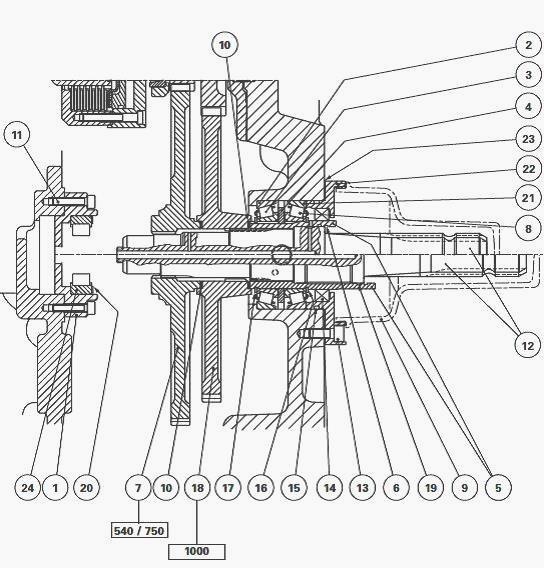

On Massey Ferguson 6455, 6465, 6480, 6290 Tractor, the driven pinions

(7) (18) are fitted on the power take-off PTO shaft located on the lower

rear housing. These pinions are constantly engaged with the driving

pinion(s) (depending on version) and driven by the upper shaft line

where the engine speed is transmitted by the power take-off clutch.

At the front, the removable shaft (12) turns on a roller bearing (24)

inserted into a fixed bearing block on the rear of the centre housing.

At the rear, the shaft is supported by a splined sleeve (5) that turns

in taper roller bearings.

Washer (4) is integral via a tab with sleeve (5) which itself is

integral with shaft (12) via splines. The sleeve is serrated all around

its outside edge and transmits speed information to the onboard

electronic system via the sensor located on the right-hand side of the

rear housing.

An oil splash from the centre housing along

with a central port and radial channels drilled in the shaft provide

lubrication of the:

- friction washers (10)

- taper roller bearings.

In the 540 rpm or 750 rpm (optional) configurations, the shaft (12) is

integral with pinion (7) via splines. Pinion (18) is an idling gear that

runs on the hubs of pinion (7) and sleeve (5). In the 1000 rpm

configuration, the shaft (12) is integral with pinion (18) via splines.

Pinion (7) is an idling gear that runs on the hub of pinion (18) and the

front bearing. The oil tightness of the rear bearing is provided by

cassette seal (14) and O’ring (15). Bearing clearance is adjusted by

shim(s) (23) placed between the rear housing and bearing (22).

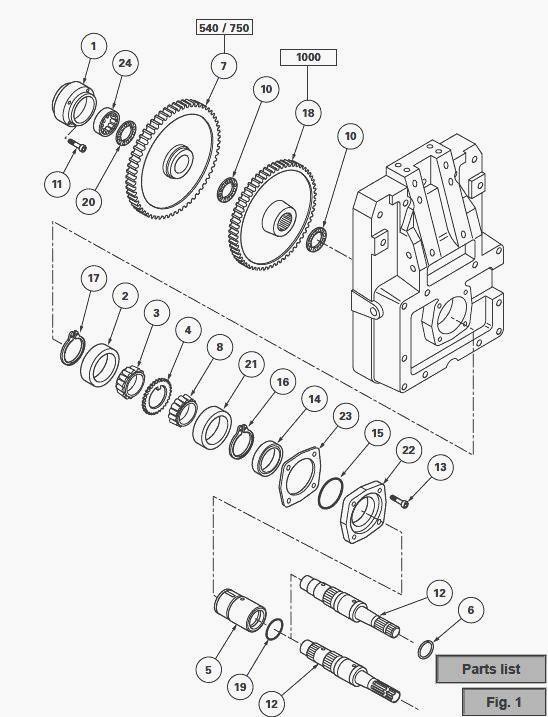

Fig.47. Part list

(1) Front bearing, (2) Bearing cup, (3) Bearing cone, (4) Castellated

washer, (5) Serrated sleeve, (6) Snap ring, (7) 540 or 750 rpm driven

pinion, (8) Bearing cone, (9) Protector, (10) Friction washer, (11)

Bolt, (12) Shaft, (13) Bolt, (14) Cassette seal, (15) O'ring, (16)

Circlip, (17) Circlip, (18) 1000 rpm driven pinion, (19) O'ring, (20)

Friction washer, (21) Bearing cup, (22) Bearing, (23) Shim(s), (24)

Roller bearing

Special point

-- The removal and refitting of the

Massey Ferguson 6455, 6465, 6480, 6290 Tractor power take-off PTO housing is necessary for all maintenance

operations on the layshaft apart from the removal of bearing (22), the

replacement of seals (14) (15) and shaft (12). The centre housing must

be drained either partially or completely depending on the operation and

must be brought up to level again after the maintenance.

Disassembling and reassembling pinions

540 - 1000 rpm or 750 - 1000 rpm

- The 540 - 1000 rpm and 750 - 1000 rpm versions have the same assembly

configuration. The only difference is that the 540 rpm and 750 rpm

pinions have a different number of teeth.

Uncouple the power take-off housing from the centre housing.

Recover the friction washer (20).

Remove snap ring (6) and support driven pinions (7) (18).

Pull shaft (12). Remove the pinions. Recover the friction washer (10).

Clean and check the components. Replace any parts found to be defective.

Check that the oil channels in shaft (12) are not obstructed. Check that

the interior of sleeve (5) is clean and free of burrs. Lubricate and fit

a new O’ring (19).

Assemble driven pinions (7) (18) and friction washers (10) smeared with

miscible grease and placed according to the overall view. Maintain the

pinions inserted and thrust against sleeve (5).

Engage shaft (12) against the shoulder of the sleeve.

Install snap ring (6).

Smear friction washer (20) with miscible grease and apply it against

bearing (24).

Couple the MF 6455, 6465, 6480, 6290 Tractor PTO housing to the centre

housing.

Disassembling and reassembling the

front bearing block (1)

Uncouple the power take-off housing from the centre housing.

Take out bolts (11). Remove the front bearing block (1).

Where necessary, note the manner in which bearing (24) is assembled and

then extract it from the bearing block.

Clean and check the components. Replace any parts found to be defective.

If disassembled, position bearing (24) using an appropriate insertion

drift, with the rounded cage holding the rollers turned to face the

forward end of shaft (12).

Install bearing block (1). Fit and tighten bolts (11) with their threads

lightly smeared with Loctite 241 and tighten to a torque of 27 - 35 Nm.

Couple the power take-off housing to the centre housing.

Disassembling and reassembling the

bearings

Uncouple the power take-off housing from the centre housing.

Take out the bolt from the lower sensor and remove it. Disassemble the

pinions and the shaft (see A).

Take out bolts (13), remove bearing block assembly (22) comprising

sleeve (5), oil seal (14), O’rings (15) (19), shim(s) (23), bearing cup

(21), bearing cones (3) (8) and castellated washer (4).

Take off bearing cup (2).

On sleeve (5), remove circlip (17). Remove bearing cone (3), castellated

washer (4), bearing cone (8) and circlip (16).

Special point

- If the MF 6455, 6465, 6480, 6290 Tractor power take-off housing,

bearing block (22), taper roller bearings (2) (3) (8) (21) or

castellated washer (4) had to be replaced, the bearings must be shimmed

again.

Clean and check the components. Replace any parts found to be defective.

Check that the oil channels in shaft (12) are not obstructed.

On sleeve (5), place circlip (16), bearing cones (3) (8) separated by

castellated washer (4). Fit circlip (17).

Install cup (2), sleeve (5) assembled, cup (21), bearing block (22) with

shim(s) (23, O’rings (15) (19). Install and tighten bolts (13) to a

torque of 72 - 96 Nm.

Install the 540 - 1000 rpm or 750 - 1000 rpm pinions and shaft (12).

Couple the Massey Ferguson 6455, 6465, 6480, 6290 Tractor power take-off PTO to the centre housing.

Install the sensor, O’ring and bolt.

Removing and refitting the shaft and replacing the oil seal.

Partially drain the centre housing in order to avoid oil from running

through the shaft bore, or raise the rear axle of the tractor (after

chocking the front wheels).

Remove O’ring (6). Take out shaft (12). Take off O’ring (19).

Check that the interior of sleeve (5) is clean and free of burrs.

Lubricate and fit a new O’ring.

Check that the channel in the shaft is not obstructed. Clean and then

engage the shaft thrust up against the shoulder on sleeve (5). Install

snap ring (6).

Remove the trolley jack.

Replacing the oil seal on rear bearing block.

Partially drain the centre housing.

Take out bolts (13), remove bearing block (22) while holding the shaft

(12) pushed forwards in order not to displace sleeve (5) on pinion (18).

Take off seal (15). Recover the shim(s) (23).

Note the direction of assembly of seal (14) and then extract it.

Clean and check the components. Replace any parts found to be defective.

If necessary, before fitting seal (14). Lightly smear the external

diameter of seal (14) with Loctite 542. Using a press, insert the

cassette seal into the bearing block (22) with its lip turned to face

taper roller bearing (8) (21).

Screw two diametrically opposed threaded rods (O 10 x 150, length

approximately 50 mm) in place of bolts (13). Check that sleeve (5) is

free from burrs. Lubricate the internal diameter of cassette seal (14)

with transmission oil. Refit the bearing block fitted with lubricated

seal (15) and the shims (23) removed during disassembly.

Hold the shaft (12) pushed forwards, as described in operation 35.

Alternatively and uniformly screw two bolts and washers on the threaded

rods so as to insert the bearing parallel with the face of the housing.

Remove the threaded rods. Fit and tighten the initial bolts (13) to

72-96 Nm.

Top up the oil level in the housings and check it on the transparent

tube mounted on the left-side of the centre housing.

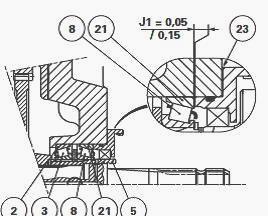

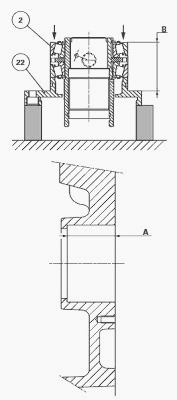

Shimming

Carry out the shimming of bearings (2) (3) and (8) (21) before fitting

seal (14).

Using a depth gauge, measure dimension A on the MF 6455, 6465, 6480,

6290 Tractor power take-off PTO

housing.

Place the sleeve prepared in operation 24, the bearing cups and bearing

block (22) thrust against a locally manufactured support.

With the help of an operator, apply strong continuous pressure around

the rim of the cup (2). At the same time, alternately turn the sleeve

left and right in order to correctly seat the bearing cones in their

cups. Measure dimension B at two opposing points. Take the average of

the two measurements.

Apply the formula B - A. Place a thickness of shim(s) (23) in order to

provide a clearance of: J1 = 0.05 mm to 0.15 mm.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader