________________________________________________________________________________

1106 Perkins - Front Housing and Accessory Drive (Remove and Install)

Front Housing

Tool Part - A - 3 Bond, B - Guide Stud (M8 by 70 mm), C – Setscrews (M10

by 50 mm), D - Straight Edge. Remove:

- the fan. If necessary, remove the alternator.

- the front pulley. Drain the coolant into a suitable container for

storage or disposal.

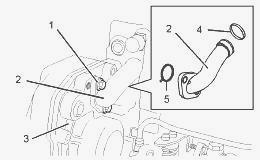

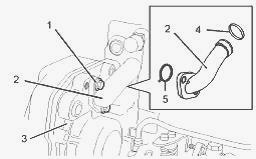

- the two setscrews (1) that secure the bypass tube (2) to the front

housing (3).

- the bypass tube (2) from the cylinder head.

- the O-rings (4) and (5) from the bypass tube (2). Discard the O-rings.

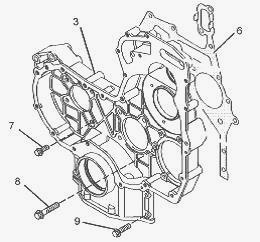

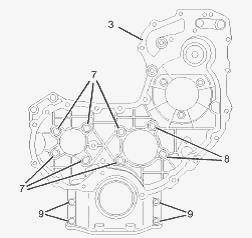

- the setscrews (7), (8) and (9) from the front housing (3). The

setscrews are three different lengths. Note the positions of the

different setscrews.

- the front housing (3) from the 1106 Perkins cylinder block.

- the joint (6). Discard the joint.

- the thrust washer from the cylinder block.

Keep all parts clean from contaminants. Contaminants may cause rapid

wear and shortened component life. Ensure that the front housing is

clean and free from damage. If necessary, replace the front housing.

Install:

- blanking plugs to a new front housing. Use Tooling (A) to seal all

D-plugs. Check the condition of the crankshaft front seal. If the front

seal is damaged, remove the front seal from the front housing. Clean all

the mating surfaces of the cylinder block.

- the thrust washer (10) into the recess in the cylinder block.

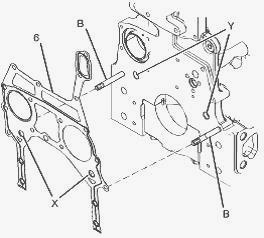

- Tooling (B) to the cylinder block. Refer to Illustration. Align a new

joint (6) with Tooling (B). Install the joint to the cylinder block.

Ensure that two circular tabs (X) on the joint are engaged in the two

holes (Y) in the cylinder block.

- Tooling (C) to the cylinder block.

- the front housing over Tooling (B) and Tooling (C) onto the 1106D

Perkins motor cylinder block.

(7) M8 by 20 mm (8) M8 by 35 mm (9) M8 by 25 mm

- the four setscrews (9) to the front housing (3) finger tight. Remove

Tooling (B). Loosely install the setscrews (7) and (8). Refer to

Illustration for the correct position of the setscrews. Align the bottom

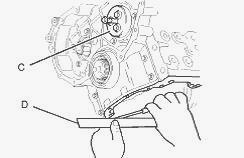

face of the front housing (3) to the lower machined face of the cylinder

block. Use a Tooling and a feeler gauge in order to check the alignment

between the front housing and the cylinder block.

Tighten the setscrews (6), (7) and (8) in the sequence that is shown in

illustration to a torque of 28 Nm (20 lb ft). Ensure that the housing

and the cylinder block are correctly aligned. Remove Tooling (C) from

the cylinder block. If necessary, install a new crankshaft front seal.

Install:

- two new O-ring seals (4) and (5) to the bypass tube (1). Use Tooling

in order to lubricate the O-ring seals.

- the bypass tube (2) to the 1106 Perkins cylinder head. Install the two

setscrews (1). Tighten the setscrews to a torque of 22 Nm (16 lb ft).

Fill the cooling system with coolant.

- the fuel injection pump.

- the timing gears. If the engine has an accessory drive, install the

accessory drive.

- the engine oil pan.

- the front pulley. If necessary, install the alternator.

- the fan.

Accessory Drive

Remove:

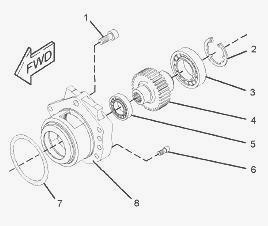

- the M10 Allen head screw (1) from the accessory drive housing (8).

- the five M8 Allen head screws (6) from the accessory drive housing

(8).

- the accessory drive housing (8) from the front housing.

- the circlip (2) from the accessory drive housing (8). Place the

accessory drive housing (8) onto a suitable support. Press the assembly

of the gear (4) and the bearings (3) and (5) out of the accessory drive

housing (8). Use a suitable puller in order to remove the bearings (3)

and (5) from the gear (4).

- the O-ring seal (7) from the accessory drive housing (8). Discard the

O-ring seal.

Inspect the condition of the teeth and the splines of the gear (4) for

wear or damage. Inspect the bearings (3) and (5), the circlip (2), and

the front housing for wear or damage. Replace any components that are

worn or damaged. Apply a small continuous bead of Tooling to the inner

surface (X) of the bearing (5). Place the gear shaft on a suitable

support. Press on the inner race of the bearing (5) until the bearing

(5) is against the shoulder of the gear (4). Remove any excess sealant.

Apply a small continuous bead of Tooling to the inner surface (Z) of the

bearing (3). Place the front face of the inner race of the bearing (3)

onto a suitable support. Press the shaft of the gear (4) into the

bearing (3) until the shoulder of the gear is against the bearing.

Remove any excess sealant.

Apply a small continuous bead of Tooling to the outer surface (Y) of the

bearing (5). Place the accessory drive housing (8) on a suitable

support. Press the assembly of the gear (4) and the bearings (3) and (5)

into the accessory drive housing. Ensure that the bearing (5) is against

the front face of the recess in the accessory drive housing (8). Remove

any excess sealant.

Install the circlip (2) into the groove in the accessory drive housing

(8). Ensure that the circlip (2) is correctly positioned in the groove.

Lightly lubricate a new O-ring seal (7) with Tooling and install the

O-ring seal into the groove in the accessory drive housing (8). Inspect

the bore in the front housing (not shown) for damage. If necessary,

replace the front housing. Lightly lubricate the bearing (3), the

bearing (5), and the gear (4) with clean engine lubricating oil. Install

the assembly of the accessory drive to the front housing.

Apply Tooling to the Allen head screws (1) and (6). Install the five M8

Allen head screws (6) to the accessory drive housing (8). Install the

M10 Allen head screw (1) to the accessory drive housing (8). Tighten the

Allen head screws to a torque of 22 Nm (16 lb ft). Ensure that there is

tactile backlash between the idler gear and the accessory drive gear.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader