________________________________________________________________________________

Massey Ferguson 3060, 3070 Tractor Push-type Clutch

Description

This is a diaphragm push-type clutch. The master cylinder is supplied by

the low pressure hydraulic system Drive to the gearbox is through the

disc (6) which engages with the splined gearbox input shaft.

MF 3070, 3085, 3065 tractor Push-type

Clutch Construction

The slave cylinder (11) and guide (17) are fitted on the front face of

the input shaft housing. The release bearing carrier (9) moves between

guide (17) and the cylinder 11.

"Composite" seals 14 and 14A seal the release bearing earner and the

slave cylinder. Seals 15V /15A and 16 seal the guide and the release

bearing carrier.

The clutch release bearing (19) is a force fit on the bearing carrier.

The self-centring release bearing is sealed. The ball bearing races are

sealed and the lubrication is maintained by the grease during rotation.

Clutch disengagement

Depressing the clutch pedal moves the control rod which in turn operates

the piston of a master cylinder. The quantity of oil displaced by this

piston passes through the hole drilled in the side of the slave cylinder

(11) and moves the release bearing carrier (9) and release bearing (19)

assembly forwards.

The diaphragm in the clutch cover (7) is compressed, releasing pressure

on the clutch plate and the disc (6) is released.

Clutch engagement

Releasing the clutch pedal causes a drop in pressure in the slave

cylinder. The diaphragm pushes the release bearing carrier rearwards and

the pressure plate forwards. The disc (6) is held between the pressure

plate and the engine flywheel and transmits drive to the gearbox input

shaft.

MF 3060, 3080, 3050 Tractor Push-type Clutch

Specifications

Clutch control - Push-type

Plate load - 1300 kg

Number of vanes - 6

Type of vane - Non-progressive

Disc diameter - 330 mm

Friction linings - Cerametallic

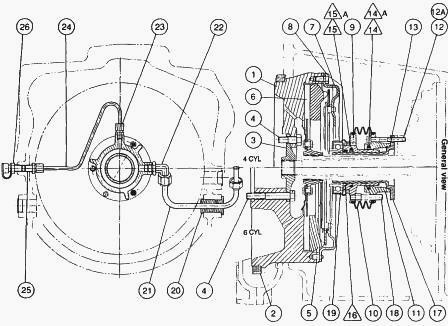

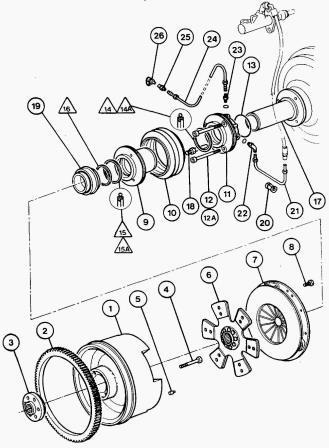

Fig. 1A/2A. Massey Ferguson 3050, 3085 Tractor Push-type Clutch

(Parts list)

(1) Engine flywheel, (2) Flywheel ring gear, (3) PTO shaft drive hub,

(4) Engine flywheel attaching bolts, (5) Clutch cover plate dowel pins,

(6) Clutch friction disc, (7)

Clutch cover plate, (8) Bolts attaching cover plate to flywheel, (9)

Clutch release bearing carrier, (10) Rubber boot, (11) Cylinder, (12)

Cylinder attaching bolt, (12A)

Cylinder attaching bolt, (13) "O" ring, (14) Cylinder oil seal, (14A)

Cylinder "O" ring, (15) Clutch release bearing carrier seal, (15A)

Clutch release bearing "O" ring, (16)

Scraper ring, (17) Guide, (18) Dowel, (19) Clutch release bearing, (20)

Supply pipe grommet, (21) Supply pipe, (22) Cylinder supply 90° union,

(23) Cylinder bleed

straight union, (24) Bleed pipe, (25) Bleed pipe union, (26) Bleed point

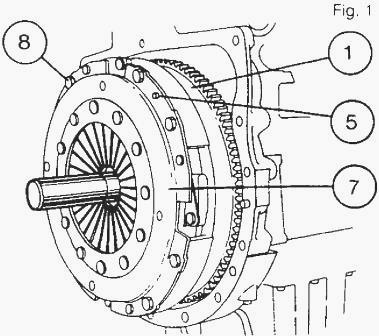

MF 3080, 3060, 3050 Tractor Clutch cover plate

Fig.1

Disassembly:

- Split the Massey Ferguson 3060, 3065 tractor between the engine and

the gearbox.

- Locate tool (4 cyl Fig.1) to retain the cover plate/disc assembly.

- Gradually slacken the bolts (8) attaching the cover plate (7) to the

engine flywheel (1).

- Remove the cover plate and the disc (6).

- Remove the three dowel pins (5) on the flywheel.

Reassembly:

- Clean the flywheel with a solvent.

- Check the flywheel friction surface.

- Lightly coat the PTO shaft hub splines in the flywheel with Molybdenum

disulphide grease.

- Fit the three dowel pins (5).

- Using tool, center the clutch disc (6) on the flywheel. The longest

section of the hub must face the diaphragm.

- Refit the clutch cover plate.

- Progressively tighten the bolts (8) to a torque of: 50-70 Nm (4 cyl.)

30-35 Nm (6 cyl.)

- Withdraw tool MF 457.

- Refit the gearbox to the engine.

MF 3060, 3080, 3050 Tractor Engine flywheel

Disassembly:

- Split the Massey Ferguson tractor between the engine and gearbox.

- Remove the engine clutch.

- Immobilize the flywheel (1).

- Remove the six bolts (4) attaching the flywheel to the crankshaft.

- Remove the flywheel and the PTO shaft hub (3).

Reassembly:

- If the friction surface of the flywheel is scored, it can be skimmed.

- Grind surface A as necessary to obtain dimension X - 26 mm mini.

Surface finish 2.5 microns maximum.

- Measure dimension Y, reduce surface B to obtain a measurement of 34.1

mm to 34.2 mm.

- Shorten the three dowel pins (5) accordingly.

- Check that the cover plate attaching bolt holes drilled in the

flywheel are the correct depth; if not, drill to the correct depth.

After skimming the flywheel clean it with a

solvent.

- The release bearing PN3384863 M92 (45,5 mm long) is only used as

repair part. If the flywheel has been skimmed on a tractor equipped with

the old bearing (41

mm long) it is mandatory to replace it by the 45,5 mm long bearing.

- Do not fit a 3100 clutch disc if the flywheel has been skimmed.

- Fit two dowel pins into the flywheel attaching holes.

- Refit the flywheel and the hub (3).

- Coat the bolts (4) with Loctite 241.

- Refit the six bolts (4) and tighten to a torque 110-140 Nm (4 and 6

cyl.) Release the engine flywheel..

- Refit the gearbox to the MF 3085, 3070, 3065 Tractor.

Flywheel ring gear replacement Disassembly:

- Remove the engine flywheel.

- Carry out procedures 2 and 3.

- Carry out procedures 4 and 5.

- Refit the engine flywheel.

Clutch release bearing

As disassembly of the clutch release bearing entails its removal from

the slave cylinder, seal replacement is recommended to avoid the risk of

leakage during service.

Disassembly - Using a suitable drift punch, remove the release bearing

through me three holes in the slave cylinder.

Reassembly - Using a suitable assembly to support the outer collar,

press the release bearing up against the release bearing earner

shoulder.

Coat the contact surface of the release bearing and carrier with Loctite

270. Do not put Loctite into the bearing.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader