________________________________________________________________________________

1106 Perkins - Electronic Control Module

The 1106 Perkins engine equipped by Electronic Control Module (ECM) (1)

with functions as a governor and a computer for the fuel system. The ECM

receives signals from the sensors in order to control the timing and the

engine speed. The electronic system consists of the Electronic Control

Module (ECM), the engine sensors and inputs from the parent machine. The

ECM is the computer. The personality module is the software for the

computer. The personality module contains the operating maps.

The operating maps define the following characteristics of the engine:

power, torque curves, speed (rpm), noise, smoke and emissions. The

factory passwords restrict changes to authorized personnel. Factory

passwords are required to clear any event code. The Electronic Control

Module (ECM) has an excellent record of reliability. Any problems in the

system are most likely to be the connectors and the wiring harness. The

ECM should be the last item in troubleshooting the engine. The

personality module contains the software with all the fuel setting

information. The information determines the engine performance. The

personality module is installed behind the access panel on the ECM.

Flash programming is the method of programming or updating the

personality module.

Engine Speed Governor - The electronic controls determine the injection

timing, the amount of fuel that is delivered to the cylinders and the

intake manifold pressure if an electronically controlled wastegate is

installed on the turbocharger. These decisions are based on the actual

conditions and the desired conditions at any given time. The governor

has software that compares the desired engine speed to the actual engine

speed. The actual engine speed is determined through the primary

speed/timing sensor and the secondary speed/timing sensor. If the

desired engine speed is greater than the actual engine speed, the

governor injects more fuel in order to increase engine speed.

Timing Considerations - Once the governor has determined the amount of

fuel that is required, the software must determine the timing of the

fuel injection. Fuel injection timing is determined by the ECM after

considering input from the following components: Engine coolant

temperature sensor, The sensor for the intake manifold air temperature,

The sensor for the intake manifold pressure. At start-up, the ECM

determines the top center position of the number 1 cylinder from the

secondary speed/timing sensor in the fuel injection pump. The Electronic

Control Module (ECM) decides when fuel injection should occur relative

to the top center position.

The ECM optimizes engine performance by control of each of the

electronic unit injectors so that the required amount of fuel is

injected at the precise point of the engine’s cycle. The electronic unit

injectors are supplied high pressure fuel from the fuel injection pump.

The ECM also provides the signal to the solenoid in the fuel injection

pump. The solenoid in the fuel injection pump controls a valve in the

fuel injection pump. This valve controls the pressure in the fuel

injection pump. Fuel that is not required for the 1106 Perkins engine is

diverted away from the fuel injection pump back to the fuel tank. The

ECM adjusts injection timing and fuel pressure for the best engine

performance, the best fuel economy and the best control of exhaust

emissions. The actual timing can be viewed with an electronic service

tool. Also, the desired timing can be viewed with an electronic service

tool.

Fuel Injection - The personality module inside the ECM sets certain

limits on the amount of fuel that can be injected. The FRC Limit is a

limit that is based on intake manifold air pressure and engine rpm. The

FRC Limit is used to control the air/fuel ratio in order to control the

engine’s exhaust emissions. When the ECM senses a higher intake manifold

air pressure, the ECM increases the FRC Limit.

A higher intake manifold air pressure indicates that there is more air

in the cylinder. When the ECM increases the FRC Limit, the ECM allows

more fuel into the cylinder. The Rated Fuel Limit is a limit that is

based on the power rating of the engine and on the engine rpm. The Rated

Fuel Limit enables the engine power and torque outputs to conform to the

power and torque curves of a specific engine model. These limits are in

the personality module and these limits cannot be changed.

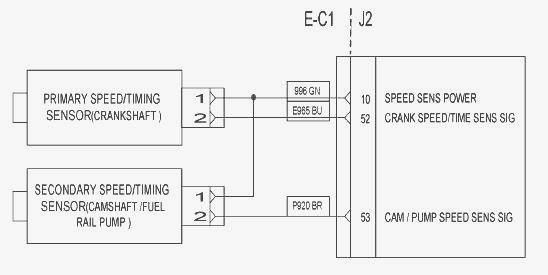

Speed/Timing Sensor - The primary engine position is a passive sensor.

The timing wheel is located on the crankshaft. The speed/timing sensor

receives a signal from the teeth on timing wheel. The extra space on the

timing wheel gives one revolution per space. The space is oriented so

that the space is 40 degrees after top center.

Schematic for speed/timing sensor

When the engine is cranking, the ECM uses the signal from the

speed/timing sensor in the fuel injection pump. When the engine is

running the ECM uses the signal from the speed/timing sensor on the

crankshaft. This speed/timing sensor is the primary source of the engine

position.

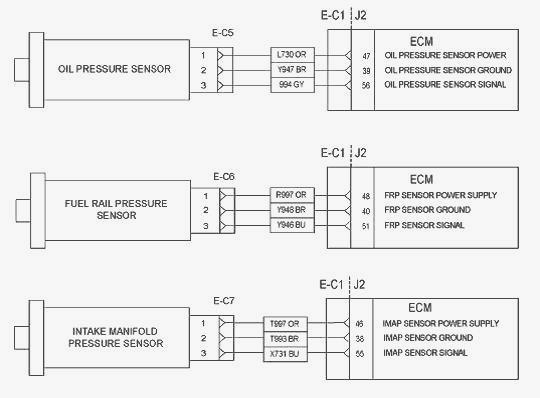

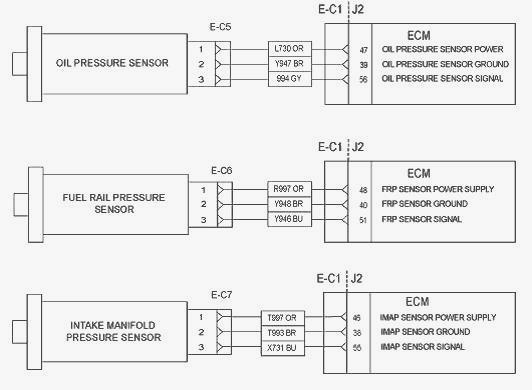

Pressure Sensors - The boost pressure sensor and the engine oil pressure

sensor are active sensors. The boost pressure sensor provides the ECM

with a measurement of inlet manifold pressure in order to control the

air/fuel ratio. This will reduce the engine smoke during transient

conditions. The operating range of the boost pressure sensors: For

standard power engines, the range is up to the following - 339 kPa

(49.169 psi) / For all high power engine, the range is up to the

following - 440 kPa (63.818 psi).

Schematic for pressure sensors

The engine oil pressure sensor provides the ECM with a measurement of

engine oil pressure. The ECM can warn the operator of possible

conditions that can damage the engine. This includes the detection of an

oil filter that is blocked. The operating range for the engine oil

pressure sensor - 55 kPa to 339 kPa (8 psi to 50 psi).

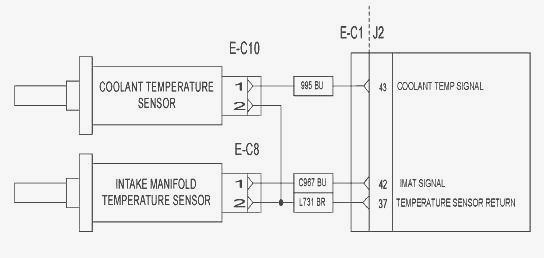

Temperature Sensors - The air inlet temperature sensor and the coolant

temperature sensor are passive sensors. Each sensor provides a

temperature input to the ECM. The ECM controls following operations:

Fuel delivery, Injection timing.

Schematic for the temperature sensors

The operating range for the sensors - 40C to 150C (40F to 302F). The

sensors are also used for engine monitoring.

Power Sources - The 1106 Perkins 6 cylinder Engine supplies power to the

ECM. The ECM powers the following components: All sensors on the engine,

The solenoid for the fuel Injection Pump, The solenoid for the Waste

gate (optional), Diagnostic connector, Electronic unit injectors. The

glow plugs are powered directly from the battery

ECM Power Supply - The power supply to the ECM and the system is drawn

from the 24 volt or the 12 volt battery. The power supply for the ECM

has the following components: Battery, disconnect switch, Key start

switch, Fuses, Ground bolt, ECM connector, Machine interface connector.

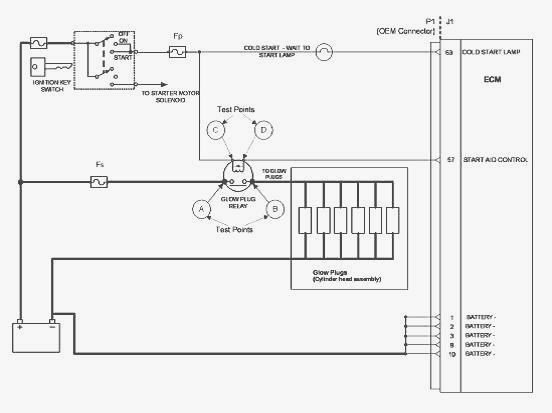

The Schematic for the ECM shows the main components for a typical power

supply circuit. Battery voltage is normally connected to the ECM. The

input from the key start switch turns on the ECM. The wiring harness can

be bypassed for troubleshooting purposes. The display screen on the

electronic service tool can be used in order to check the voltage

supply.

Power Supply for the Pressure Sensors / for the Glow plugs - The ECM

supplies 5.0 ± 0.2 DC volts through the ECM connector to each sensor.

The power supply is protected against short circuits. A short in a

sensor or a wiring harness will not cause damage to the ECM.

Schematic for pressure sensors

Schematic for the glow plugs

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader