________________________________________________________________________________

Perkins 1106D - Vibration Damper and Pulley remove and install

Removal Procedure

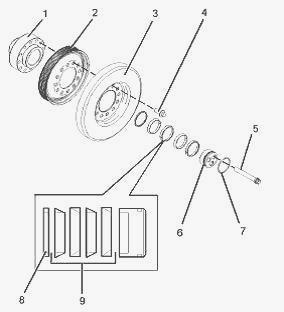

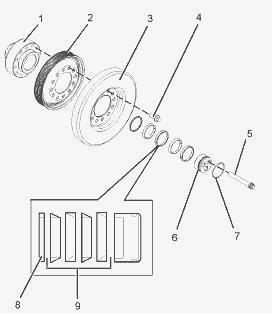

Pulleys with Split Lock Rings

Remove: the Alternator belt. Install

Tooling into one of the unused threads in the assembly of the crankshaft

pulley, the vibration damper and the crankshaft adapter.

- the setscrews (4).

- the vibration damper (3) and the crankshaft pulley (2) from the

crankshaft adapter (1).

- Tooling from the crankshaft adapter (1). Use a suitable tool in order

to prevent the crankshaft from rotating. Use Tooling to remove the three

torx screws (5). Hold a wood block against the crankshaft adapter (1).

Strike the wood block with a hammer in order to loosen the split lock

rings (9).

- the crankshaft adapter (1) from the crankshaft.

- the thrust block (6) from the crankshaft adapter (1).

- the O-ring seal (7) from the thrust block (6). Discard the O-ring

seal.

- the split lock rings (9) and the spacer (8) from the crankshaft

adapter (1). Note the position and orientation of the split lock rings

and the spacer.

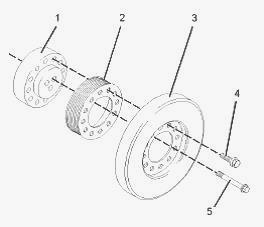

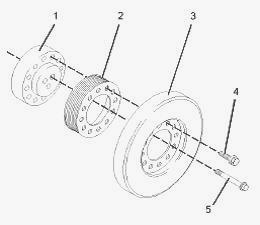

Pulleys without Split Lock Rings

Remove:

- the alternator belt. The weight of the assembly of the crankshaft

pulley, the vibration damper and the crankshaft adapter is approximately

22 kg (48 lb).

- Remove the vibration damper and the crankshaft pulley before the

crankshaft adapter is removed from the engine.

- one of the setscrews (4). Install Tooling into the assembly of the

crankshaft pulley, the vibration damper and the crankshaft adapter.

- the five remaining setscrews (4).

- the vibration damper (3) and the crankshaft pulley (2) from the

crankshaft adapter (1).

- Tooling from the crankshaft adapter (1). Use a suitable tool in order

to prevent the crankshaft from rotating. Use Tooling to remove the three

torx screws (5).

- the crankshaft adapter (1) from the crankshaft.

Installation Procedure

Pulleys with Split Lock Rings

Ensure that the crankshaft adapter, the split lock rings, the spacer and

the thrust block are clean and free from damage. Replace any components

that are damaged. Install:

- a new O-ring seal (7) to the thrust block (6).

- the spacer (8) to the crankshaft adapter (1).

- both pairs of split lock rings (9) to the crankshaft adapter (1).

There is an internal split lock ring and an external lock ring. Ensure

that the split lock rings are installed in the correct position. Refer

to Illustration. Position the gap in the split lock rings at 180 degrees

away from each other. Ensure that the front of the crankshaft is clean

and free from damage.

- the crankshaft adapter (1) onto the crankshaft. Align the holes in the

thrust block with the holes in the crankshaft.

- the thrust block (6) into the crankshaft adapter (1).

- the three torx screws (5) to the thrust block (6). Use a suitable tool

in order to prevent the crankshaft from rotating. Use Tooling to tighten

the torx screws to a torque of 200 Nm (147 lb ft). Repeat Step two more

times in order to ensure correct torque.

- Tooling to the crankshaft adapter (1). Align the crankshaft pulley (2)

with Tooling.

- the crankshaft pulley to the crankshaft adapter (1). Inspect the

vibration damper for damage. If necessary, replace the vibration damper.

Align the vibration damper (3) with Tooling.

- the vibration damper to the crankshaft adapter (1).

- the four setscrews (4) to the assembly of the crankshaft pulley, the

vibration damper and the crankshaft adapter. The setscrews should be

evenly spaced. Remove Tooling. Use a suitable tool in order to prevent

the crankshaft from rotating. Tighten the setscrews (4) to a torque of

115 Nm (85 lb ft).

- the alternator belt.

Pulleys without Split Lock Rings

Ensure that the crankshaft adapter and the front of the crankshaft are

clean and free from damage. Install the crankshaft adapter (1) to the

crankshaft. Install:

- the three torx screws (3) to the crankshaft adapter (1). Use a

suitable tool in order to prevent the crankshaft from rotating. Use

Tooling to tighten the torx screws to a torque of 200 N·m (147 lb ft).

Repeat Step two more times in order to ensure correct torque.

- Tooling to the crankshaft adapter (1). Align the crankshaft pulley (2)

with Tooling. Install the crankshaft pulley to the crankshaft adapter

(1). Inspect the vibration damper for damage. If necessary, replace the

vibration damper.

Align the vibration damper (3) with Tooling.

- the vibration damper to the crankshaft adapter (1).

- the setscrews (4) to the assembly of the crankshaft pulley, the

vibration damper and the crankshaft adapter. Remove Tooling.

- the remaining setscrew (4). The setscrews should be evenly spaced. Use

a suitable tool in order to prevent the crankshaft from rotating.

Tighten the setscrews (4) to a torque of 115 N·m (85 lb ft).

- the alternator belt.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader