________________________________________________________________________________

1106 Perkins motor - Cylinder Head (Remove and Install)

Removal Procedure

If necessary, remove the secondary fuel filter and the fuel filter base.

If necessary, remove the fuel priming pump and the primary fuel filter. Remove:

- the exhaust manifold.

- the fuel manifold.

- the electronic control module and the mounting bracket.

- the electronic unit injectors.

- the valve mechanism cover base.

- the glow plugs. Drain the coolant from the cooling system into a

suitable container for storage or for disposal.

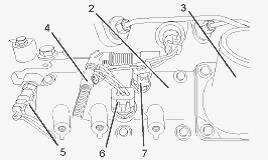

Disconnect the upper radiator hose (not shown) from the water

temperature regulator housing (1) on the cylinder head. Remove the air

inlet hose (not shown) from the inlet connection (3) on the inlet

manifold (2). Follow Steps to disconnect the harness assembly (4) from

the coolant temperature sensor (5). Slide the locking tab (not shown)

into the unlocked position. Disconnect the harness assembly (4) from the

coolant temperature sensor (5).

Follow Steps to disconnect the harness assembly (4) from the boost

pressure sensor (6). Slide the locking tab (not shown) into the unlocked

position. Disconnect the harness assembly (4) from the boost pressure

sensor (6). Follow Steps to disconnect the harness assembly (4) from

inlet air temperature sensor (7).

Slide the locking tab (not shown) into the unlocked position. Disconnect

the harness assembly (4) from the inlet air temperature sensor (7).

Remove all cable ties that secure the harness assembly (4) to the

cylinder head or to the inlet manifold. The harness assembly should be

positioned in order to avoid causing an obstruction during the removal

of the cylinder head.

Loosen the tube clips for the tube assembly (8). Remove the tube

assembly (8) for the fuel return from the cylinder head and from the

transfer pump (not shown). Plug the port in the transfer pump with a new

plug. Cap the tube assembly with new caps. If the 1106 Perkins diesel

engine has a wastegate solenoid, loosen the tube clips for the tube

assembly (9). Remove the tube assembly (9) from the wastegate solenoid

(not shown) and from the cylinder head. Plug the port in the wastegate

solenoid with a new plug. Cap the tube assembly with new caps.

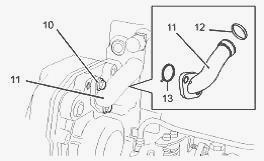

Remove the two setscrews (10). Remove the bypass tube (11) from the

cylinder head. Remove the O-ring seals (12) and (13) from the bypass

tube (11). Discard the O-ring seals.

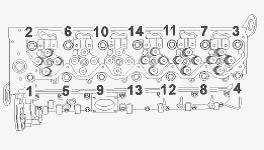

Sequence for tightening the setscrews for the cylinder head - Gradually

loosen the setscrews (14) in the reverse numerical order to the

tightening sequence. Refer to the illustration. Follow the correct

sequence in order to help prevent distortion of the cylinder head.

Remove the setscrews (14) from the cylinder head (15).

Attach a suitable lifting device (16) to the cylinder head (15). Support

the weight of the cylinder head. The weight of the cylinder head is

approximately 66 kg (145.5 lb). A spreader bar must be used in order to

distribute the weight of the cylinder head during the lifting operation.

Use the suitable lifting device (16) to carefully lift the cylinder head

(15) off the cylinder block. Do not use a lever to separate the cylinder

head from the cylinder block. Take care not to damage the machined

surfaces of the cylinder head during the removal procedure.

Remove the cylinder head gasket (17). Discard the cylinder head gasket.

Note the position of the dowels (18) in the cylinder block. If

necessary, remove the water temperature regulator (1) from the cylinder

head (15). If necessary, remove the inlet manifold (2) from the cylinder

head (15).

Installation Procedure

Thoroughly clean the mating surfaces of the 1106 Perkins cylinder head

and the cylinder block. Do not damage the mating surfaces of the

cylinder head of the cylinder block. Ensure that no debris enters the

cylinder bores, the coolant passages, or the lubricant passages. Inspect

the mating surface of the cylinder head for distortion. If the mating

surface of the cylinder head is distorted beyond maximum permitted

limits, replace the cylinder head. If necessary, install the inlet

manifold to the cylinder head.

Inspect the dowels (18) for damage. If necessary, replace the dowels in

the cylinder block. Install Tooling to the cylinder block. Align the

cylinder head gasket (17) with the dowels (18). Install the cylinder

head gasket (17) onto the cylinder block.

Use a suitable lifting device (16) to lift the cylinder head (15). The

weight of the cylinder head is approximately 66 kg (145.5 lb). A

spreader bar must be used in order to distribute the weight of the

cylinder head during the lifting operation. Use Tooling to align the

cylinder head with the cylinder block. Install the cylinder head to the

cylinder block. Ensure that the cylinder head is correctly positioned on

the dowels (18). Remove Tooling.

Clean the setscrews (14). Follow Steps for the procedure to inspect the

setscrews. Check the length of the setscrews. Some diesel engines have

all setscrews of the same length. Some engines have two longer

setscrews. Use a straight edge to check the threads of the setscrews.

Refer to Illustration. Replace any setscrews that show visual reduction

in the diameter of the thread over length (Y). Lubricate the threads and

the shoulder of the setscrews (14) with clean engine oil.

Sequence for tightening the setscrews for the cylinder head - Install

the setscrews (14) to the cylinder head (16). If the 1106 Perkins motor

has two longer setscrews, install the longer setscrews in holes (X).

Tighten the setscrews to a torque of 50 Nm (37 lb ft) in the numerical

sequence. Tighten the setscrews to a torque of 100 Nm (74 lb ft) in the

numerical sequence. Refer to Illustration. Turn the setscrews through an

additional 225 degrees in the numerical sequence. Refer to Illustration.

Use Tooling to achieve the correct final torque.

Use Tooling in order to lubricate the O-ring seals. Install two new

O-ring seals (12) and (13) to the bypass tube (11). Install the bypass

tube in the cylinder head. Install the setscrews (10). Tighten the

setscrews to a torque of 22 Nm (16 lb ft).

Remove the plugs and caps from the ports and tube assemblies. Install

the tube assembly (8) for the fuel return to the cylinder head and to

the transfer pump. Secure the tube clips for the tube assembly (8). If

the diesel engine has a wastegate solenoid, install the tube assembly

(9) for the wastegate solenoid to the cylinder head. Secure the tube

clips for the tube assembly (9).

Follow Steps to connect the harness assembly (4) to the inlet air

temperature sensor (7). Connect the harness assembly (4) to the inlet

air temperature sensor (7). Slide the locking tab (not shown) into the

locked position. Follow Steps to connect the harness assembly (4) to the

boost pressure sensor (6). Connect the harness assembly (4) to the boost

pressure sensor (6). Slide the locking tab (not shown) into the locked

position. Follow Steps to connect the harness assembly (4) to the

coolant temperature sensor (5).

Connect the harness assembly (4) to the coolant temperature sensor (5).

Slide the locking tab (not shown) into the locked position. Use new

cable ties in order to secure the harness assembly to the cylinder head

and to the inlet manifold. Ensure that the harness assembly is not

strained. Ensure that the harness assembly is clear of other engine

components. Install the inlet hose (not shown) to the inlet connection

(3) on the inlet manifold (2).

If necessary, install the water temperature regulator housing (1) to the

cylinder head. Connect the upper radiator hose (not shown) to the water

temperature regulator housing (1) on the cylinder head. Fill the cooling

system with coolant. If necessary, fill the engine oil pan to the

correct level that is indicated on the engine oil level gauge.

Install:

- the glow plugs.

- the valve mechanism cover base.

- the electronic unit injectors.

- the electronic control module and the mounting bracket.

- the fuel manifold.

- the exhaust manifold.

- If necessary, install the fuel filter base and the secondary fuel

filter

- If necessary, install the fuel priming pump and the primary fuel

filter.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader