________________________________________________________________________________

Massey Ferguson 5445, 5460 Tractor Ground PTO 2WD version

Massey Ferguson 5445, 5460

Tractors may be fitted with ground PTO. Unlike the independent PTO

system where the PTO speed depends on the engine speed, the proportional

PTO is driven by the rear differential pinion and the PTO shaft speed is

proportional to the travel speed of the tractor.

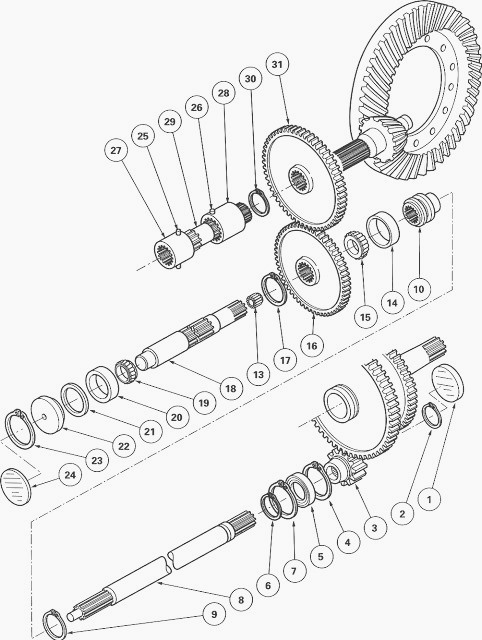

The pinion comprises a gear (31) constantly meshed with either the gear

(16) (2WD). The sliding gear (10) secures the shaft (8) in rotation with

the shaft (18) (2WD). The gear (3) fitted at the end of the shaft (8)

drives the 540 rpm gear on the rear PTO line.

The movement of the sliding gear (10) is obtained by a pad hinged on a

pin fitted on the left in the lower part of the rear axle housing and

controlled by a rod and a cable operated by a lever in the cab.

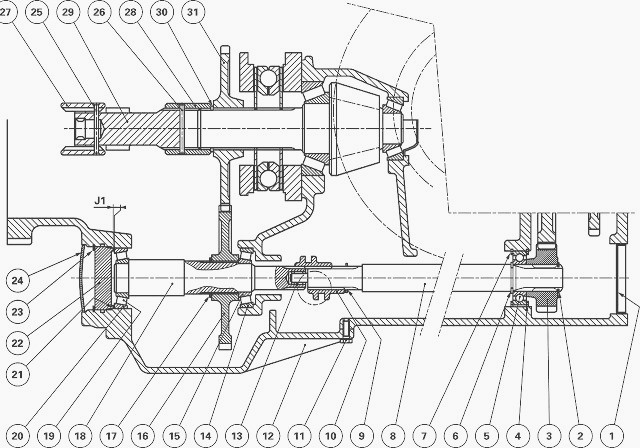

Fig.65. Parts list 2WD

(01) Plug, (02) Circlip, (03) Gear, (04) Circlip, (05) Bearing, (06)

Circlip, (07) Circlip, (08) Shaft, (09) Circlip, (10) Sliding gear, (11)

Screw, (12) Cover plate, (13) Needle roller bearing, (14) Cup, (15)

Cone, (16) Gear, (17) Circlip, (18) 2WD shaft, (19) Cone, (20) Cup, (21)

Shim(s), (22) Spacer, (23) Circlip, (24) Plug, (25) Double pin, (26)

Double pin, (27) Sleeve, (28) Sleeve, (29) Shaft, (30) Circlip, (31)

Gear

Disassembling the MF 5445, 5460

tractor ground PTO (2WD

version)

Chock the tractor. Drain the rear axle housing. Remove the lubrication

pipe from the engine clutch or the Power Shuttle (depending on version)

that is fitted to the lower cover plates of the centre housing and the

gearbox.

Remove the screws (11).

Remove the cover plate (12). Recover the spring (3).

Remove the retainer pipe (4) from the control rod (7) and the detent

plunger (2).

Disconnect the control cable (1) and remove the rod (7). The pad (1) is

free fitted in the centreline of the rod (7).

Remove the "O" ring (5).

Remove the hitch hook. Extract the plug (1).

Remove the circlip (2). Take off the gear (3).

Remove the circlip (4).

Take out the shaft (8) with the bearing (5) and then remove the sleeve

(10). If necessary, remove the circlip (7).

Take off circlips (6) (9).

Extract bearing (5) using a press.

Extract the plug (24).

Take off the circlip (23) and spacer (22).

Remove shims (21). Remove cup (20).

Take out shaft (18) complete with bearing cone (19).

Take off the circlip (17) while supporting the gear (16).

Remove the gear (16) and the cone (15).

Extract the cone (19) and take the circlip (17) off the shaft (18). Pair

up the cones and the cups if they are to be reused. The bearing (13) is

force fitted into the shaft (18).

Extract the cup (14) using a suitable puller. If the gear (31) is

removed, it is necessary to remove the right-hand hydraulic cover plate.

Chock the tractor. Apply the hand brake. Raise the tractor using a jack.

Position the axle stand.

Remove the wheel. Remove the right-hand hydraulic cover plate.

Massey Ferguson 5445, 5460 Tractors with no creeper unit

Drive out the double pins (25) (26) from the coupling sleeves (27) (28).

Slide the sleeves towards each other on the shaft (29).

Remove the shaft and sleeve assembly. Remove the circlip (30).

Remove the gear (31). On 2WD tractors (without proportional PTO) the

gear (31) is absent, but the circlip (30) must still be fitted.

Massey Ferguson 5445, 5460 Tractors with a creeper unit

Remove the fork, the sleeve assembly, the connecting shaft and the

coupler.

Remove the circlip (30). Remove the gear (31).

Reassembling the ground PTO (2WD

version)

If carrying out an operation on the

gear (31)

Tractors with a creeper unit

Install the gear (31).

Install the circlip (30).

Install the fork, the sleeve assembly (28) the connecting shaft and the

coupler. Replace the pins. Adjust the fork.

Tractors with no creeper unit

Install the gear (31).

Install the circlip (30).

Install the assembly (connecting shaft and sleeves) then position the

coupling sleeves (27) (28) on the shaft (29).

Install the double pins (25) (26) on the coupling sleeves. Turn the

sleeve (28. Replace the pins. The long pin is fitted to the sleeve (27).

MF 5445, 5460 Tractors with or without creeper unit

Install the cup (14) up against the shoulder of the housing.

Install the cone (19) on the shaft (18) up against the shoulder, using a

press and a suitable fixture, then position the circlip (17).

Check for the presence of the needle roller bearing (13).

In order to turn the shaft to carry out J1 shimming, do not fit the gear

(16). Position cone (15). Fit shaft (18) assembled with the cone (19)

and circlip (17).

Install the cup (20), the spacer (22) and the circlip (23). For correct

shimming, make sure that the spacer moves freely in the bore of the

housing.

Carry out shimming of the shaft (18) in order to obtain: J1 = 0 to 0.10

mm.

Put a dial gauge feeler pin against the end of spacer (22).

Through the opening of the cover plate (12), pull on the shaft, while

turning it alternately from right to left to correctly seat the cones in

the cups.

Set the dial gauge to zero.

Depending on the clearance measured, select the correct thickness of

shims.

Take off the circlip (23) and spacer (22). Take out shaft (18) assembled

with the cone (19) and circlip (17) while supporting the cone (15).

Refit the gear (16), the shaft (18) and the cup (20).

Apply two spots of grease to the shims (21).

Install the spacer (22) and circlip (23).

Replace or clean the plug (24) and its mating face on the housing.

Smear the corner of the plug housing with Loctite 542 and then fit the

plug.

Place the sliding gear (10) on the shaft (18). Turn the small shoulder E

towards the shaft (18).

Fit circlips (6) (9) on shaft (8).

Using a suitable fixture, fit the bearing (5) using a press onto the

shaft (8), in contact with the circlip (6).

Check for the presence of circlip (7).

Install the assembled shaft (8) in the housing.

Install the circlip (4).

Install the gear (3).

Install the circlip (2).

Check the movement of the sliding gear (10) through the opening of the

cover plate (12).

Replace or clean the plug (1) and its mating face on the housing.

Smear the plug with Loctite 542, then fit it slightly set back from the

face of the housing.

Install the rod (7) (fitted with a new "O" ring (5)) by placing the pad

(1) in the groove of the sliding gear (10).

Clean and degrease the mating faces (cover plate and housing).

Smear the mating face of the cover plate with a sealing product (Master

joint 510 or equivalent).

Screw two opposing guide studs into the housing.

Install the retainer pipe (4), the control rod and the detent plunger

(2) and the spring (3).

Install the cover plate (12) and the lubrication pipe for the engine

clutch or the Power Shuttle (depending on version).

Take out the guide studs. Tighten the screws to a torque of 130 - 170

Nm.

Reconnect the proportional PTO control cable (1).

Adjust the control.

Top up the rear axle oil level.

Install the hitch hook (for tractors fitted with an auto-hitch, check

that it operates correctly).

Check the correct operation of the proportional PTO.

Check tightness:

- of the mating faces

- of the cover plate underneath the rear axle housing

- Hydraulic unions

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader