________________________________________________________________________________

Tractor Power Take-off (РТО)

The power take-off housing, fitted to the rear of the centre housing,

houses all mechanical components of the rear power take-off on the

tractors. The power take-off PTO is independent of the transmission.

On tractors fitted with a Heavy gearbox, the input shaft is integral via

splines with the vibration damper fixed to the engine flywheel. It

transmits the engine speed to the power take-off multidisc clutch via a

shaft line comprising two layshafts.

The first layshaft is linked by splines to the engine input shaft and,

at the front, to the hydraulic pump drive pinion. The second layshaft is

splined at the front on the hydraulic pump drive pinion and at the rear

on the power take-off PTO clutch.

On tractors fitted with an AG150 or AG250 Powershift gearboxes, the

engine speed is transmitted to the power take-off clutch by a shaft line

comprising four shafts.

The first shaft is likewise driven via the vibration damper fitted to

the engine flywheel. The second shaft, passing through the gearbox, is

linked to the third shaft by a sleeve and drives the hydraulic pump

drive pinion.

As in the version mentioned above, the last shaft is splined at the

front on the hydraulic pump drive pinion and at the rear on the PTO

clutch.

Types of power take-off (PTO)

available

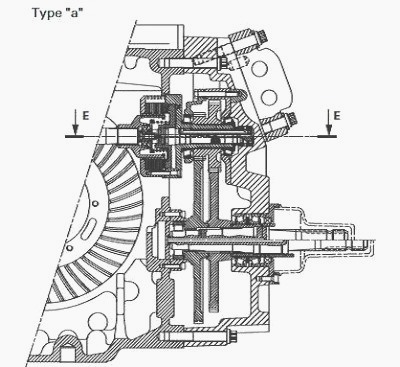

"a" : with long or short removable shaft - 540 / 1000 rpm or with an

option of 750 / 1000 rpm

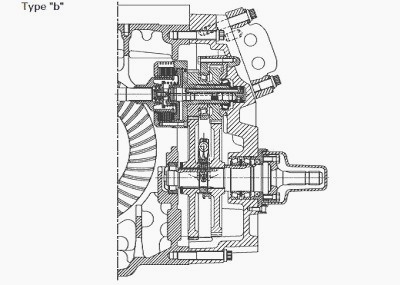

"b" : with a jaw coupler and short or long shaft with disc - 540 / 1000

rpm or 750 / 1000 rpm

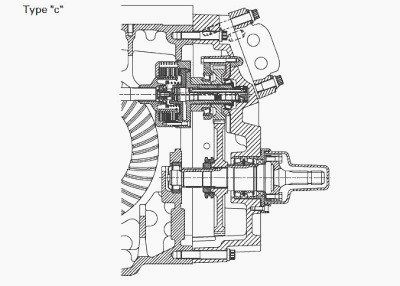

"c" : with fixed coupler and shaft with disc - 1000 rpm

PTO Type "a"

- the clutch unit is integral via splines with a double pinion that is

constantly engaged with the 540 / 1000 rpm or 750 / 1000 rpm pinions

that rotate the 1000 rpm shaft or the 750 rpm shaft at the required

speed.

PTO Type "b"

- the clutch unit is integral via splines with two pinions that are

constantly engaged with the 540 / 1000 rpm or 750 / 1000 rpm pinions

that rotate the power take-off РТО output shaft when the coupler is

either moved forwards, to the 540 / 1000 rpm position, or rearwards to

the 1000 rpm position, depending on the speed required.

PTO Type "c"

- the clutch unit is integral via splines with a single pinion that is

constantly engaged with the 1000 rpm pinion that rotates the power

take-off PTO output shaft.

- In the type "c", a spacer replaces the 540 or 750 rpm drive pinion.

The coupler is integral via splines with the 1000 rpm drive pinion. It

is held in place by a snap ring located on the hub. This hub is itself

immobilised by another snap ring fitted on the output shaft.

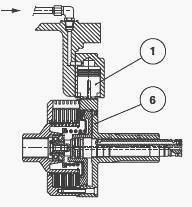

When the clutch is disengaged and the control button in the cab is

placed in the PTO brake position, the 17 bar pressure acts upon piston

(1) and it enters in contact with the outside edge of unit (6) and thus

brakes its rotation.

Construction PTO

The clutch, located on the upper shaftline, is supported by two taper

roller bearings. The bearing cups are fitted in two carriers fixed to

the power take-off PTO housing and the bearing cones are positioned on

two spans inside the clutch housing.

The front bearing cone is force fitted on:

- the clutch unit (PTO type "a")

- the 540 or 750 rpm pinion drive pinion (PTO type "b")

- the spacer (PTO type "c")

The rear bearing cone is mounted free on all types. The bearing

clearance is adjusted by means of shims placed between the two carriers.

The lower shaft line comprises:

- A unit fixed by bolts on the rear of the centre housing, in which a

roller bearing (type "a" PTO) is fitted. On the other types, this

bearing is force fitted, preceded by an oil deflector, in the centre

housing.

- A rear bearing comprising two taper roller bearings; their clearance

is adjusted by shims placed between the power take-off housing and the

bearing.

On the type "a" power take-off, the previously stated bearings are

fitted on a sleeve integral with the power take-off output shaft.

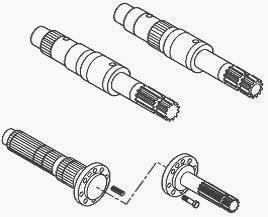

- A cassette seal provides oil tightness for the bearing. Depending on

the type of power take-off, the type of tool that is to be driven and

the recommended rotational speed, the output shafts ((removable or with

interchangeable end-piece) may be of different lengths and have 6, 20 or

21 splines.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader