________________________________________________________________________________

1106 Perkins diesel engine with electronically controlled

The 6 cylinder 1106D diesel engine uses an Electronic Control Module (ECM) that receives signals from the fuel injection pump and other sensors in order to control the fuel injectors. The pump supplies fuel to the fuel injectors. The six cylinders are arranged in-line. The cylinder head assembly has two inlet valves and two exhaust valves for each cylinder.

The ports for the exhaust valves are on the right side of the cylinder

head. The ports for the inlet valves are on the left side of the

cylinder head. Each cylinder valve has a single valve spring. Each

cylinder of 6 cylinder diesel has a piston cooling jet that is installed

in the cylinder block. The piston cooling jet sprays engine oil onto the

inner surface of the piston in order to cool the piston.

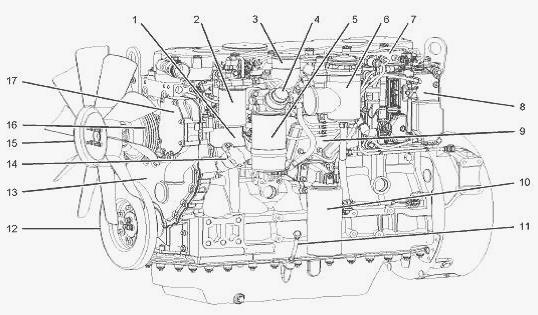

Left side view of the Perkins 1106D motor - (1) Fuel Injection Pump (2)

Secondary fuel filter (3) Air intake (4) Hand primer (5) Primary fuel

filter (6) Crankcase breather (7) Fuel manifold (8) Electronic control

module (9) Oil cooler (10) Oil filter (11) Dipstick (12) Damper (13)

Timing case cover (14) Oil filler (15) Fan (16) Fan pulley (17) Water

pump

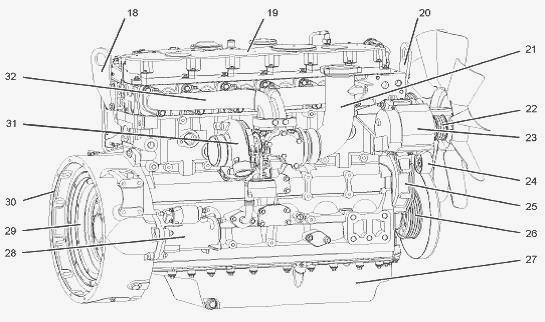

Right side view of the 6 cylinder 1106 Perkins motor - (18) Rear lifting

eye (19) Valve mechanism cover (20) Front lifting eye (21) Exhaust elbow

(22) Alternator pulley (23) Alternator (24) Belt tensioner (25) Timing

case (26) Crankshaft pulley (27) Oil pan (28) Starting motor (29)

Flywheel (30) Flywheel housing (31) Turbocharger (32) Exhaust manifold

The pistons have a Quiescent combustion chamber in the top of the piston

in order to achieve clean exhaust emissions. The piston pin is

off-center in order to reduce the noise level. The pistons have two

compression rings and an oil control ring. The groove for the top ring

has a hard metal insert in order to reduce wear of the groove. The skirt

has a coating of graphite in order to reduce wear when the engine is

new.

The correct piston height is important in order to ensure that the

piston does not contact the cylinder head. The correct piston height

also ensures the efficient combustion of fuel which is necessary in

order to conform to requirements for emissions. A piston and a

connecting rod are matched to each cylinder. The piston height is

controlled by the distance between the center of the big end bearing and

the center of the small end bearing of the connecting rod.

Three different lengths of connecting rods are available in order to

attain the correct piston height. The three different lengths of

connecting rods are made by machining the blank small end bearing of

each rod at three fixed distances vertically above the centerline of the

big end bearing. . The crankshaft has seven main bearing journals. End

play is controlled by thrust washers which are located on both sides of

the number six main bearing. The timing case is made of aluminum.

The timing gears are stamped with timing marks in order to ensure the

correct assembly of the gears. When the number 1 piston is at the top

center position on the compression stroke, the marked teeth on the idler

gear will match with the marks that are on the fuel injection pump, the

camshaft, and the gear on the crankshaft. There is no timing mark on the

rear face of the timing case. The crankshaft gear turns the idler gear

which then turns the following gears: the camshaft gear, the fuel

injection pump.

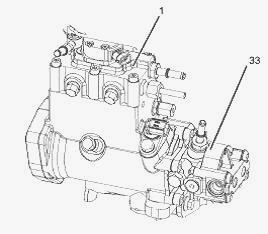

The camshaft and the fuel injection pump run at half the rpm of the

crankshaft. The cylinder bores are machined into the cylinder block. The

fuel injection pump (1) that is installed on the left side of the

Perkins 1106D engine is gear-driven from the timing case. The fuel

transfer pump (33) is attached to the fuel injection pump (1). The fuel

transfer pump draws low pressure fuel from the primary fuel filter. The

fuel transfer pump delivers the fuel to the secondary filter at a

pressure of 400 kPa (58 psi) to 500 kPa (72.5200 psi).

The fuel injection pump draws fuel from the secondary filter. The fuel

injection pump increases the fuel to a maximum pressure of 130 MPa

(18855 psi). The fuel injection pump delivers the fuel to the fuel

manifold. The fuel injection pump is not serviceable. Adjustments to the

pump timing should only be made by personnel that have had the correct

training. The fuel injection pump uses the engine ECM to control the

engine RPM.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader