________________________________________________________________________________

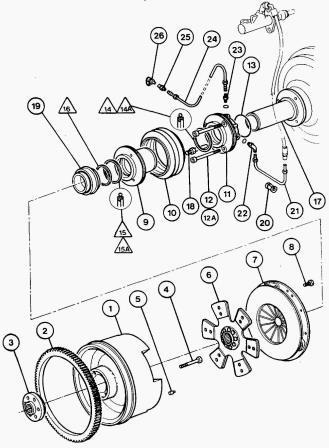

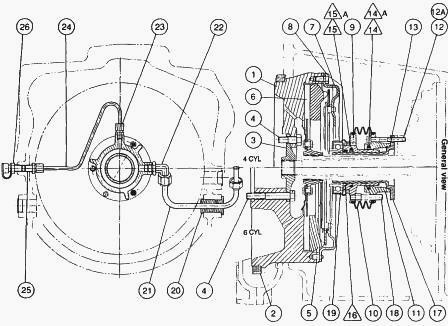

MF 3050, 3080 Tractor Push-type Clutch hydraulic slave cylinder

Hydraulic slave cylinder assembly

Fig. 1A/2A. Massey Ferguson MF 3060, 3080, 3050 Tractors

Push-type Clutch

Removal:

- Split the Massey Ferguson 3085, 3070 tractor between the engine and

the gearbox.

- Disconnect the bleed pipe and supply pipe from the slave cylinder

assembly.

- To remove the hydraulic slave cylinder assembly complete, do not

separate the bearing carrier fully from the cylinder to gain access to

the attaching bolts.

- Pull the release bearing carrier 40 mm away from the cylinder and

remove the boot (10).

- Using short Allen keys, unscrew the two bolts (12) and bolts (12A).

Refitment:

- Coat the bolts with Loctite 241. Fit and tighten the bolts to a torque

of: 8 diam: 25-35 Nm 10 diam: 40-70 Nm.

- Refit the boot (10). Refit the bleed pipe (24) and supply pipe (21).

- Refit the gearbox to the MF 3065, 3085, 3070 tractor.

- Remove air from the clutch hydraulic control system.

- To avoid damage to the release bearing carrier (9) use plastic

protective jaws and grip the collar lightly.

Slave cylinder seal

Replacement:

- Split the Massey Ferguson 3060, 3070 tractor between the engine and

the gearbox.

- Disconnect the bleed pipe (24) and the supply pipe (21).

- Remove the rubber boot (10).

- Withdraw the push-type clutch release bearing carrier (9) from the

slave cylinder (11).

- Remove the two bolts (12) and the bolt (12A)

- Remove the slave cylinder-guide assembly.

- Separate the slave cylinder and the guide (17).

- Remove the "O" ring (13)

- Remove: the elbow union (22), the straight union (23),

- Remove the rod (18)

- Remove the MF 3060, 3085, 3065 tractor clutch release bearing.

Disassembly

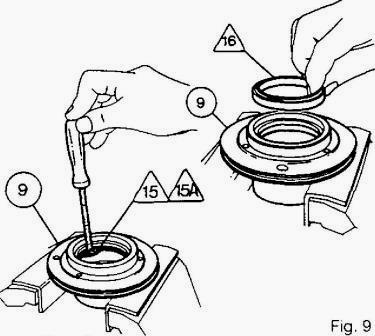

Fig.9

Remove:

- on the release bearing carrier (9): the scraper ring 16, the seal 15

and the "O" ring 15A (Fig.9).

- on the slave cylinder (11): the seal 14 and the "O" ring 14A.

To remove the seals and "O" rings, use a suitably protected screwdriver

(Fig.9). The bores and grooves of the parts must be free from scoring

and damage.

Reassembly of "o" ring 14A and bush 14 in cylinder.

- Clean the cylinder (11).

- Position the cylinder with the groove facing upwards.

- Lubricate and it the "O" ring 14A in the groove. Do not twist it.

- Form the seal 14 into a heart-shape. Important: The lip of the seal

must face outwards.

- Fit the seal 14 into the groove and push it gradually towards the "O"

ring 14AV

- Lubricate the seal and the cylinder bore.

- To ensure seat seated properly, use bearing carrier as a mandrill.

Lubricate the release bearing carrier (9)

- Insert the release bearing carrier (9) in the front of the Massey

Ferguson 3080, 3085, 3065 tractor clutch cylinder (11) using the tool.

- Turn the release bearing carrier approximately one turn in the

cylinder to bed in seal. Remove the release bearing carrier: the seal 14

is now fitted.

- Reassembly of "O" ring 15A and seal 15 on release bearing carrier (9).

- Clean the release bearing carrier.

- Position the release bearing carrier with the groove facing upwards.

- Lubricate and fit the "O" ring 15A in the groove. Do not twist it.

- Form the seal 15 into a heart-shape. Important: The lip of the seal 15

must face outwards.

- Fit the seal 15 into the groove and push it gradually towards the "O"

ring 15AV Note: To ensure seal seated properly, use guide as a mandril.

- Lubricate the seal 15 and the guide (17). Insert the guide (17) into

the front of the release bearing carrier (9) using the tool shown.

- Turn the guide approximately one turn. Remove the guide. The seal 15

is now fitted.

- Using a suitable arrangement to support the bearing carrier, press in

the scraper ring 16.

- Fit the release bearing.

- Lubricate the seal 15Y the seal 16and the release bearing carrier

bore.

- Fit the rod (18) after coating it with Loctite 241. Tighten to &

torque of 25-35 Nm.

- Lubricate the guide (17), the seal (14) and the release bearing

carrier (9).

- Position the "O" ring (13) on the guide.

- Assemble the cylinder (11) with the guide (17).

- Refit the bolts (12) and (12A).

- Press the release bearing carrier (9) into the cylinder (11) so as to

leave a gap of 40 mm to allow access for the Allen keys to tighten bolts

(12) and (12A).

- Screw on the unions (22) and (23).

- Locate the slave cylinder assembly on the Speeds-shift cover.

- Coat the bolts (12) and (12A) with Loctite 241. Using the short Allen

keys, tighten to a torque oL 8 diam. : 25-35 Nm 10 diam. : 40-70 Nm

- Fit the boot (10). Refit the bleed pipe (24) and supply pipe (21).

- Refit the gearbox to the MF 3060, 3080, 3050 tractor.

- Remove air from the clutch hydraulic control system.

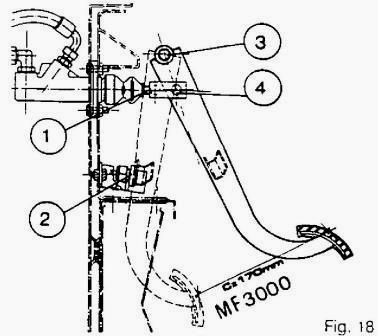

Fig.18

Removing air from the clutch hydraulic system.

Checking piston travel in the slave cylinder.

Clutch pedal adjustment.

Before assembly coat the pins (3) and (4) with molybdenum disulphide

grease.

Coat the threads of the rod (1) (Fig, 18) with Loctite 542. Adjust the

rod to obtain a pedal travel of 170 mm between the disengaged position

(pedal up against the stop (2)) and the engaged position.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader