________________________________________________________________________________

1106 Perkins diesel - Crankshaft (Remove and install)

Removal Procedure

Remove the engine oil pump. Remove the front housing. Remove the

crankshaft rear seal. Remove the rocker shaft and pushrods. If

necessary, remove the cylinder head. If necessary, remove the pistons

and connecting rods. The 1106 Perkins diesel should be mounted on a

suitable stand and placed in the inverted position. If the cylinder

head, the pistons and the connecting rods have not been removed already,

remove the connecting rod bearings. Ensure that the main bearing caps

are marked for the location and orientation.

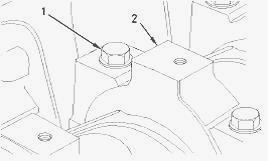

Remove the setscrews (1) and the main bearing caps (2) from the cylinder

block. Remove the lower main bearing shells (3) from the main bearing

caps (2). Keep the lower main bearing shells with the respective main

bearing caps. The lower main bearing shells are plain bearings that have

no oil holes.

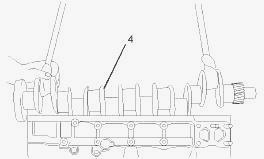

Attach lifting straps and a suitable lifting device to the crankshaft

(4). Lift the crankshaft (4) out of the cylinder block. The weight of

the crankshaft is approximately 61 kg (134.5 lb). Do not damage any of

the finished surfaces on the crankshaft. When the crankshaft is removed

from the engine, the crankshaft must be supported on a suitable stand in

order to prevent damage to the crankshaft timing ring.

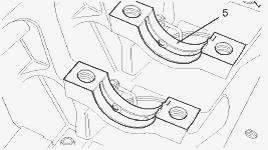

Remove the upper main bearing shells (5) from the 1106D Perkins cylinder

block. Keep the upper main bearing shells with the respective main

bearing caps. The upper main bearing shells have a groove and two oil

holes. Remove the two thrust washers from number six main bearing in the

cylinder block. If necessary, remove the crankshaft timing ring. If

necessary, remove the crankshaft gear.

Installation Procedure

Clean the crankshaft and inspect the crankshaft for wear or damage. If

necessary, replace the crankshaft or recondition the crankshaft. If

necessary, install the crankshaft gear. If necessary, install a new

crankshaft timing ring Ensure that the parent bores for the bearing

shells in the cylinder block are clean. Ensure that the threads for the

main bearing setscrews in the cylinder block are clean and free from

damage.

Clean the main bearing shells and the thrust washers. Inspect the main

bearing shells and the thrust washers for wear or damage. If necessary,

replace the main bearing shells and the thrust washers. If the main

bearing shells are replaced, check whether oversize main bearing shells

were previously installed. If the thrust washers are replaced, check

whether oversize thrust washers were previously installed.

Install upper main bearing shells (5) to the cylinder block. Ensure that

the locating tabs for the upper main bearing shells are seated in the

slots in the cylinder block. The upper main bearing shells have a groove

and two oil holes. Lubricate the upper main bearing shells (5) with

clean engine oil.

Attach lifting straps and a suitable lifting device to the crankshaft

(4). Lift the crankshaft (4) into the cylinder block. The weight of the

crankshaft is approximately 61 kg (134.5 lb). Do not damage any of the

finished surfaces on the crankshaft. Do not damage the main bearing

shells.

Lubricate the thrust washers (6) with clean engine oil. Install the

thrust washers (6) into number six main bearing in the cylinder block.

The thrust washers have a locating tab at one end. Ensure that the

locating tabs are correctly seated in the cylinder block. Install lower

main bearing shells (3) into the main bearing caps (2). Ensure that the

locating tabs for the lower main bearing shells are correctly seated

into the slots in the bearing caps.

The lower main bearing shells are plain bearings that do not have oil

holes. Lubricate the lower main bearing shells (3) and lubricate the

journals of the crankshaft (4) with clean engine oil. Install the main

bearing caps (2) to the cylinder block. Ensure the correct location and

orientation of the main bearing caps (2). The locating tabs for the

upper and the lower main bearing shells should be on the same side of

the 1106 Perkins diesel engine.

Lubricate the threads of the setscrews (1) with clean engine oil.

Lubricate the underside of the heads of the setscrews (1) with clean

engine oil. Install the setscrews (1) to the main bearing caps (2).

Evenly tighten the setscrews in order to pull the caps into position.

Ensure that the caps are correctly seated. Do not tap the main bearing

caps into position as the bearing shells may be dislodged.

Tighten the setscrews (1) to a torque of 80 Nm (59 lb ft). Turn the

setscrews (1) through an additional 90 degrees. Use Tooling to achieve

the final torque. Rotate the crankshaft in order to ensure that there is

no binding. Check the crankshaft end play. Push the crankshaft toward

the front of the engine. Install Tooling to the cylinder block and the

rear face of the crankshaft. Push the crankshaft toward the rear of the

engine. Use Tooling to measure the crankshaft end play. The permissible

crankshaft end play is 0.17 mm (0.007 inch) to 0.41 mm (0.016 inch).

If the crankshaft has been replaced or the crankshaft has been

reconditioned, inspect the height of the piston above the cylinder

block. If the crankshaft has not been replaced or the crankshaft has not

been reconditioned, install the connecting rod bearings. If necessary,

install the pistons and connecting rods. If necessary, install the

cylinder head. Install the rockershaft and pushrods. Install the

crankshaft rear seal. Install the front housing. Install the engine oil

pump.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader